EN 10210 S355J2Hndiyo inopisa-yakapera structural hollow chikamu simbi maereranoEN 10210ine simba shoma regoho re 355 MPa (yemadziro emadziro ≤ 16 mm) uye zvakanaka zvinokanganisa zvivakwa pakudzika kwakadzika kusvika ku -20 ° C, zvichiita kuti zvive zvakanaka kuti zvishandiswe munzvimbo dzakasiyana-siyana dzekuvaka uye mainjiniya.

Hongu, EN 10210 =BS EN 10210.

TS EN 10210 uye EN 10210 zvakafanana mune zvehunyanzvi zvemukati uye zvese zvinomiririra zviyero zveEurope zvekugadzira, kugadzira, uye zvinodiwa zvezvikamu zve thermoformed structural hollow.

BS EN 10210 ndiyo vhezheni yakagamuchirwa muUK, nepo EN 10210 iri chiyero cheEuropean-wide. Masangano akasiyana epasirese epasi anogona kutanga mwero nemapfupikiso emunyika, asi musimboti weiyo mwero unoramba uripo.

Hollow zvikamu zvinogona kuiswa muzvikamu sedenderedzwa, sikweya kana rectangular, kana elliptical.

Zvakare nekuti iri kupisa rakapedzwa maitiro zvinoenderana neEN 10210, inotevera chidimbu inogona kushandiswa.

HFCHS= inopisa yakapera denderedzwa hollow zvikamu;

HFRHS= inopisa yapera sikweya kana rectangular hollow zvikamu;

HFEHS= inopisa yakapera elliptical hollow zvikamu.

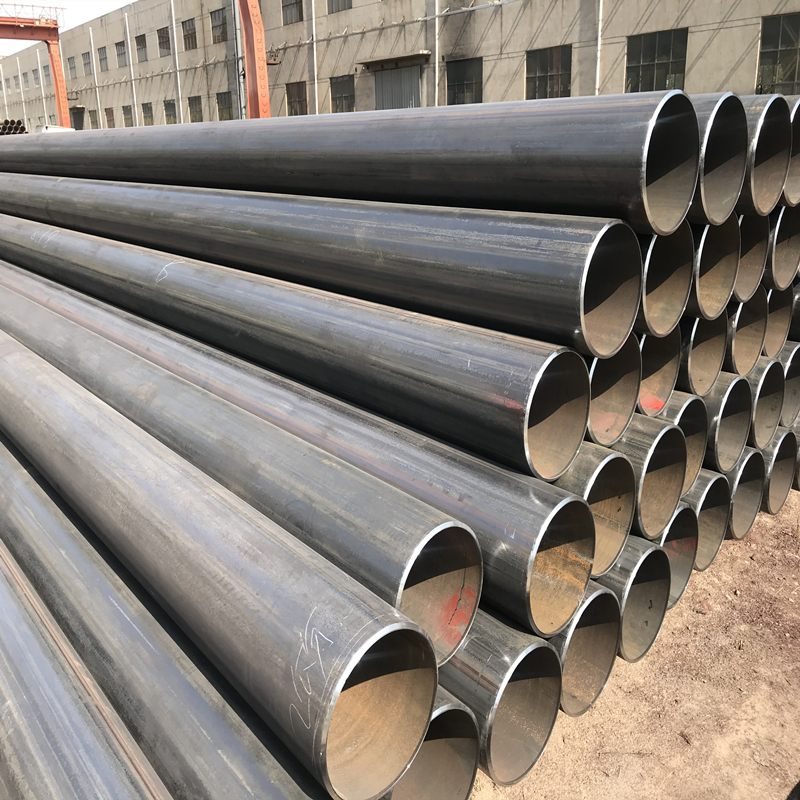

Round: Outer dhayamita kusvika 2500 mm;

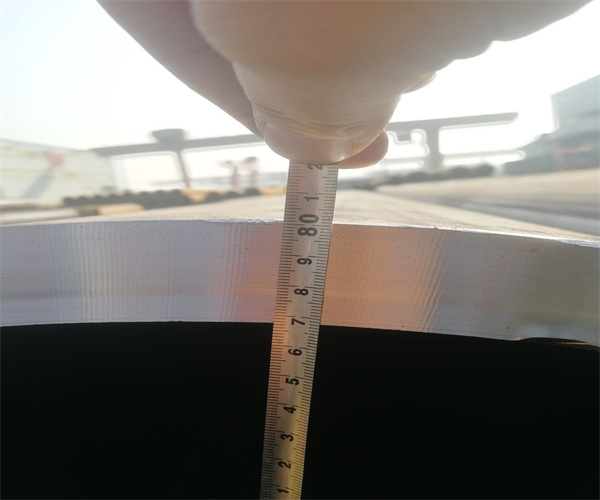

Wall ukobvu kusvika 120 mm.

Ehe, hapana nzira yekugadzira machubhu ehukuru uhu uye ukobvu hwemadziro kana ERW welding process ikashandiswa.

ERW inogona kugadzira machubhu anosvika 660mm ane mudhuri ukobvu hwe20mm.

Simbi inogona kugadzirwa kana kuburikidza neaisina musono kana weldingprocess.

Pakati pewelding process, nzira dzakajairwa welding dzinosanganisiraERW(electric resistance welding) uyeSAW(yakanyura arc welding).

Pakati pezvimwe,ERWinyanzvi yewelding inobatanidza nhengo dzesimbi pamwe chete nenzira yekudzivirira kupisa uye kumanikidza. Iyi tekinoroji inoshanda kune akasiyana siyana ezvishandiso uye ukobvu uye inogonesa inobudirira welding process.

SAW, kune rumwe rutivi, inzira yewelding inoshandisa granular flux kuvhara arc, iyo inopa kupinza kwakadzika uye nani weld quality uye inonyanya kukodzera kune welding mahwendefa akakora.

Tevere, inzira yeERW, inova nzira yekugadzira ine hunyanzvi inoshandiswa zvakanyanya kugadzira machubhu akasiyana siyana esimbi nemaprofile.

Izvo zvinofanirwa kucherechedzwa kuti kune isina alloyed uye yakanaka-zviyo makomba zvikamu zvinogadzirwa newelding process, kugadzirisa welds hazvibvumidzwe kunze kwekunyudzwa kwearc welding.

Hunhu JR, JO, J2 uye K2 - kupisa kwapera,

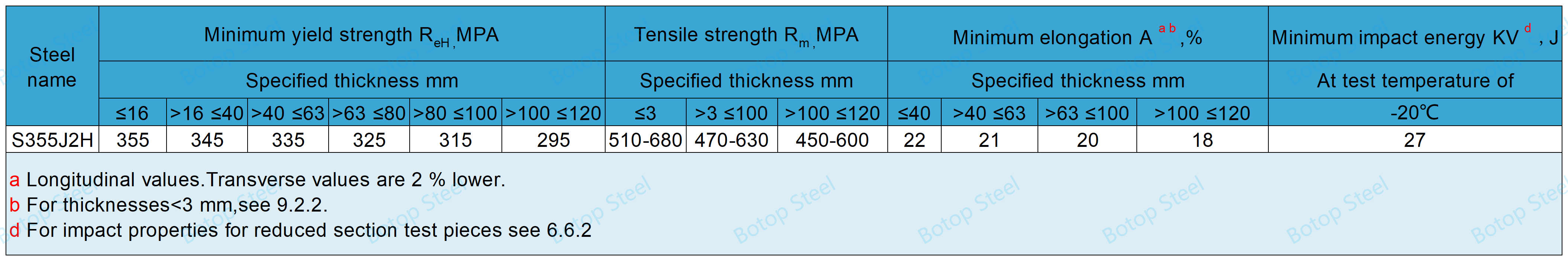

Iko kusimba kwegoho shoma reS355J2H simbi pombi haina kugadzikiswa, inoshanduka neyakasiyana madziro ukobvu.

Kunyanya, simba regoho reS355J2H rinogadziriswa maererano nechiyero apo rusvingo rwemadziro rushoma kudarika kana kuenzana ne16mm, asi kana rusvingo ruchiwedzera, simba regoho richaderedzwa, saka kwete yose S355J2H simbi pombi inogona kusvika zvishoma zvishoma goho simba re355MPa.

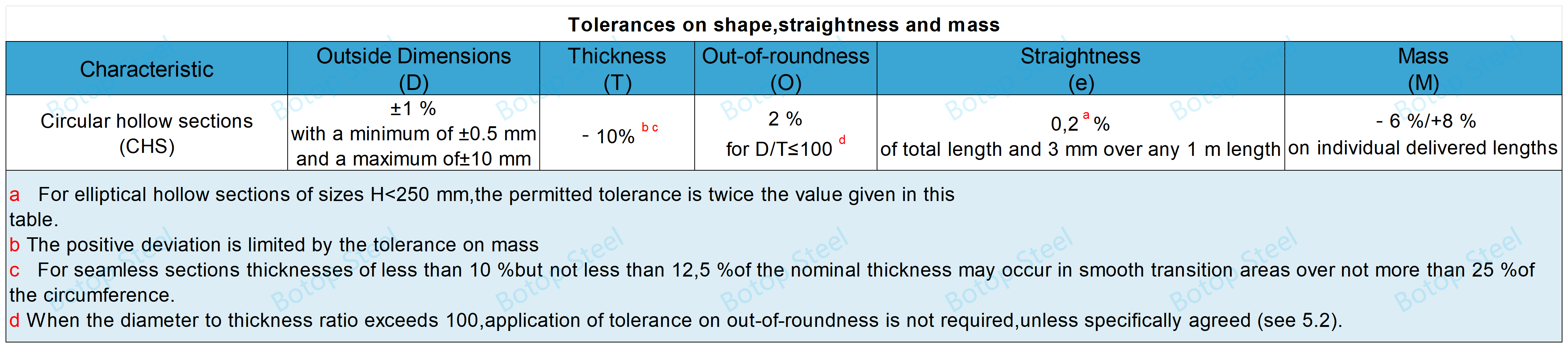

Kushivirira pachimiro, kutwasuka uye kuwanda

Kushivirira kureba

| Rudzi rwehurefua | Hurefu kana kureba L | Kushivirira |

| Random urefu | 4000≤L≤16000 ine huwandu hwe2000 pachinhu cheodha | 10 % yezvikamu zvinopihwa zvinogona kunge zviri pazasi pezvishoma zveyero yakaodha asi isiri pfupi pane 75 % yehurefu hwehurefu. |

| Hurefu hwakaenzana | 4000≤L≤16000 | ± 500 mmb |

| Hurefu chaihwo | 2000≤L≤6000 | 0 - +10mm |

| 6000c | 0 - +15mm | |

| aMugadziri anogadza panguva yekubvunza uye odha rudzi rwehurefu hunodiwa uye kureba kana kureba. bOntion 21 kushivirira pane annrevimata kureba ndeye 0 - +150mm cHurefu hwakajairika huripo 6 m uye 12 m. | ||

S355J2H simbi pombi irefu-yakasimba structural simbi pombi ine yakanaka welding performance uye yakaderera-tembiricha inokonzeresa kuoma, saka ine zvakawanda zvekushandisa mundima dzakawanda dzeindasitiri.

1. Kuvaka: inoshandiswa mumabhiriji, shongwe, zvimiro zvemafuremu, kutakura njanji, subways, mafuremu edenga, mapaneru emadziro, uye zvimwe zvivakwa zvekuvaka.

2. Piping system: Inoshandiswa sepombi yekutakura zvinwiwa, kunyanya panguva dzinodiwa simba rakawanda uye kupikisa.

3. Marine uye offshore engineering: inoshandiswa muzvivakwa zvengarava, mapuratifomu ekumahombekombe, uye zvimwe zvimiro zveinjiniya zvemugungwa.

4. Indasitiri yemagetsi: inoshandiswa muzvivakwa zvesimba senge shongwe dzemagetsi emhepo, mapuratifomu ekuchera mafuta, uye mapaipi.

5. Dzvinyiriro midziyo: inoshandiswa mukugadzira midziyo yekumanikidza mukuteerana neakananga welding uye kupisa kudiwa kwekurapa.

6. Mining industry: inoshandiswa kune zvimiro zvezvimiro zvemigodhi yekutsigira zvimiro, maconveyor masisitimu, uye ore yekugadzira michina.

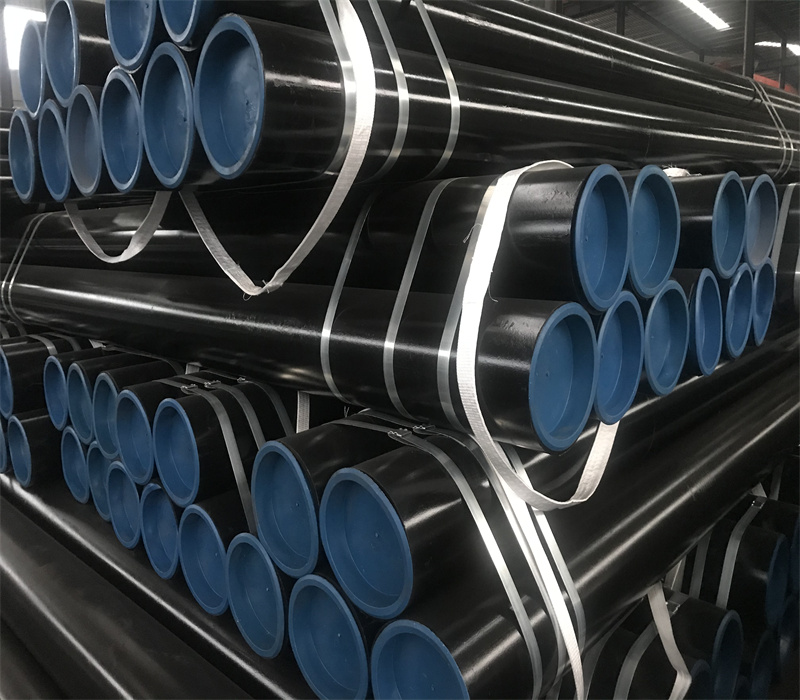

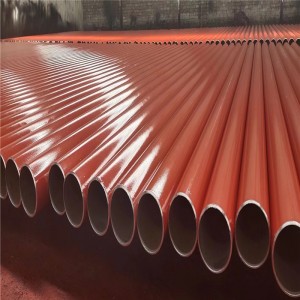

Bare pombi kana Nhema / Varnish coating (yakagadzirirwa);

mumasumbu kana mukusununguka;

Zvose zvinopera nevadziviriri vekupedzisira;

Magumo akajeka, bevel end (2"uye pamusoro ane bevel ends, degree: 30 ~ 35 °), yakarukwa uye yakabatana;

Kumaka.