EN 10219 S355J0Hari ainotonhora-yakagadzirwa weldedstructural hollow simbi pombi kutiEN 10219, neine shoma goho simba re355 MPa(pombi madziro ukobvu ≤ 16 mm) uye simba rekuita rinenge27 J pa 0°C.

Yakagadzirwa uchishandisa welding yemagetsi kana yakanyura arc welding matekiniki pasina kudikanwa kwekutevera kupisa kurapwa, iwo akakodzera kune akasiyana siyana ekuvaka uye einjiniya maitiro ekushandisa, kusanganisira akakosha maumbirwo ezvikamu zvakaita semirwi yerutsigiro rwenheyo.

BS EN 10219 ndiyo European Standard EN 10219 yakagamuchirwa neUK.

Inosanganisira inotonhora-yakaumbwa weldeddenderedzwa, sikweya, rectangular, uye ellipticalstructural hollow zvikamu.

CFCHS = inotonhora-yakaumbwa denderedzwa hollow chikamu;

CFRHS = inotonhora yakaumbwa sikweya kana rectangular hollow chikamu;

Isu tine hunyanzvi hwekupa zvemhando yepamusoro denderedzwa hollow chikamu (CHS) pombi yesimbi kusangana neako akasiyana einjiniya zvaunoda.

Wall ukobvu ≤40mm;

Circular: Outer dhayamita kusvika 2500 mm;

Zvikamu zvemakomba zvikamu zvinogadzirwa newelding yemagetsi kana yakanyura arc welding (SAW).

TS EN 10219 makomba zvikamu zvinounzwa zvakatonhora-zvakaumbwa pasina kunotevera kupisa kupisa, asi welds anogona kunge ari mune welded kana kupisa-kupisa mamiriro.

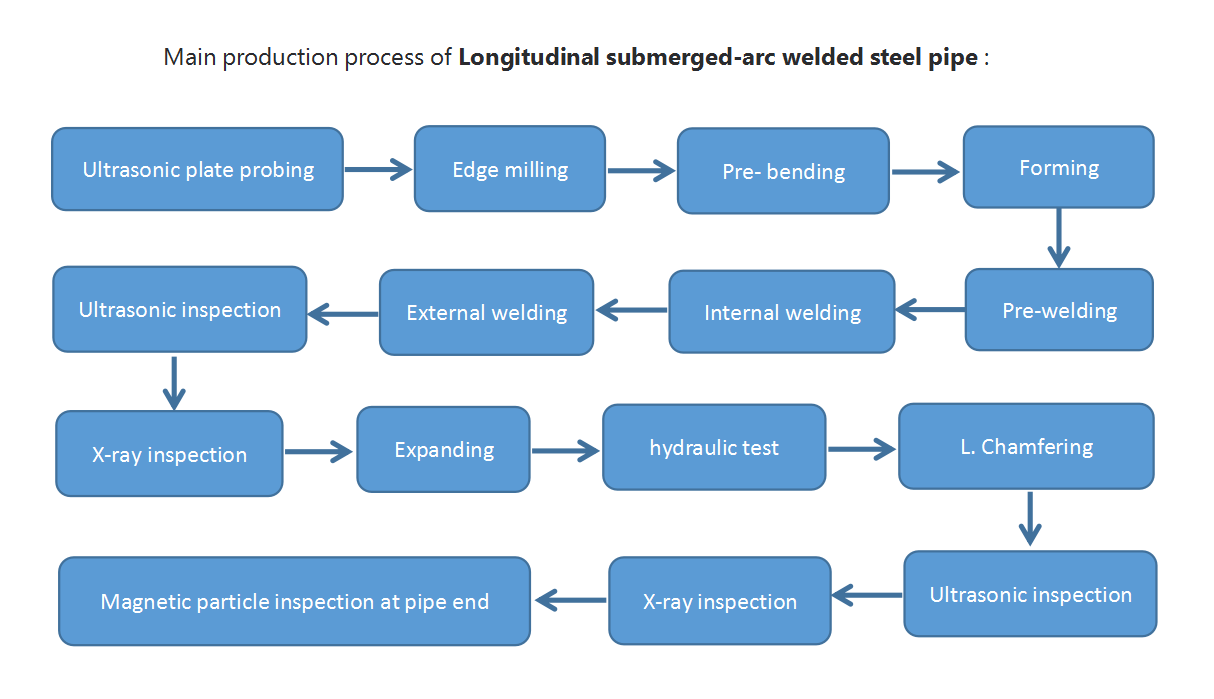

Kana yakanyura arc welding tekinoroji ikashandiswa, inogona kuiswa mukatiLSAW(SAWL) (Longitudinal Submerged Arc Welding) uyeSSAW(HSAW)(Spiral Submerged Arc Welding) zvichienderana negwara remusono weld.

LSAWine zvakakosha zvakanakira mukugadzirwa kweyakakura-diameteruyemapaipi esimbi makobvuuye inonyanya kuenderana nemamiriro ekushandisa uko kusimba kwepamusoro, mhando, uye hukuru chaihwo hunodiwa zvakanyanya.

JCOEinzira yakakosha uye inomiririra mukugadzirwa kweLSAW simbi pombi. Zita rekuita rinobva pamatanho mana makuru ekugadzira pombi: J-kuumba, C-kugadzira, O-kugadzira, uye Kuwedzera.

Isu tiri yepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe yakawanda yesimbi pombi mhinduro!

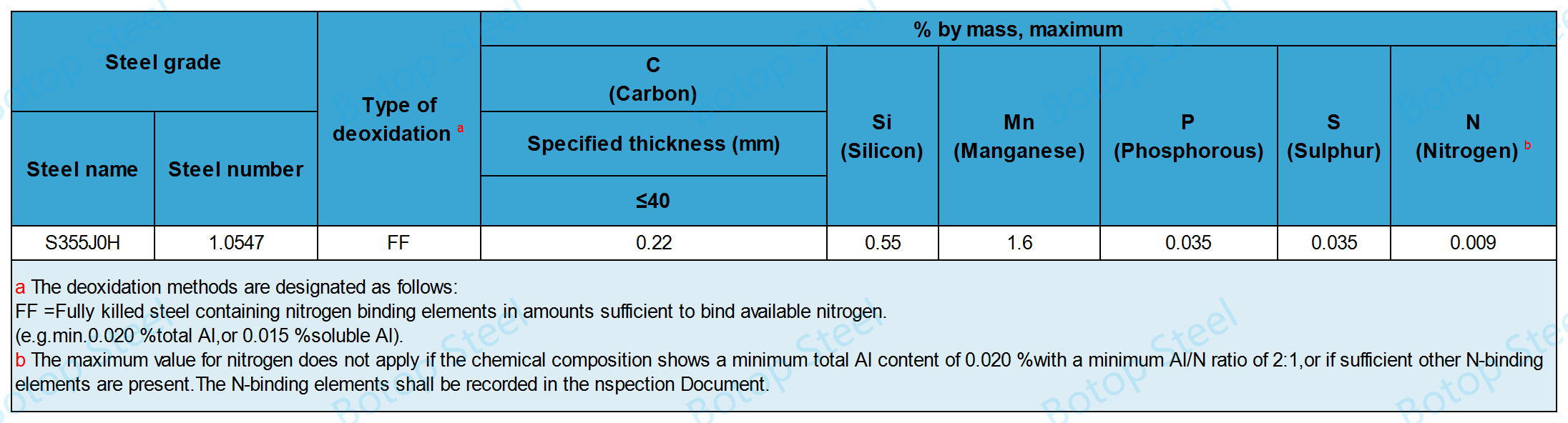

Cast Analysis

Kemikari kuongororwa kwesimbi pombi raw materials

S355J0H Maximum carbon yakaenzana kukosha(CEV): 0.45%.

CEV = C + Mn/6 +(Cr + Mo + V)/5 + (Ni + Cu)/15.

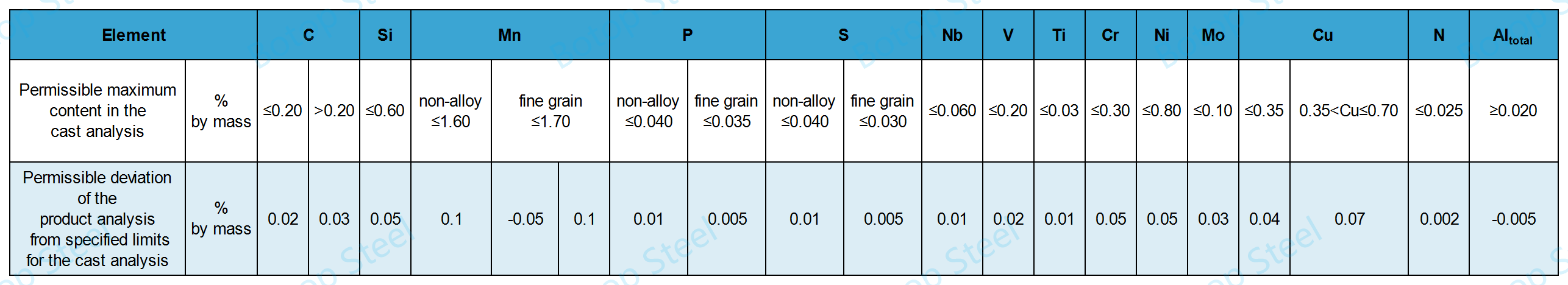

Product Analysis

Kuongororwa kwemakemikari ezvikamu zvakapedzwa

Kutsauka kwekuongororwa kwechigadzirwa kubva pamiganho yakatsanangurwa yekuongorora yekukanda kuchave zvichienderana nezvinodiwa pazasi.

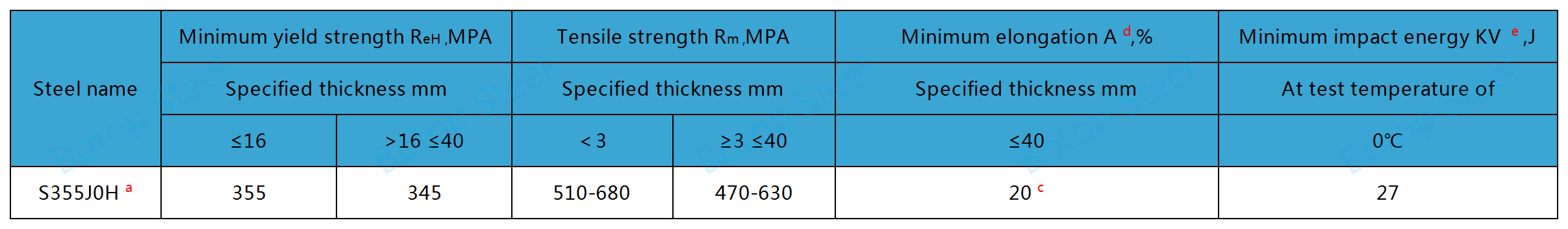

Kurerutsira kunetseka kunodarika 580 ° C kana kweinopfuura awa imwe chete kunogona kutungamirira mukushata kwezvinhu zvemuchina.

Iyo tensile bvunzo ichaitwa zvinoenderana neEN 10002-1.

Iyo bvunzo yekukanganisa ichaitwa zvinoenderana neEN 10045-1.

a Iyo yekukanganisa zvivakwa inosimbiswa chete kana Sarudzo 1.3 yatsanangurwa.

c Kumasaizi echikamu D/T <15 (denderedzwa) uye (B+H)/2T <12,5 (square uye rectangular) kureba kwediki kunoderedzwa ne2.

d Pakukora <3 mm ona 9.2.2.

e Zvekukanganisa zvivakwa zvezvimedu zvebvunzo zvakaderedzwa ona 6.7.2.

Notes: Impact kuyedzwa haidiwe kana ukobvu hwataurwa huri <6mm.

Welds mune yakanyura arc welded hollow zvikamu zvinoyedzwa zvinoenderana ne EN 10246-9 yekugamuchira kirasi U4 kana radiographically zvinoenderana ne EN 10246-10 yemhando yemhando kirasi R2.

NDT (RT) Kuedza

NDT (UT) Kuedza

Hydrostatic Testing

Isu tinoshandisa akasiyana-siyana asiri ekuparadza maitiro ekuyedza uye hydrostatic pressure bvunzo kuti tive nechokwadi chekusimba uye kusimba kwepombi yega yega. Isu tinopa vatengi vedu zvigadzirwa zvepimbi zvesimbi zvinosangana nepamusoro-soro yekuchengeteka uye kuvimbiswa kwehutano.

Hollow chikamu machubhu anogadzirwa zvinoenderana neEN 10219 anogoneka.

Kana welding, kutonhora kutsemuka munzvimbo yeweld ndiyo njodzi huru sezvo ukobvu, simba nhanho, uye CEV yechigadzirwa ichiwedzera. Cold cracking inokonzerwa nekubatanidzwa kwezvinhu zvakati wandei:

mazinga akakwirira ehydrogen diffusible mu weld metal;

brittle chimiro munzvimbo inopisa-inopisa;

kwakakosha tensile stress concentrations mune welded joint.

EN 10219 mapaipi esimbi akakodzera kupisa dip galvanizing. Kusarudzwa kunogona kuitwa maererano nezvinodiwa chaizvo.

Inofanira kuva nenzvimbo yakatsetseka inoenderana nenzira yekugadzira inoshandiswa; mabumps, voids, kana shallow longitudinal grooves inokonzerwa nekugadzira nzira inotenderwa chero iyo yakasara ukobvu iri mukati mekushivirira.

Kuremara kwepamusoro kunogona kubviswa nekukuya, kunze kwekunge ukobvu hwechikamu chakagadziridzwa chisina kuderera pane hudiki hunobvumidzwa ukobvu hunotsanangurwa mu EN 10219-2.

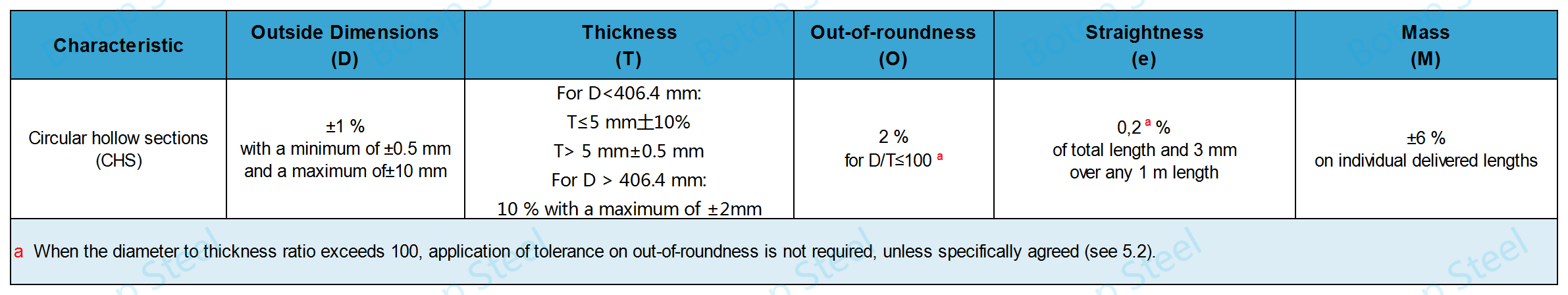

Kushivirira paChimiro, Kururama uye Misa

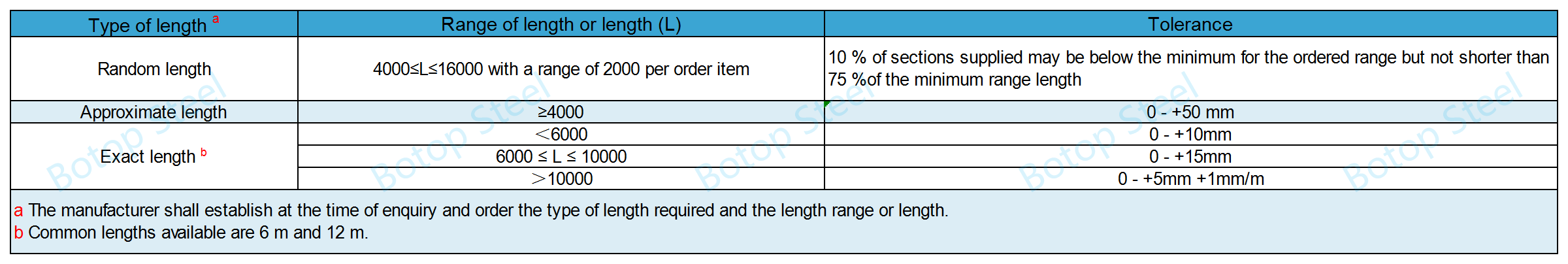

Kushivirira Kureba

Weld Height

Iyo weld urefu inodiwa inoshanda chete kune SAW machubhu.

| Ukobvu, mm | Maximum weld bead urefu, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

TS EN 10219 S355J0H simbi pombi isimbi yakasimba uye isingadziviriri zvinhu zvakakodzerwa nehupamhi hwezvivakwa uye zvivakwa zveinjiniya, zvinosanganisira mirwi yepombi.

1. Murwi wepombi: S355J0H simbi pombi inonyanya kukodzera kushandiswa semirwi yenheyo nekuda kwesimba rayo uye kusagadzikana kwekuora uye inoshandiswa zvakanyanya pakuvaka mawharves, mabhiriji, nheyo dzekuvaka, uye mamwe mapurojekiti anoda nheyo dzakadzika.

2. Zvivako zvekuvaka: Inowanzo shandiswa kune zvikamu zvakaita se skeleton zvimiro, makoramu anotsigira, uye matanda ezvivakwa.

3. Kufambisa kwepaipi: Yakanyatsokodzerawo kushandiswa sepombi yekutakura oiri negasi nzendo refu. Nekudaro, inowanzovharwa kuti iwedzere hupenyu hwesevhisi, semuenzaniso 3LPE, FBE, galvanized, nezvimwe.

4. Michina yekuvaka: Inogona kushandiswa kugadzira mabhureki uye zvikamu zveakasiyana michina yekuvaka.

5. Zvivako zveveruzhinji: senge ma bleachers munhandare dzemitambo nezvimwe zvivakwa zvekutsigira zvivakwa zvakakura zveveruzhinji.

EN 10210 S355J0H: Hollow chikamu che thermoforming welded zvimiro. Kunyange zvazvo inonyanya kushandiswa kwe thermoforming, makemikari ayo uye maitiro emagetsi akafanana neaya eS355J0H uye anogona kushandiswa sechinhu chakanaka chakaenzana.

ASTM A500 Giredhi C: Inoshandiswa mukugadzira welded kana isina musono-inotonhora-yakaumbwa denderedzwa, sikweya, uye rectangular machubhu ezvimiro zvekushandisa. ASTM A500 Giredhi C inopa goho rakafanana uye kusimba kwekusimba kwezvivakwa uye zvemichina zvimiro.

CSA G40.21 350W: Iyi ndiyo Canadian Standards Association yakatarwa iyo inovhara huwandu hwakawanda hwemagadzirirwo esimbi mamakisi. 350W giredhi simbi ine goho rakafanana uye kusimba kusimba kune S355J0H.

JIS G3466 STKR490: Iyi i square uye rectangular chubhu zvinhu zvekushandisa zvimiro sezvakatsanangurwa muJapan Industrial Standard (JIS). Inokodzera kuvaka zvivakwa uye mechanical zvinangwa.

Kubva pakavambwa muna 2014.Botop Steelrave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa rakanakisa, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges. Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) Pipe yesimbi

ASTM A671/A671M LSAW Simbi Pipe

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Simbi Pipe

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Giredhi X70 LSAW Simbi Pipe

EN10219 S355J0H Structural LSAW(JCOE) Simbi Pipe