STPT 370igiredhi reiyo Japanese standard JIS G 3456 yemapombi esimbi kabhoni, inoshandiswa pakumanikidza pombi munzvimbo dzine tembiricha dzinopfuura 350°C. Inogona kunge isina musono kana welded pombi uchishandisa electric resistance welding (RW) process. Iyo mechanical properties ye STPT 370 zvinhu ishoma tensile simba re 370 MPa uye shoma shoma simba re 215 MPa.

Kana iwe uchitsvaga mugadziri uye mutengesi wepombi dzesimbi dzinosangana neJIS G 3456 standard, saka isu tiri shamwari yauri kutsvaga. Bata nesu nhasi uye isu tichafara kukubatsira!

Inokodzera madhayamita ekunze 10.5 mm - 660.4 mm (6A - 650A) (1/8B - 26B).

A uye B inzira mbiri dzekutaura dhayamita yezita muyero yeJapan. Kunyanya, A inoenderana neDN, nepo B inoenderana neNPS.

JIS G 3456 STPT 370 inogona kugadzirwa uchishandisa iyoisina musononzira yekugadzira kana iyoelectric resistance welding(RW) maitiro.

Nzira yekugadzira inopindiranawo nenzira dzakasiyana dzekupedzisa kutarisana nemamiriro akasiyana ekushandisa.

| Chiratidzo chegiredhi | Chiratidzo chekugadzira nzira | |

| Pombi yekugadzira nzira | Kupedzisa nzira | |

| JIS G 3456 STPT370 | Pasina musono: S | Kupisa-kupedzwa: H Kutonhora-kupedzwa: C |

| Magetsi anopokana akaiswa welded: E Butt welded: B | Kupisa-kupedzwa: H Kutonhora-kupedzwa: C Sezvo magetsi anopokana akaiswa welded: G | |

STPT 370 inofanira kunge ichipiswa.

1. Kupisa-kupedzwa kwesimbi isina musono pombi: Sekugadzirwa kwakaderera-tembiricha annealing kana normalizing inogona kuiswa sezvinodiwa;

2. Cold-yakapera seamless simbi pombi: Low-tembiricha annealing kana normalizing;

3. Kupisa-kupedzwa kwemagetsi kupikisa welded simbi pombi: Sezvakagadzirwa Low-temperature annealing kana normalizing inogona kushandiswa sezvinodiwa;

4. Kutonhora-kupedzwa kwemagetsi kushorwa welded uye Semagetsi kuramba welded simbi pombi: Low-tembiricha annealing kana normalizing.

| Chiratidzo chegiredhi | C | Si | Mn | P | S |

| JIS G 3456 STPT370 | 0.25% yakawanda | 0.10 - 0.35% | 0.30 - 0.90% | 0.035%. | 0.035%. |

Kana zvichidikanwa, zvimwe zvinhu zvinogona kuwedzerwa.

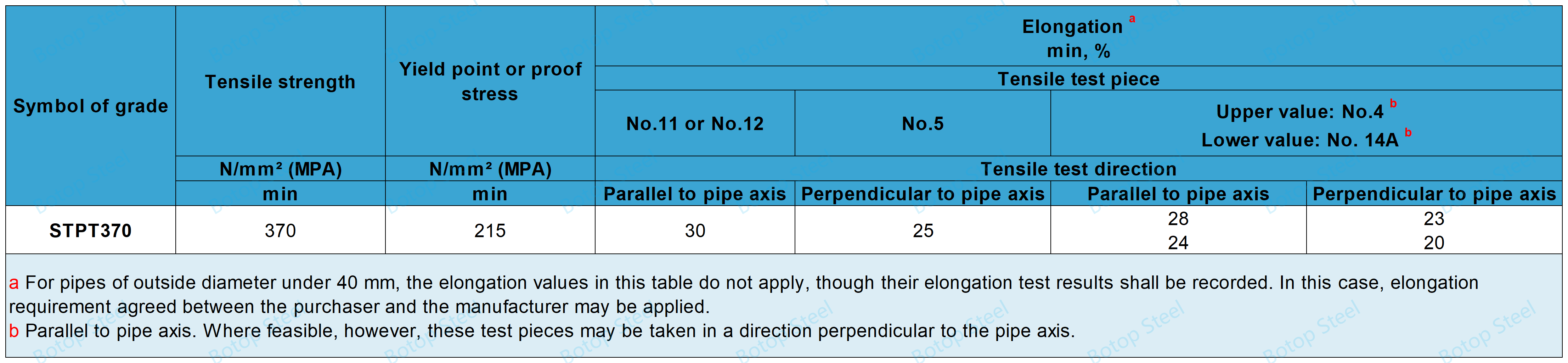

Kusimba Kwesimba, Goho Poindi kana Humbowo Stress, uye Elongation

Flattening Property

Inokodzera mapaipi ane dhayamita yekunze inopfuura 60.5 mm.

Muenzaniso unoiswa pakati pemapuratifomu maviri uye wakatsetseka. Kana chinhambwe chiri pakati pemahwendefa maviri chasvikaH, hapana kutsemuka pamusoro peiyo simbi pombi specimen.

H = 1.08t/(0.08+ t/D)

н: kureba pakati peplatens (mm);

t: kukora kwemadziro epombi (mm);

D: kunze kwedhayamita yepombi (mm);

Bendability

Inokodzera mapaipi esimbi ane dhayamita yekunze ye60.5 mm kana pasi.

Kana iyo sampuli yakakomberedzwa yakatenderedza mandrel kune yemukati radius ye6 nguva yekunze dhayamita yepombi, iyo muenzaniso inoongororwa uye hapana kuputika kunowanikwa.

| Nominal rusvingo ukobvu | Purogiramu nhamba: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Minimum hydraulic test pressure, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Kana iyo dhayamita yekunze uye ukobvu hwemadziro epombi yesimbi isiri chiyero, nzira dzinotevera dzinogona kushandiswa kuona giredhi rakakodzera rekutsanangurwa:

Chekutanga, sarudza giredhi rehurongwa giredhi riri padyo nesaizi isiri-standard; chechipiri, sarudza giredhi yezvido nekuverenga kukosha kweP.

Mune nzira mbiri, kukosha kudiki kunofanirwa kusarudzwa segiredhi rekupedzisira.

P = 2st/D

P: test pressure (MPa);

t: kukora kwemadziro epombi (mm);

D: kunze kwedhayamita yepombi (mm);

s: 60% yehushoma hushoma kukosha kwegoho poindi kana chiratidzo chekusimbisa;

Nzira dzakajairwa dzisiri dzekuparadza dzekuyedza dzinosanganisira ultrasonic bvunzo (UT) uye eddy ikozvino kuyedza (ET).

Paunenge uchiita ultrasonic inspection, referensi inofanira kuitwa kuJIS G 0582, uye kana mhedzisiro yekuongorora yakaenzana kana kupfuura iyo yereferensi chiyero chekirasi yeUD, inoonekwa sekutadza.

Paunenge uchiita eddy ikozvino yekuongorora, kutaurwa kunofanira kuitwa kune JIS G 0583. Kana chigumisiro chekuongorora chakaenzana kana kudarika chiyero chechiratidzo chekirasi yeEY, inofungidzirwa kuti haina kukodzera.

Zviyero zvakajairwa uye kukora kwemadziro ari pakati pe10.5 mm kusvika 660.4 mm akanyorwa muJIS G 3456, inovasimbi pombi uremu tafura uye purogiramu inoenderana Nha.

Purogiramu 10,Purogiramu 20,Purogiramu 30,Chirongwa 40,Chirongwa 60,Chirongwa 80,Chirongwa 100,Chirongwa 120,Purogiramu 140,Chirongwa 160.

Kubva pakavambwa muna 2014.Botop Steelrave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa rakanakisa, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges. Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

Ndapota inzwa wakasununguka kutibata nesu uye isu tichafara kupindura mibvunzo yako.