JIS G 3444: Carbon simbi machubhu eyakajairwa chimiro.

Inotsanangura zvinodikanwa zvekabhoni simbi mapaipi anoshandiswa muinjiniya nekuvaka, senge shongwe dzesimbi, scaffolding, nheyo mirwi, nheyo mirwi, uye anti-slip piles.

STK 400pombi yesimbi ndeimwe yemagiredhi akajairika, ine michina yeasimba shoma rekusimba re400 MPauye asimba shoma regoho re235 MPa. Simba rayo rakanaka rekugadzirisa uye kusimbaita kuti ive yakakodzera kune akawanda akasiyana maapplication.

Zvinoenderana nehuwandu hwekusimba kwesimba resimbi pombi yakakamurwa kuita 5 makirasi, ayo ari:

STK 290, STK 400, STK 490, STK 500, STK 540.

General chinangwa Outer dhayamita: 21.7-1016.0mm;

Nheyo dzenheyo uye mirwi yekudzvinyirirwa kwevhu OD: pazasi 318.5mm.

| Chiratidzo chegiredhi | Chiratidzo chekugadzira nzira | |

| Pombi yekugadzira nzira | Kupedzisa nzira | |

| STK 290 | Pasina musono: S Magetsi anopokana akaiswa welded: E Butt welded: B Automatic arc welded: A | Kupisa-kupedzwa: H Kutonhora-kupedzwa: C Sezvo magetsi anopokana akaiswa welded: G |

| STK 400 | ||

| STK 490 | ||

| STK 500 | ||

| STK 540 | ||

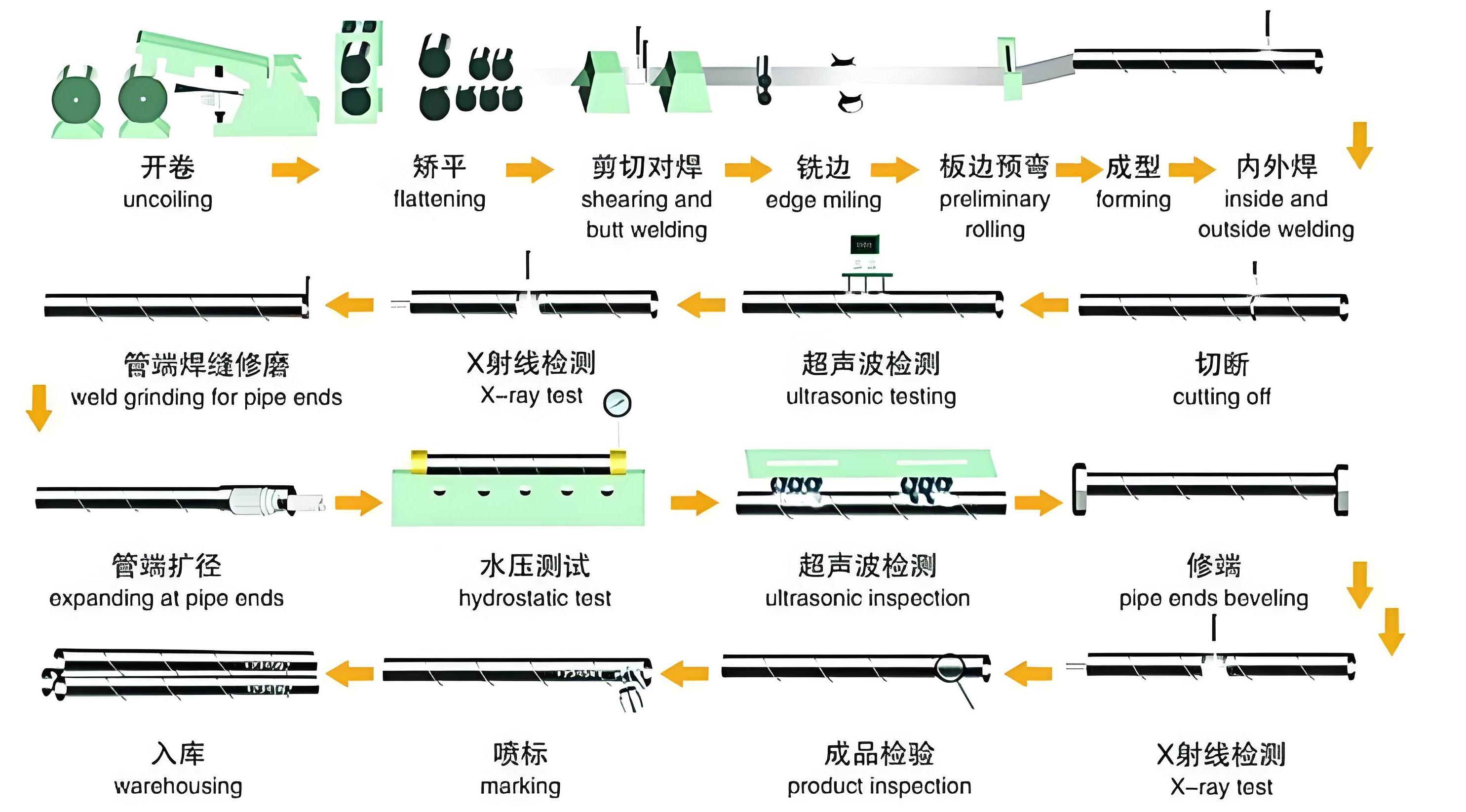

Iyo machubhu ichagadzirwa nekubatanidzwa kwechubhu yekugadzira nzira uye nzira yekupedzisa iyo inoratidzwa.

Kunyanya, ivo vanogona kuiswa mumhando nomwe dzinotevera, saka sarudza mhando yakakodzera zvinoenderana nezvinodiwa zvakasiyana:

1) Kupisa-kupedza seamless simbi chubhu: -SH

2) Cold-yakapera seamless simbi chubhu: -SC

3) Semagetsi kuramba welded simbi chubhu: -EG

4) Kupisa-kupedzwa kwemagetsi kuramba welded simbi chubhu: -EH

5) Kutonhora-kupedzwa kwemagetsi kuramba welded simbi chubhu: -EC

6) Butt-weld simbi machubhu: -B

7) Otomatiki arc welded simbi machubhu: -A

| Kuumbwa Kwemakemikaria% | |||||

| Chiratidzo chegiredhi | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | max | ||

| STK 400 | 0.25 | - | - | 0.040 | 0.040 |

| aAlloy zvinhu zvisina kubatanidzwa mutafura ino uye zvinhu zvakaratidzwa ne "-" zvinogona kuwedzerwa kana zvichidikanwa. | |||||

STK 400isimbi yakaderera-kabhoni ine yakanaka weldability uye inoshanda kune zvimiro zvekushandisa zvinoda welding. Phosphorus nesarufa zvinodzorwa pamazinga akaderera kubatsira kuchengetedza kuoma kwese uye kushanda kwechinhu. Kunyange zvazvo zvakakosha zvesilicon uye manganese zvisingapiwi, zvinogona kugadziriswa mukati memiganhu inobvumirwa kuti uwedzere zvinhu zvesimbi zvakare.

Tensile Simba uye Goho Poindi kana Humbowo Stress

Kusimba kwekusimba kweweld kunoshanda kune otomatiki arc welded machubhu. Ndiyo nzira yeSAW welding.

| Chiratidzo chegiredhi | Kusimba simba | Goho poindi kana chiratidzo chekusimbisa | Kusimba kusimba mu weld |

| N/mm² (MPA) | N/mm² (MPA) | N/mm² (MPA) | |

| min | min | min | |

| STK 400 | 400 | 235 | 400 |

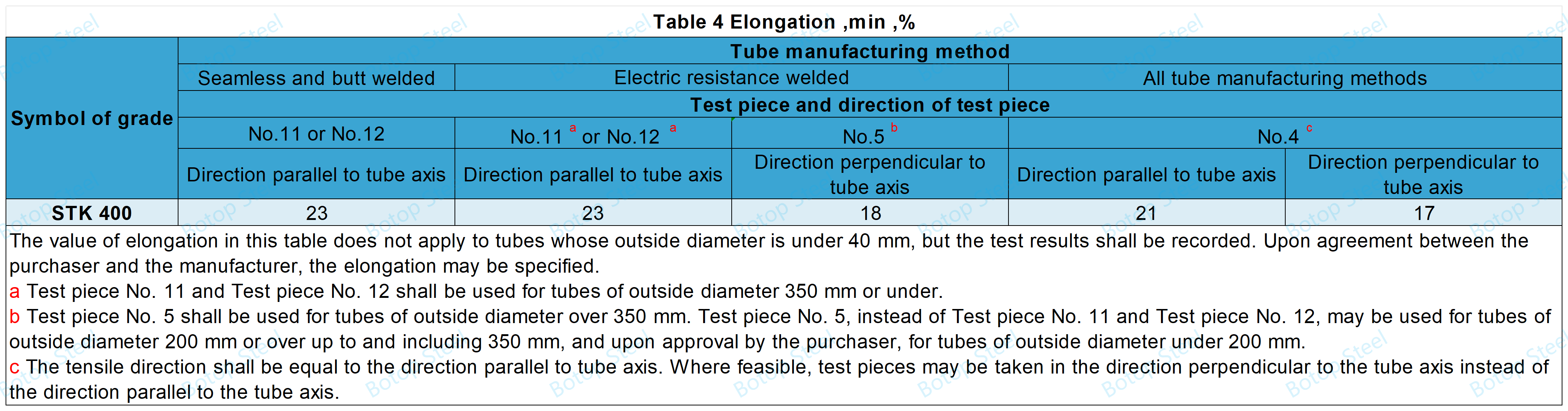

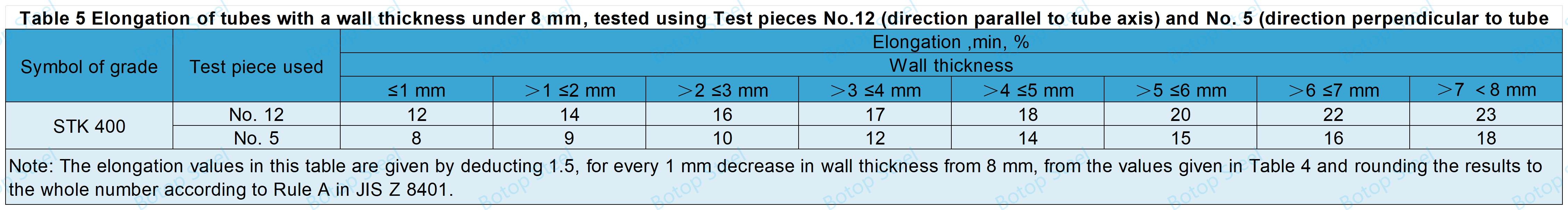

Kuwedzera kweJIS G 3444

Iyo elongation inoenderana neiyo chubhu yekugadzira nzira inoratidzwa muTafura 4.

Zvisineyi, kana bvunzo dzekusimba dzichiitwa paTest Piece No. 12 kana Test Piece No.5 yakatorwa kubva muchubhu iri pasi pe8 mm muhukobvu hwemadziro, kureba kuchaenderana neTafura 5.

Patembiricha yemumba (5 °C kusvika 35 °C), isa mufananidzo pakati pemahwendefa maviri akafuratira uye wodzvanya zvakasimba kuti uaise pasi kusvika kureba H ≤ 2/3D pakati pemahwendefa, wozotarisa pakatsemuka mumuenzaniso.

Patembiricha yemumba (5 °C kusvika 35 °C), kotamisa mufananidzo uchitenderedza humburumbira pakona yekukotama ye90 ° uye nepakati pepakati radius isingadariki 6D uye tarisa muenzaniso kune makatsemuka.

Hydrostatic bvunzo, isingaparadze bvunzo dze welds, kana mamwe maedzo anozobvumiranwa pachine nguva pane zvinoenderana nezvinodiwa.

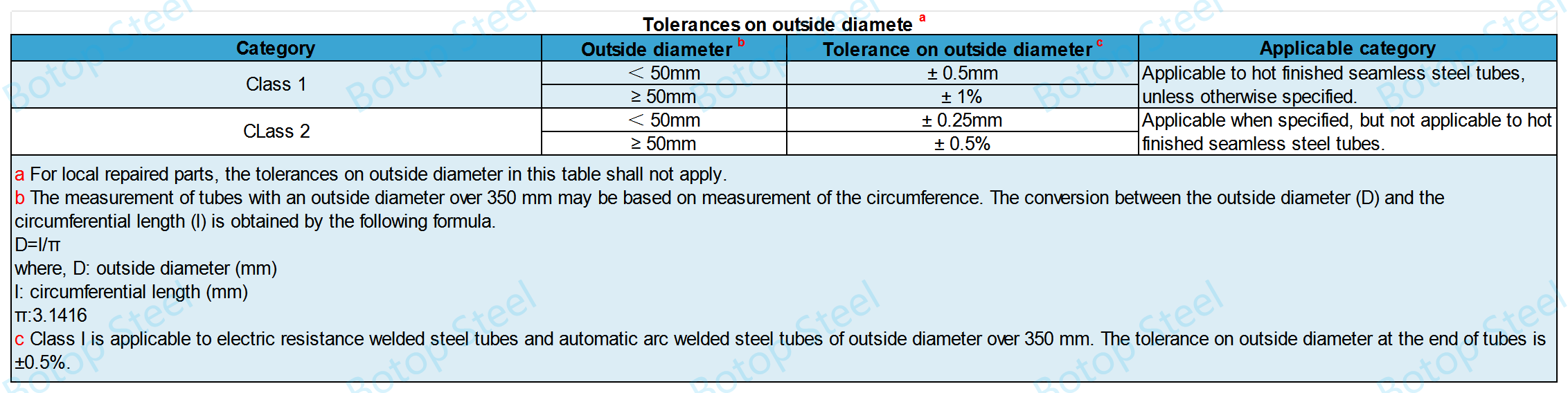

Kunze Diameter Kushivirira

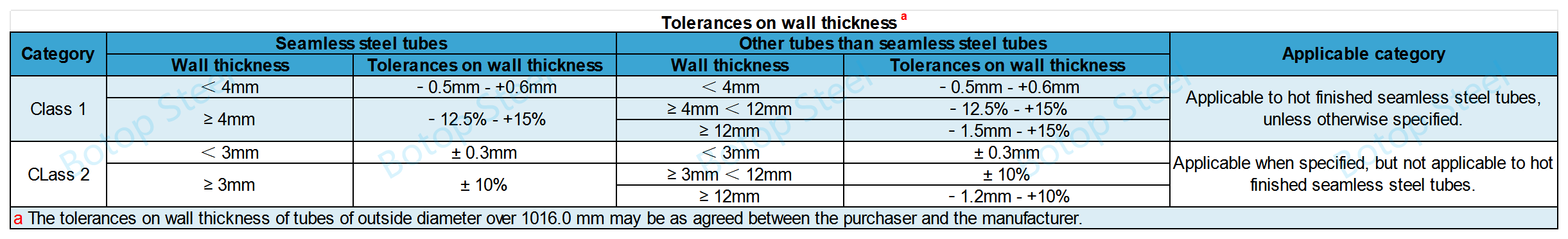

Wall Thickness Tolerance

Kureba Kushivirira

Hurefu ≥ hurefu hwakatarwa

Iko mukati uye kunze kwekunze kwepombi yesimbi ichave yakatsetseka uye isina zvikanganiso zvisina kunaka kune ues.

Pombi imwe neimwe yesimbi ichanyorwa nemashoko anotevera.

a)Chiratidzo chegiredhi.

b)Chiratidzo chekugadzira nzira.

c)Dimensions.Iyo dhayamita yekunze uye ukobvu hwemadziro hucharatidzwa.

d)Zita kana chidimbu chemugadziri.

Kana kumaka pachubhu kwakaoma nekuti dhayamita yekunze idiki kana kuti kana zvakumbirwa nemutengi, chiratidzo chinogona kupihwa pabundle rega rega remachubhu nenzira yakakodzera.

Anti-corrosion coatings senge zinc-rich coatings, epoxy coatings, pendi coating, etc. inogona kuiswa kune ekunze kana mukati.

STK 400 inopa chiyero chakanaka chesimba uye hupfumi, zvichiita kuti ive yakakodzera kune akawanda einjiniya uye mapurojekiti ekuvaka.

STK 400 machubhu esimbi anowanzo shandiswa muindasitiri yekuvaka uye anonyanya kukodzera kushandiswa sezvinhu zvimiro zvakaita sembiru, matanda, kana mafuremu muzvivakwa zvekutengesa uye zvekugara.

Inokodzerawo mabhiriji, zvimiro zvekutsigira, uye mamwe mapurojekiti anoda simba repakati uye kusimba.

Inogona zvakare kushandiswa kugadzira migwagwa yekurinda, mafirati ezviratidzo zvetraffic, uye zvimwe zvivakwa zveveruzhinji.

Mukugadzira, STK 400 inogona kushandiswa kugadzira mafuremu uye zvimiro zvekutsigira zvemuchina nemidziyo nekuda kwekunaka kwayo kutakura mutoro uye kushanda kwayo.

Ndokumbira utarise kuti kunyangwe zviyero izvi zvakafanana mukushandisa uye kuita, panogona kunge paine misiyano midiki mune chaiyo makemikari kuumbwa uye mamwe ma mechanic zvivakwa paramita.

Paunenge uchitsiva zvinhu, izvo zvinodikanwa zvezviyero zvinofanirwa kufananidzwa zvakadzama kuti ive nechokwadi chekuti zvinhu zvakasarudzwa zvinosangana nehunyanzvi uye kuchengetedza zviyero zveprojekiti.

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.

Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.