JIS G 3455iJapan Industrial Standard (JIS) yekushanda kwepamusoro-soro patembiricha ye350 °C kana yakaderera, kunyanya yezvikamu zvemakanika.

STS370 simbi pombiipombi yesimbi ine simba shoma re 370 MPa uye simba shoma regoho re 215 MPa, ine carbon content isingapfuuri 0.25% uye silicon content pakati pe 0.10% ne 0.35%, uye inonyanya kushandiswa mumashandisirwo anoda simba rakakwirira uye rakanaka weldability, zvakadai sezvivako zvekuvaka, mabhiriji, zvikepe zvekumanikidzika.

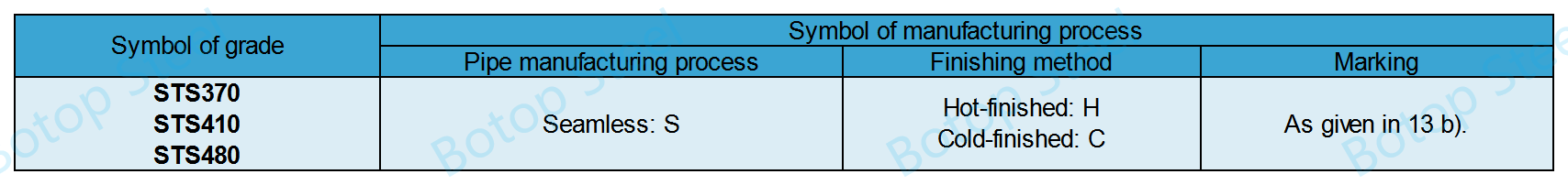

JIS G 3455 ine mamakisi matatu.STS370, STS410, STA480.

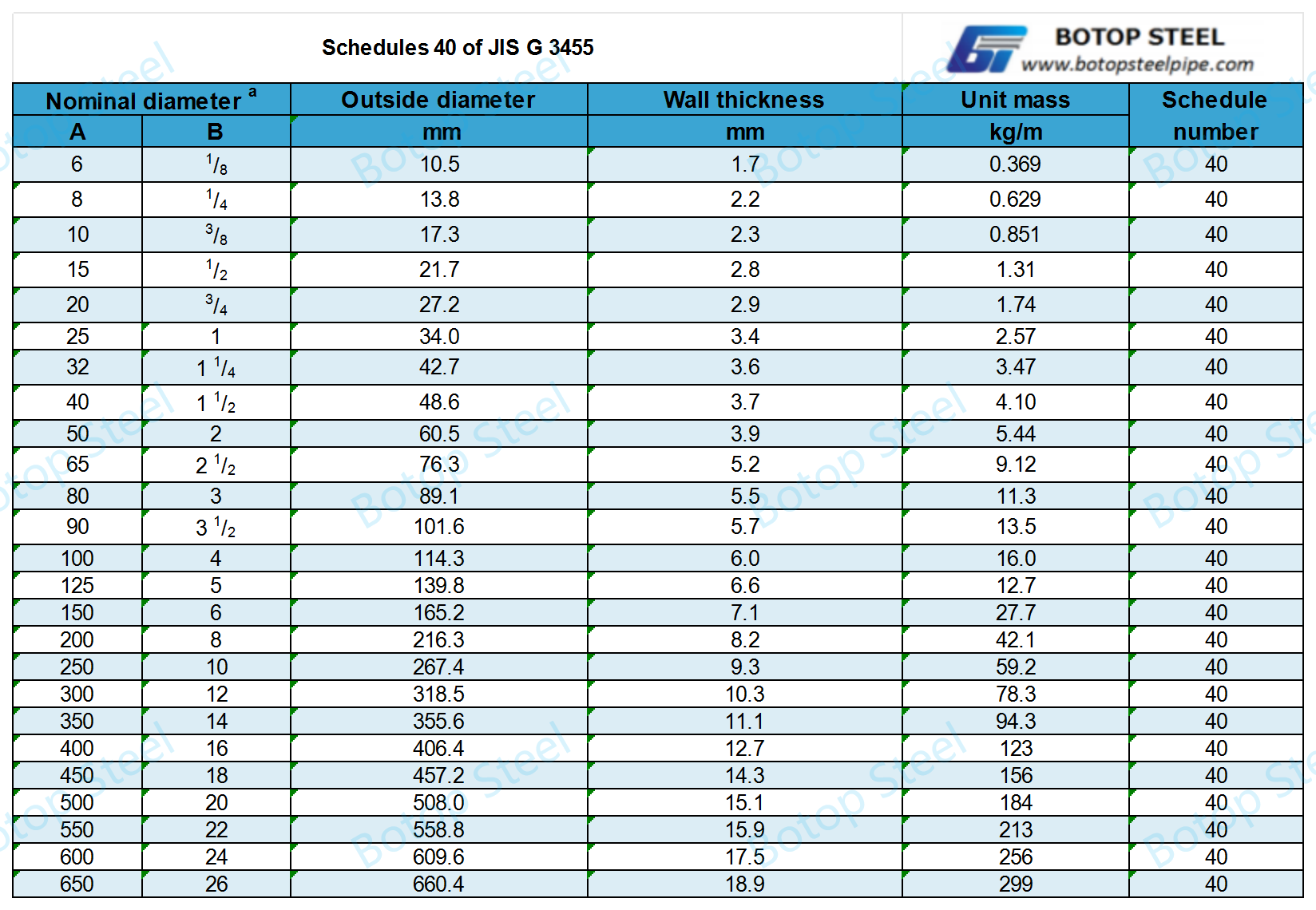

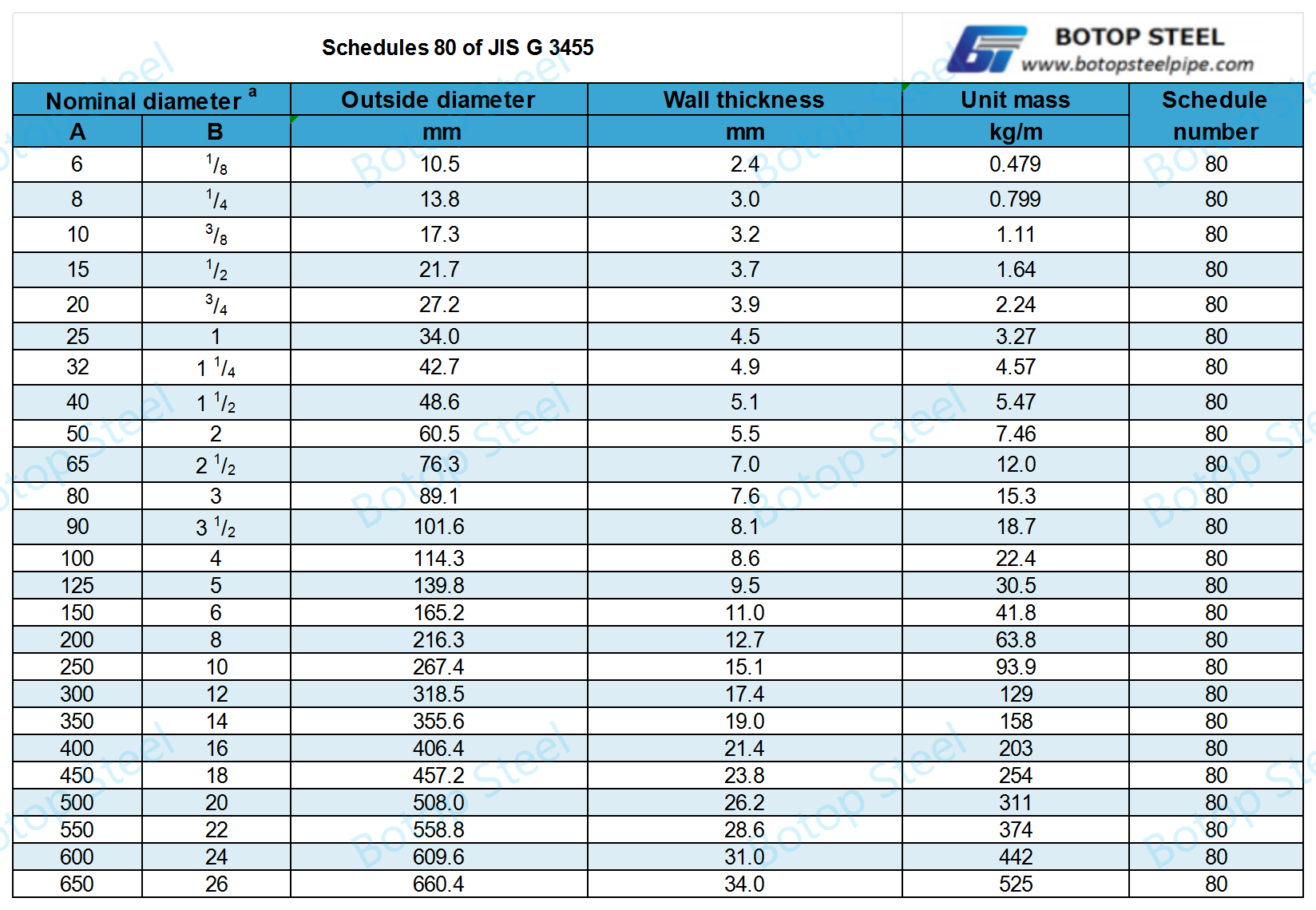

Kunze dhayamita 10.5-660.4mm (6-650A) (1/8-26B).

Machubhu anozogadzirwa kubva kunesimbi yakaurayiwa.

Simbi yakaurayiwa isimbi yakabviswa zvachose isati yakandwa mumaingo kana mamwe mafomu. Maitiro acho anosanganisira kuwedzera deoxidizing agent yakadai sesilicon, aluminium, kana manganese kusimbi isati yaoma. Izwi rekuti "akaurawa" rinoratidza kuti hapana oxygen reaction inoitika musimbi panguva yekusimba.

Nekubvisa okisijeni, simbi yakaurayiwa inodzivirira kuumbwa kwemhepo inoputika musimbi yakanyungudutswa, nokudaro kudzivirira porosity uye mhepo inoputika muchigadzirwa chekupedzisira. Izvi zvinoguma mune imwe homogeneous uye dense simbi ine yepamusoro michina zvivakwa uye chimiro chekuvimbika.

Simbi yakaurayiwa inonyanya kukodzera kushandiswa kunoda hutano hwepamusoro uye kusimba, zvakadai semidziyo yekumanikidza, zvivakwa zvakakura, uye mapaipi ane zvinodiwa zvemhando yepamusoro.

Nekushandisa simbi yakaurayiwa kugadzira machubhu, unogona kuve nechokwadi chekushanda kuri nani uye hupenyu hurefu hwesevhisi, kunyanya munzvimbo dziri pasi pemitoro inorema uye kumanikidzwa.

Yakagadzirwa uchishandisa isina musono nzira yekugadzira yakasanganiswa neyokupedzisa nzira.

Kupisa-kupedza seamless simbi pombi: SH;

Kutonhora-kupedzwa seamless simbi pombi: SC.

Yekugadzira isina musono nzira, inogona kupatsanurwa kuita seamless simbi pombi ine dhayamita yekunze inodarika 30mm uchishandisa kupisa kunopisa kugadzira, uye 30mm uchishandisa kutonhora kwekupedzisa kugadzira.

Heino kuyerera kwekugadzirwa kweHot-yakapedza isina musono.

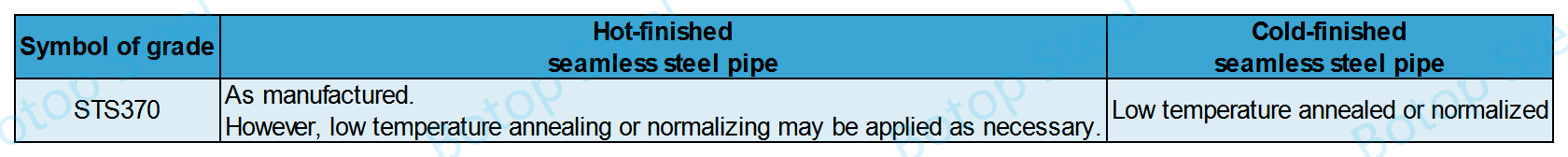

Kudzika-tembiricha annealing inonyanya kushandiswa kuvandudza kushanda kwezvinhu, kuderedza kuomarara, nekuvandudza kuoma, uye inokodzera simbi inotonhora.

Normalizing inoshandiswa kuvandudza simba uye kuoma kwezvinhu, kuitira kuti simbi inonyatsokodzera kutsungirira mechanical stress uye kuneta, inowanzoshandiswa kuvandudza kushanda kwesimbi inotonhora.

Kuburikidza neaya maitiro ekupisa kupisa, chimiro chemukati chesimbi chinogadziridzwa uye zvimiro zvayo zvinovandudzwa, zvichiita kuti ive yakakodzera kushandiswa mukuda maindasitiri ekushandisa.

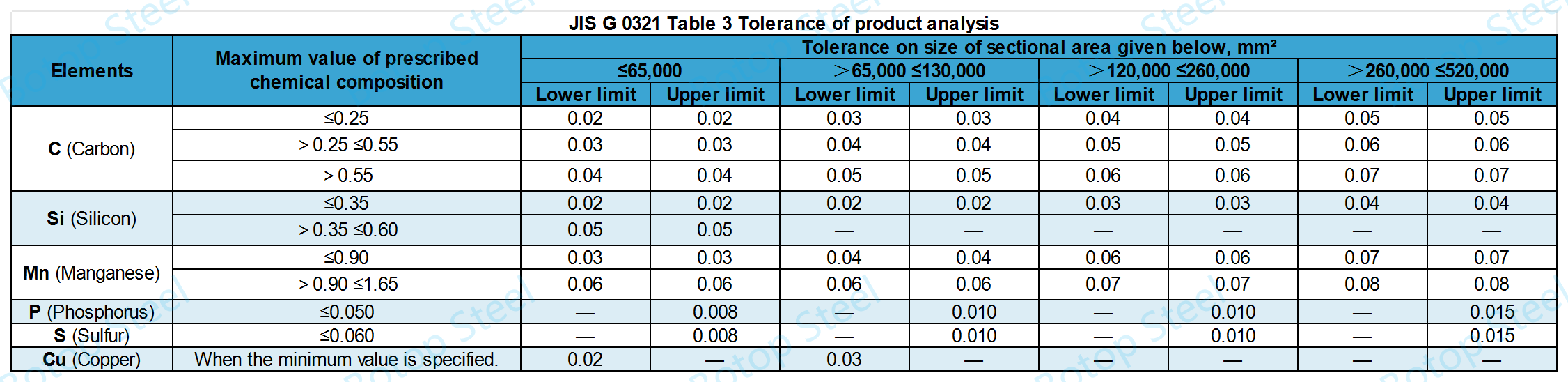

Kuongororwa kwekupisa kuchave maererano neJIS G 0320. Kuongorora kwechigadzirwa kuchave maererano neJIS G 0321.

| giredhi | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| STS370 | 0.25% yakawanda | 0.10-0.35% | 0.30-1.10% | 0.35% yakakura | 0.35% yakakura |

Kuongorora kupisainonyanya kunangwa pakuedza kemikari yezvigadzirwa zvemhando.

Nekuongorora kemikari yezvigadzirwa zvezvakagadzirwa, zvinokwanisika kufanotaura uye kugadzirisa matanho ekugadzirisa uye mamiriro angave achidiwa mukugadzirwa kwekugadzira, senge kupisa kupisa paramita uye kuwedzera kwealloying zvinhu.

Kuongorora kwechigadzirwainoongorora kemikari yezvigadzirwa zvakapedzwa kuona kutevedza uye kunaka kwechigadzirwa chekupedzisira.

Ongororo yechigadzirwa inova nechokwadi chekuti shanduko dzese, kuwedzera kana chero kusachena kunobvira muchigadzirwa panguva yekugadzira kuri pasi pesimba uye kuti chigadzirwa chekupedzisira chinosangana nehunyanzvi hwekuita uye zvinodiwa zvekushandisa.

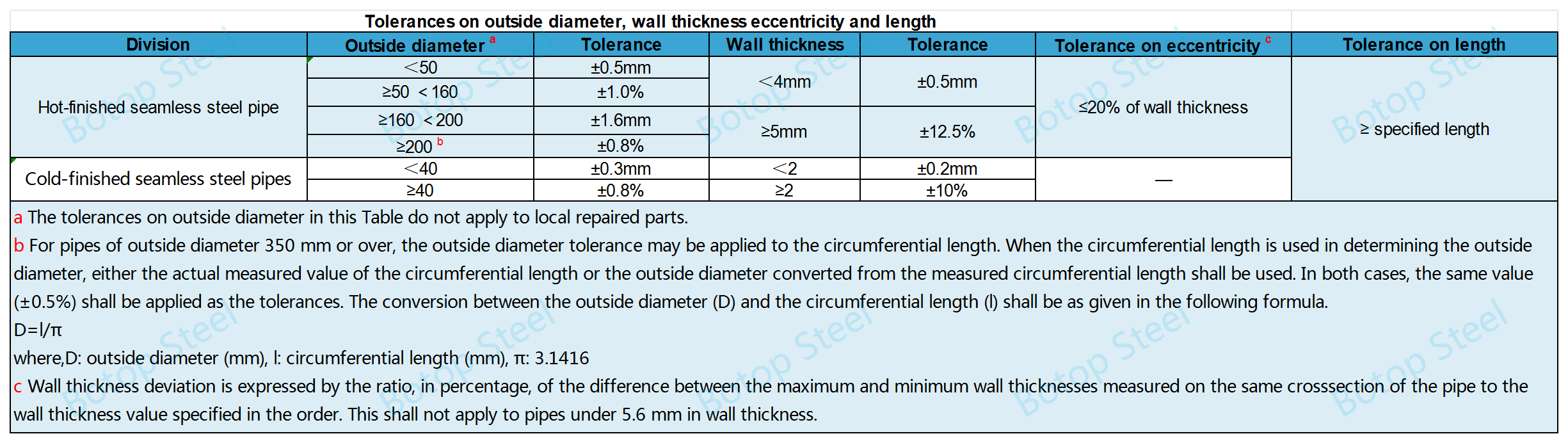

JIS G 3455 kukosha kwekuongororwa kwechigadzirwa hakungoenderana chete nezvinodiwa zvezvinhu zviri patafura iri pamusoro, asiwo huwandu hwekushivirira hunoenderana nezvinodiwa zveJIS G 3021 Tafura 3.

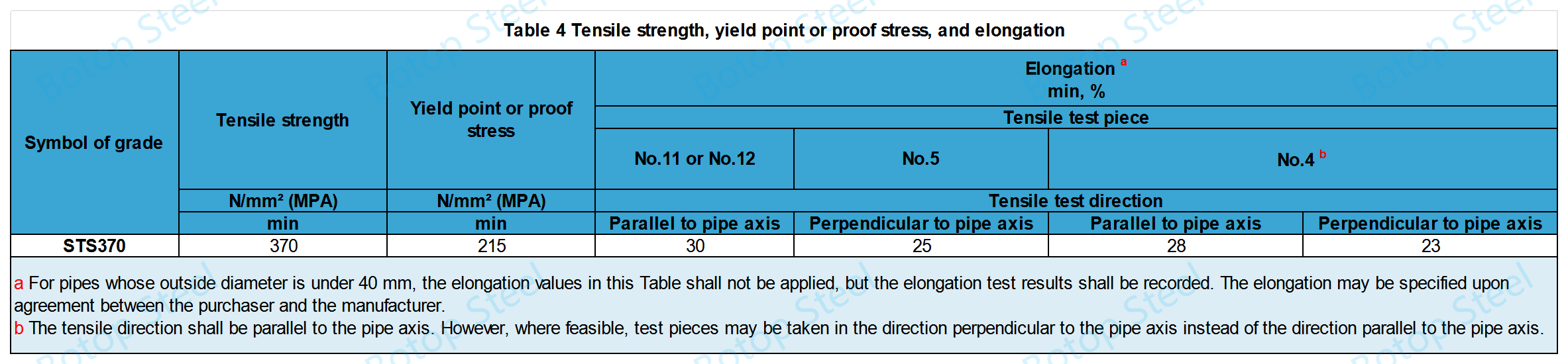

Elongation values for Test piece No. 12 (parallel to pipe axis) uye Test chidimbu Nha. 5 (perpendicular to pipe axis) inotorwa kubva papombi pasi pe8 mm muukobvu hwemadziro.

| Chiratidzo chegiredhi | Test piece inoshandiswa | Elongation min, % | ||||||

| Kukora kwemadziro | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| STS370 | Nhamba 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Nhamba 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Hukoshi hwekurebesa patafura iyi hunowanikwa nekubvisa 1.5% kubva pahukoshi hwekurebesa hwakapihwa muTebhurari 4 kune yega yega 1 mm inodzikira mukukora kwemadziro kubva pa8 mm, uye nekutenderedza mhedzisiro kuenda kunhamba zvichienderana neMutemo A weJIS Z 8401. | ||||||||

Muedzo wekubata kumeso unogona kusiiwa kunze kwekunge zvatsanangurwa neimwe nzira nemutengi.

Isa muenzaniso mumushini uye ugoiputira kusvikira chinhambwe chiri pakati pemapuratifomu maviri chasvika pamutengo wakatarwa H. Zvadaro tarisa muenzaniso wezvimedu.

Paunenge uchiyedza kupikisa kwakakomba welded pombi, mutsara uri pakati peiyo weld nepakati pepombi ndeye perpendicular kune yekumanikidza kutungamira.

H=(1+e)t/(e+t/D)

H: chinhambwe pakati pemapuleti (mm)

t: kukora kwemadziro echubhu (mm)

D: kunze kwedhayamita yechubhu (mm)

е:nguva dzose inotsanangurwa yegiredhi imwe neimwe yechubhu.0.08 yeSTS370: 0.07 yeSTS410 uye STS480.

Inokodzera mapaipi ane dhayamita yekunze ye ≤ 50 mm.

Muenzaniso wacho haungave wakatsemuka kana wakakotama pa90 ° nedhayamita yemukati katanhatu kupfuura dhayamita rekunze kwepombi.

Kona yekukotama ichayerwa pakutanga kwekubhenda.

Yese pombi yesimbi inoda kuongororwa hydrostatically kana isiri-destructivelykuve nechokwadi chemhando uye kuchengetedzwa kwepombi uye kusangana nezviyero zvekushandisa.

Hydraulic Test

Kana pasina kudzvanywa kweyedzo kunotsanangurwa, iyo shoma hydro yekuyedza kudzvanywa ichatemwa zvinoenderana nePipe Schedule.

| Nominal rusvingo ukobvu | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Minimum hydraulic test pressure, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Kana iyo madziro emadziro ekunze kwekunze kwepombi yesimbi isiri iyo yakakosha kukosha mutafura yehuremu hwepombi yesimbi, zvinodikanwa kushandisa fomuro kuverenga kukosha kwekumanikidza.

P=2st/D

P: test pressure (MPa)

t: kukora kwemadziro epombi (mm)

D: kunze dhayamita yepombi (mm)

s: 60 % yehushoma kukosha kwegoho poindi kana chiratidzo chekusimbisa chakapihwa.

Kana iyo yakaderera hydrostatic bvunzo yekumanikidza yenhamba yechirongwa chakasarudzwa ichipfuura bvunzo yekumanikidza P yakawanikwa neformula, iyo yekumanikidza P ichashandiswa seyakaderera hydrostatic test pressure pachinzvimbo chekusarudza iyo shoma hydrostatic test pressure mutafura iri pamusoro.

Muedzo usingaparadzi

Kuedza kusingaparadzi kwemachubhu esimbi kunofanirwa kuitwa neultrasonic kana eddy ikozvino kuyedza.

Forultrasonichunhu hwekuongorora, chiratidzo kubva kune referenzi sampuli ine referensi chiyero chekirasi UD sezvakatsanangurwa mukatiJIS G 0582ichaonekwa seyero yearamu uye ichava nechiratidzo chekutanga chakaenzana kana chikuru kupfuura chiyero chearamu.

Iyo yakajairwa yekuona senitivity yeeddy currentbvunzo ichave chikamu EU, EV, EW, kana EX yakatsanangurwa mukatiJIS G 0583, uye hapazove nemasaini akaenzana kana makuru kupfuura masiginecha anobva kumuenzaniso wereferenzi une chiyero chereferenzi chechikamu chakataurwa.

For morePipe Weight Charts uye Pipe Schedulesmukati mechiyero, unogona kudzvanya kuburikidza.

Schedule 40 pombi yakanyatsokodzera kune yakaderera kusvika yepakati-kudzvanywa maapplication nekuti inopa ine mwero madziro ukobvu inodzivirira huremu hwakawandisa uye mutengo uchisimbisa simba rakakwana.

Schedule 80 piping inoshandiswa zvakanyanya munzvimbo dzemaindasitiri dzinoda kudzvanywa kwepamusoro-soro, senge makemikari ekugadzirisa masisitimu uye oiri uye gasi kufambisa pombi, nekuda kwekugona kwayo kumirisana nedzvinyiriro yakakwira uye yakasimba mechanicha inokanganisa nekuda kwekukora kwayo kwemadziro, ichipa kumwe kuchengetedzeka, chengetedzo, uye kugara kwenguva refu.

Imwe neimwe chubhu ichanyorwa nemashoko anotevera.

a)Chiratidzo chegiredhi;

b)Chiratidzo chekugadzira nzira;

c)DimensionsMuenzaniso 50AxSch80 kana 60.5x5.5;

d)Zita remugadziri kana chiziviso.

Kana dhayamita rekunze rechubhu imwe neimwe riri diki uye zvakaoma kumaka chubhu imwe neimwe, kana kuti mutengi paanoda kuti tsanga imwe neimwe yemachubhu yamaka, sumbu rega rega rinogona kumakwa nenzira yakakodzera.

STS370 yakakodzera kune yakaderera-kudzvanywa asi yakakwira-tembiricha yekutamisa masisitimu.

Heating systems: Muguta rekudziya kana chivako chikuru chekudziya masisitimu, STS370 inogona kushandiswa kutakura mvura inopisa kana chiutsi nekuti inogona kumirisana nekumanikidza uye tembiricha shanduko muhurongwa.

Simba zvinomera: Mukugadzirwa kwemagetsi, nhamba huru ye-high-pressure steam pombi inodiwa, uye STS370 ndiyo yakakodzera zvinhu zvekugadzira mapaipi aya nokuti inogona kumira kwenguva yakareba yekushisa kwepamusoro uye nzvimbo dzekushanda.

Compressed air systems: Mukugadzira uye otomatiki mitsara yekugadzira, mhepo yakadzvanywa ndiyo yakakosha sosi yesimba, uye STS370 simbi pombi inoshandiswa kuvaka pombi yeaya masisitimu kuti ave nechokwadi chekuchengetedza uye kushanda kwemhepo.

Kushandiswa kwemaitiro uye general mashini: Nekuda kweiyo yakanaka mekiniki zvivakwa, STS370 inogona zvakare kushandiswa mukugadzirwa kweakasiyana masisitimu uye emakanika zvikamu, kunyanya mumashandisirwo panodiwa imwe simba rekumanikidza.

JIS G 3455 STS370 isimbi yekabhoni inoshandiswa mubasa repamusoro-soro. Zvinhu zvinotevera zvinogona kutariswa zvakaenzana kana zvakada kuenzana:

1. ASTM A53 Giredhi B: Inokodzera zvakajairwa zvimiro uye zvemichina zvikumbiro uye nekufambisa mvura.

2. API 5L Giredhi B: Yepamusoro-kudzvanywa mafuta uye gasi pombi dzekufambisa.

3. DIN 1629 St37.0: Yeyakajairwa mechanical engineering uye ngarava kuvaka.

4. EN 10216-1 P235TR1: Seamless simbi pombi nokuda yakakwirira tembiricha uye yakakwirira kumanikidzwa nharaunda.

5. ASTM A106 Giredhi B: Seamless kabhoni simbi pombi nokuda kwepamusoro-tembiricha basa.

6.ASTM A179: Seamless inotonhora-inodhonzwa nyoro machubhu esimbi uye mapaipi epasi-tembiricha sevhisi.

7. DIN 17175 St35.8: Seamless chubhu zvinhu zve boilers uye kumanikidza midziyo.

8. EN 10216-2 P235GH: Machubhu asina musono uye mapaipi eisina-alloy uye alloy simbi yekumusoro-tembiricha uye yakakwirira-kudzvinyirira nharaunda.

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana. Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.

Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.