API (American Petroleum Institute Standard) 5L ndiyo chiyero chepasi rose chepombi yesimbi inoshandiswa mumapombi ekufambisa masisitimu.

API 5L inovhara simbi pombi kune akasiyana mashandisirwo ekufambisa gasi rechisikigo, oiri, uye zvimwe zvinwiwa.Zuva rekushanda reiyo 46th edition: kutanga muna Mbudzi 1, 2018.

Kana iwe uchingoda kuwana pfungwa yakajairika yeAPI 5L, ndapota tinyaAPI 5L Pipe Specification Overview.

Navigation Buttons

Chii Chakagadziridzwa muAPI 5L 46th

Kwakabva API 5L PSL

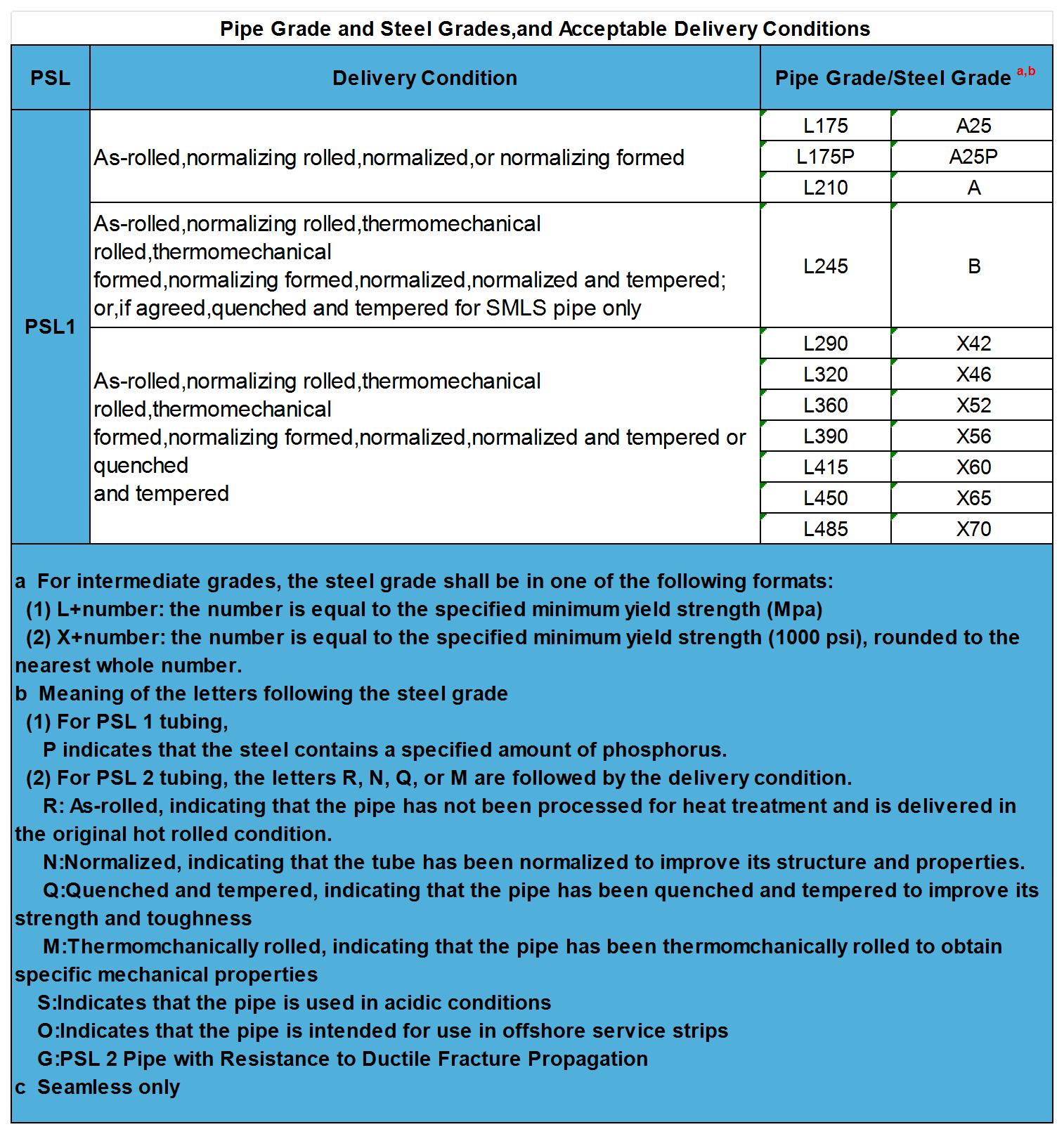

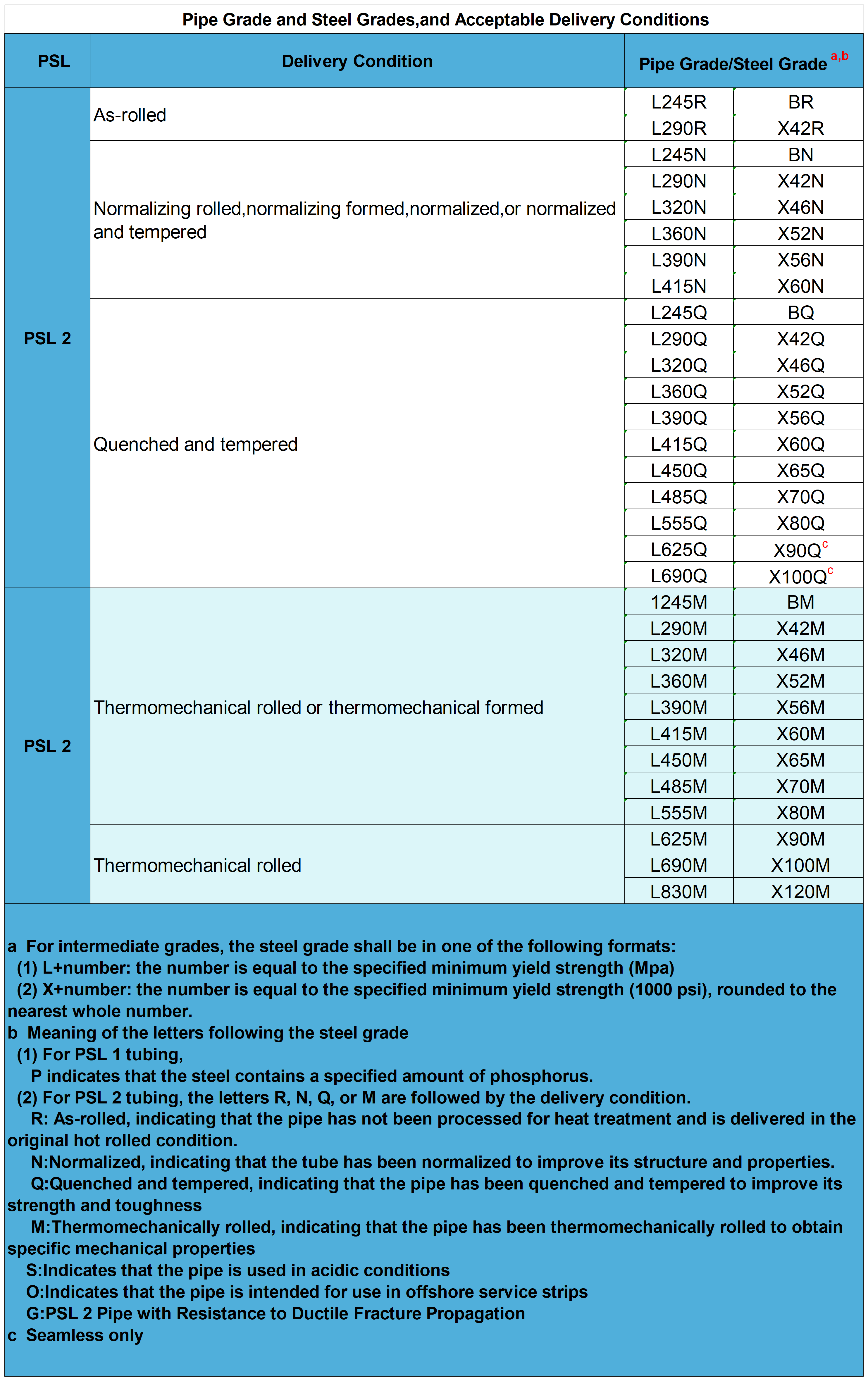

Kurongeka kweSimbi Magiredhi uye Pipe Magiredhi

Inobvumirwa Delivery States

Raw Materials eSimbi Mapaipi

Mhando dzeSimbi Pipe uye Tube Inopera Yakavharwa ne API 5L

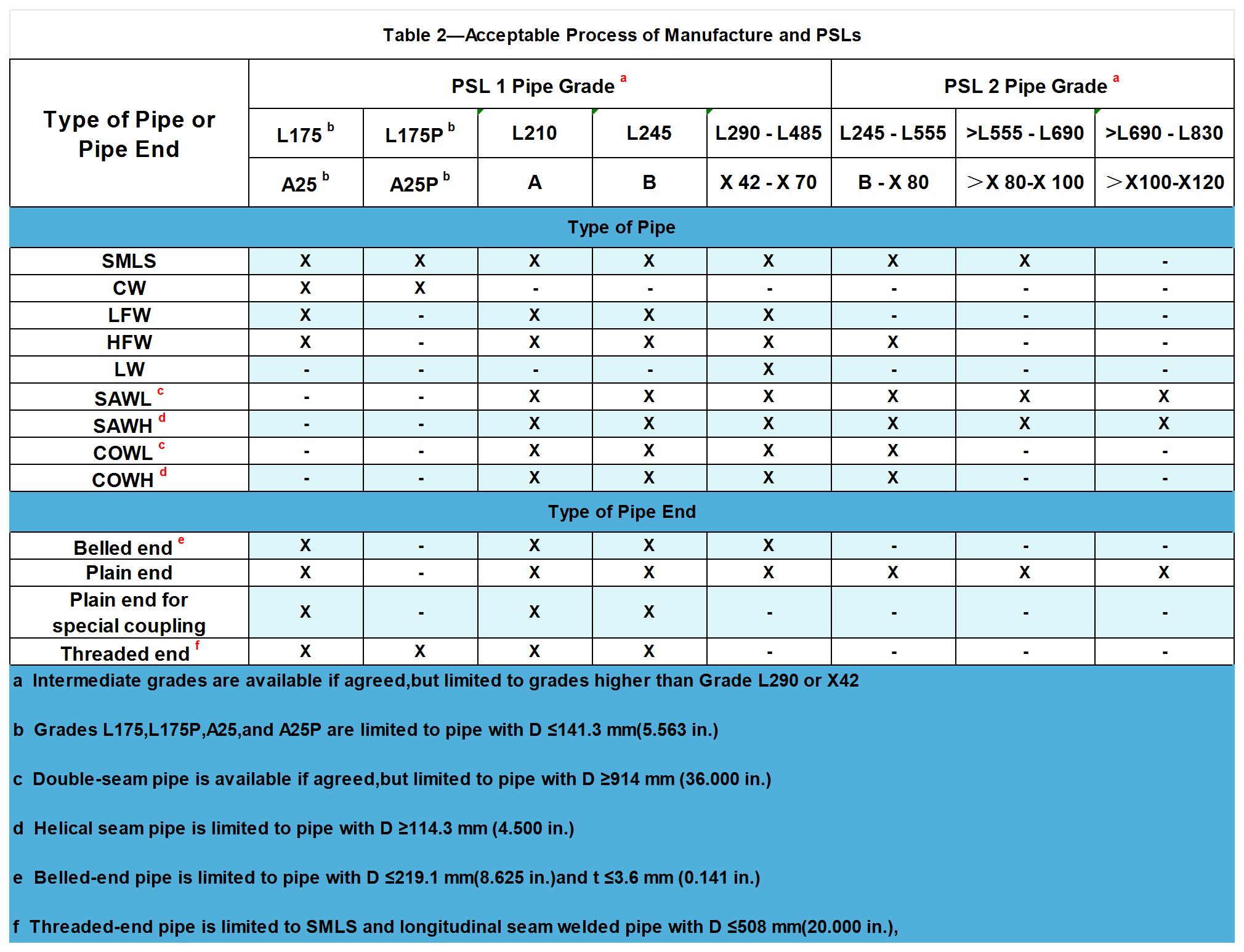

Inogamuchirwa Kugadzira Maitiro ePSL2 Simbi Tubing

Kuongororwa kwekuonekwa uye kukanganisa kwakajairika kweAPI 5L

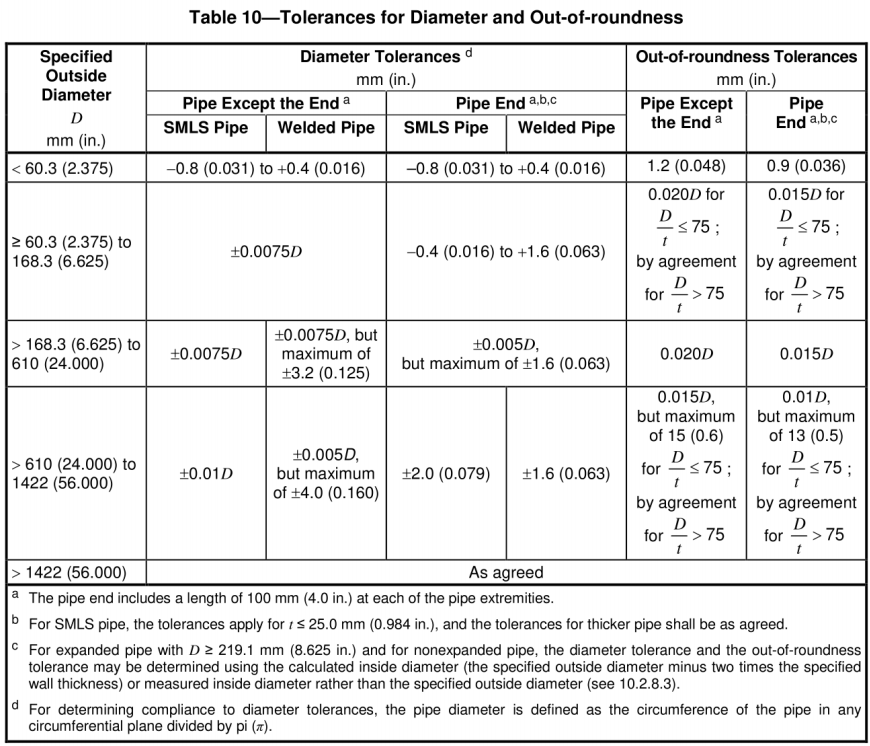

Dimensional Inspection (Dimensional Deviations)

API 5L Yekuongorora Zvinhu

Kumaka kwepombi uye Nzvimbo

Equivalence Standard

Zvigadzirwa zvedu zvinoenderana

Chii Chakagadziridzwa muAPI 5L 46th

Updates

Yakagadziridzwa uye yakawedzerwa zvinodiwa zvemilled joints;

Updated zvinodiwa pombi kupera perpendicularity;

Yakagadziridzwa kuomarara zvinodiwa zveAPI 5LPSL 2 mapaipi enzvimbo dzakavava uye API 5L PSL 2 mapaipi enzvimbo dzekunze;

New

API 5L PSL 2 pombi yemashandisirwo anoda longitudinal epurasitiki strain kugona.

Kwakabva API 5L PSL

PSL: Pipeline Specification Level pfupiso;

Yakakamurwa kuita: API 5L PSL 1 uye API 5L PSL 2.

Kurongeka kweSimbi Magiredhi uye Pipe Magiredhi

L + nhamba(iro bhii L rinoteverwa neyakatsanangurwa kushomeka goho resimba muMPa):

L175, L175P, L210, L245, L290, L320, L360, L390, L415, L450, L485, L555, L625, L690, L830

X + nhamba(nhamba iri kutevera vara X inotsanangura hushoma hwesimba mu1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

Uye giredhi A negiredhi b.Giredhi A=L210 Giredhi B=L 2459

Inobvumirwa kutumira nyika

Cherechedza: L415/X60 kana mamakisi epamusoro haafaniri kushandiswa panzvimbo yeL360/X52 kana mamakisi akaderera pasina chibvumirano chemutengi.

Raw Materials eSimbi Mapaipi

Ingot, billet, billet, strip (coil) kana ndiro.

Cherechedza:

1. The raw material yeAPI 5L PSL2pombi yesimbi inofanira kuva simbi yakatsetseka.

2. Steel strip (coil) kana ndiro inoshandiswa kugadzira API 5L PSL2 simbi pombi haingatakure chero tack welds.

Mhando dzeSimbi Pipe uye Tube Inopera Yakavharwa ne API 5L

Welded Simbi Pipe

CW Pipe:Nzira yekugadzira musono nekudziisa tambo muchoto uye nekudzvanya nemuchina pakaumbwa pamwe chete, umo macoil anotevedzana emucheka akange abatanidzwa pamwechete kuti ape kuenderera kunoenderera kwekuyerera kwechigayo chewelding.

COWHPipe:Tubular chigadzirwa chine helical seam imwe inogadzirwa nemusanganiswa wegasi simbi arc uye yakanyura arc welding, umo gasi simbi arc weld bead haina kubviswa zvachose nekunyudzwa kwearc welding inopfuura.

COWL Pipe:Tubular chigadzirwa chine imwe kana maviri longitudinal seams inogadzirwa nemusanganiswa wegasi simbi arc uye yakadzika arc welding, umo gasi simbi arc weld bead haina kubviswa zvachose nekunyudzwa kwearc welding inopfuura.

EW Pipe:Tubular chigadzirwa chine one longitudinal seam inogadzirwa neyakaderera-kana yakakwirira-frequency magetsi welding.

HFW Pipe:EWpipe yakagadzirwa' ine welding current frequency yakaenzana kana kupfuura 70 kHz.

LFW Pipe:EW pombi inogadzirwa ine welding ikozvino frequency isingasviki 70 kHz.

LW Pipe:Tubular chigadzirwa chine one longitudinal seam inogadzirwa nelaser welding.

SAWH Pipe:Tubular chigadzirwa chine helical seam imwe inogadzirwa neyakanyura arc welding process.

SAWLPipe:Tubular chigadzirwa chine imwe kana maviri longitudinal seams inogadzirwa neyakanyura arc welding.

Seamless Simbi Pipe

SMLS pombi:Kupisa yakatenderedzwa seamless simbi pombi uye inotonhora yakakungurutswa seamless simbi pombi, kune dzimwe nzira dzekugadzirisa, senge kutonhora kudhirowa, kutonhora kudhirowa, forging, nezvimwe.

API 5L PSL2 Pipe mhando dzeakakosha maapplication

Kupokana neDuctile Fracture Propagation (G)

Sour Service Condition Pipe (S)

Offshore Service Condition Pipe (O)

Inoda Longitudinal Plastic Strain Capacity Pipe

Pipe End Types

Socket End, Flat End, Special Clamp Flat End, Threaded End.

Cherechedza:

1. Socket ends, pombi inopera kune yakakosha clamps, uye threaded pombi inogumira ndeye API 5L PSL1 chete.

2. L175 P/A25 P giredhi resimbi API 5L PSL1 pombi yesimbi ichagadzirwa nemigumo ine threaded, uye API 5L PSL1 simbi pombi yemamwe magiredhi esimbi achagadzirwa ane flat ends.

3. API 5L PSL 2 machubhu achaunzwa ane flat ends.

Inogamuchirwa Kugadzira Maitiro ePSL2 Simbi Tubing

| Tafura 3-Inogamuchirwa Manufacturing Routes yePSL 2 Pipe | ||||

| Rudzi rwePipe | Kutanga Materia | Kugadzira Pipe | Pipe Kupisa Kurapa | Delivery Condition |

| SMLS | Ingot, bloom, kana billet | As-akakungurutswa | - | R |

| Normalizing kuumba | - | N | ||

| Kupisa kuumba | Normalizing | N | ||

| Kudziya uye kudziya | Q | |||

| Kupisa kuumba uye kutonhora kupedza | Normalizing | N | ||

| Kudziya uye kudziya | Q | |||

| HFW | Normalizing-yakakungurutswa coil | Kutonhora kuumba | Kurapa kupisaa ye weld nzvimbo chete | N |

| Thermomechanical-yakakunguruka coil | Kutonhora kuumba | Kurapa kupisaa ye weld nzvimbo chete | M | |

| Kurapa kupisaa ye weld nzvimbo uye kushushikana kudzikamisa pombi yese | M | |||

| Se-yakakungurutswa kana thermomechanical-yakakunguruka coil | Kutonhora kuumba | Normalizing | N | |

| Kudzima uye tempering | Q | |||

| Kutonhora kuumbwa kunoteverwa nekupisa kuderedza pasi pekudzora tembiricha inokonzera a normalized condition | - | N | ||

| Kutonhora kuumbwa kuchiteverwa thermomechanical kugadzira yepipe | - | M | ||

| SAW kana COW | Normalized kana normalizing- coil kana ndiro | Kutonhora kuumba | - | N |

| As-akakungurutswa thermomechanical-yakakunguruka normalizing-yakakungurutswa, kana normalized | Kutonhora kuumba | Normalizing | N | |

| Thermomechanical-yakakunguruka coil kana ndiro | Kutonhora kuumba | - | M | |

| Kudzimwa uye kushatirwa ndiro | Kutonhora kuumba | - | Q | |

| As-akakungurutswa thermomechanical-yakakunguruka normalizing-yakakungurutswa, kana normalized coil kana ndiro | Kutonhora kuumba | Kudzima uye tempering | Q | |

| As-akakungurutswa thermomechanical-yakakunguruka normalizing-yakakungurutswa, kana normalized coil kana ndiro | Normalizing kuumba | - | N | |

| aOna ISO 5L 8.8 yemishonga yekupisa inoshanda | ||||

Kuongororwa kwekuonekwa uye kukanganisa kwakajairika kweAPI 5L

Zvitarisiko

Nzvimbo yekunze yepombi ichave yakatsetseka uye isina kukanganisa kunogona kukanganisa simba uye kuvhara zvinhu zvepombi.

Makangano Makuru

Nibbled edges:Nibbled edges inogona kuwanikwa zvakanyanya nekutarisa kwekuona.

Arc inopisa:Kupisa kweArc kuchatongwa sekusina kunaka.

Arc burns inoverengeka yenzvimbo dzakakanganisika dzenzvimbo dzakaumbwa nekunyunguduka kwesimbi kunokonzerwa nearc pakati pe electrode kana grounding electrode uye pamusoro pepombi yesimbi.

Nzvimbo dzekusangana inzvimbo dzinopindirana pedyo nemutsara we weld wepombi yeEW, zvichikonzerwa nekusangana pakati pe electrode inopa welding ikozvino uye pamusoro pepombi.

Delamination:Chero kudonhedza kana kusanganisirwa kunowedzera pamusoro pepombi kana kumeso kwakakomberedzwa uye iri > 6.4 mm (0.250 mukati) mukureba kwedenderedzwa pakutariswa kwekuona kuchaonekwa sechirema.

Kutsauswa kweGeometric:Kutsauka kwejometri (semuenzaniso, chivharo chakafuratira kana pout, nezvimwewo), kunze kwegomba rekudonhedza, rinokonzerwa nekuumbwa kwechubhu kana mashandiro ekugadzira.Nharaunda pakati penzvimbo yakanyanyisa uye kuwedzerwa kweiyo yakajairika contour yechubhu, kureva, kudzika kwakakura kupfuura 3.2 mm (0.125 mukati), ichaonekwa sechirema.

Drop pits ichave ≤ 0.5 D mune chero nzira.

Kuoma: Kana kuongorora kwekuona kunoratidza kufungidzirwa kuomarara, inotakurika kuomarara tester ichashandiswa kuita bvunzo yekuomarara, uye imwe-point indentation ine kuomarara kukosha kunodarika 35 HRC, 345 HV10, kana 327 HBW ichaonekwa isina kukwana kana saizi. ye indentation yakakura kupfuura 50 mm (2.0 mukati) mune chero nzira.

Defect Handling

Ndokumbira utarise kune zvinodiwa muAPI 5L Appendix C yekubata.

Dimensional Inspection (Dimensional Deviations)

Pipe Weight Chati uye Weight Kutsauka

Weight Formula

M=(DT)×T×C

M ndiyo huremu pahurefu hweyuniti;

D ndiyo yakataurwa kunze kwedhayamita, inoratidzwa mumamirimita (inches);

T ndiyo yakatsanangurwa madziro ukobvu, inoratidzwa mumillimeters (inches);

C ndeye 0.02466 yekuverenga mumayuniti eSI uye 10.69 yekuverenga mumayuniti eUSC.

PIPE WEIGHT CHARTS NEZVIRONGWA

pombi uremu matafura mu API 5L anotaurwa nezvawoISO 4200uyeASME B36.10M, iyo inopa zviyero zvepaipi ine dhayamita yekunze yakatsanangurwa uye kukora kwemadziro.

Purogiramu 40 uye Chirongwa 80zvakabatanidzwa pazasi, kana uchida kuona iyo yakazara pombi chirongwa,ndapota tinya pano!

Uremu Kutsauka

Unhu hwepombi imwe neimwe maererano nedzidziso: uremu: 95% ≤ theoretical uremu ≤ 110;

Kutsauka uye yakawedzera-yakaonda kududzira machubhu: 5% ≤ 110% yehuremu hwedzidziso;

L175, L175P, A25, uye A25P simbi mamakisi: 95% ≤ 110% of theoretical uremu.

Outer Diameter uye Wall Thickness Range

| Tafura 9-Inotenderwa Inotsanangurwa Kunze Diameter uye Yakatsanangurwa Rusvingo Hukobvu | ||

| Yakatsanangurwa Kunze Diameter D mm (mu.) | Yakatsanangurwa Kukobvu Kwemadziro t mm (mu.) | |

| Special Light Sizesa | Regular Sizes | |

| ≥10.3 (0.405)kusvika<13.7 (0.540) | - | ≥1.7 (0.068)kusvika≤2.4 (0.094) |

| ≥13.7 (0.540)kusvika<17.1 (0.675) | - | ≥2.2 (0.088)kusvika≤3.0 (0.118) |

| ≥17.1 (0.675)kusvika<21.3 (0.840) | - | ≥2.3 (0.091)ku≤3.2 (0.125 |

| ≥21.3 (0.840)kusvika<26.7 (1.050) | - | ≥2.1 (0.083)kusvika≤7.5(0.294) |

| ≥26.7(1.050)kusvika<33.4(1.315) | - | ≥2.1 (0.083)kusvika≤7.8 (0.308) |

| ≥33.4(1311}5)kusvika<48.3 (1.900) | - | ≥2.1 (0.083)kusvika≤10.0 (0.394) |

| ≥48.3 (1.900)kusvika<60.3 (2.375) | - | ≥2.1 (0.083)kusvika≤12.5 (0.492) |

| ≥60.3 (2.375)kusvika<73.0 (2.875) | ≥2.1 (0.083)kusvika≤3.6 (0.141) | >3.6 (0.141)kusvika≤14.2 (0.559) |

| ≥73.0 (2.875)kusvika<88.9(3.500) | ≥2.1 (0.083)kusvika≤3.6 (0.141) | >3.6 (0.141)kusvika≤20.0 (0.787) |

| ≥88.9 (3.500)kusvika<101.6(4.000) | ≥2.1 (0.083)kusvika≤4.0 (0.156) | >4.0 (0.156)kusvika≤22.0 (0.866) |

| ≥101.6(4.000)kusvika<168.3 (6.625) | ≥2.1 (0.083)kusvika≤4.0 (0.156) | >4.0(0.156)kusvika≤25.0 (0.984) |

| ≥168.3 (6.625)kusvika<219.1 (8.625) | ≥2.1 (0.083)ku≤4.0 (0.156 | >4.0 (0.156)kusvika≤40.0(1.575) |

| ≥219.1 (8.625)kusvika<273.1 (10.750) | ≥3.2 (0.125)ku≤4.0 (0.156 | >4.0 (0.156)kusvika≤40.0 (1.575 |

| ≥273.1 (10.750)kusvika<323.9 (12.750) | ≥3.6 (0.141)kusvika≤5.2 (0.203) | >5.2 (0.203)kusvika≤45.0 (1.771) |

| ≥323.9(12.750)kusvika<355.6(14.000) | ≥4.0 (0.156)kusvika≤5.6 (0.219) | >5.6 (0.219)kusvika≤45.0(1.771 |

| ≥355.6(14.000)kusvika<457(18.000) | ≥4.5 (0.177)kusvika≤7.1 (0.281) | >7.1 (0.281)kusvika≤45.0(1.771 |

| ≥457 (18.000)kusvika<559 (22.000) | ≥4.8 (0.188)kusvika≤7.1 (0.281) | >7.1 (0.281)kusvika≤45.0(1.771) |

| ≥559 (22.000)kusvika<711(28.000) | ≥5.6 (0.219)kusvika≤7.1 (0.281) | >7.1 (0.281)kusvika≤45.0(1.771) |

| ≥711 (28.000)kusvika<864(34.000) | ≥5.6(0.219)kusvika≤7.1 (0.281) | >7.1 (0.281)kusvika≤52.0 (2.050) |

| ≥864 (34.000)kusvika<965(38.000) | - | ≥5.6 (0.219)kusvika≤52.0 (2.050) |

| ≥965(38.000)kusvika<1422 (56.000) | - | ≥6.4 (0.250)kusvika≤52.0 (2.050) |

| ≥1422(56.000)kusvika<1829 (72.000) | - | ≥9.5 (0.375)kusvika≤52.0 (2.050 |

| ≥1829(72.000)kusvika<2134(84.000) | - | ≥10.3 (0.406)kusvika≤52.0 (2.050) |

| aPombi ine musanganiswa wedhayamita yekunze yakatsanangurwa uye ukobvu hwemadziro hunotsanangurwa sepombi yakakosha-saizi yemwenje;mamwe masanganiswa akapihwa mutafura ino anotsanangurwa sepombi-saizi yenguva dzose. | ||

Diameter uye Roundness Kutsauka

Kutsauka Kwemadziro

| Tafura 11-Kushivirira kweKukora Kwemadziro | |

| Kukora Kwemadziro t mm (mu.) | Kushiviriraa mm (mu.) |

| SMLS Pipeb | |

| ≤4.0 (0.157) | +0.6(0.024) -0.5 (0.020) |

| >4.0 (0.157)kusvika <25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146)kana+0.1t, chero mukuru -3.0 (0.120) kana-0.1t, chero chikuru |

| Welded Pipecd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| >5.0 (0.197)kusvika<15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aKana odha yekutenga ichidoma minus kushivirira kwehukobvu hwemadziro hudiki pane hukoshi hunoshanda hwapihwa mutafura ino, kuwedzera kushivirira kweukobvu hwemadziro kuchawedzerwa nehuwandu hunokwana kuchengetedza kushivirira kunoenderana. bPapombi ine D2 355.6 mm (14.000 in.) uye 1 2 25.0 mm (0.984 mukati.), kushivirira kwemadziro munzvimbo kunogona kudarika kuwedzera kushivirira kwemadziro emadziro nekuwedzera 0.05t, chero bedzi kuwedzera kushivirira kwehuwandu (ona 9.14) haina kudarika. cIyo plus kushivirira kwemadziro ukobvu haishande kune weld nzvimbo. dOna 9.13.2 yezvimwe zvirambidzo. | |

Kutsauka Kweurefu

Yakagadzika-kureba tubing tolerances: Kutsauka kureba kunofanirwa kuve 500 mm (20 inches).

Random kureba pombi tolerances:

| Tafura 12-Kushivirira kweRandom Length Pipe | |||

| Random Length Designation m(ft) | Minimum Length m (ft) | Minimum Average Length Pachinhu chimwe nechimwe cheOdha m (ft) | Maximum Length m (ft) |

| Yakarukwa-uye-yakabatanidzwa Pipe | |||

| 6(20) | 4.88(16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9(30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67(35.0) | 13.72(45.0 |

| Plain-end Pipe | |||

| 6(20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00(26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72(45.0) |

| 15(50) | 5.33 (17.5) | 13.35(43.8) | 16.76(55.0) |

| 18(60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24(80) | 8.53 (28.0) | 21.34(70.0) | 25.91(85.0) |

Kutsauka Kururama

Kutsauka kwese kubva kumutsara wakatwasuka pamusoro pehurefu hwose hwepombi huchava <0.2% yehurefu hwepombi;

Kutsauka kwenzvimbo kubva pamutsetse wakatwasuka kuchave <3.2 mm (0.125 mu) pamusoro pe 1.5 m (5.0 ft) kureba kwepombi imwe neimwe.

Bevel Angle Kutsauka

Chubhu ine t > 3.2 mm (0.125 mu) magumo akafuratira achagadzirwa ane weld bevel ine bevel angle ye30 ° -35 °.

Upamhi hweDeveled Root Surface

1.6 mm (0.063 mukati) nekutsauka kwe ± 0.8 mm (0.031 mukati).

Range yeInner Cone Angle (chete yesimbi isina musono pombi)

| Tafura 13-Maximum Angle yeInternal Taper yeSMLS Pipe | |

| Yakatsanangurwa Kukobvu Kwemadziro t mm (mu.) | Maximum Angle yeTaper madhigirii |

| <10.5(0.413) | 7.0 |

| 10.5 (0.413)kusvika <14.0 (0.551) | 9.5 |

| 14.0 (0.551)kusvika <17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

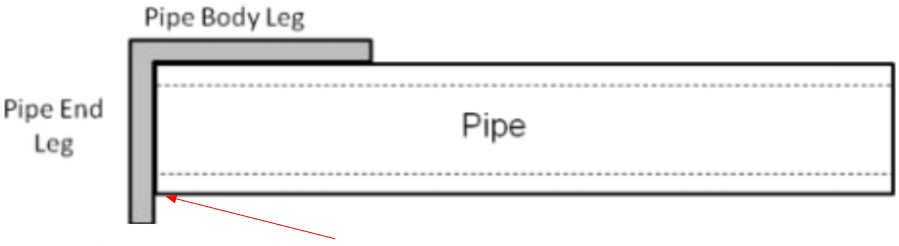

Pipe End Squareness (kunze-kwe-squareness)

Iyo yekunze-ye-squareness inoyerwa semukana pakati pekupedzisira kwepombi uye gumbo rekupedzisira pombi, iro richava 1.6 mm (0.063 mukati.).

Welding Seam Kutsauka

Mitsetse/Sheet Misalignment:

Kune electro-welded (EW) uye laser-welded (LW) pombi, iyo misalignment haifanire kuguma nekusara kwemadziro ukobvu pane weld iyo ishoma pane yakaderera inotenderwa madziro ukobvu.

Kune iyo Submerged Arc Welded (SAW) uye Combination Welded (COW) pombi, iyo misalignment haifanire kudarika iyo inoenderana tsika dzakapihwa muTafura 14 yeAPI 5L.

Burrs (electro-welded (EW) uye laser-welded (LW) machubhu):

Mabhara ekunze anozobviswa kune akanyanya kunyungudika mamiriro (ine base material).

Mabhura emukati haafanire kureba 1.5 mm (0.060 mukati) kupfuura contour yechubhu, uye ukobvu hwemadziro padanho rekubvisa burr hahuzove hushoma pane hudiki hunobvumidzwa ukobvu hwemadziro.

Weld Height( Submerged Arc Welding (SAW) uye Combination Welding (COW) Pipe):

Bvisa hurefu hwasara hwemukati weld mukati mehushoma hwe 100 mm (4.0 mukati) yepombi inopera pamagumo epombi, uye geda weld kuitira kuti irege kukwira kupfuura 0.5 mm (0.020 mukati) pamusoro pepamusoro. wepombi iri pedyo.

API 5L Yekuongorora Zvinhu

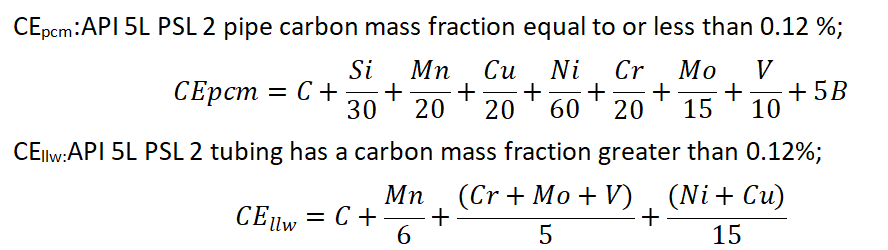

Kuumbwa Kwemakemikari

Test Method: Tarisa kune ISO 9769 kana ASTM A751.

Iko kemikari ye API 5L PSL1 uye API 5L PSL2 simbi pombi t > 25.0 mm (0.984 mu) ichagadziriswa nekutaurirana kunoenderana nemakemikari ezvinyorwa mumatafura anoenderana.

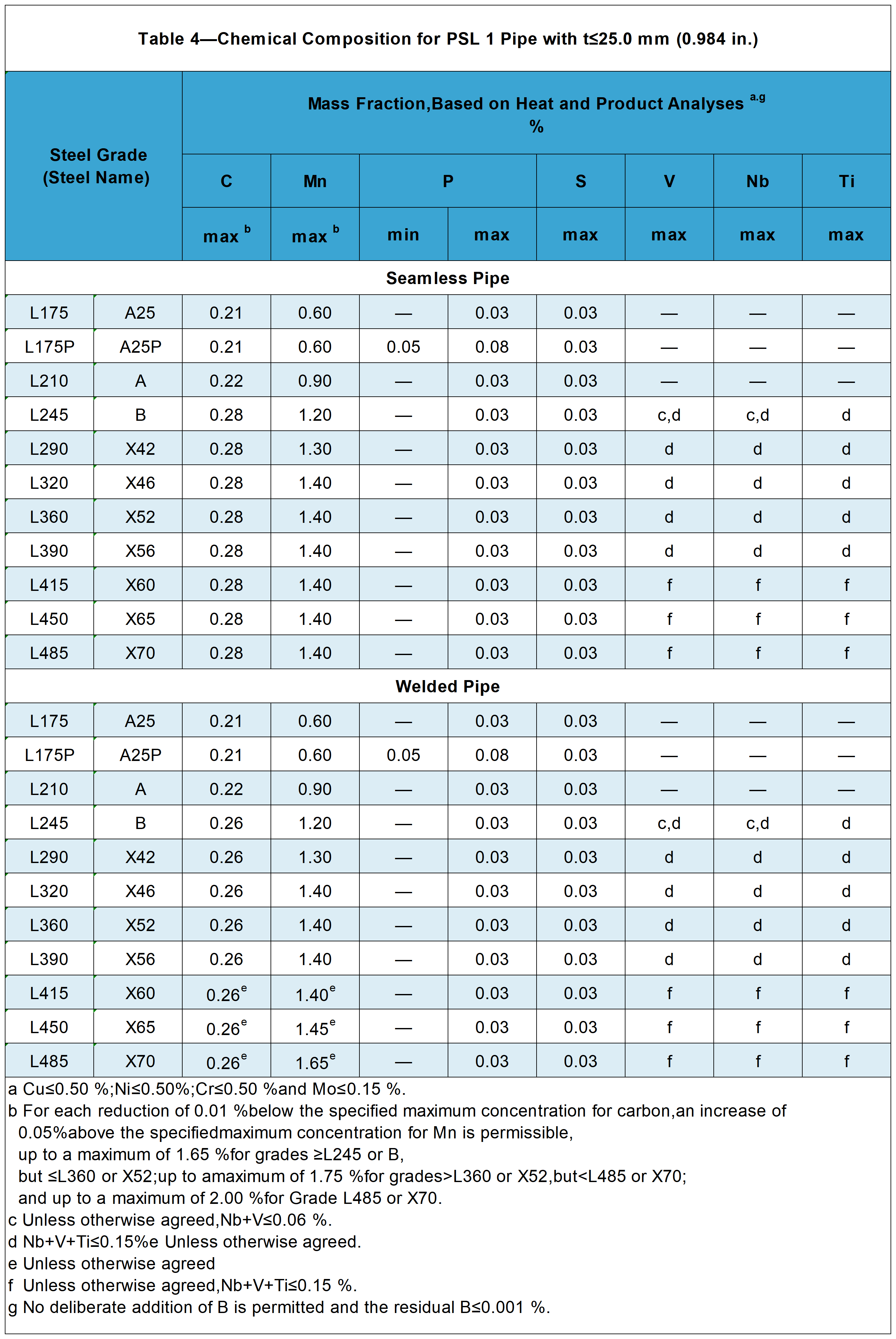

Kemikari Inoumbwa yePSL 1 Pipe ine t≤25.0 mm (0.984 mukati.)

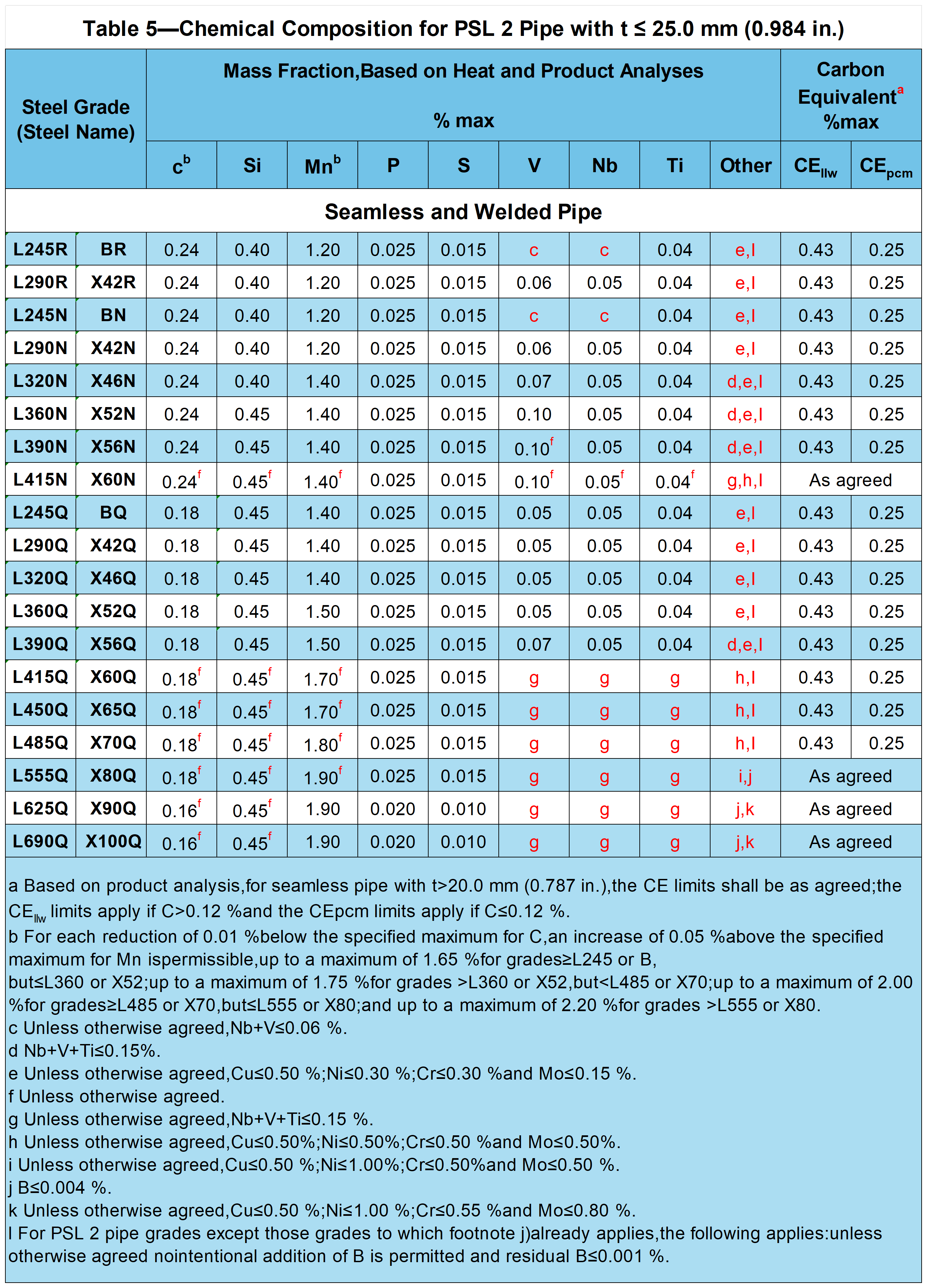

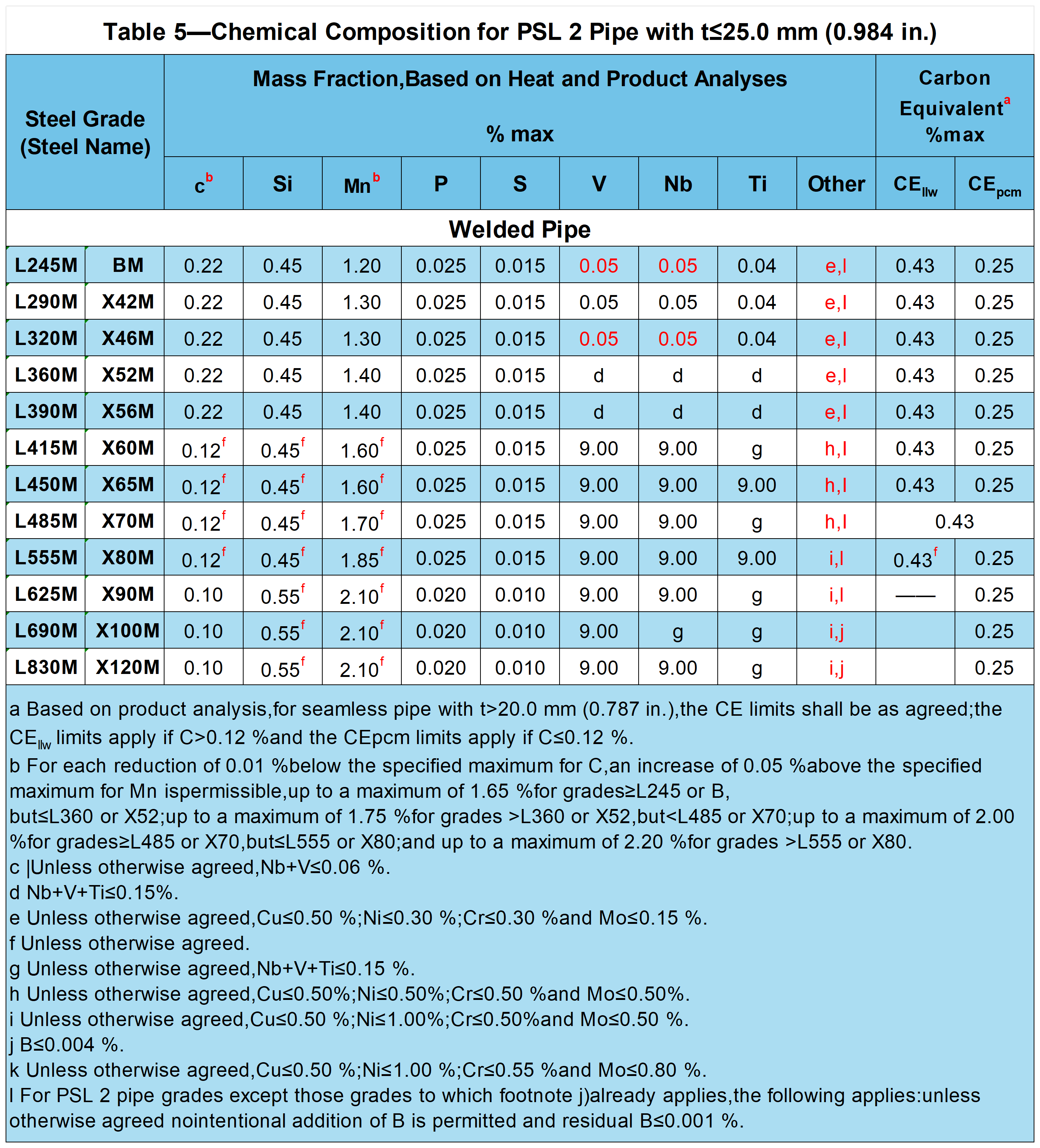

Kemikari Inoumbwa yePSL 2 Pipe ine t≤25.0 mm (0.984 mukati.)

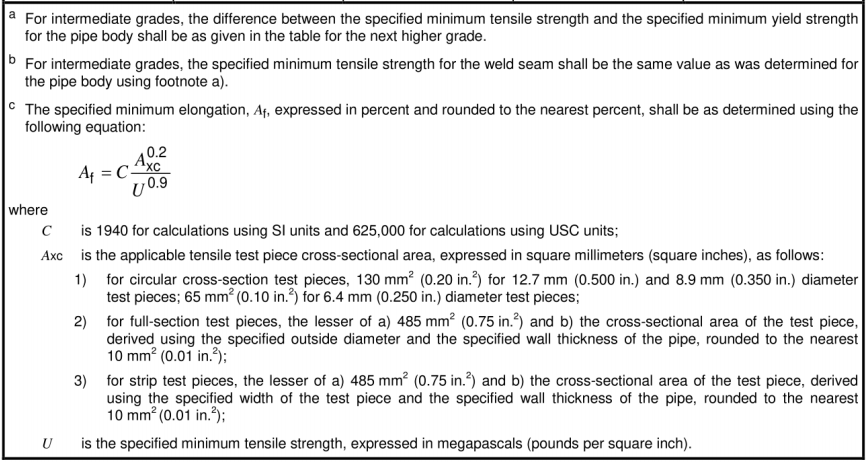

Tensile Properties

Nzira dzekuyedza: Ichaitwa zvinoenderana neISO 6892-1 kana ASTM A370.

Zvinodiwa kune Mhedzisiro yeTensile Miedzo yePSL 1 Pipe

| Tafura 6-Zvinodiwa Zvemhedzisiro yeTensile Miedzo yePSL 1 Pipe | ||||

| Pipe Grade | Pipe Muviri weSeamless uye Welded Pipe | Weld Seam yeEW, LW, SAW, uye COW Pipe | ||

| Goho Simbaa Rku.5 MPa(psi) | Tensile Simbaa Rm MPa(psi) | Elongation (pa50 mm kana 2 mukati.) Af % | Tensile Simbab Rm MPa(psi) | |

| min | min | min | min | |

| L175 kana A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| L175P kana A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 kana A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 kana B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 kana X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| L320 kana X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 kana X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| L390 kana X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 kana X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| L450 kana X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| L485 kana X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

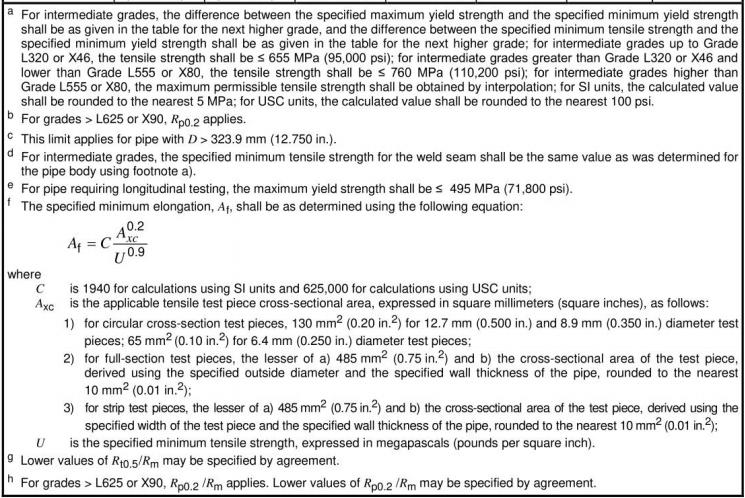

Zvinodiwa kune Mhedzisiro yeTensile Miedzo yePSL 2 Pipe

| Tafura 7-Zvinodiwa Zvemhedzisiro yeTensile Miedzo yePSL 2 Pipe | |||||||

| Pipe Grade | Pipe Muviri weSeamless uye Welded Pipe | Weld Seam zveHFW SAW uye CoW Pipe | |||||

| Goho Simbaa Rto.5 MPa(psi) | Tensile Simbaa Rm MPa (psi) | Ratioac Rt0.5/Rm | Elongation (pa50 mm kana 2 mukati.) Af % | Tensile Simbad Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R kana BR L245N kana BN L245Q kana BQ L245M kana BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R kana X42R L290N kana X42N L290Q kana X42Q L290M kana X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N kana X46N L320Q kana X46Q L320M kana X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N kana X52N L360Q kana X52Q L360M kana X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N kana X56N L390Q kana X56Q L390M kana X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N kana X56N L390Q kana X56Q L390M kana X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N kana X60N L415Q kana X60Q L415M kana X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q kana X65Q L450M kana X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q kana X70Q L485M kana X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q kana X80Q L555M kana X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M kana X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q kana X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M kana X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q kana X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M kana X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Kureba kwezana panguva yekuzorora kuchataurwa kune zvienzaniso zvine hurefu hwegeji ye50 mm (2 mukati).

Kune mienzaniso ine geji kureba isingasviki 50 mm (2 mukati), kureba panguva yekuzorora kuchashandurwa kuita kurebesa pa50 mm (2 mukati) zvinoenderana neISO 2566-1 kana ASTM A370.

Hydrostatic Pressure Test

Nzira yekuedza: API 5L 10.2.6.

Ese saizi yemusono (SMLS) pombi uye welded pombi ine D ≤ 457 mm (18.000 mukati) ichave nenguva yekudzikamisa isingasviki 5 masekonzi.welded pombi ine D> 457 mm (18.000 mukati) ichava nenguva yekudzikamisa isingasviki masekonzi gumi.

Bend Test

Nzira dzekuedza: Muedzo wekupeta unoenderana nezvinodiwa neISO 8491 kana ASTM A370.

Hapana chikamu chemuenzaniso chichatsemuka uye weld haizotsemuka.

Iyo L175P/A25P giredhi isimbi yakakwenenzverwa phosphorus inopa kuita kurinani kweshinda kupfuura L175/A25 simbi asi yakanyanya kuoma kubhenda.

Flattening Test

Nzira dzekuedza: Iyo yekumanikidza bvunzo ichaenderana nezvinodiwa zve ISO 8492 kana ASTM A370.

Mufambo uri pakati pemahwendefa maviri uchave wekuti hapana kutsemuka kweweld kuchaitika kusvika nhambwe yakatarwa yasvikwa.

Inotungamirirwa Bending Test

Nzira dzekuedza: Iyo inotungamirwa yekukotama bvunzo inoenderana nezvinodiwa zve ISO 5173 kana ASTM A370.

Kuoma Muedzo

Nzira yekuedza: Kuomarara bvunzo zvinoenderana neISO 6506, ISO 6507, ISO 6508, kana ASTM A370.

Kana mapundu akaoma anofungidzirwa anowanikwa mukutariswa kwechitarisiko, inotakurika yekuomarara tester inofanirwa kushandiswa pakuomarara.

CVN Impact Test yeAPI 5L PSL2 Steel Pipe

Nzira dzekuedza: Iyo charpy kukanganisa bvunzo inosangana nezvinodiwa zveASTM A370.

DWT Muedzo weAPI 5L PSL2 Welded Pipe

Nzira yekuyedza: Iyo DWT bvunzo ichave inoenderana neAPI5L3.

Macro-Kuongorora uye Metallographic Test

Mukati nekunze weld deviations ye submerged arc welded (SAW) uye combi-welded (COW) pombi ichaongororwa ne macroscopic kuongorora.

Pamachubhu anoda kurapwa kupisa kweweld, ongororo yesimbi ichaitwa kuona kuti HAZ yese yakabatwa nekupisa zvakafanira munzira yakazara yemadziro.

Kune machubhu asingade weld kupisa kurapwa, metallographic ongororo ichaitwa kuona kuti hapana yakasara untempered martensite.

Kuedza Kusina Kuparadza (chete kune matatu yakakosha-chinangwa API 5L PSL2 mapaipi)

Nzira yekuedza: API 5L Annex E.

Kumaka kwepombi uye Nzvimbo

Zvakajairika zvekumaka zvinhu zvesimbi chubhu:

Zita remugadziri wepombi kana chiratidzo;

Kumaka "API Spec 5L".(Kazhinji zvakapfupikiswa kuAPI 5L.) Zvigadzirwa zvinofambirana nezvinodarika mwero mumwe chete zvinogona kunyorwa nezita remwero wega wega.

Yakatsanangurwa Kunze Diameter

Yakatarwa madziro ukobvu

Pipe giredhi (zita resimbi)

Pipe type

Kureba (kureba kwepombi mum kusvika padyo 0.01 m (mu ft kusvika padyo chegumi chetsoka))

Nzvimbo yesimbi pombi zviratidzo

D ≤ 48.3 mm (1.900 mu) pombi yesimbi: Matebhu anogara achigadzirwa pamwe nekureba kwepombi yesimbi kana anogona kuchengetedzwa kune simbi pombi bundle.

Pombi ine D > 48.3 mm (1.900 mukati):

Kunze kwepamusoro: Kutanga pane imwe nzvimbo yekunze kwepombi pakati pe450 mm uye 760 mm (1.5 ft uye 2.5 ft) kubva kune imwe mugumo wepombi.

Mukati mepamusoro: Tanga kuisa chiratidzo mukati mepombi inenge 150 mm (6.0 mukati) kubva kune imwe mugumo wepombi.

Equivalence Standard

Yepasirese uye yedunhu pombi uye machubhu zviyero izvo API 5L yakaenzana kana, mune mamwe mamiriro, imwe sarudzo, pamwe nehuwandu hwekushandisa-chaiwo zviyero:

Zviyero zvepasi rose nedunhu

1. ISO 3183 - Muyero wepombi yepasi rose yeindasitiri yemafuta negesi yakaburitswa neInternational Organisation for Standardization uye ine hukama zvakanyanya neAPI 5L.

2. EN 10208 - European Standard yemapombi esimbi ekutakura gasi remafuta uye zvinwiwa.

3. GB/T 9711 - chiyero chenyika cheChinese chekutakura masisitimu muindasitiri yemafuta negesi.

4. CSA Z245.1 - Canadian Standard inovhara mutsara pombi yekufambisa kwemafuta uye gasi.

5. GOST 20295 - Russian Standard for steel line pipe yekutakura kwemafuta nemafuta zvigadzirwa.

6. IPS (Iranian Petroleum Standards) - Iranian Petroleum Standards for line pombi yemafuta uye gasi indasitiri.

7. JIS G3454, G3455, G3456 - Japanese Industrial Standards yemapombi ekufambisa emakirasi akasiyana-siyana.

8. DIN EN ISO 3183 - German Industrial Standard yakavakirwa pa ISO 3183 yemutsetse pombi.

9. AS 2885 - Australian Standard for line pombi masisitimu ekufambisa kwemafuta uye gasi.

Mashandisirwo Akananga Mitemo

1. API 5CT - American Petroleum Institute standard yeoiri tsime casing uye tubing, iyo, kunyangwe ichinyanya kushandiswa mumatsime emafuta, yakakoshawo muindasitiri yemafuta negesi.

2. ASTM A106 - American Society for Testing and Materials standard for seamless uye welded carbon steel pipe ye-high-temperature service.

3. ASTM A53 - National Institute for Testing and Materials standard for seamless and welded carbon steel pombi, inowanzo shandiswa pakufambisa mvura pakamuri tembiricha kana tembiricha yakaderera.

4. ISO 3834 - International Organisation for Standardization standard yemhando yezvinodiwa, yakatarisana nemhando yekusimbisa masisitimu emasimbi akaiswa.

5. dnv-os-f101 - Norwegian classification society standard for submarine poping systems for offshore oiri uye gasi kutapurirana mapaipi.

6. MSS SP-75 - Manufacturers Standards Society mwero wakanangana nekusimba kwepamusoro, hombe dhayamita yedenderedzwa yakakwenenzverwa pombi dzesimbi.

Quality Management uye Environmental Suitability Standards

1. NACE MR0175/ISO 15156 - Zvinodiwa zvezvinhu zvinoshandiswa mumafuta uye gasi kudhirowa munzvimbo dzine sulfur-ine hydrocarbon, izvo, kunyangwe zvine chekuita nekusarudzwa kwezvinhu, zvakakosha kuti ive nechokwadi chekudzivirira kusvibiswa kwezvinhu zvinoshandiswa muindasitiri yemafuta negesi.

Zvigadzirwa zvedu zvinoenderana

API 5L PSL1&PSL2 GR.B Longitudinal Submerged-arc Welded Pipe

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Carbon Steel Pipe

API 5L GR.B Kukobvu Kwemadziro Kurema Kwesimbi Pipe Yesimbi Yekugadzira Mechanical

API 5L Gr.X52N PSL 2 Seamless Simbi Pipe ACC.Ku IPS-M-PI-190(3) & NACE MR-01-75 yebasa rinovava

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Mafuta neGasi Carbon Seamless Simbi Pipe

API 5L GR.B Isina Mutsetse Pipe Yekudzvanya uye Mamiriro

API 5L/ASTM A106/ASTM A53 Gr.B isina Musono Carbon Simbi Pipe

BotopSteel inyanzvi yeChinaWelded Carbon Steel Pipes Mugadziri & SuppliersKupfuura makore gumi nematanhatu ne8000+ Matani eSeamless Linepipe muStock Mwedzi wega wega.Takagadzirira kukupindurai mukati memaawa makumi maviri nemana akati wandei mushure mekutambira chikumbiro chimwe chete uye zvakare kuvandudza zvakanakira uye kurongeka kune zvazvinogoneka.

tags: API 56 46th, Dimensional Deviations, PSL1, PSL2,vatengesi, vagadziri, mafekitori, masheya, makambani, maholese, tenga, mutengo, quotation, yakawanda, yekutengesa, mutengo.

Nguva yekutumira: Mar-22-2024