AS/NZS 1163inotsanangura inotonhora-yakaumbwa, inopikisa-welded, simbi yesimbi hollow pombi zvikamu zvezvakajairwa zvimiro uye zveinjiniya zvikumbiro pasina kunotevera kupisa kupisa.

Masisitimu akajairwa anoshanda kuAustralia neNew Zealand.

Navigation Buttons

Classification by Cross-section Shape

AS/NZS 1163 Yepakati Giredhi Classification

Raw Material

Manufacturing Process

AS/NZS 1163 Chemical Kuumbwa

AS/NZS 1163 Tensile Test

AS/NZS 1163 Impact Test

Cold Flattening Test

Non-destructive Examination

Kushivirira kweChimiro neMisa

Kushivirira Kwekureba

AS/NZS 1163 SSHS Rondedzero yePipe Saizi uye Weight Tables Inosanganisirwa

Kugadziriswa Kwekunze uye Kukanganisa Kwekuzora

Galvanized

AS/NZS 1163 Kumaka

Zvikumbiro zve AS/NZS 1163

Zvigadzirwa zvedu zvinoenderana

Classification by Cross-section Shape

Mhando nhatu muAS/NZS 1163 dzinogona kuiswa muzvikamu zvinoenderana nechimiro chemuchinjiko-chikamu, ayo ari:

Circular hollow sections (CHS)

Rectangular hollow zvikamu (RHS)

Square Hollow Sections (SHS)

Chinangwa chechinyorwa chino ndechekupfupisa zvinodiwa zvemachubhu esimbi ane denderedzwa hollow zvikamu.

AS/NZS 1163 Yepakati Giredhi Classification

Magiredhi matatu muAS/NZS 1163 zvichibva padiki goho resimba (MPA) yechigadzirwa chakapedzwa:

C250, C350 uye C450.

Inoenderana ne0 ℃ yakaderera-tembiricha kukanganisa bvunzo giredhi iyo pombi yesimbi inogona kusangana:

C250L0, C350L0 uye C450L0.

Iyo chiyero zvakare inotara kuti nzira chaiyo yekuratidza giredhi resimbi pombi ndeiyi:

AS/NZS 1163-C250 or AS/NZS 1163-C250L0

Raw Material

hot-rolled coil kana Cold-rolled coil

Iyo inotonhora-yakakungurutswa coil inopisa-yakakungurutswa coil iyo yakave pasi pekutonhora-inokunguruka kuderedzwa kweinodarika 15%.Iyo coil ichave iine subcritical annealing kutenderera iyo inodzokorora chimiro uye inoumba nyowani ferrite tsanga.Izvo zvinhu zvinoguma zvakafanana nehot-rolled coil.

Fine-grained simbi inotsanangurwa seyakagadzirwa zvinhu zvemakoiri esimbi.Simbi dzine austenitic tsanga saizi yenhamba 6 kana yakatsetseka kana yakaedzwa zvinoenderana neAS 1733.

Simbi iyi inogadzirwa neBasic Oxygen Method (BOS) kana Electric Arc Furnace (EAF) maitiro uye inogona kunatswa neVacuum Arc Remelting (VAR), Electroslag Remelting (ESR), kana neyechipiri simbi yekugadzira maitiro seVacuum Degassing kana Calcium Injection. .

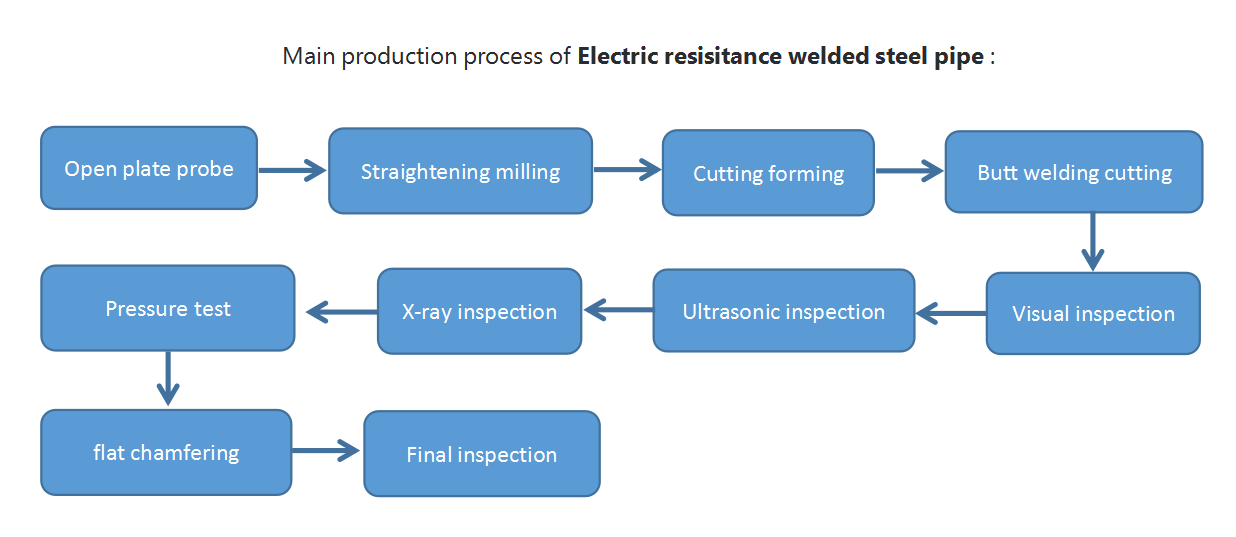

Manufacturing Process

Iyo yakapedzwa hollow chikamu chigadzirwa chinogadzirwa nekutonhora-kuumba maitiro uye kushandiswaelectric resistance-welding (ERW)matekiniki ekubatanidza mipendero yemitsetse.

Iyo weld seam inofanirwa kureba uye ichave nekugumburwa kwekunze kubviswa.

Ikoko hakuzovi nekutevera kupisa kwese kurapwa pachigadzirwa chakapedzwa.

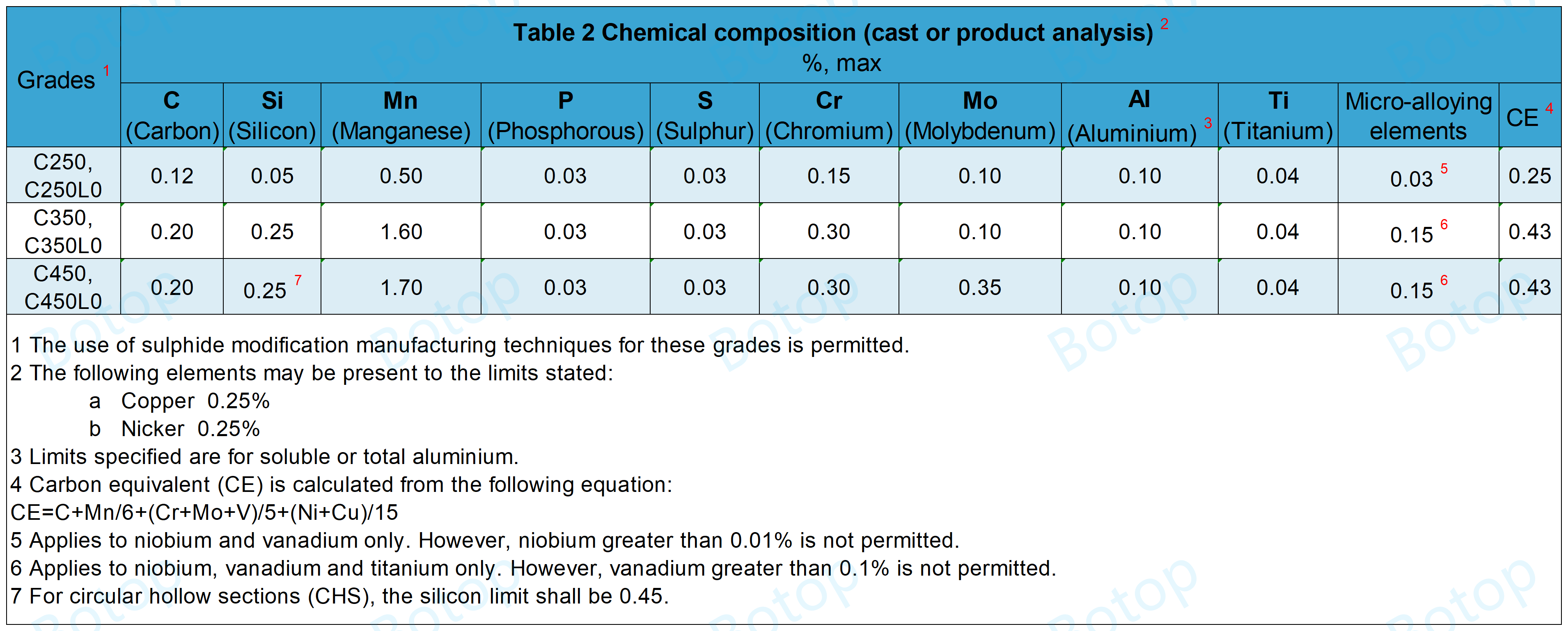

AS/NZS 1163 Chemical Kuumbwa

AS/NZS 1163 muyedzo yekuumbwa kwemakemikari yakakamurwa kuita nyaya mbiri:

imwe nyaya ndeye zvigadzirwa zvekuongororwa kwemakemikari,

imwe yacho yakapedzwa pombi yesimbi yekuongorora.

Kukandira Kuongorora kweSimbi

Kuongororwa kwesimbi kwesimbi kuchaitwa kubva kune imwe neimwe inopisa kuti ione kuenzana kwezvinhu zvakatarwa.

Mumamiriro ezvinhu apo zvisingagoneke kutora sampuli kubva musimbi yemvura, ongororo pamasampuli ebvunzo akatorwa zvinoenderana neAS/NZS 1050.1 kana ISO 14284 inogona kutaurwa sekuongorora kwakakandwa.

Kuongororwa kwesimbi kwesimbi kuchaenderana nemiganhu yegiredhi rakakodzera rakapihwa mukatiTafura 2.

Kemikari Kuongororwa kweChigadzirwa Chekupedzisira

AS/NZS 1163haakurudzire kuongororwa kwemakemikari echigadzirwa chekupedzisira.

Kana kuyedzwa kukaitwa, kunofanirwa kuenderana nemiganhu yakapihwa mukatiTafura 2uye kushivirira kunopiwa mukatiTafura 3.

| TABLE 3 Chigadzirwa chekuongorora kushivirira kwemagiredhi akapihwa muTafura 2 | |

| Element | Kushivirira pamusoro pemuganhu mukuru |

| C(Kabhoni) | 0.02 |

| Si(Silicon) | 0.05 |

| Mn(Manganese) | 0.1 |

| P(Phosphorous) | 0.005 |

| S(Sarufa) | 0.005 |

| Cr(Chromium) | 0.05 |

| Ni(Nickel) | 0.05 |

| Mo(Molybdenum) | 0.03 |

| Cu(Mhangura) | 0.04 |

| AI(Aluminium) (zvese) | -0.005 |

| Micro-alloying zvinhu (niobium uye vanadium chete) yeMaGrade C250, C250L0 | 0.06 ine niobium isingapfuuri 0.020 |

| Micro-alloying elements (niobium, vanadium, uye titanium chete) zveMagiredhiC350, C350L0, C450, C450L0 | 0.19 ine vanadium isingapfuuri 0.12 |

AS/NZS 1163 Tensile Test

Nzira yekuedza: AS 1391.

Kusati kwaitwa tembiricha yekuedza, mufananidzo wacho uchadziirwa kusvika kune tembiricha isingasviki 15 min nekudziya kune tembiricha iri pakati pe150°C ne200°C.

| Giredhi | Minimum goho simba | Minimum tensile simba | Minimum elongation sechikamu yehurefu hwegeji i5.65√S0 | ||

| kuita/t | |||||

| ≤ 15 | >15 ≤30 | >30 | |||

| MPA | MPA | % | |||

| C250, C250L0 | 250 | 320 | 18 | 20 | 22 |

| C350, C350L0 | 350 | 430 | 16 | 18 | 20 |

| C450, C450L0 | 450 | 500 | 12 | 14 | 16 |

AS/NZS 1163 Impact Test

Nzira yekuedza: pa 0 ° C maererano ne AS 1544.2.

Pasati paitwa bvunzo yekukanganisa, mufananidzo wacho uchadziiswa nekudziya kusvika pakati pe150 ° C ne200 ° C kwete isingasviki gumi nemashanu min.

| Giredhi | Test tembiricha | Simba shoma rakanyura, J | |||||

| Saizi yebvunzo chidimbu | |||||||

| 10mm × 10mm | 10mm × 7.5mm | 10mm × 5mm | |||||

| Avhareji ye3 bvunzo | Individual test | Avhareji ye3 bvunzo | Individual test | Avhareji ye3 bvunzo | Individual test | ||

| C250L0 C350L0 C450L0 | 0℃ | 27 | 20 | 22 | 16 | 18 | 13 |

Cold Flattening Test

Chidimbu chekuyedza chinogadzikiswa kusvika chinhambwe chiri pakati penzvimbo chiri 0.75 kuita kana kushoma.

Irege kuratidza zviratidzo zvekutsemuka kana kuremara.

Non-destructive Examination

Sechinhu chisiri-chinosungirwa, welds mune mhango zvikamu zve welded zvimiro zvinogona kuiswa kune isinga paradza bvunzo (NDE).

Kushivirira kweChimiro neMisa

| Type | Range | Kushivirira |

| Hunhu | - | Zvikamu zvedenderedzwa |

| Zviyero zvekunze (do) | - | ± 1%, ine hushoma hwe ± 0.5 mm uye huwandu hwe ± 10 mm |

| Hukobvu (t) | kuita≤406,4 mm | 土10% |

| kusvika >406.4 mm | ± 10% nehukuru hwe ±2 mm | |

| Kunze-kutenderera (o) | Kunze dhayamita(bo)/madziro ukobvu(t)≤100 | ±2% |

| Kutwasuka | hurefu hwakazara | 0.20% |

| Misa (m) | uremu hwakatarwa | ≥96% |

Ukobvu:

Ukobvu (t) huchayerwa panzvimbo isingasviki 2t (Zvinoreva kuti 2x mudhuri ukobvu) kana 25 mm, chero idiki, kubva pane weld seam.

kunze-kwe-kutenderera:

Kubuda-kwe-kutenderera (o) kunopihwa ne:o=(itamax-itamin)/do×100

Kushivirira Kwekureba

| Rudzi rwehurefu | Range m | Kushivirira |

| Random urefu | 4m kusvika 16m ne kureba kwe2m pa odha chinhu | 10% yezvikamu zvinopihwa zvinogona kunge zviri pazasi pezvishoma zveyero yakaodha asi isiri pasi pe75% yezvishoma. |

| hurefu husina kutaurwa | VOSE | 0-+100mm |

| Kureba chaiko | ≤ 6m | 0-+5mm |

| >6m ≤10m | 0-+15mm | |

| >10m | 0-+(5+1mm/m)mm |

AS/NZS 1163 SSHS Rondedzero yePipe Saizi uye Weight Tables Inosanganisirwa

Mu AS/NZS 1163, mazita ezvikamu zvakajairika zvinotonhora-zvakaumbwa structural hollow zvikamu (SSHS) muAustralia neNew Zealand zvinopihwa.

Aya mazita anopa mazita echikamu, hukuru hwezita, maitiro echikamu, uye hunhu.

| Kunze Diameter | Ukobvu | Masperunitlength | External pamusoro penzvimbo | Ratio | |

| do | t | pakureba kweyuniti | per unit mass | ||

| mm | mm | kg/m | m²/m | m²/t | kuita/t |

| 610.0 | 12.7CHS | 187 | 1.92 | 10.2 | 48.0 |

| 610.0 | 9.5CHS | 141 | 1.92 | 13.6 | 64.2 |

| 610.0 | 6.4CHS | 95.3 | 1.92 | 20.1 | 95.3 |

| 508.0 | 12.7CHS | 155 | 1.60 | 10.3 | 40.0 |

| 508.0 | 9.5CHS | 117 | 1.60 | 13.7 | 53.5 |

| 508.0 | 6.4CHS | 79.2 | 1.60 | 20.2 | 79.4 |

| 457.0 | 12.7CHS | 139 | 1.44 | 10.3 | 36.0 |

| 457.0 | 9.5CHS | 105 | 1.44 | 13.7 | 48.1 |

| 457.0 | 6.4CHS | 71.1 | 1.44 | 20.2 | 71.4 |

| 406.4 | 12.7CHS | 123 | 1.28 | 10.4 | 32.0 |

| 406.4 | 9.5CHS | 93.0 | 1.28 | 13.7 | 42.8 |

| 406.4 | 6.4CHS | 63.1 | 1.28 | 20.2 | 63.5 |

| 355.6 | 12.7CHS | 107 | 1.12 | 10.4 | 28.0 |

| 355.6 | 9.5CHS | 81.1 | 1.12 | 13.8 | 37.4 |

| 355.6 | 6.4CHS | 55.1 | 1.12 | 20.3 | 55.6 |

| 323.9 | 2.7CHS | 97.5 | 1.02 | 10.4 | 25.5 |

| 323.9 | 9.5CHS | 73.7 | 1.02 | 13.8 | 34.1 |

| 323.9 | 6.4CHS | 50.1 | 1.02 | 20.3 | 50.6 |

| 273.1 | 9.3CHS | 60.5 | 0.858 | 14.2 | 29.4 |

| 273.1 | 6.4CHS | 42.1 | 0.858 | 20.4 | 42.7 |

| 273.1 | 4.8CHS | 31.8 | 0.858 | 27.0 | 56.9 |

| 219.1 | 8.2CHS | 42.6 | 0.688 | 16.1 | 26.7 |

| 219.1 | 6.4CHS | 33.6 | 0.688 | 20.5 | 34.2 |

| 219.1 | 4.8CHS | 25.4 | 0.688 | 27.1 | 45.6 |

| 168.3 | 71CHS | 28.2 | 0.529 | 18.7 | 23.7 |

| 168.3 | 6.4CHS | 25.6 | 0.529 | 20.7 | 26.3 |

| 168.3 | 4.8CHS | 19.4 | 0.529 | 27.3 | 35.1 |

| 165.1 | 5.4CHS | 21.3 | 0.519 | 24.4 | 30.6 |

| 165.1 | 5.0CHS | 19.7 | 0.519 | 26.3 | 33.0 |

| 165.1 | 3.5CHS | 13.9 | 0.519 | 37.2 | 47.2 |

| 165.1 | 3.0CHS | 12.0 | 0.519 | 43.2 | 55.0 |

| 139.7 | 5.4CHS | 17.9 | 0.439 | 24.5 | 25.9 |

| 139.7 | 5.0CHS | 16.6 | 0.439 | 26.4 | 27.9 |

| 139.7 | 3.5CHS | 11.8 | 0.439 | 37.3 | 39.9 |

| 139.7 | 3.0CHS | 10.1 | 0.439 | 43.4 | 46.6 |

| 114.3 | 6.0CHS | 16.0 | 0.359 | 22.4 | 19.1 |

| 114.3 | 5.4CHS | 14.5 | 0.359 | 24.8 | 21.2 |

| 114.3 | 4.8CHS | 13.0 | 0.359 | 27.7 | 23.8 |

| 114.3 | 4.5CHS | 12.2 | 0.359 | 29.5 | 25.4 |

| 114.3 | 3.6CHS | 9.83 | 0.359 | 36.5 | 31.8 |

| 114.3 | 3.2CHS | 8.77 | 0.359 | 41.0 | 35.7 |

| 101.6 | 5.0CHS | 11.9 | 0.319 | 26.8 | 20.3 |

| 101.6 | 4.0CHS | 9.63 | 0.319 | 33.2 | 25.4 |

| 101.6 | 3.2CHS | 7.77 | 0.319 | 41.1 | 31.8 |

| 101.6 | 2.6CHS | 6.35 | 0.319 | 50.3 | 39.1 |

| 88.9 | 5.9CHS | 12.1 | 0.279 | 23.1 | 15.1 |

| 88.9 | 5.0CHS | 10.3 | 0.279 | 27.0 | 17.8 |

| 88.9 | 5.5CHS | 11.3 | 0.279 | 24.7 | 16.2 |

| 88.9 | 4.8CHS | 9.96 | 0.279 | 28.1 | 18.5 |

| 88.9 | 4.0CHS | 8.38 | 0.279 | 33.3 | 22.2 |

| 88.9 | 3.2CHS | 6.76 | 0.279 | 41.3 | 27.8 |

| 88.9 | 2.6CHS | 5.53 | 0.279 | 50.5 | 34.2 |

| 76.1 | 5.9CHS | 10.2 | 0.239 | 23.4 | 12.9 |

| 76.1 | 4.5CHS | 7.95 | 0.239 | 30.1 | 16.9 |

| 76.1 | 3.6CHS | 6.44 | 0.239 | 37.1 | 21.1 |

| 76.1 | 3.2CHS | 5.75 | 0.239 | 41.6 | 23.8 |

| 76.1 | 2.3CHS | 4.19 | 0.239 | 57.1 | 33.1 |

| 60.3 | 5.4CHS | 7.31 | 0.189 | 25.9 | 11.2 |

| 60.3 | 4.5CHS | 6.19 | 0.189 | 30.6 | 13.4 |

| 60.3 | 3.6CHS | 5.03 | 0.189 | 37.6 | 16.8 |

| 48.3 | 5.4CHS | 5.71 | 0.152 | 26.6 | 8.9 |

| 48.3 | 4.0CHS | 4.37 | 0.152 | 34.7 | 12.1 |

| 48.3 | 3.2CHS | 3.56 | 0.152 | 42.6 | 15.1 |

| 42.4 | 4.9CHS | 4.53 | 0.133 | 29.4 | 8.7 |

| 42.4 | 4.0CHS | 3.79 | 0.133 | 35.2 | 10.6 |

| 42.4 | 3.2CHS | 3.09 | 0.133 | 43.1 | 13.3 |

Kugadziriswa Kwekunze uye Kukanganisa Kwekuzora

Chitarisiko

Chigadzirwa chakapedzwa hachina zvikanganiso zvinokanganisa kusimba kwemaitiro ezvinyorwa.

Kubviswa kweSurface Defects

Kana kukanganisa kwepamusoro kunobviswa nejecha, nzvimbo ine jecha ichava neshanduko yakanaka.

Ukobvu hwemadziro hwakasara munzvimbo ine jecha haifaniri kunge iri pasi pe90% yezita rehukobvu.

Weld Kugadziriswa kweSurface Defects

Welds ichave yakasimba, iyo weld ichinyatsobatanidzwa pasina under cuting kana kupindirana.

Simbi inokwenenzverwa ichaita 1.5 mm pamusoro penzvimbo yakakungurutswa uye simbi inobuda ichabviswa nekukuya nevhu rakamoneredzwa.

Galvanized

Magalvanized round hollow sections ane dhayamita yekunze ye ≤ 60.3 mm uye mamwe akaumbwa maburi zvikamu zvakaenzana achakwanisa kumira 90° bend kutenderedza grooved mandrel.

Iyo yakavharidzirwa yebhati haifanire kuratidza zviratidzo zvekutsemuka kana kuremara mushure mekuvhiyiwa kwekukotama.

AS/NZS 1163 Kumaka

Zvinotevera zvinoonekwa kamwechete musimbi pombi inomaka.

(a) Zita remugadziri kana chiratidzo, kana zvese.

(b) Saiti yemugadziri kana chigayo, kana zvese.

(c) Kuzivikanwa kwemavara akasiyana, anoteedzeka, ayo achave mune imwe kana ese ari maviri emafomu anotevera:

(i) Nguva uye zuva rekugadzirwa kwechigadzirwa.

(ii) A serialized identification number ye quality control/ assurance and traceability zvinangwa.

Muenzaniso:

BOTOP CHINA AS/NZS 1163-C350L0 457×12.7CHS×12000MM PIPE NO.001 HEAT NO.000001

Zvikumbiro zve AS/NZS 1163

Architectural and Engineering Structures: Inoshandiswa mukutsigira zvivakwa zvezvivakwa, senge zvivakwa zvepamusoro-soro uye nhandare.

Zvifambiso: Zvinoshandiswa mukuvaka mabhiriji, tunnel, uye zvivakwa zvenjanji.

Oiri, gasi, uye migodhi: inoshandiswa mukuvaka oiri rigs, zvicherwa zvemigodhi, uye zvine hukama masisitimu ekufambisa.

Mamwe maindasitiri anorema: anosanganisira furemu zvimiro zvekugadzira zvidyarwa nemichina inorema.

Zvigadzirwa zvedu zvinoenderana

Isu tiri yepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe yakawanda yesimbi pombi mhinduro!

Tags: as/nzs 1163,chs, zvimiro, erw, vatengesi, vagadziri, mafekitari, masheya, makambani, tengesa, kutenga, mutengo, quotation, zvakawanda, kutengesa, mutengo.

Nguva yekutumira: Kubvumbi-21-2024