ASTM A334 machubhu ndeye kabhoni uye alloy simbi machubhu akagadzirirwa yakaderera-tembiricha maapplication uye anogadzirwa uchishandisa isina musono uye welded maitiro.

Mamwe masaizi echigadzirwa anogona kunge asiri kuwanikwa pasi peiyi dhizaini nekuti kurema kwemadziro ukobvu kune mhedzisiro yakaipa pakudzika-tembiricha maitiro.

Grade Classification

ASTM A334 ine magiredhi akati wandei enzvimbo dzakasiyana dzekudzikira-tembiricha.

Grade 1, Grade 3, Grade 6, Grade 7, Grade 8, Grade 9, uye Grade 11.

Iwo magiredhi anoenderanaalloy simbi machubhu ari Grade 3, Grade 7, Grade 8, Grade 9, uye Grade 11..

Yega yega giredhi resimbi ine yaro chaiyo makemikari kuumbwa uye mechanic zvivakwa zvinodiwa, pamwe nediki mhedzisiro yekuyedza tembiricha maitiro anofanirwa kusangana.

Manufacturing Processs

Machubhu achagadzirwa neisina musonokana otomatikiwelding processpasina kuwedzera kwesimbi yekuzadza mukushanda kwewelding.

Kupisa Kurapa

Giredhi 1, 3, 6, 7 ne9

Gadzirisai nekudziisa kusvika kune tembiricha yakafanana isingasviki 1550 °F [845 °C] uye inotonhorera mumhepo kana mukamuri yekutonhodza yechoto chinodzorwa nemhepo.

Kana kushatirwa kuchidiwa, kunoda kutaurirana.

Zvemagiredhi ari pamusoro emachubhu esimbi asina musono chete:

Dzorera uye udzore kushanda kunopisa uye tembiricha yekupisa-kupedza kushanda kusvika pakupedza tembiricha kubva ku1550 - 1750 °F [845 - 955℃] uye kutonhorera muchoto chinodzorwa kubva kune yekutanga tembiricha isingasviki 1550 °F [ 845 °C].

Grade 8

Sarudza imwe yeiyi nzira dzinotevera dzekurapa kupisa.

Kudzima uye Kutsamwa;

Kaviri Normalized uye Hasha.

Grade 11

Kuti atore machubhu eGrade 11 zvinoenderana nechibvumirano chemutengi nemutengesi.

Kana machubhu eGiredhi 11 akavharirwa anozoiswa muhuwandu hwe1400 - 1600℉[760 - 870 °C].

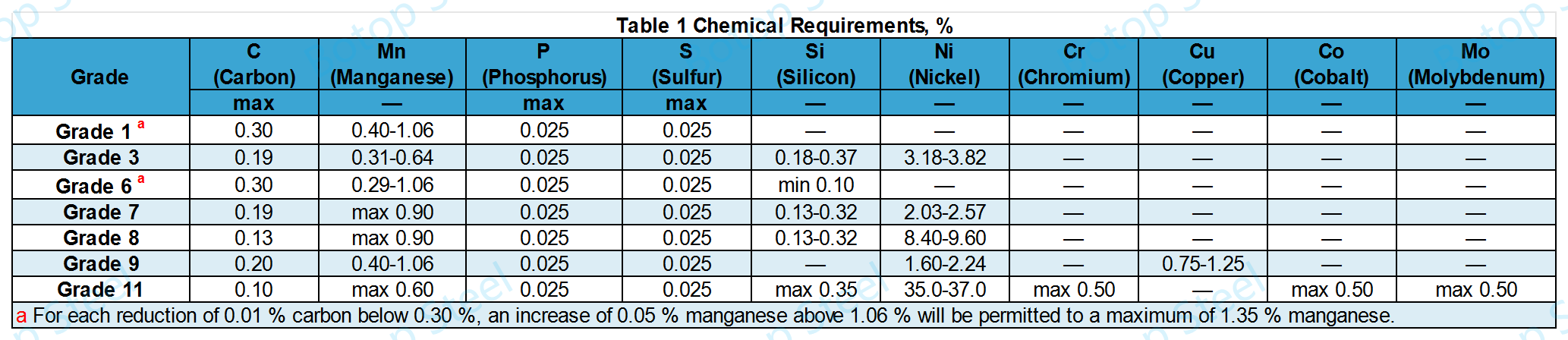

ASTM A334 Chemical Kuumbwa

Kune masimbi eGiredhi 1 kana Giredhi 6, hazvibvumidzwe kupa magiredhi ealloying kune chero zvinhu kunze kweizvo zvinodikanwa.Zvisinei, inobvumirwa kuwedzera zvinhu zvakakosha kuti deoxidation yesimbi.

ASTM A334 Mechanical Miedzo

Mechanical property inodiwa haishande kune tubing idiki pane 1/8 in. [3.2 mm] kunze kwedhayamita uye ine mudhuri ukobvu uri pasi pe0.015 in. [0.4 mm].

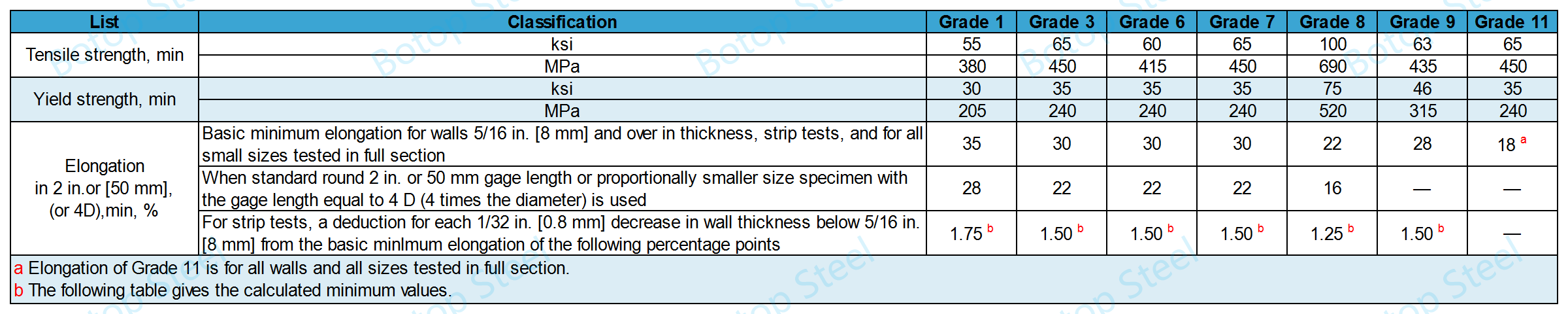

1. Tensile Property

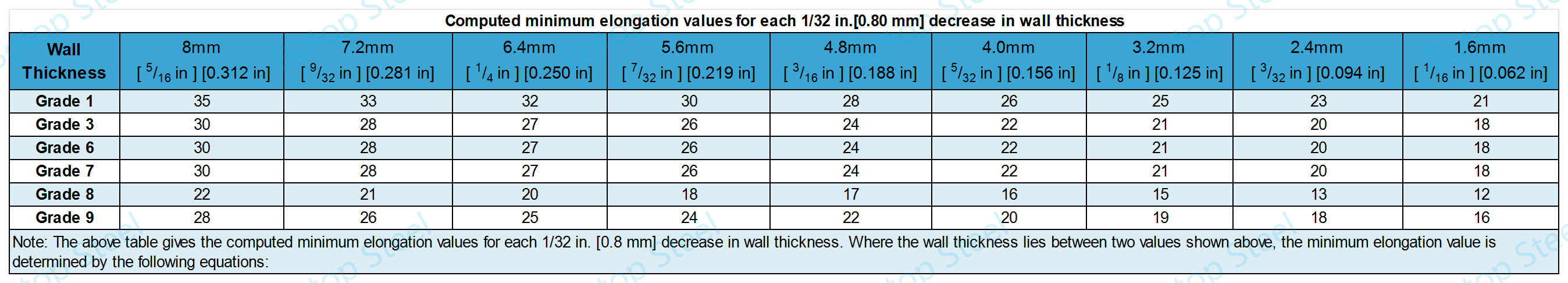

Kurebesa zvishoma kwakaverengerwa kune imwe neimwe 1/32 inch [0.80 mm] mukukora kwemadziro:

Pamachubhu madiki pane 1/2 in. [12.7 mm] kunze kwedhayamita, ukoshi hwekurebesa hwakapihwa kune mitsetse yemifananidzo ichashanda.

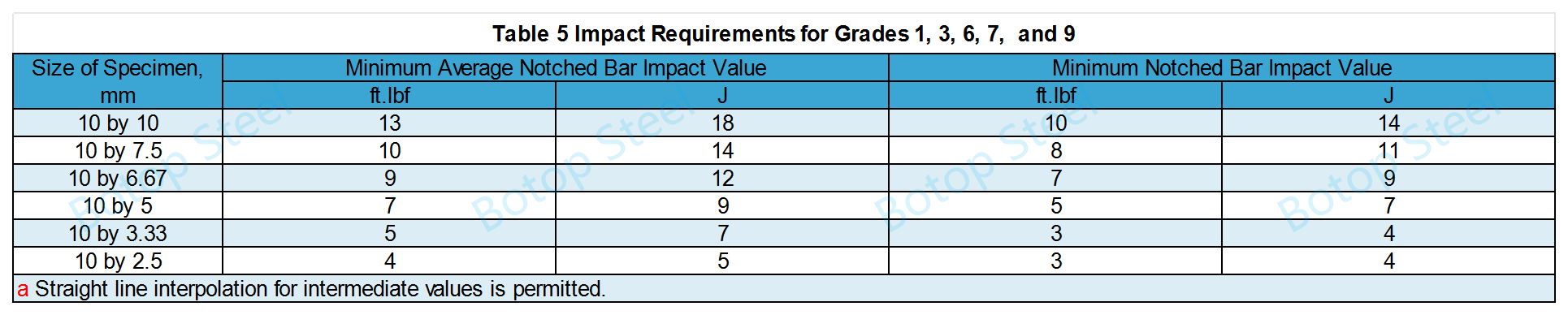

2. Miedzo Yemigumisiro

Sarudza tembiricha yakakodzera uye inoenderana simba rekuita zvinoenderana negiredhi uye ukobvu hwemadziro.

Impact Simba

Impact Temperature

| Giredhi | Impact Test Temperature | |

| ℉ | ℃ | |

| Grade 1 | -50 | -45 |

| Grade 3 | -150 | -100 |

| Grade 6 | -50 | -45 |

| Grade 7 | -100 | -75 |

| Grade 8 | -320 | -195 |

| Grade 9 | -100 | -75 |

3. Kuoma Muedzo

| Giredhi | Rockwell | Brinell |

| Grade 1 | B85 | 163 |

| Grade 3 | B90 | 190 |

| Grade 6 | B90 | 190 |

| Grade 7 | B90 | 190 |

| Grade 8 | - | - |

| Grade 11 | B90 | 190 |

4. Flattening Test

Muedzo wekubata kumeso uchaitwa pamienzaniso kubva kumagumo ega ega echubhu imwe yakapedzwa yemujenya wega wega asi kwete iyo inoshandiswa pakuyedza flare kana flange.

5. Flare Test (Seamless Tubes)

Imwe bvunzo yemoto ichaitwa pazvienzaniso kubva kumagumo ega ega echubhu imwe yakapedzwa yejeti rega rega, asi kwete iyo inoshandiswa pakuyedza kubhenda.

6. Flange Test (Welded Tubes)

Imwe bvunzo yeflange ichaitwa pamienzaniso kubva kumagumo ega ega echubhu imwe yakapedzwa yejeti rega rega, asi kwete iyo inoshandiswa pakuyedza kubhenda.

7. Reverse Flattening Test

Pamachubhu akaiswa welded, imwe reverse flattening bvunzo ichaitwa pamuenzaniso kubva pamamita 1500 ega ega echubhu yapera.

Hydrostatic kana Nondestructive Electric Test

Imwe neimwe pombi ichave isinga gadzirise yemagetsi kuyedzwa kana hydrostatically kuyedzwa zvinoenderana neSpecification A1016/A1016M.

Zvikumbiro zveASTM A334 Steel Pipe

Inonyanya kushandiswa kutakura zvinwiwa kana magasi akadai segasi rechisikigo, oiri, uye mamwe makemikari pakudziya kwakaderera.

1. Cryogenic piping systems: inowanzoshandiswa pakuvaka pombi masisitimu ekutakurwa kwemvura ye cryogenic (eg liquefied natural gas, liquid nitrogen).Nekuda kwekunaka kwayo cryogenic zvimiro, inokwanisa kuchengetedza simba remakanika uye kuomarara pane tembiricha yakaderera.

2. Vanopisa kupisa uye condensers: Heat exchangers uye condensers inogona kushandiswa zvinobudirira kutonhora kana kupisa process media, kunyanya mumakemikari uye petrochemical industries.

3. Dzvinyiriro midziyo: inogonawo kushandiswa kugadzira midziyo yekumanikidza yakagadzirirwa mabasa e cryogenic.Iyi midziyo inogona kushandiswa kuchengetedza cryogenic makemikari kana ehunyanzvi maindasitiri maitiro.

4. Refrigeration systems uye midziyo: Machubhu aya anoshandiswa kutakura mafiriji, kunyanya panodiwa zvinhu zvisingadziviriri zvinodzivirira.

ASTM A334 Yakaenzana Standard

EN 10216-4: Inovhara asina-alloyed uye alloyed simbi machubhu, ayo akatsanangura yakaderera-tembiricha zvinhu.

JIS G 3460: inoenderana nealloy simbi machubhu ebasa re cryogenic.

GB/T 18984: inoshanda kune isina musono simbi machubhu e cryogenic pressure midziyo.Inotsanangura zvakadzama magadzirirwo nekugadzirwa kwemachubhu esimbi akakodzera kune yakanyanya kuderera-tembiricha nharaunda.

Kunyange zvazvo zviyero izvi zvingasiyana muhuwandu uye zvakananga zvinodiwa, zvakafanana muchinangwa chavo chose uye kushandiswa, kunova nechokwadi chekuchengetedza uye kushanda kwepombi dzesimbi munzvimbo dze cryogenic.

Zvigadzirwa zvedu zvinoenderana

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

Tags: ASTM A334, kabhoni simbi nyere, astm a334 gr 6, astm a334 gr 1.

Nguva yekutumira: May-20-2024