ASTM A500 simbiinotonhora-yakagadzirwa welded uye isina musono kabhoni simbi yekumisikidza tubing yewelded, riveted, kana bolted mabhiriji uye zvivakwa zvekuvaka uye zvakajairwa zvimiro zvinangwa.

Navigation Buttons

Hollow Chikamu Chimiro

Grade Classification

Size Range

Raw Materials

Manufacturing Nzira

Tube End Type

Kupisa Kurapa

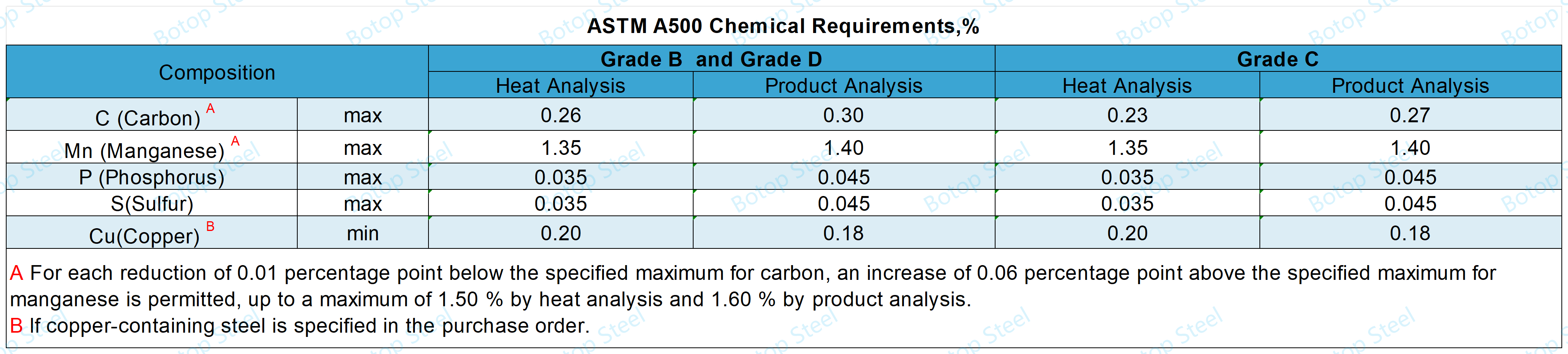

Kemikari Kuumbwa kweASTM A500

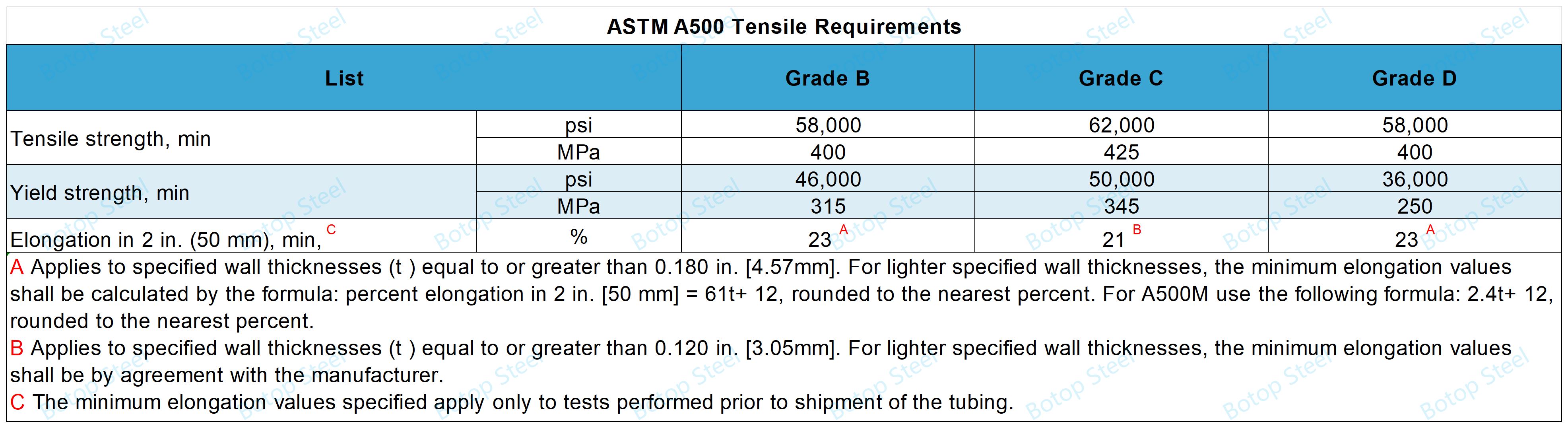

Tensile Zvinodiwa zveASTM A500

Flattening Test

Flaring Test

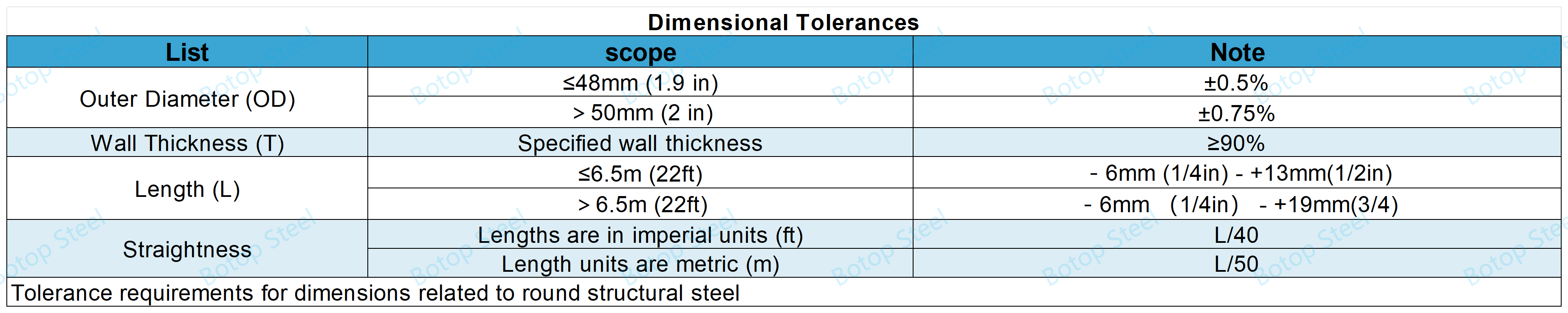

Dimensional Kushivirira kweASTM A500

Tube Marking

Zvikumbiro zveASTM A500

Zvimwe Zvishandiso zveASTM A500

Zvigadzirwa zvedu zvinoenderana

Hollow Chikamu Chimiro

Zvinogona kudarodenderedzwa, mativi mana, rectangular, kana mamwe maumbirwo akakosha.

Ichi chinyorwa chinotarisa pane izvo zvinodikanwa zveASTM A500 zvekutenderera simbi yekugadzira.

Grade Classification

ASTM A500 inoronga simbi pombi kuita mamakisi matatu,giredhi B, giredhi C, uye giredhi D.

Zvakakosha kucherechedza kuti shanduro dzekare dzeASTM A500 dzaivewo neGiredhi A, iyo yakabviswa mune yazvino vhezheni ye2023.

Size Range

Kune machubhu ane dhayamita yekunze ≤ 2235mm [88in] uye ukobvu hwemadziro ≤ 25.4mm [1in].

Raw Materials

Simbi ichagadzirwa neimwe kana kupfuura yeanotevera maitiro:okisijeni yakakosha kana choto chemagetsi.

Basic Oxygen Process: Iyi inzira yemazuva ano inokurumidza kugadzira simbi, iyo inoderedza kabhoni yemukati nekufuridza okisijeni musimbi yenguruve yakanyungudutswa, ichibvisa zvimwe zvisingadiwe sesarufa nephosphorus. Inokodzera kukurumidza kugadzirwa kwehuwandu hwakawanda hwesimbi.

Electric Furnace process: Iyo Electric Furnace process inoshandisa yakakwira tembiricha yemagetsi arc kunyungudutsa zvimedu uye nekudzikisa zvakananga simbi, uye inonyanya kubatsira pakugadzira hunyanzvi mamakisi uye kudzora alloy nziyo, pamwe nediki kugadzirwa kwebatch.

Manufacturing Nzira

Seamless kana welding process.

Welded tubing ichagadzirwa kubva simbi-yakatenderedzwa nemagetsi-resistance-welding (ERW) process. Iyo weld seam inofanira kusungirirwa kuti ive nechokwadi chekusimba kwepombi.

Mapombi anogadzirwa newelding process kazhinji haana weld yemukati inobviswa.

Tube End Type

Kana zvisinganyanyi kudiwa, machubhu ekuumbwa anofanira kunge ariflat-enduye kuchena kweburrs.

Kupisa Kurapa

Grade B uye Grade C

Inogona kuderedzwa kana kuderedzwa-kunetseka.

Anealing inopedzwa nekudziisa chubhu kusvika pakupisa kwepamusoro uye wozoitonhodza zvishoma nezvishoma. Annealing inorongazve iyo microstructure yezvinhu kuti ivandudze kusimba kwayo uye kufanana.

Kubvisa kushushikana kunowanzoitwa nekudziisa tembiricha yakadzikira (kazhinji yakadzikira pane yekuvhara) wozoibata kwenguva yakati rebei woitonhodza. Izvi zvinobatsira kudzivirira kukanganisa kana kuputika kwezvinhu panguva yekushanda kunotevera senge welding kana kucheka.

Grade D

Kurapa kwekupisa kunodiwa.

Inofanira kuitwa pakupisa kweinenge1100 ° F (590 ° C) kweawa imwe pa25 mm rusvingo ukobvu.

Kemikari Kuumbwa kweASTM A500

Nzira yekuedza: ASTM A751.

Tensile Zvinodiwa zveASTM A500

Mienzaniso inosangana nezvinodiwa zveASTM A370, Appendix A2.

Flattening Test

Welded Round Structural Tubes

Weldductilitytest: Uchishandisa sampuli inokwana masendimita mana (100 mm) kureba, gadzirisa mufananidzo ne weld pa 90 ° kusvika kune nzira yekuisa kusvikira chinhambwe pakati pemahwendefa chiri pasi pe 2/3 yekunze kwepaipi. mufananidzo wacho haufanirwe kuputika kana kuputsika mukati kana kunze kwekunze panguva iyi.

Pipe ductility test: ramba uchigadzirisa muenzaniso kusvikira chinhambwe pakati pemahwendefa chiri pasi pe 1/2 yepombi yekunze dhayamita. panguva ino, pombi haifaniri kuva nekuputika kana kuputsika mukati uye kunze kwekunze.

Kupereratest: Ramba uchidzikamisa sampuli kusvika kutyoka kwaitika kana kusvika izvo zvinodikanwa zvemadziro zvakasangana. Kana humbowo hwekupenengura ply, zvinhu zvisina kugadzikana, kana mawelds asina kukwana akawanikwa panguva yekuyedzwa kwekubata kumeso, mufananidzo wacho unozotongwa usingagutse.

Seamless Round Structural Tubes

Kureba Kwemuenzaniso: Hurefu hwemuenzaniso unoshandiswa pakuedza hausi pasi pe2 1/2 mukati (65 mm).

Ductility test: Pasina kutsemuka kana kutsemuka, mufananidzo wacho wakatsetseka pakati pemahwendefa anoenderana kusvika chinhambwe chiri pakati pemahwendefa chiri pasi peiyo "H" kukosha yakaverengerwa neinotevera fomula:

H=(1+e)t/(e+t/D)

H = chinhambwe pakati pemapureti ekufuratira, mukati [mm],

e= deformation paurefu hweyuniti (nguva dzose kune yakapihwa giredhi resimbi, 0.07 yeGiredhi B, uye 0.06 yeGiredhi C),

t= yakatsanangurwa kukora kwemadziro echubhu, mukati [mm],

D = yakatsanangurwa kunze kwedhayamita yetubhing, in. [mm].

Kupereratest: Ramba uchidzikamisa mufananidzo kusvikira muenzaniso waputsika kana madziro akapesana emuenzaniso asangana.

Kukundikanacriteria: Laminar peeling kana isina simba zvinhu zvinowanikwa mukati meyedzo yekutsvedza ichave chikonzero chekurambwa.

Flaring Test

Muedzo wekupisa unowanikwa kune akatenderera machubhu ≤ 254 mm (10 mukati) mudhayamita, asi hazvisungirwe.

Dimensional Kushivirira kweASTM A500

Tube Marking

Mashoko anotevera anofanira kuverengerwa:

Zita remugadziri: Iri rinogona kunge riri zita rizere remugadziri kana chidimbu.

Brand kana Mucherechedzo: Zita rechiratidzo kana chiratidzo chinoshandiswa nemugadziri kusiyanisa zvigadzirwa zvawo.

Specification Designator: ASTM A500, iyo haifaniri kusanganisira gore rekubudiswa.

Tsamba Yegiredhi: B, C kana D giredhi.

Kune machubhu ezvimiro ≤ 100mm (4in) mudhayamita, mavara anogona kushandiswa kumaka ruzivo rwekuzivikanwa zvakajeka.

Zvikumbiro zveASTM A500

Nekuda kweiyo yakanakisa mechanic zvivakwa uye weldability, ASTM A500 simbi pombi inoshandiswa mune dzakasiyana siyana zvimiro uko kusimba uye kusimba kunodiwa.

Kuvaka: Inoshandiswa kutsigira zvivakwa zvekuvaka senge mafuremu masisitimu, zvimiro zvedenga, arch dhizaini zvinhu, uye akatenderera makoramu.

Kuvakwa kwebhiriji: Zvezvimiro zvemabhiriji, senge denderedzwa-inotakura mbiru uye trusses yemabhiriji.

Industrial infrastructure: Muzvivakwa zvakakura zvemaindasitiri senge oiri negesi zvivakwa, zvidyarwa zvemakemikari, uye zvigayo zvesimbi, machubhu esimbi akatenderera anoshandiswa kuvaka zvivakwa zvekutsigira uye pombi dzekufambisa.

Zvifambiso zvehurongwa: Yezvikwangwani zvetraffic, mapango emwenje, uye maguardrail struts.

Kugadzira michina: Sechikamu chemichina nemidziyo inorema, senge michina yekurima, midziyo yemugodhi, uye michina yekuvaka.

Utilities: Inoshandiswa mumapaipi emvura, gasi, petroleum zvigadzirwa, nezvimwewo, uye sewaya uye tambo dzekudzivirira pombi.

Zvivako zvemitambo: Mukuvakwa kwenzvimbo dzemitambo, machubhu esimbi akatenderera anoshandiswa kugadzira mabheji, shongwe dzekuvhenekesa, uye zvimwe zvivakwa zvinotsigira.

Furnicha nekushongedza: Round structural simbi machubhu anoshandiswa kugadzira fenicha yesimbi, yakadai semakumbo ematafura uye zvigaro, pamwe chete nezvinhu zvekushongedza zvemazuva ano mukati mekugadzirwa kwemukati.

Fence uye njanji masisitimu: Inoshandiswa senzvimbo dzefenzi uye masisitimu enjanji, kunyanya panodiwa kusimba kwechimiro nekusimba

Zvimwe Zvishandiso zveASTM A500

ASTM A501: Iyi ndiyo chiyero chekupisa-yakaumbwa kabhoni simbi yekumisikidza tubing, yakafanana neASTM A500, asi inoshanda kune inopisa-inogadzira maitiro ekugadzira.

ASTM A252: Yakajairwa yesimbi pombi mirwi yekushandiswa munheyo uye basa rekuputira.

ASTM A106: Seamless kabhoni simbi pombi, inowanzoshandiswa munzvimbo yakakwirira-tembiricha.

ASTM A53: Imwe mhando yekabhoni simbi pombi yekumanikidza uye mashandisirwo emagetsi, anoshandiswa zvakanyanya mukufambisa kwemvura masisitimu.

EN 10210: MuEurope, iyo EN 10210 yakajairwa inotsanangura tekinoroji yekuendesa mamiriro eakapisa-akaumbwa akaumbwa makomba zvikamu, zvine nzvimbo dzekushandisa dzakafanana kune ASTM A500.

CSA G40.21: Chiyero cheCanada chinopa huwandu hwakasiyana hwemasimbi emhando yesimbi mune dzakasiyana siyana magiredhi esimba anogona kushandiswa kune mamwe maapplication.

JIS G3466: Japanese Industrial Standard for square uye rectangular machubhu ekabhoni simbi kuitira kushandiswa kwemaitiro.

IS 4923: Indian Standard kune inotonhora-yakaumbwa welded kana isina musono kabhoni simbi yemaitiro makomba zvikamu.

AS/NZS 1163: Australian neNew Zealand zviyero zvezvimiro zvesimbi machubhu uye makomba zvikamu.

Zvigadzirwa zvedu zvinoenderana

Kubva payakavambwa muna 2014, Botop Steel yave inotungamira kabhoni simbi pombi mutengesi kuChamhembe kweChina, inozivikanwa nebasa rayo repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana. Chigadzirwa chakakura chekambani chinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe nepombi fittings, flanges, uye specialty simbi.

Nekuzvipira kwakasimba kune mhando, Botop Steel inoshandisa zvakaomesesa zvidzoreso uye bvunzo kuti ive nechokwadi chekuvimbika kwezvigadzirwa zvayo. Chikwata chayo chine ruzivo chinopa zvigadziriso zvemunhu uye rutsigiro rwenyanzvi, nekutarisa kugutsikana kwevatengi.

Tags: astm a500, astm a500 giredhi b, astm a500 giredhi c, astm a500 giredhi d.

Nguva yekutumira: May-04-2024