ASTM A513 simbiiyo kabhoni uye alloy simbi pombi uye chubhu yakagadzirwa kubva inopisa-yakakunguruswa kana inotonhora-yakakungurutswa simbi seyakagadzirwa nemagetsi resistance welding (RW) process, iyo inoshandiswa zvakanyanya mumhando dzese dzemakina zvimiro.

Navigation Buttons

Mhando uye Thermal Mamiriro ezvinhu eASTM A513

Grade Classification

ASTM A513 Size Range

Hollow Chikamu Chimiro

Raw Materials

ASTM A513 Manufacturing Matanho

Hot Treatment

Welding Seam Kubata

Kemikari Kuumbwa kweASTM A513

Mechanical Properties yeASTM A513

Kuoma Muedzo

Flattening Test

Flaring Test

Hydrostatic Test Round Tubing

Nondestructive Electric Test

Kushivirira kweRound Pipe Dimensions

Kushivirira kweSikweya uye Rectangular Tube Dimensions

Zvitarisiko

Coating

Kumaka

ASTM A513 Zvikumbiro

Zvatiri Zvakanakira

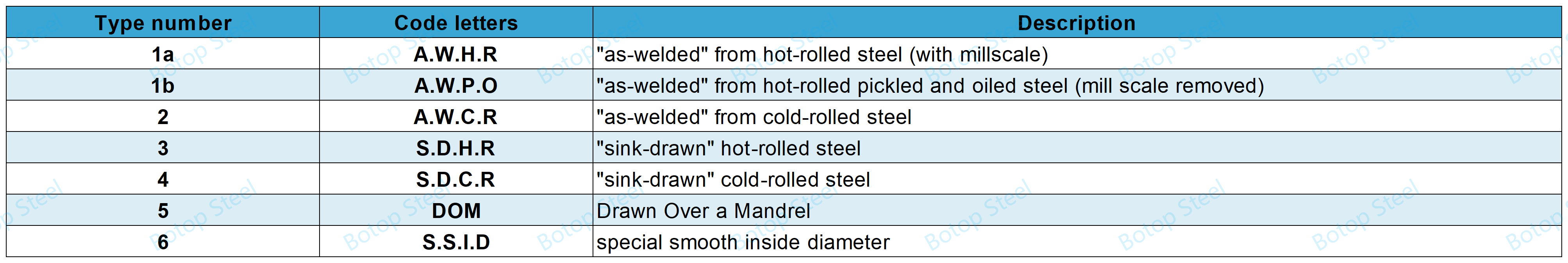

Mhando uye Thermal Mamiriro ezvinhu eASTM A513

Kupatsanurwa kunobva pamamiriro akasiyana-siyana kana maitiro epombi yesimbi.

Grade Classification

ASTM A513 inogona kunge iri kabhoni kana alloy simbi, zvichienderana nekushandiswa chaiko.

Carbon Steel

MT 1010, MT 1015, MT X 1015, MT 1020, MT X 1020.

1006, 1008, 1009, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1023, 1024, 1026, 1025, 1033, 1035, 1040, 1050, 1060, 1524.

Alloys Steel

1340, 4118, 4130, 4140, 5130, 8620, 8630.

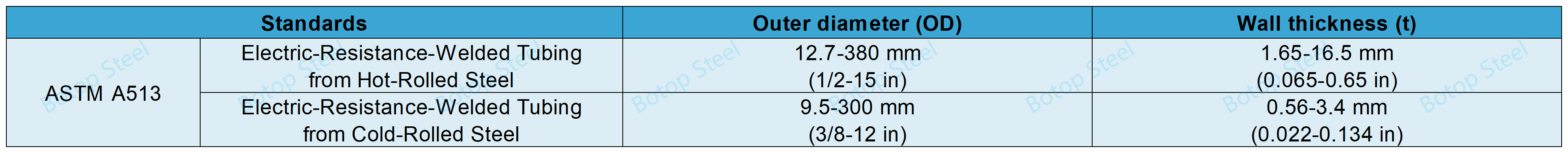

ASTM A513 Size Range

Hollow Chikamu Chimiro

Round

Sikweya kana rectangular

Mamwe maumbirwo

seyakakwenenzverwa, ine hexagonal, ine octagonal, yakatenderedzwa mukati uye ine hexagonal kana yeoctagonal kunze, ine mbabvu mukati kana kunze, katatu, yakatenderedzwa rectangular uye D maumbirwo.

Raw Materials

Simbi inogona kugadzirwa nenzira ipi zvayo.

Iyo yekutanga kunyunguduka inogona kusanganisira yakaparadzana degassing kana kunatsa uye inogona kuteverwa nechipiri kunyunguduka, senge electro slag kana vacuum-arc remelting.

Simbi inogona kukandwa mune ingots kana inogona kukanda tambo.

ASTM A513 Manufacturing Matanho

Machubhu achagadzirwa neelectric-resistance-welded (ERW)process uye ichagadzirwa kubva kune inopisa-yakakungurutswa kana inotonhora-yakakungurutswa simbi sezvakatsanangurwa.

ERW pombi magadzirirwo ekugadzira weld nekukochekera zvinhu zvesimbi kuita humburumbira uye kuisa kuramba uye kumanikidza pakureba kwayo.

Kupisa-yakakungurutswa Simbi: Muchigadziro chekugadzira, simbi inopisa inotanga kupiswa pakupisa kwepamusoro, ichibvumira simbi kuti iparadzwe muhurumende yepurasitiki, izvo zvinoita kuti zvive nyore kuchinja chimiro uye ukuru hwesimbi. Pakupera kwekupisa kunopisa, zvinhu zvinowanzoyerwa uye zvakakanganiswa.

Cold-Rolled Steel: Simbi inotonhora inoputirwa zvakare mushure mekunge zvinhu zvatonhora kuti zviwane saizi yaidiwa uye chimiro. Iyi nzira inowanzoitwa pakamuri yekupisa uye inoguma nesimbi ine nani pamusoro pemhando uye hukuru hwakanyanya.

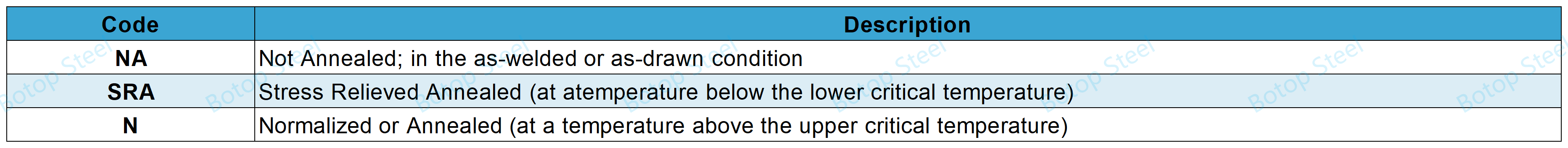

Hot Treatment

Kana mamiriro ekupisa asina kutaurwa, iyo chubhu inogona kupihwa mune iyo NA mamiriro.

Kana mushonga wekupedzisira wekupisa uchitsanangurwa, tight oxide inowanzoitika.

Kana nzvimbo isina oxide yatsanangurwa, chubhu inogona kupenya yakanyungudutswa kana kunyungudutswa pasarudzo yemugadziri.

Welding Seam Kubata

Welds dzekunze dzinofanira kucheneswa

Internal welds ichava neurefu hwakasiyana zvinodiwa zvichienderana neRudzi.

Zvakananga zvinodikanwa zvinogona kuwanikwa muASTM A513, chikamu 12.3.

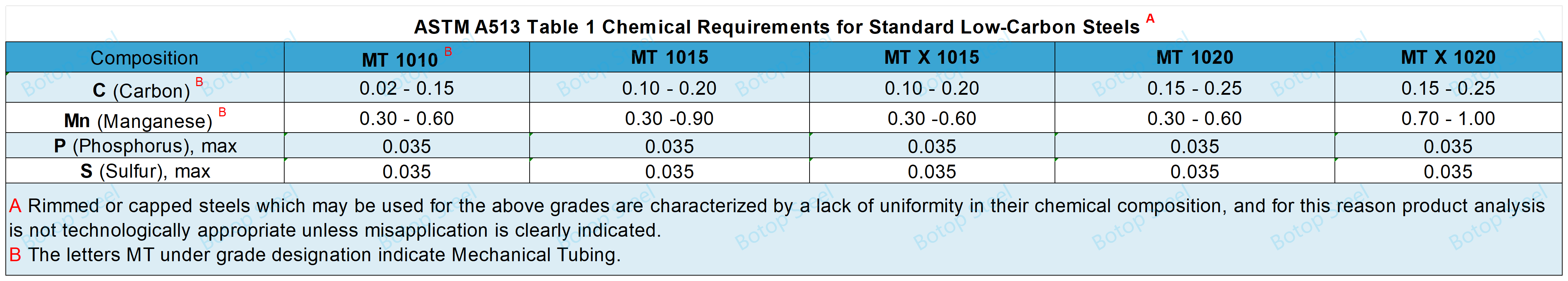

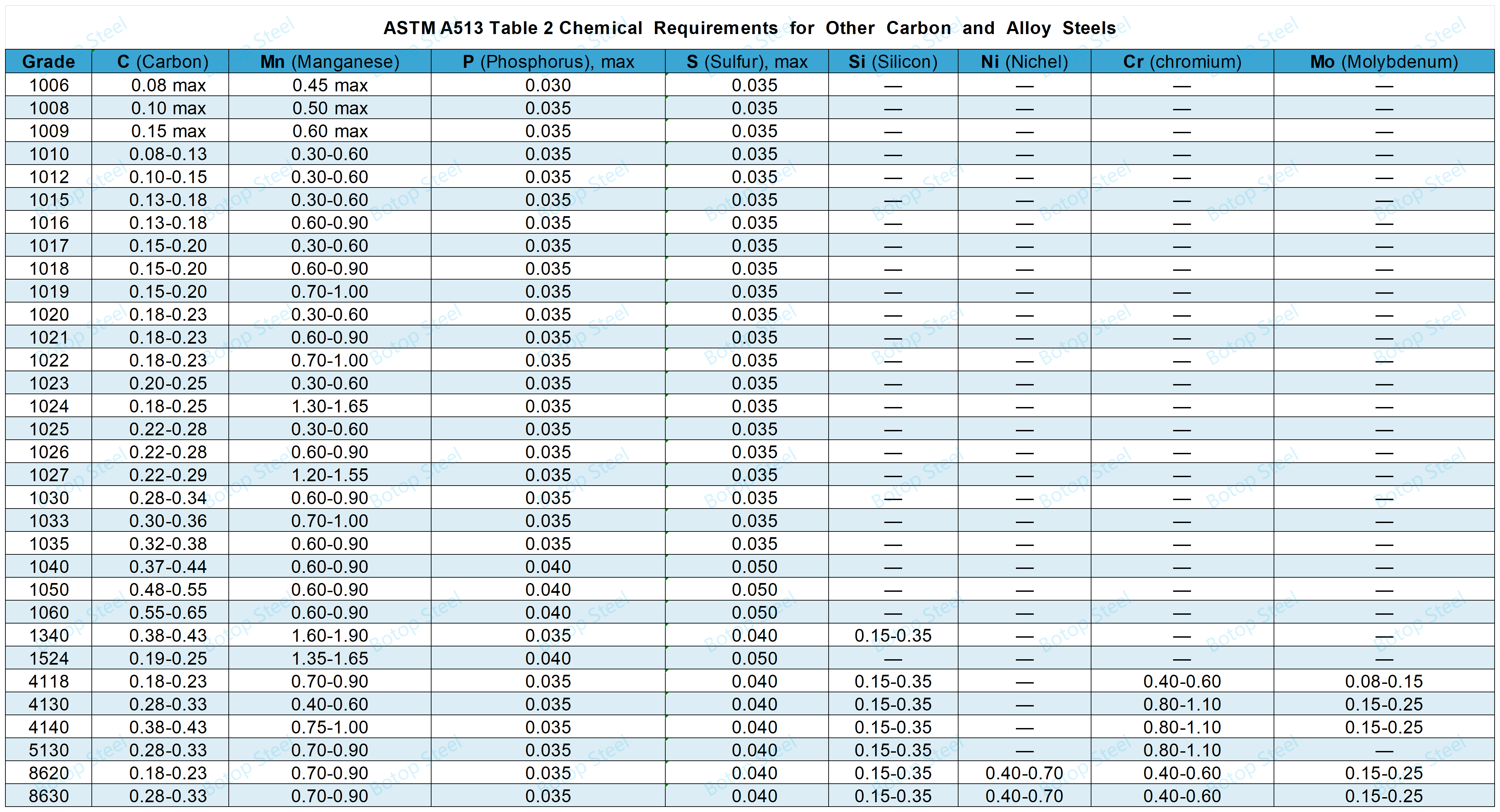

Kemikari Kuumbwa kweASTM A513

Simbi ichaenderana nezvinodiwa zvemakemikari zvinotsanangurwa muTafura 1 kana Tafura 2.

Kana kabhoni simbi mamakisi akarairwa kubva pachiyero, hazvitenderwe kupa alloy mamakisi anongoda kuti awedzere chero chinhu kunze kweakanyorwa muTable I ne2.

Kana pasina giredhi rakatsanangurwa, mamakisi MT 1010 kuburikidza neMT 1020 aripo.

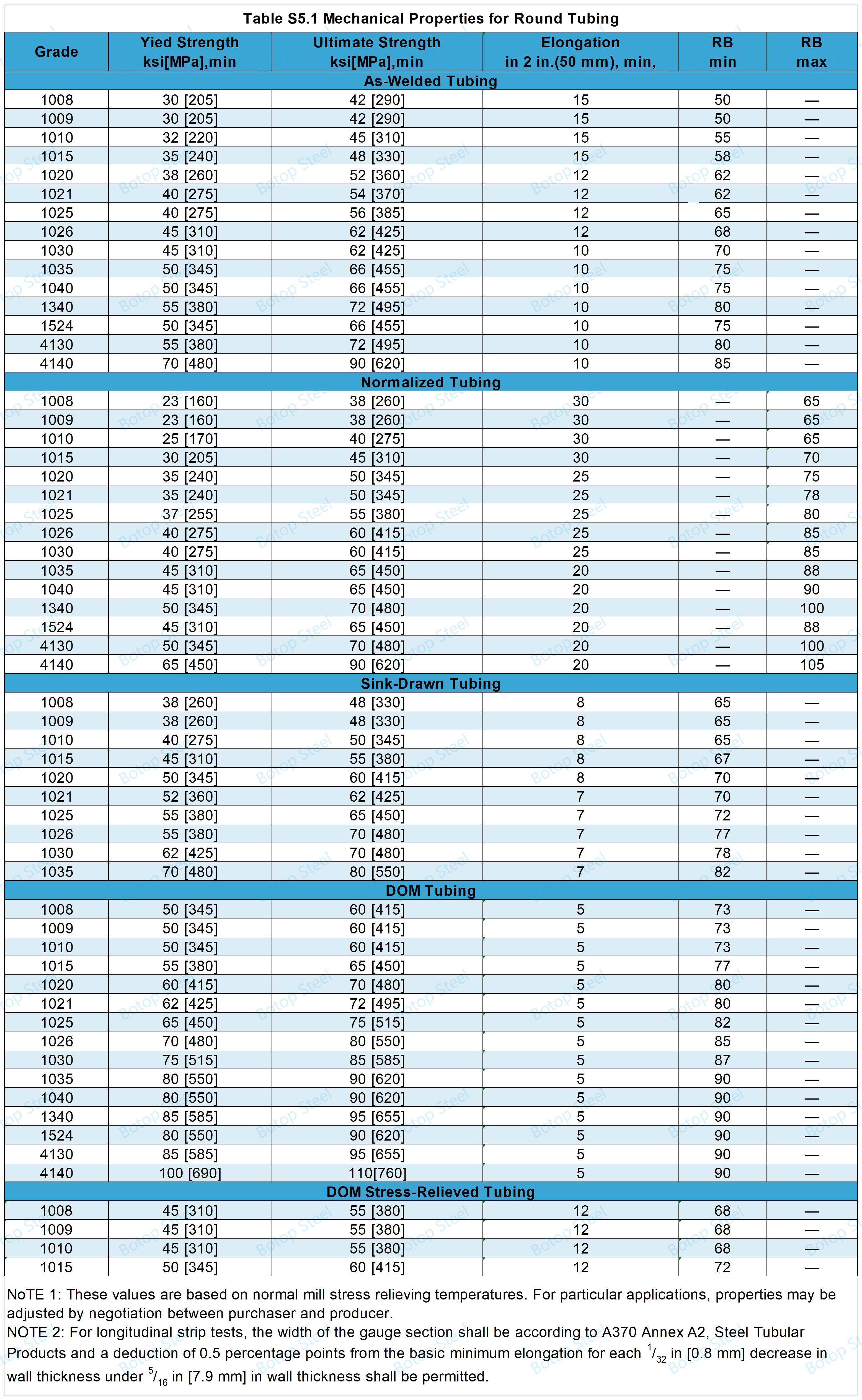

Mechanical Properties yeASTM A513

Tensile test ichaitwa kamwe chete pajeti.

Kana "Inodiwa Tensile Properties" inotsanangurwa muKutenga Order, kutenderera tubing kunoenderana nezvinodiwa zvekusimba uye kwete hazvo kumiganhu yekuomarara inoratidzwa muTafura 5.

Kuoma Muedzo

1% yemachubhu ese mujenya rega rega uye asiri pasi pe5 machubhu.

Flattening Test

Machubhu akatenderedzwa uye machubhu anoumba mamwe maumbirwo kana ari denderedzwa anoshanda.

Hapana kuvhurika muweld kuchaitika kusvika chinhambwe chiri pakati pemarata chave pasi pezvikamu zviviri kubva muzvitatu zvekutanga dhayamita rekunze kwetubhing.

Hapana kuputika kana kuputsika musimbi yepasi kuchaitika kusvikira chinhambwe pakati pemahwendefa chiri pasi pechikamu chimwe chete kubva muzvitatu chepakutanga dhayamita yekunze kwetubhing asi pasina chiitiko chisingasviki kashanu ukobvu hwemadziro echubhu.

Humbowo hwekucheneswa kana kutsva zvinhu hazvizogadzirike panguva yekubata bata, uye weld haizoratidze hurema hunokuvadza.

Ongorora: Kana yakadzikira D-to-t ratio tubing ikaedzwa, nekuti kuomarara kwakaiswa nekuda kwejometri kwakakwira zvisingaite mukati mukati menzvimbo dzenhanhatu negumi nembiri, kutsemuka kuri panzvimbo idzi hakuzove chikonzero chekurambwa kana chiyero cheD-to-t chiri pasi pegumi.

Flaring Test

Machubhu akatenderedzwa uye machubhu anoumba mamwe maumbirwo kana ari denderedzwa anoshanda.

Chikamu chechubhu chinenge 4 in.[100 mm] pakureba chichamira chichibatidzwa nemudziyo une kona inosanganisirwa ne60° kusvikira chubhu iri pamuromo wemoto yawedzerwa 15 % yepakati pepakati, pasina kutsemuka kana kuratidza kukanganisa.

Hydrostatic Test Round Tubing

Yese tubing ichapihwa hydrostatic bvunzo.

Chengetedza hushoma hwe hydro test pressure kwete pasi pe5s.

The pressure inoverengwa se:

P=2St/D

P= shoma hydrostatic test pressure, psi kana MPa,

S= inobvumirwa fiber kushushikana kwe14,000 psi kana 96.5 MPa,

t= kutsanangurwa kwemadziro ukobvu, mukati kana mm,

D= yakataurwa kunze kwedhayamita, mukati kana mm.

Nondestructive Electric Test

Icho chinangwa chebvunzo iyi kuramba machubhu ane hurema hunokuvadza.

Imwe neimwe chubhu ichaedzwa neasingaparadzi bvunzo yemagetsi zvinoenderana neKudzidzira E213, Dzidzira E273, Dzidzira E309, kana Dzidzira E570.

Kushivirira kweRound Pipe Dimensions

Kuti uwane rumwe ruzivo, ndapota ona tafura inoenderana muyero.

Outer Diameter

Tafura 4Diameter Tolerances yeRudzi I (AWHR) Round Tubing

Tafura 5Dhiyamita Kushivirira kweMarudzi 3, 4, 5, uye 6 (SDHR, SDCR, DOM, uye SSID) Round Tubing

Tafura 10Diameter Tolerances yeRudzi rwechipiri (AWCR) Round Tubing

Kukora Kwemadziro

Tafura 6Kushivirira Kwemadziro eRudzi I (AWHR) Round Tubing (Inch Units)

Tafura 7Kushivirira Kwemadziro eRudzi I (AWHR) Round Tubing (SI Units)

Tafura 8Kushivirira kweWall Thickness kweMarudzi 5 ne6 (DOM neSSID) Round Tubing (Inch Units)

TADZA 9Kushivirira kweWall Thickness kweMarudzi 5 ne6 (DOM neSSID) Round Tubing (SI Units)

Tafura 11Kushivirira Kwemadziro eRudzi rwechipiri (AWCR) Round Tubing (Inch Units)

Tafura 12Kushivirira Kwemadziro eRudzi rwechipiri (AWCR) Round Tubing (SI Units)

Urefu

Tafura 13Cheka-Kureba Kushivirira kweLathe-Cheka Round Tubing

Tafura 14Kureba Kushivirira kwePunch-, Saw-, kana Disc-Cut Round Tubing

Squareness

Tafura 15Kushivirira (Inch) yeSquareness yeCheka (Ehe End) Kana Yakatsanangurwa YeRound Tubing

Kushivirira kweSikweya uye Rectangular Tube Dimensions

Kuti uwane rumwe ruzivo, ndapota ona tafura inoenderana muyero.

Outer Diameter

Tafura 16Kushivirira, Kunze Dimensions Square uye Rectangular Tubing

Radii reMakona

Tafura 17Radii yeMakona eMagetsi-Resistance-Welded Square uye Rectangular Tubing

Urefu

Tafura 18Kureba Kushivirira-Square uye Rectangular Tubing

Twist Tolerances

Tafura 19Twist Tolerances Magetsi-Kupikisa-Welded for Square uye Rectangular-Mechanical Tubing

Zvitarisiko

Iyo tubing haifaniri kuremara uye ichava nemagumo akafanana nemushandi.

Coating

Tubing ichaputirwa nefirimu remafuta isati yatumirwa kuti idzore ngura.

Inodzivirira ngura kubva pakuitika munguva pfupi.

Kana iyo odha ikataura kuti tubing inotumirwa isina ngura inodzoreredza mafuta, firimu remafuta ane ngozi kugadzirwa richaramba riri pamusoro.

Kumaka

Iyo pamusoro pesimbi inocherechedzwa uchishandisa nzira yakakodzera uye ine ruzivo rwunotevera:

Zita remugadziri kanabrand

Saizi yakatarwa

Type

nhamba yeoda yemutengi,

Nhamba yakajairika, ASTM A513.

Mabarcode anogona zvakare kushandiswa senzira inopindirana yekuzivikanwa.

ASTM A513 Zvikumbiro

Indasitiri yemotokari: Inoshandiswa mumafuremu ezvigaro zvemotokari, zvimisikidzo, makoramu ekutungamirira, mabhuraketi, uye zvimwe zvikamu zvemotokari.

Indasitiri yekuvaka: sechitsigiro chezvivakwa zvekuvaka, senge machubhu emachubhu, magadhi, njanji, nezvimwe.

Machinamanufacturing: Inoshandiswa mukugadzirwa kwezvinhu zvakasiyana-siyana zvemagetsi, zvakadai se hydraulic system cylinders, zvikamu zvinotenderera, mabheji, nezvimwewo.

Midziyo yekurima: Mukugadzira michina yekurima, inoshandiswa kugadzira zvimiro zvemidziyo yekurima, masisitimu ekufambisa, nezvimwe.

Furniture Manufacturing: Inoshandiswa mukugadzira fenicha dzesimbi dzakasiyana-siyana, semasherufu emabhuku, mafuremu emacheya, mafuremu emibhedha, zvichingodaro.

Midziyo yemitambo: munzvimbo dzemitambo uye kugadzirwa kwemidziyo, inoshandiswa sezvikamu zvesimbi, semidziyo yekusimbisa muviri, zvibodzwa zvebasketball, zvibodzwa zvenhabvu, nezvimwe.

Industrial zvivako: inoshandiswa mukugadzira mabhandi ekutakurisa, rollers, matangi, uye zvimwe zvinhu zvemaindasitiri emidziyo.

Zvatiri Zvakanakira

Kubva payakavambwa muna 2014, Botop Steel yave inotungamira kabhoni simbi pombi mutengesi kuChamhembe kweChina, inozivikanwa nebasa rayo repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana. Chigadzirwa chakakura chekambani chinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe nepombi fittings, flanges, uye specialty simbi.

Nekuzvipira kwakasimba kune mhando, Botop Steel inoshandisa zvakaomesesa zvidzoreso uye bvunzo kuti ive nechokwadi chekuvimbika kwezvigadzirwa zvayo. Chikwata chayo chine ruzivo chinopa zvigadziriso zvemunhu uye rutsigiro rwenyanzvi, nekutarisa kugutsikana kwevatengi.

Tags: ASTM A513, kabhoni simbi, mhando 5, mhando 1, dom.

Nguva yekutumira: Chivabvu-07-2024