ASTM A671 ipombi yesimbi yakagadzirwa kubva mundiro yekumanikidza yemhando yeplate,Magetsi-Fusion-Welded (EFW)yenzvimbo dzepamusoro-soro pane ambient uye yakaderera tembiricha.

Inonyanya kukodzera kune zvikumbiro zvinoda kugadzikana kwepamusoro-kugadzikana uye chaiyo yakaderera-yekushisa zvinhu.

Navigation Buttons

ASTM A671 Size Range

Yakakurudzirwa mhando: mapaipi esimbi ane DN ≥ 400 mm [16 mu] uye WT ≥ 6 mm [1/4].

Inogona zvakare kushandiswa kune mamwe saizi yepombi, chero inosangana nezvimwe zvese zvinodiwa zveiyi tsanangudzo.

ASTM A671 Kumaka

Kuti tinzwisise zviri nani ASTM A671, ngatitangei kunzwisisa zvirimo zvekumaka. Izvi zvinobatsira kujekesa chiyero chekushandiswa uye maitiro eiyi chiyero.

Muenzaniso weSpray Marking:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 HEAT NO.4589716

BOTOP: Zita remugadziri.

EFW: Simbi chubhu yekugadzira maitiro.

ASTM A671: Executive Standard yeSimbi Tubing.

CC60-22: Mapfupiso egiredhi:cc60 uye kirasi 22.

16" x SCH80: Diameter uye Rusvingo Hukobvu.

HEAT NO. 4589716: Kupisa kwete. yekugadzira machubhu esimbi.

Iyi ndiyo yakajairika fomati yeASTM A671 yekupfapfaidza kunyora.

Hazvina kuoma kuwana ASTM A671 mugiredhi uye kirasi mbiri zvikamu, saka aya maviri emhando anomiririra izvo zvinorehwa.

Grade Classification

Yakakamurwa zvichienderana nerudzi rwendiro inoshandiswa kugadzira machubhu esimbi.

Magiredhi akasiyana anomiririra akasiyana maumbirwo emakemikari uye ma mechanical zvimiro zvekumanikidza kwakasiyana uye tembiricha mamiriro.

Semuenzaniso, mamwe mamakisi ari plain carbon steels, asi mamwe masimbi ane alloying akawedzerwa, akadai nickel steels.

| Pipe Grade | Rudzi rweSimbi | Kutsanangurwa kweASTM | |

| Aihwa. | Giredhi/kirasi/rudzi | ||

| CA 55 | plain carbon | A285/A285M | Gr C |

| CB 60 | plain carbon, vakaurawa | A515/A515M | Gr 60 |

| CB 65 | plain carbon, vakaurawa | A515/A515M | Gr 65 |

| CB 70 | plain carbon, vakaurawa | A515/A515M | Gr 70 |

| CC 60 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516/A516M | Gr 60 |

| CC 65 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516/A516M | Gr 65 |

| CC 70 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516/A516M | Gr 70 |

| CD70 | manganese-silicon, yakajairika | A537/A537M | Cl 1 |

| CD80 | manganese-silicon, yakadzimwa uye yakatsamwa | A537/A537M | Cl 2 |

| CFA 65 | nickel simbi | A203/A203M | Gr A |

| CFB 70 | nickel simbi | A203/A203M | Gr B |

| CFD 65 | nickel simbi | A203/A203M | Gr D |

| CFE 70 | nickel simbi | A203/A203M | Gr E |

| CG100 | 9% nickel | A353/A353M | |

| CH 115 | 9% nickel | A553/A553M | Type 1 |

| CJA 115 | alloy simbi, kudzimwa uye hasha | A517/A517M | Gr A |

| CJB 115 | alloy simbi, kudzimwa uye hasha | A517/A517M | Gr B |

| CJE 115 | alloy simbi, kudzimwa uye hasha | A517/A517M | Gr E |

| CJF 115 | alloy simbi, kudzimwa uye hasha | A517/A517M | Gr F |

| CJH 115 | alloy simbi, kudzimwa uye hasha | A517/A517M | Gr H |

| CJP 115 | alloy simbi, kudzimwa uye hasha | A517/A517M | Gr P |

| CK 75 | carbon-manganese-silicon | A299/A299M | Gr A |

| CP 85 | alloy simbi, kuomesa zera, kudzimwa uye kunaya kupisa kunorapwa | A736/A736M | Gr A, Kirasi 3 |

Kuronga Kwekirasi

Machubhu akaiswa muzvikamu zvinoenderana nerudzi rwekupisa kwekupisa kwavanogashira panguva yekugadzira uye kuti kana kwete ivo vanoongororwa radiographical uye kudzvanywa kwakaedzwa.

Iwo mapoka akasiyana anoratidza zvakasiyana-siyana zvekupisa kurapa kwemachubhu.

Mienzaniso inosanganisira normalizing, kushushikana mupfungwa, kudzima, uye kuzvidzora.

| Kirasi | Kurapa kwekupisa papombi | Radioography, ona chinyorwa: | Pressure test, ona chinyorwa: |

| 10 | hapana | hapana | hapana |

| 11 | hapana | 9 | hapana |

| 12 | hapana | 9 | 8.3 |

| 13 | hapana | hapana | 8.3 |

| 20 | kushushikana kwakadzikira, ona 5.3.1 | hapana | hapana |

| 21 | kushushikana kwakadzikira, ona 5.3.1 | 9 | hapana |

| 22 | kushushikana kwakadzikira, ona 5.3.1 | 9 | 8.3 |

| 23 | kushushikana kwakadzikira, ona 5.3.1 | hapana | 8.3 |

| 30 | normalized, ona 5.3.2 | hapana | hapana |

| 31 | normalized, ona 5.3.2 | 9 | hapana |

| 32 | normalized, ona 5.3.2 | 9 | 8.3 |

| 33 | normalized, ona 5.3.2 | hapana | 8.3 |

| 40 | normalized uye hasha, ona 5.3.3 | hapana | hapana |

| 41 | normalized uye hasha, ona 5.3.3 | 9 | hapana |

| 42 | normalized uye hasha, ona 5.3.3 | 9 | 8.3 |

| 43 | normalized uye hasha, ona 5.3.3 | hapana | 8.3 |

| 50 | kudzimwa uye kushatirwa, ona 5.3.4 | hapana | hapana |

| 51 | kudzimwa uye kushatirwa, ona 5.3.4 | 9 | hapana |

| 52 | kudzimwa uye kushatirwa, ona 5.3.4 | 9 | 8.3 |

| 53 | kudzimwa uye kushatirwa, ona 5.3.4 | hapana | 8.3 |

| 70 | kudzimwa uye kunaya kwemvura kunorapwa | hapana | hapana |

| 71 | kudzimwa uye kunaya kwemvura kunorapwa | 9 | hapana |

| 72 | kudzimwa uye kunaya kwemvura kunorapwa | 9 | 8.3 |

| 73 | kudzimwa uye kunaya kwemvura kunorapwa | hapana | 8.3 |

Kupisa kwekushandiswa kunofanira kuonekwa pakusarudza zvinhu. Reference inogona kuitwa kune yakatarwa ASTM A20/A20M.

Raw Materials

Mahwendefa emhando yepamusoro emidziyo yekumanikidza, ruzivo rwemhando, uye zviyero zvekuuraya zvinogona kuwanikwa mutafura mukatiGrade Classificationkumusoro.

Welding Key Points

Welding: Seams ichave yakapetwa kaviri, yakazara-inopinda-yakaiswa welded.

Welding ichaitwa zvinoenderana nemaitiro akatsanangurwa muChikamu IX cheASME Boiler uye Pressure Vessel Code.

Mawelds anozoitwa nemaoko kana otomatiki nemagetsi maitiro anosanganisira kuiswa kwesimbi yekuzadza.

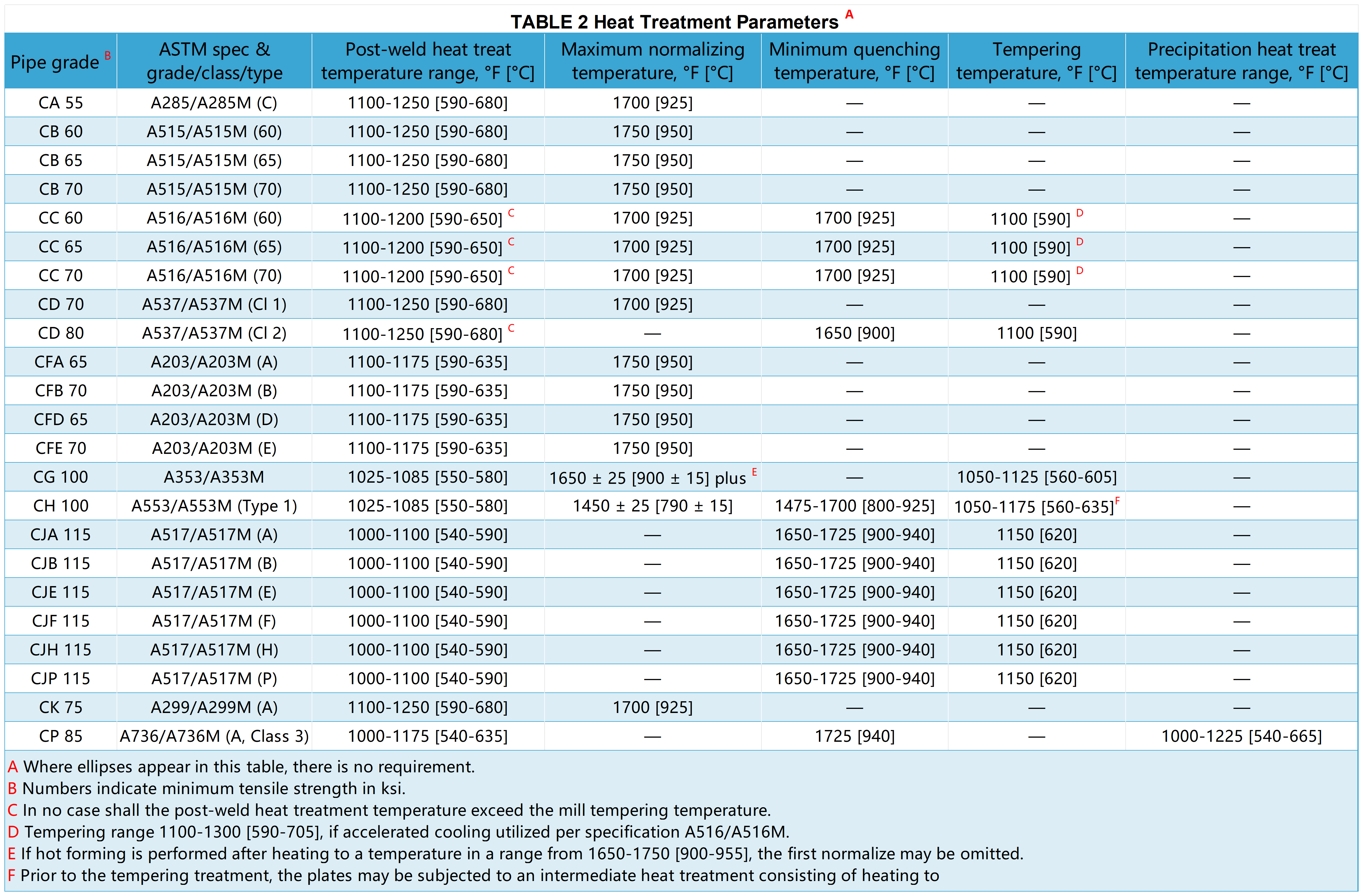

Kurapa Kupisa Kwemakirasi Akasiyana

Makirasi ese kunze kwe10, 11, 12, uye 13 achabatidzwa kupisa muchoto chinodzorwa kusvika ±25 °F[± 15°C].

Makirasi 20, 21, 22, uye 23

Ichave nekudziya zvakafanana mukati meiyo post-weld kupisa-kupisa tembiricha yakaratidzwa muTable 2 kwehushoma hwe1 h/in. [0.4 h/cm] yeukobvu kana kuti 1 h, chero chikuru.

Makirasi 30, 31, 32, uye 33

Ichave yakaenzana kupisa kune tembiricha mu austenitizing renji uye isingapfuure iyo yakanyanya normalizing tembiricha inoratidzwa muTebhurari 2 uye yozotonhodzwa mumhepo pakamuri tembiricha.

Makirasi 40, 41, 42, uye 43

Iyo pombi ichave yakajairika.

Iyo pombi ichadziyiswa kune tembiricha yekudziya inoratidzwa muTebhurari 2 sediki uye inobatwa patembiricha isingaite 0.5 h/in.[0.2 h/cm] yeukobvu kana kwe0.5 h, chero yakakura, uye yakatonhodzwa nemhepo.

Makirasi 50, 51, 52, uye 53

Iyo pombi ichapiswa zvakafanana kune tembiricha mukati meiyo austenitizing renji uye isingapfuure yakanyanya kudzima tembiricha inoratidzwa muTafura 2.

Zvadaro, bvisa mumvura kana mafuta. Mushure mekudzima, pombi ichadzoserwa kune yakaderera tembiricha yekushisa inoratidzwa muTable 2 uye inobatwa ipapo.

tembiricha yepasi pe0,5 h/inch yeukobvu kana kuti 0,5 h, chero yakakura, uye yakatonhodzwa nemhepo.

Makirasi 70, 71, 72, uye 73

Mapombi anofanirakuve nekudziyirwa zvakafanana kune tembiricha mune austenitizing renji, isingapfuure yakanyanya kudzima tembiricha inoratidzwa muTafura 2, uye yozodzimwa mumvura kana mafuta.

Mushure mekudzima pombi ichadzoserwa mukati memvura yekupisa yekurapa inoratidzirwa muTable 2 kwenguva ichatemwa nemugadziri.

ASTM A671 Yekuedza Mapurojekiti

Kuumbwa Kwemakemikari

Zvinoenderana nezvinodiwa zvinoenderana nemayero ekushandiswa kwezvinhu zvakabikwa, kuongororwa kwemakemikari, mhedzisiro yekuyedza kusangana nezvinodiwa.

Tension Test

Mapaipi ese akasungwa anogadzirwa kune iyi dhizaini anofanirwa kuve nemuchinjiko-weld tensile bvunzo mushure mekupedzisira kupisa kupisa, uye mibairo inofanirwa kuenderana nehwaro hwezvinhu zvinodiwa kune yekupedzisira kusimba kwesimba reyakatarwa ndiro zvinhu.

Pamusoro pezvo, Magiredhi CD XX neCJ XXX, kana aya ari eKirasi 3x, 4x, kana 5x, uye Giredhi CP ye6x uye 7x ichave neyakachinjika base metal tensile bvunzo inoitwa pamienzaniso yakachekwa kubva papombi yapera. Mhedzisiro dzebvunzo idzi dzinosangana neadiki mechanical bvunzo zvinodiwa zveiyo plate yakatarwa.

Transverse Inotungamirirwa Weld Bend Test

Iyo bend bvunzo ichave inogamuchirwa kana pasina mitswe kana humwe hurema hunodarika1/8mukati. [mamirimita matatu] mune chero nzira iripo musimbi inopinza kana pakati peiyo weld nehwaro simbi mushure mekukotama.

Mitswe inotangira kumucheto kwemuenzaniso panguva yekuedzwa, uye ishoma pane1/4mukati. [6 mm] kuyerwa kune chero nzira haizotariswe.

Pressure Test

Makirasi X2 uye X3 pombi ichaedzwa zvinoenderana neSpecification A530/A530M, Hydrostatic Test Zvinodiwa.

Radiographic Examination

Hurefu hwakazara hweweld yega yega yeClass X1 neX2 ichaongororwa neradiographical zvinoenderana nekuzadzisa zvinodiwa zveASME Boiler uye Pressure Vessel Code, Chikamu VIII, Paragraph UW-51.

Kuongororwa kweradiographic kunogona kuitwa kusati kwaitwa kupisa.

ASTM A671 Chitarisiko

Pombi yakapedzwa haifaniri kuva nezvinokuvadza uye ichava nemagumo akafanana neanoshanda.

Inobvumirwa Kutsauka muhukuru

| Sports | Kushivirira Kukosha | Cherechedza |

| Kunze Diameter | ±0.5% | Kubva pachiyero che circumferential |

| Kunze-kwe-Roundness | 1%. | Musiyano pakati pemadhayamita makuru uye madiki ekunze |

| Alignment | 1/8 mu[3 mm] | Kushandisa mupendero wakatwasuka wemamita 10 wakaiswa kuitira kuti migumo yose ibatane nepombi |

| Ukobvu | 0.01 mu [0.3 mm] | Ukobvu hwemadziro hudiki hudiki pane hwataurwa nezita |

| Urefu | 0 - +0.5in [0 - +13mm] | magumo asina kugadzirwa |

Zvikumbiro zveASTM A671 Steel Tubing

Energy Industry

Inoshandiswa kutakura cryogenic zvinwiwa mumagasi echisikigo ekurapa zvidyarwa, zvigadziriso, uye zvivakwa zvekugadzira makemikari.

Industrial Refrigeration Systems

Yekushandisa muchikamu che cryogenic chefiriji uye air conditioning masisitimu kuti ive nechokwadi chekugadzikana kwehurongwa uye kuchengetedzeka.

Utilities

Zvekuchengetedza uye zvekufambisa zvemagasi ane liquefied.

Kuvaka uye Kuvaka

Inoshandiswa kumapurojekiti ezvivakwa pane tembiricha yakaderera kana yakanyanyisa mamiriro ezvakatipoteredza, senge inotonhora yekuchengetedza kuvaka.

Isu tiri mumwe weanotungamira welded welded kabhoni simbi pombi uye isina musono simbi pombi vagadziri uye vatengesi kubva kuChina, nehupamhi hwemhando yepamusoro simbi pombi mu stock, isu takazvipira kukupa iwe uzere huzere hwesimbi pombi mhinduro. Kuti uwane rumwe ruzivo rwechigadzirwa, ndapota inzwa wakasununguka kutibata nesu, isu tinotarisira kukubatsira iwe kuwana yakanakisa simbi pombi sarudzo pane zvaunoda!

Tags: ASTM a671, efw, cc 60, kirasi 22, vatengesi, vagadziri, mafekitari, masheya, makambani, wholesale, kutenga, mutengo, quotation, zvakawanda, kutengesa, mutengo.

Nguva yekutumira: Kubvumbi-19-2024