TS EN 10210 machubhu esimbiari kupisa-apedzwa mhango zvikamu zveisina kusanganiswa uye yakanaka-zviyo simbi kune dzakasiyana siyana dzezvivakwa uye zvemichina zvimiro zvekushandisa. Iine zvikamu zvakatenderera, mativi mana, rectangular, uye oval.

EN 10210 uye BS EN 10210 zviyero zvakafanana asi nemasangano akasiyana.

Navigation Buttons

BS EN 10210 Chikamu

BS EN 10210 Size Range

Raw Materials

BS EN 10210 Zita reSimbi

Kuendesa Mamiriro eBS EN 10210

Kemikari Kuumbwa kweBS EN 10210

Mechanical Properties yeBS EN 10210

Impact Miedzo

Weldability

Dimensional Tolerance

Surface Kuonekwa

Galvanized

Kugadziriswa kweSurface Defects

BS EN 10210 Kumaka

Applications

Zvigadzirwa zvedu zvinoenderana

BS EN 10210 Chikamu

NeRudzi rweSimbi

Unalloyed uye alloyed special steels

Masimbi asinalloyed:S235JRH, S275JOH ,S275J2H, S355JOH, S355J2H, S355K2H , S275NH,S275NLH,S355NH,S355NLH.

Alloyed special steels: S420NH, S420NLH, S460NH, S460NLH.

Nzira yakapfava yekuzivikanwa ndeye: muzita resimbi, kana simba regoho reindex richitanga nenhamba '4', yesimbi yealloy.

By Manufacturing Process

Zvikamu zvemakomba zvikamu zvinofanirwa kugadzirwa neisina musono kana welded maitiro.

Seamless inosanganisira: kupisa-kupedzwa uye kutonhora-kupedzwa

Kazhinji welds dzinosanganisira Electric Resistance Welding (RW) uye pasi peArc Welding (SAW): LSAW, SSAW.

Magetsi akakwenenzverwa makomba zvikamu kazhinji haadi zvemukati weld trimming.

By Cross-section Shape

CHS: denderedzwa hollow zvikamu;

RHS: square or rectangular hollow zvikamu;

EHS: elliptical hollow zvikamu;

Ichi chinyorwa chakarongwa ne circular cross-section (CHS) yezvinyorwa zvakakodzera.

BS EN 10210 Size Range

Wall ukobvu: ≤120mm

Kunze dhayamita

Round (CHS): Outer diameter≤2500 mm;

Square (RHS): Outer diameter≤ 800 mm × 800 mm;

Rectangular (RHS): Outer diameter≤750 mm × 500 mm;

Ovhari (EHS): Kunze dhayamita≤ 500 mm × 250 mm.

Raw Materials

Simbi isina kusanganiswa uye yakanaka yezviyo.

Simbi isina kuvharwa hunhu ina JR, JO, J2, uye K2 inotsanangurwa.

Fine zviyo simbi: mana hunhu N uye NL anotsanangurwa.

Simbi dzezviyo dzakatsetseka simbi dzine chimiro chezviyo chakanaka, chine ferrite saizi yezviyo ≥ 6.

BS EN 10210 Zita reSimbi

Kune asiri-alloy simbi hollow zvikamu simbi zita rinosanganisira

Muenzaniso: BS EN 10210-S275J0H

ine zvikamu zvina:S, 275, J0, uye H.

1.S: inoratidza kuti simbi yekugadzira.

2.Nhamba yenhamba(275): ukobvu ≤ 16mm kweiyo shoma yakataurwa goho simba, muMPa.

3.JR: inoratidza kuti pakamuri tembiricha ine chaiwo maitiro ekuita;

J0: inoratidza kuti pa 0 ℃ ine chaiyo kukanganisa zvivakwa;

J2 kana K2: inoratidzwa mu -20 ℃ ine chaiyo maitiro ekuita;

4.H: inoratidza zvikamu zvisina mhango.

Kune yakanaka zviyo simbi structural hollow zvikamu simbi zita rinosanganisira

Muenzaniso: EN 10210-S355NLH

Iine zvikamu zvishanu:S, 355, N, L, uye H.

1. S: inoratidza simbi yekugadzira.

2. Nhamba yenhamba(355): Ukobvu ≤ 16mm hushoma hunotsanangurwa goho simba, chikwata iMPa.

3. N: yakamisikidzwa kana yakajairwa kukungurutswa.

4. L: chaiyo inokanganisa zvivakwa pa -50 °C.

5.H: inoreva chikamu chisina.

Kuendesa Mamiriro eBS EN 10210

JR, J0, J2 uye K2 - kupisa kwapera.

N uye NL - yakajairika. Normalized inosanganisira normalized rolled.

JR, J0, J2 uye K2 - inopisa yakashanda

N uye NL - Normalizing. Normalizing inosanganisira normalizing rolling.

Zvinogona kuve zvakafanira kune zvisina musono mhango zvikamu zvine madziro ukobvu pamusoro pe10 mm, kana kana T/D yakakura kupfuura 0,1, kuisa yakakurumidza kutonhora mushure mekusimbisa kuti uwane iyo yakarongwa chimiro, kana kudzima mvura uye kudziya kuti uwane iyo yakatsanangurwa michina zvivakwa.

Kune zvikamu zvisina musono zvisina musono zvine madziro makubvu anodarika 10 mm, kana iyo T / D yakakura kupfuura 0.1, yakakurumidza kutonhora mushure mekuita austenitization inogona kudikanwa kuti uwane iyo yaunoda chimiro, kana kudzima mvura uye kudziya kuti uwane yakatsanangurwa michina zvivakwa.

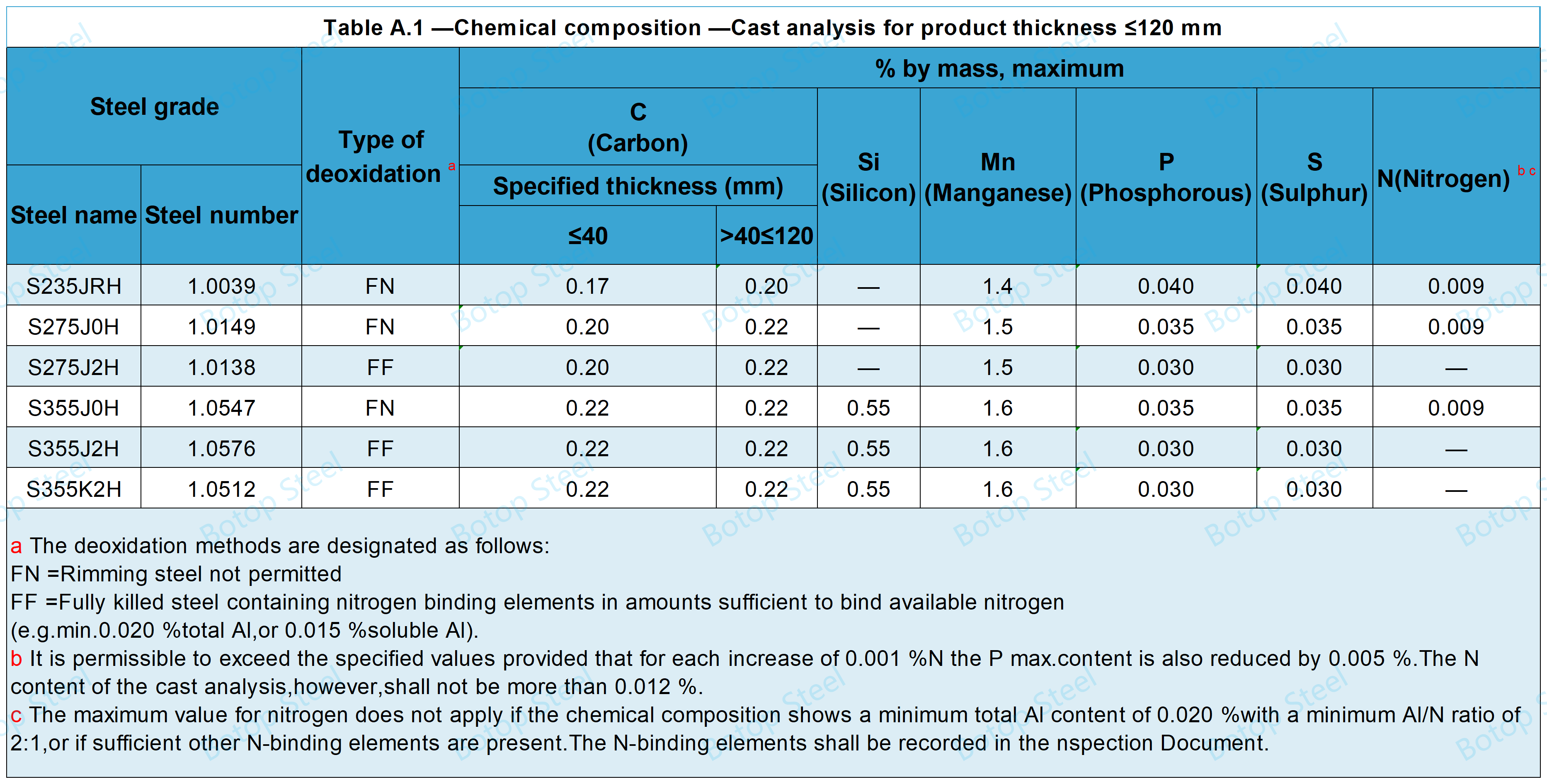

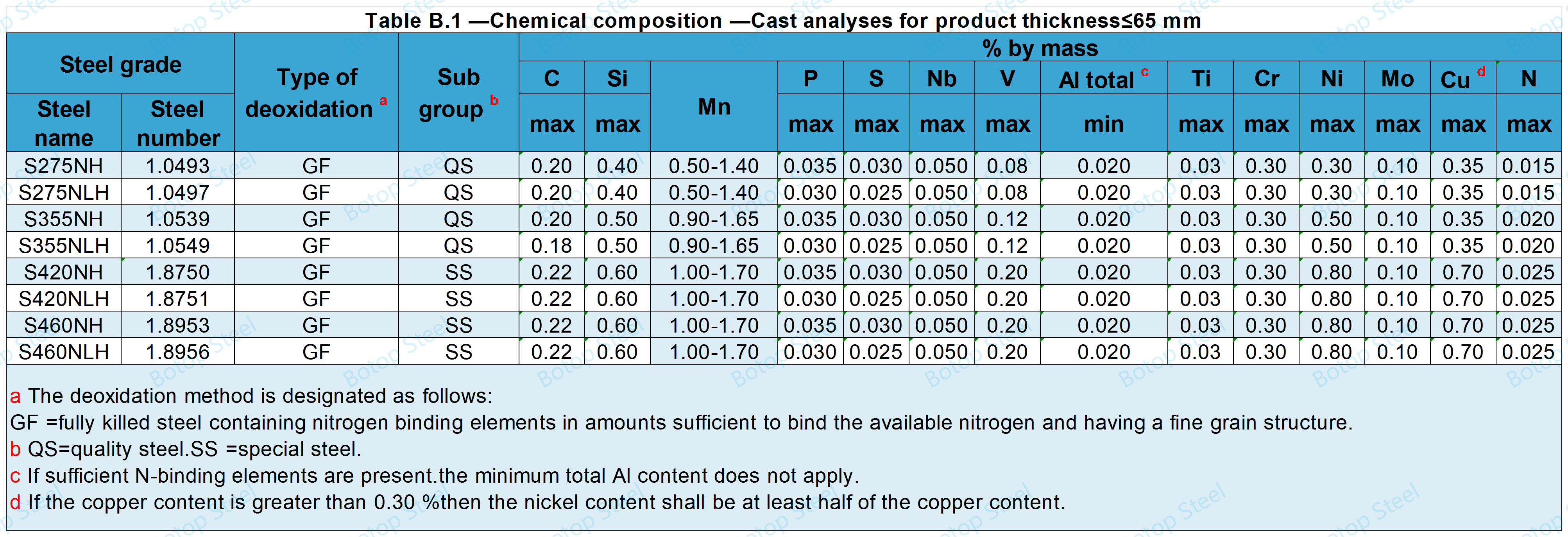

Kemikari Kuumbwa kweBS EN 10210

Zvisiri-alloy Steels - Chemical composition

Fine Grain Steels - Chemical kuumbwa

Pakusarudza CEV inotevera fomula ichashandiswa:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

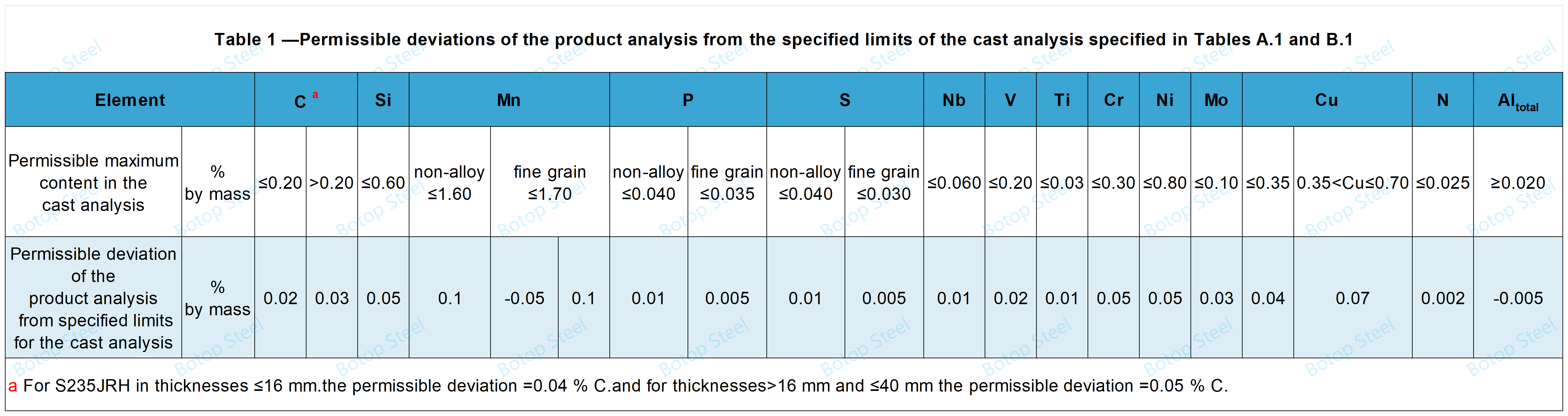

Kutsauka muChemical Composition

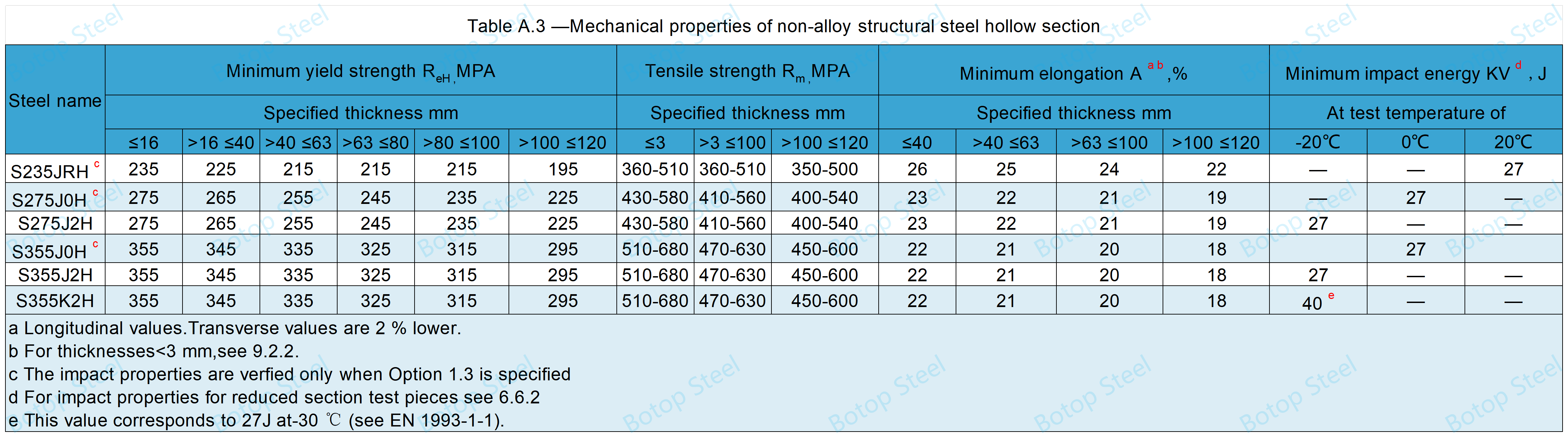

Mechanical Properties yeBS EN 10210

Kurerutsira kunetseka kunodarika 580 ° C kana kweinopfuura awa imwe chete kunogona kutungamirira mukushata kwezvinhu zvemuchina.

Masimbi asina-alloy - Mechanical Properties

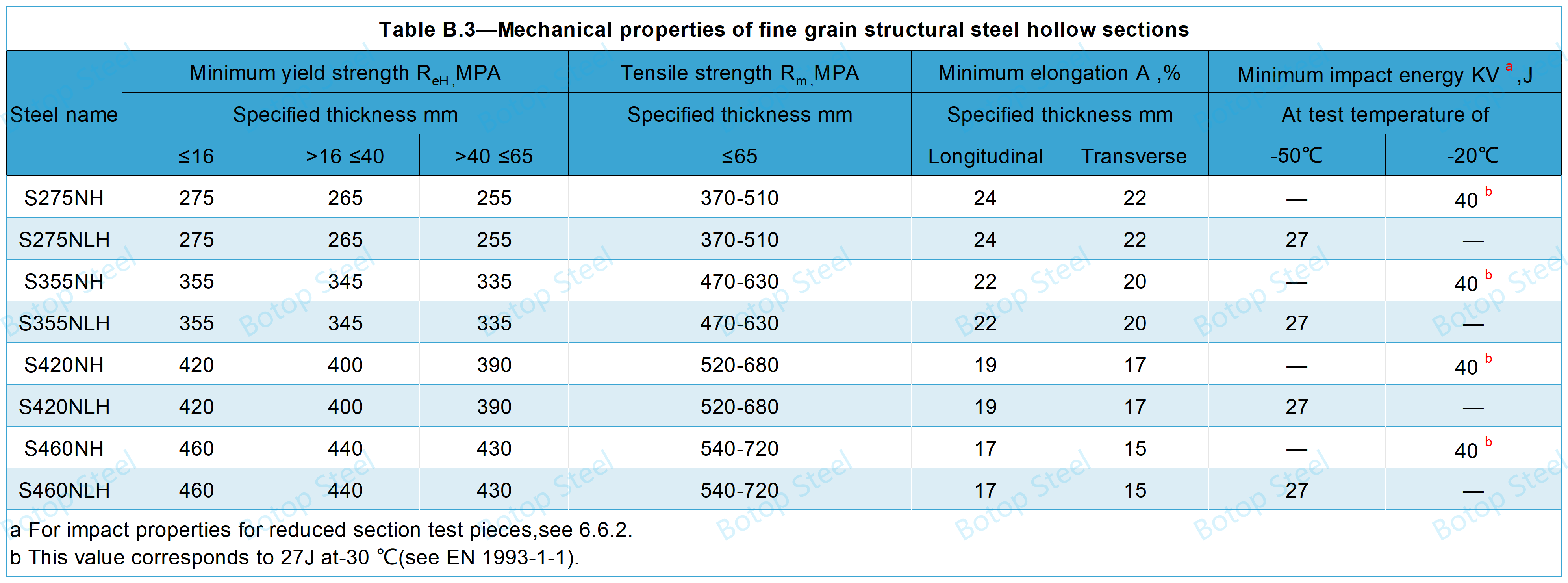

Fine Grain Steels - Mechanical Properties

Impact Miedzo

Kuongororwa kwemhedzisiro hakudiwe kana ukobvu hwakatsanangurwa

Yakajairwa V-notched mienzaniso zvinoenderana neEN 10045-1 ichashandiswa.

Kana iyo yezita chigadzirwa ukobvu husina kukwana kugadzirira kweakamisikidzwa emhando, bvunzo dzinozoitwa uchishandisa sampuli nehupamhi husingasviki 10 mm, asi isingasviki 5 mm.

Weldability

Masimbi ari muBS EN 10210 anobatika.

EN 1011-1 uye EN 1011-2 inotsanangura izvo zvakajairika zvinodikanwa zvezvigadzirwa zve welded.

Kuputika kutonhora munzvimbo yeweld ndiyo njodzi huru sekukora kwechigadzirwa, chiyero chesimba, uye CEV inowedzera.

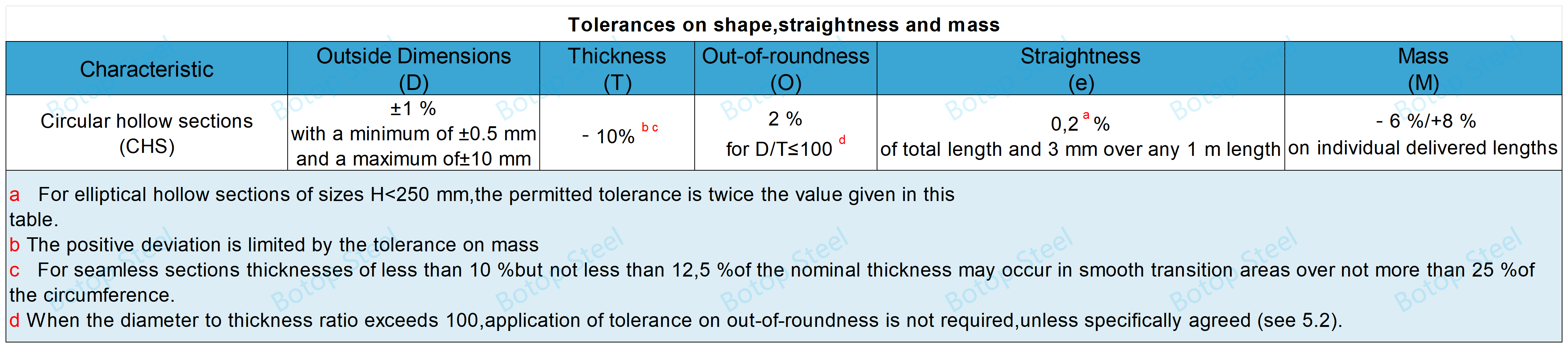

Dimensional Tolerance

Kushivirira paChimiro, Kururama uye Misa

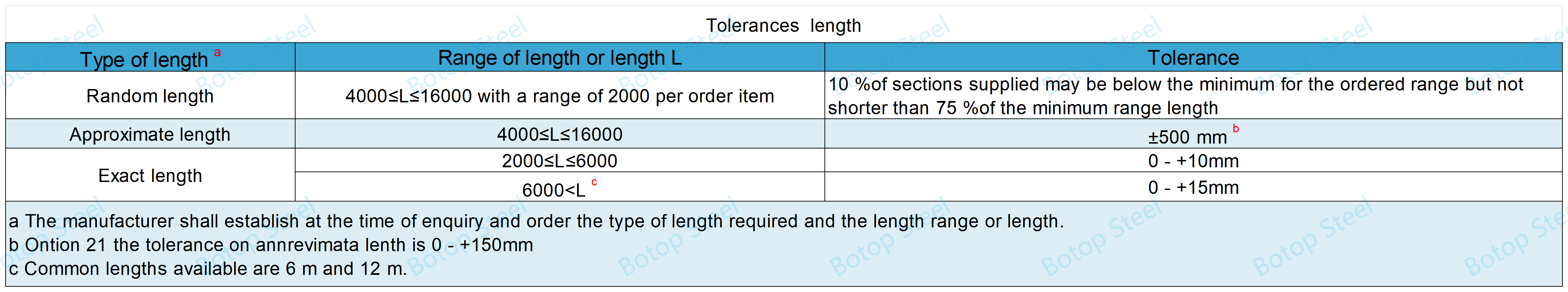

Kushivirira Kwekureba

Seam Kureba kweSAW Weld

Kushivirira pakureba kwemukati nekunze weld musono kune yakanyura arc welded hollow zvikamu.

| Ukobvu, T | Maximum weld bead urefu, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Iyo BS EN 10210 yakajairika inovhara zvese zvisina musono uye welded inopisa-yakapedzwa hollow chikamu zvigadzirwa. Iyo mikuru yewelding maitiro ndeye resistance welding (ERW) uye submerged arc welding (SAW). Mawelds ari muERW simbi mapaipi haaonekwe zvakanyanya, nepo SAW welds anowanzo rough uye anooneka zvakanyanya nekuda kweSAW.

Surface Kuonekwa

Pamusoro pacho pachava nekupera kwakatsetseka kunoenderana nekugadzira nzira inoshandiswa;

Kana ukobvu huri mukati mekushivirira, mabumps, grooves, kana shallow longitudinal grooves inokonzerwa nekugadzira nzira inobvumirwa.

Galvanized

Zvigadzirwa muBS EN 10210 zvakakodzerwa nekupisa dip galvanizing kurapwa.

TS EN ISO 1461 inofanira kushandiswa kutsanangura zvinodiwa zvekupfeka.

Zinc coatings inoshandiswa nekunyudzwa mumushonga wakanyunguduka une kanenge 98% zinc content.

Kugadziriswa kweSurface Defects

Kuremara kwepamusoro kunogona kubviswa nekukuya nemugadziri, chero ukobvu hwakagadziriswa husiri hudiki pane hudiki hunobvumidzwa ukobvu.

Kana yakagadzirwa neiyo welding process, kugadziriswa kwewelds hakubvumidzwe kunze kwekunyudzwa kwearc welding.

Non-alloy simbi pombi inogona kugadziriswa kuburikidza welding wepombi muviri. Alloy simbi pombi inogona kusagadziriswa nekuchipisa muviri.

BS EN 10210 Kumaka

Zviri mukati mesimbi pombi yekumaka zvinofanirwa kuve ne:

ndiro zita resimbi, semuenzaniso EN 10210-S275JOH.

izita kana chiratidzo chemugadziri.

kodhi yekuzivikanwa, semuenzaniso nhamba yekuodha.

TS EN 10210 machubhu esimbi anogona kucherechedzwa nenzira dzakasiyana siyana kuti ave nechokwadi chekuzivikanwa uye kuteedzera kuve nyore, kungave nekupenda, kutsika, kunamatira mavara, kana mamwe mavara anogona kushandiswa ega kana musanganiswa.

Applications

Nekuda kwesimba rayo repamusoro, kusimba kwakanaka, uye kukwenenzverwa, BS EN 10210 inokwanisa kushingirira kwakasiyana siyana nharaunda uye kurodha mamiriro uye inoshandiswa zvakanyanya mumhando dzakasiyana dzezvimiro zvekushandisa.

Kuvaka zvivakwa: semuenzaniso marangwanda ezvivakwa zvepamusoro-soro, matenga edzimba dzenhandare, uye zvinhu zvinotsigira mabhiriji.

Mechanical engineering: mafuremu uye zvinotsigira zvemichina uye inorema midziyo.

Civil engineering: senge tunnel zvitsigiro, makoramu ebhiriji, uye zvimwe zvinotakura zvinotakura zvinhu.

Zvifambiso zvezvivakwa: kusanganisira zvikamu zvemigwagwa uye mabhiriji enjanji.

Energy sector: semuenzaniso shongwe dzematurbine emhepo uye zvimwe zvimiro zvezvivakwa zvesimba.

Zvigadzirwa zvedu zvinoenderana

Isu tiri yepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe yakawanda yesimbi pombi mhinduro!

Tags: bs en 10210, en 10210,s275j2h,s275j0h,s355j2h.

Nguva yekutumira: Kubvumbi-25-2024