BS EN 10219 simbiinotonhora-yakaumbwa simbi dzesimbi dzakagadzirwa kubva kune dzisiri-alloy uye dzakatsetseka-grained simbi dzezvimiro zvekushandisa pasina kunotevera kupisa kupisa.

EN 10219 uye BS EN 10219 zviyero zvakafanana asi nemasangano akasiyana.

Navigation Buttons

BS EN 10219 Chikamu

BS EN 10219 Size Range

Raw Materials uye Delivery Conditions

BS EN 10219 Zita reSimbi

Kemikari Inoumbwa yeBS EN 10219

Mechanical Properties yeBS EN 10219

Impact Miedzo

Non-destructive Testing

Chitarisiko uye Kugadzirisa Kukanganisa

Dimensional Tolerances

Galvanized

BS EN 10219 Kumaka

Applications

Zvigadzirwa zvedu zvinoenderana

BS EN 10219 Chikamu

NeRudzi rweSimbi

Unalloyed uye alloyed special steels.

Unalloyed steels:

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H,S275NH, S275NLH, S355NH, S355NLH.

Alloyed special steels:

S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH.

Nzira iri nyore yekutaura mutsauko: mhando dzesimbi dzine M kana 4 alloys, uye alloying zvimiro zvesimbi zvinogona kukurumidza kuzivikanwa.

By Manufacturing Process

Maitiro ekugadzira anonyanya kushandiswa kugadzira mapaipi esimbi zvinoenderana neBS EN 10219 inosanganisira.Magetsi Resistance Welding (ERW) uye Submerged Arc Welding (SAW).

SAW inogona kuverengerwazve muLongitudinal Submerged Arc Welding (LSAW) uye Spiral Submerged Arc Welding (SSAW) zvichibva pachimiro cheiyo weld seam.

By Cross-section Shape

CFCHS: Cold Yakagadzirwa denderedzwa hollow zvikamu;

CFRHS: Cold Yakagadzirwa sikweya kana rectangular hollow zvikamu;

CFEHS: Cold Yakagadzirwa elliptical hollow zvikamu;

Iri bepa rinotarisa pane CFCHS (Cold Formed Circular Hollow Section).

BS EN 10219 Size Range

Rusvingo ukobvu: T ≤ 40mm

Kunze kwedhayamita (D):

Kutenderera (CHS): D ≤ 2500 mm;

Square (RHS): D ≤ 500 mm × 500 mm;

Rectangular (RHS): D ≤ 500 mm × 300 mm;

Ovhari(EHS): D ≤ 480 mm × 240 mm.

Raw Materials uye Delivery Conditions

Masimbi asina-alloy

per Appendix A, yakakungurutswa kana kuti Standardized/Standardized Rolled (N) yeJR, J0, J2, uye K2steels;

Fine zviyo simbi

Per Appendix B, Yakamisikidzwa/Yakamisikidzwa Rolling (N) yeN uye NLsteels;

Maererano neAppendix B.M uye ML, simbi dzaive thermomechanically rolled (M).

Iwo makomba zvikamu zvichaunzwa zvakatonhora-zvakaumbwa pasina kunotevera kupisa kwekupisa kunze kwekunge weld musono unogona kunge uri mune se-welded kana kupisa-kugadziriswa mamiriro.

Kune SAW hollow zvikamu pamusoro pe508 mm kunze kwedhayamita, zvingave zvakafanira kuita inodziya yekuumba oparesheni, iyo isingakanganise ma mechanic properties, kuitira kuti isangane nekunze-kwe-kutenderera kushivirira zvinodiwa.

BS EN 10219 Zita reSimbi

Iyo yekutumidza zita gungano reBS EN 10219 yakafanana neBS EN 10210, iyo inoshandisa iyo EN10027-1 standard.

Kune asiri-alloy simbi hollow zvikamu, zita resimbi rinosanganisira

Muenzaniso: Simbi yezvivakwa (S) ine simba rakaderera rakatarwa pakukora isingapfuuri 16 mm ye 275 MPa, ine simba shoma rekuita simba re 27 J pa 0 ℃(J), hollow chikamu (H).

BS EN 10219-S275J0H

Iine zvikamu zvina:S, 275, J0, uye H.

1. S: inoratidza kuti simbi yekugadzira.

2. Numerical value (275): ukobvu ≤ 16mm nokuda kwehuwandu hwakatarwa simba regoho, muMPa.

3. JR: inoratidza kuti pakamuri tembiricha ine chaiwo maitiro ekuita;

J0: inoratidza kuti pa 0 ℃ ine chaiyo kukanganisa zvivakwa;

J2 or K2: inoratidzwa mu -20 ℃ ine chaiyo maitiro ekuita;

4. H: inoratidza zvikamu zvisina mhango.

Kune yakanaka zviyo simbi structural hollow zvikamu simbi zita rinosanganisira

Muenzaniso: Simbi yeStructural (S) ine simba rakaderera rakatarwa pakukora isingapfuuri 16 mm ye355 MPa.normalized fine grain steel feedstock (N), ine simba shoma rekuita simba re 27 J pa -50 ℃(L), hollow chikamu (H).

EN 10219-S355NLH

Iine zvikamu zvishanu:S, 355, N, L, uye H.

1. S: inoratidza simbi yekugadzira.

2. Kukosha kwenhamba(355): ukobvu ≤ 16mm shoma yakataurwa goho simba, chikwata iMPa.

3. N: yakamisikidzwa kana yakajairwa kukungurutswa.

4. L: chaiyo inokanganisa zvivakwa pa -50 °C.

5. H: inoreva chikamu chisina.

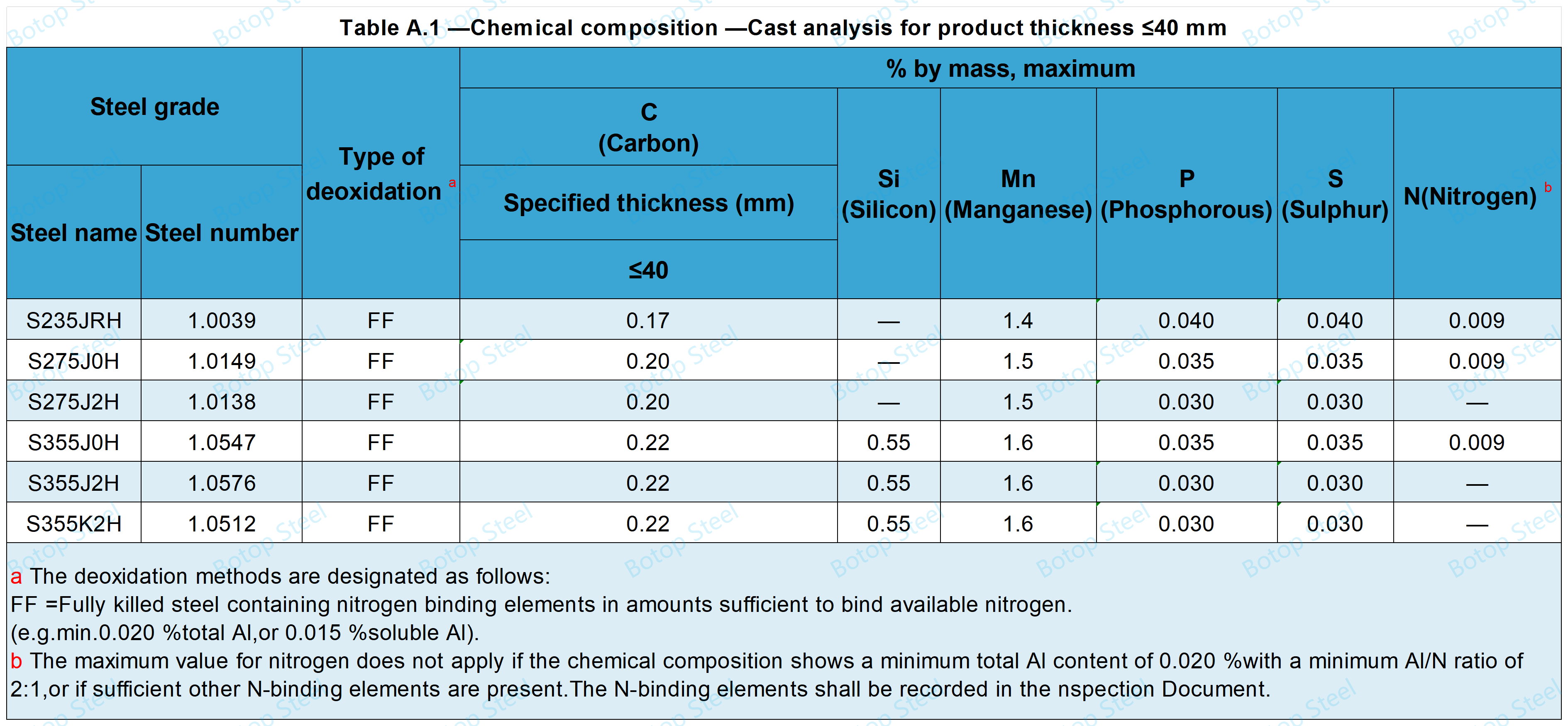

Kemikari Inoumbwa yeBS EN 10219

Zvisiri-alloy Steels - Chemical Composition

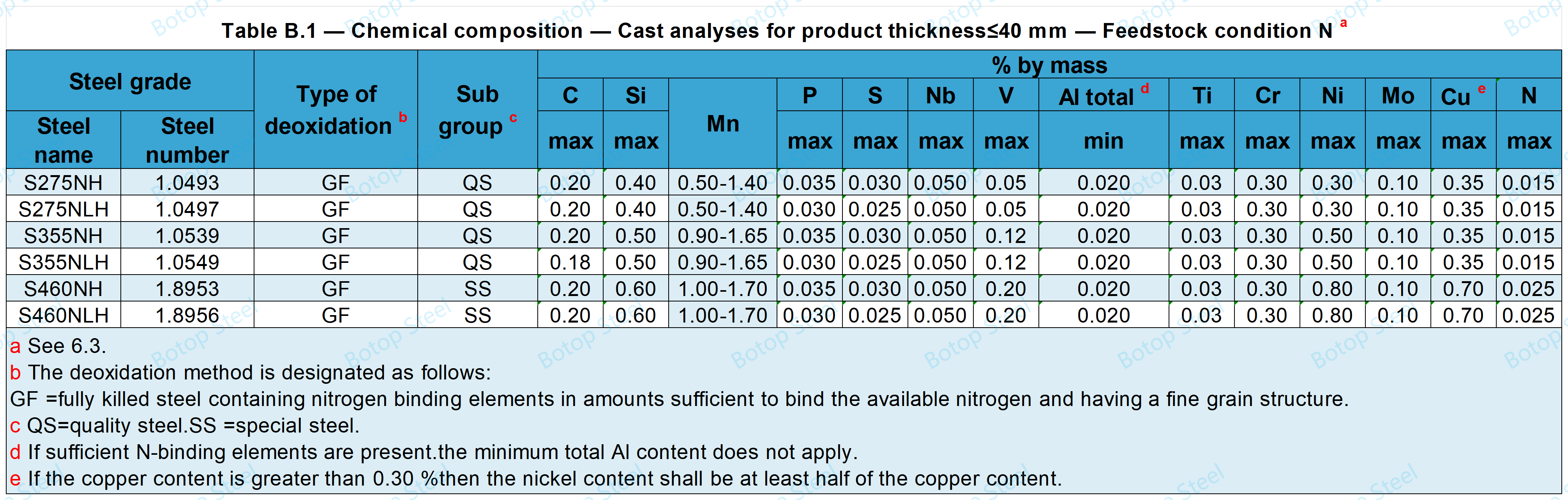

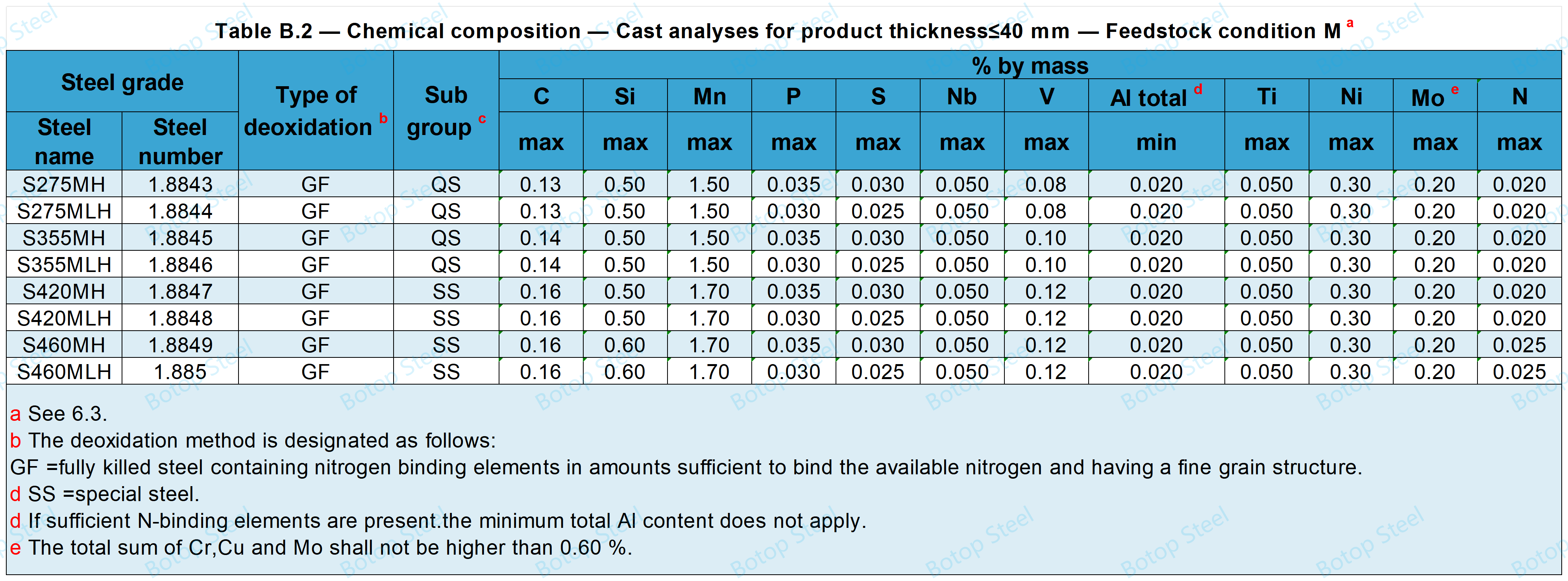

Fine Grain Steels - Chemical kuumbwa

Kana simbi yakatsetseka ikashandiswa seyakagadzirwa, inogona kuiswa muM uye N zvinoenderana nemamiriro ekutumira, uye makemikari anodiwa emhando mbiri idzi anogona kusiyana.

Pakusarudza CEV nzira inotevera ichashandiswa: CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Feedstock condition N

Feedstock mamiriro M

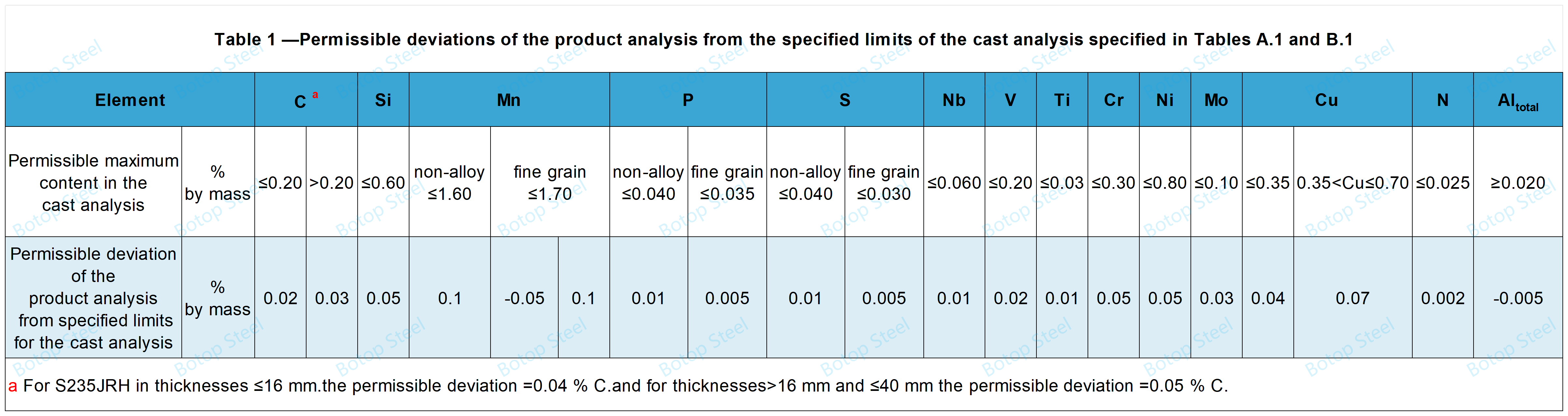

Kutsauka muChemical Composition

Mechanical Properties yeBS EN 10219

Inofanirwa kuitwa zvinoenderana neEN 1000-2-1. Muedzo uchaitwa mukupisa kubva pa10°C kusvika pa35°C.

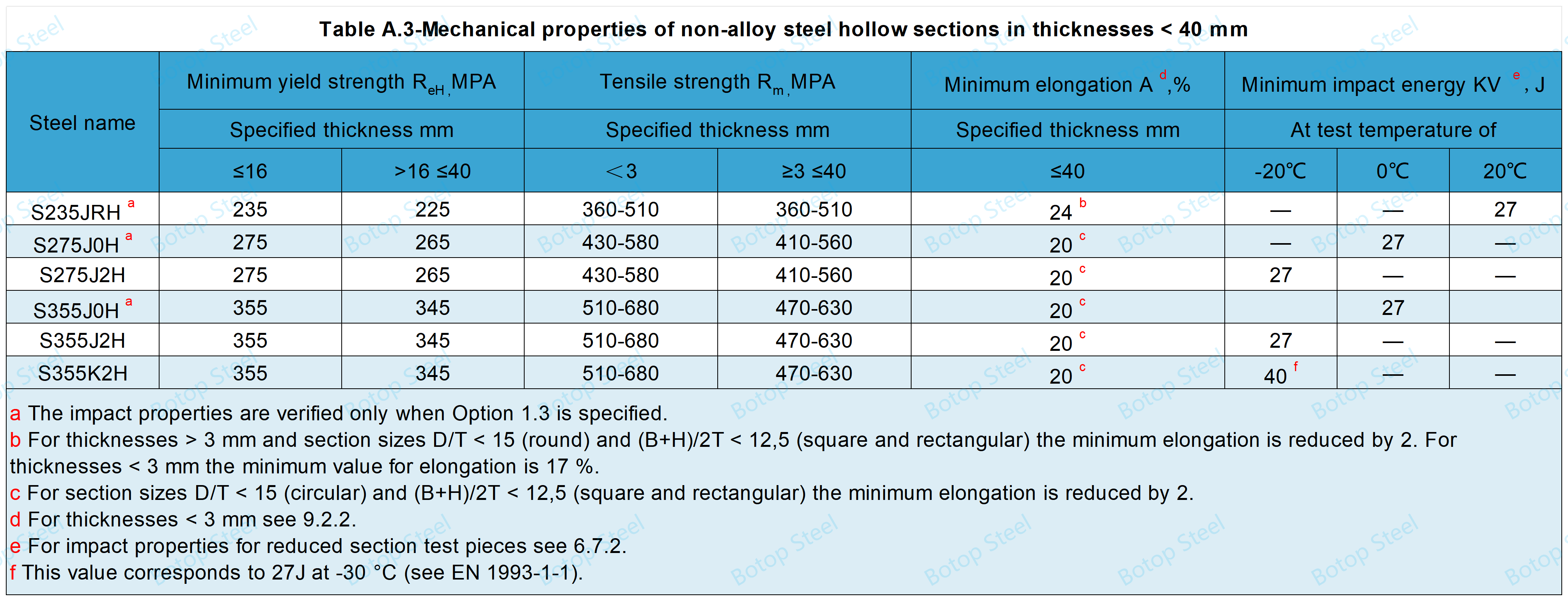

Masimbi asina-alloy - Mechanical Properties

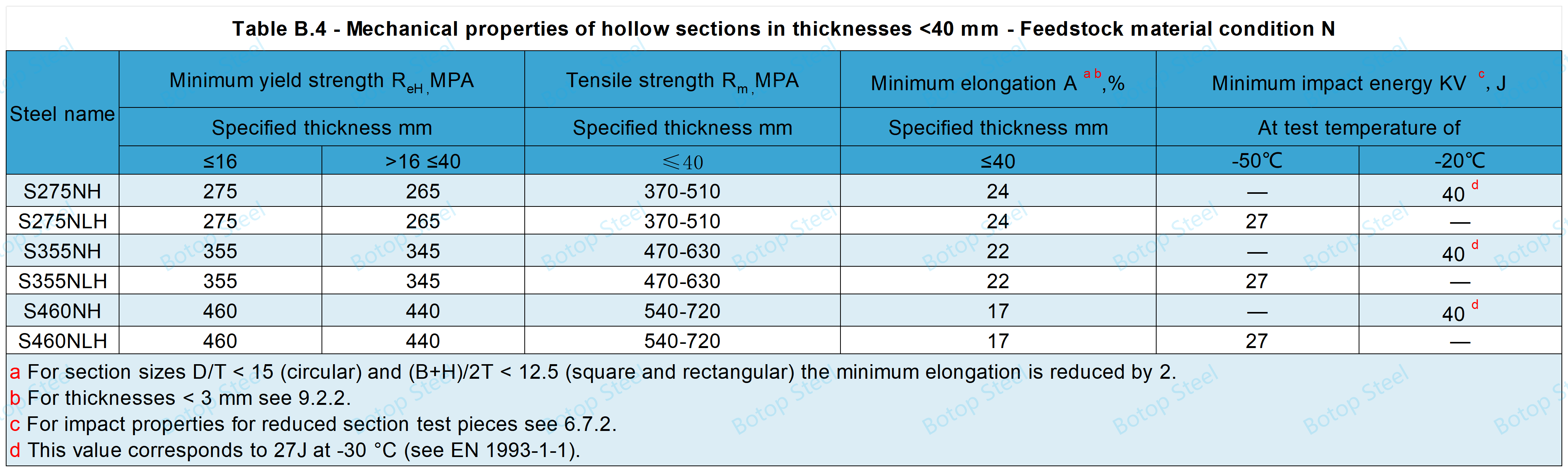

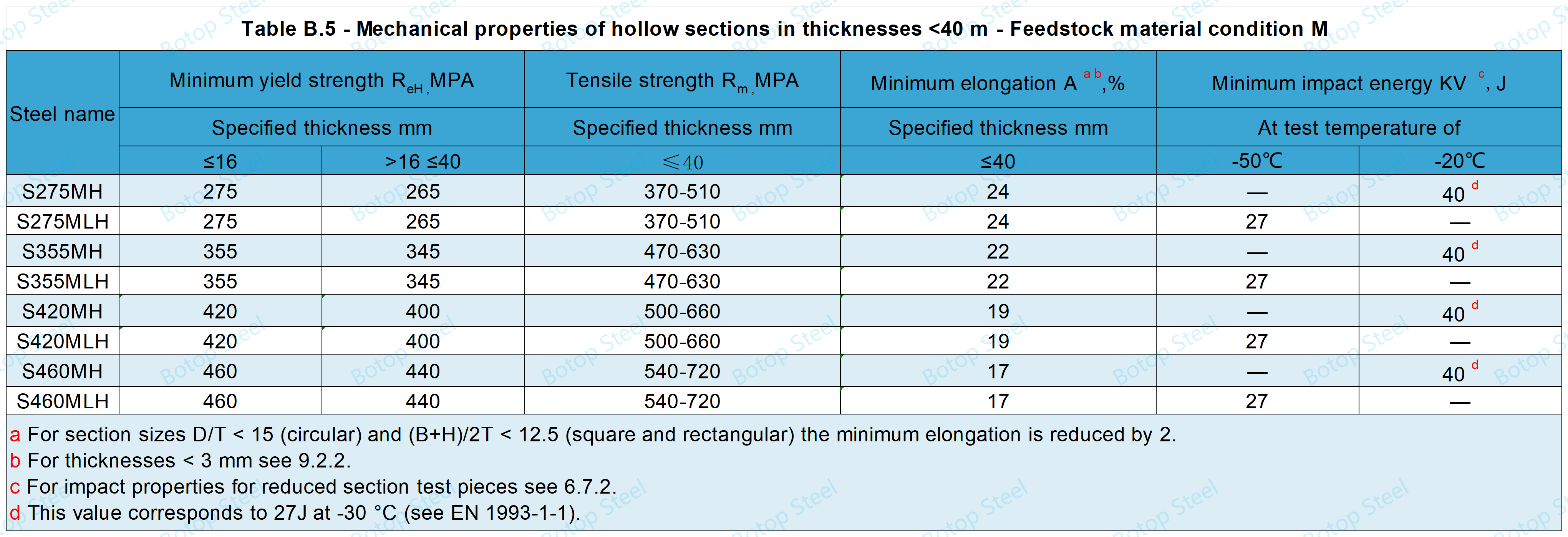

Fine Grain Steels - Mechanical Properties

Kana simbi yakatsetseka ikashandiswa seyakagadzirwa, inogona kuiswa muM uye N zvinoenderana nemamiriro ekutumira, uye michina yemhando mbiri idzi inogona kusiyana.

Feedstock condition N

Feedstock zvinhu mamiriro M

Impact Miedzo

Iyo bvunzo yekukanganisa ichaitwa zvinoenderana neEN 10045-1.

Avhareji kukosha kweseti yezvienzaniso zvitatu ichaenzana kana yakakura kudarika kukosha kwatarwa.

Ukoshi hwega hwega hunogona kunge huri pasi pemutengo wakatarwa, asi hausi pasi pe70% yehukoshi ihwohwo.

Non-destructive Testing

Paunenge uchiita NDT pamawelds muzvikamu zvisina kusimba zvemukati, zvinotevera zvinodiwa zvinofanirwa kuzadzikiswa.

Magetsi Welded Zvikamu

Isa chimwe chezvinotevera zvinodiwa:

a) EN 10246-3 kusvika padanho rekugamuchira E4, kunze kwekuti iyo inotenderera chubhu/pancake coil tekinoroji haitenderwe;

b) EN 10246-5 kusvika padanho rekugamuchira F5;

c) EN 10246-8 kusvika padanho rekugamuchira U5.

Yakanyura Arc Welded Zvikamu

Iyo weld seam yeakanyudzwa arc welded hollow zvikamu zvichayedzwa zvinoenderana neEN 10246-9 kusvika kugamuchirwa level U4 kana neradiography zvinoenderana neEN 10246-10 ine mufananidzo wemhando kirasi R2.

Chitarisiko uye Kugadzirisa Kukanganisa

Surface Kuonekwa

Zvikamu zvisina makomba zvichange zvine nzvimbo yakatsetseka inoenderana nenzira yekugadzira inoshandiswa; mabumps, grooves kana shallow longitudinal grooves inokonzerwa nekugadzira nzira inotenderwa kana iyo yakasara ukobvu iri mukati mekushivirira.

Migumo yechikamu chegomba ichachekwa nenzira yakaenzana kune axis yechigadzirwa.

Defect Repair

Kuremara kwepamusoro kunogona kubviswa nekukuya chero ukobvu hausi kushoma pane hudiki hunobvumidzwa ukobvu hwakatsanangurwa muBS EN 10219-2 mushure mekugadzirisa.

Kune zviyo zvakatsetseka zvisina makomba zvikamu, kugadziriswa kwemuviri newelding hakubvumidzwe kunze kwekunge kwakabvumiranwa neimwe nzira.

Matanho ekugadzirisa weld anoenderana nezvinodiwa zve EN ISO 15607, EN ISO 15609-1, uye EN ISO 15614-1.

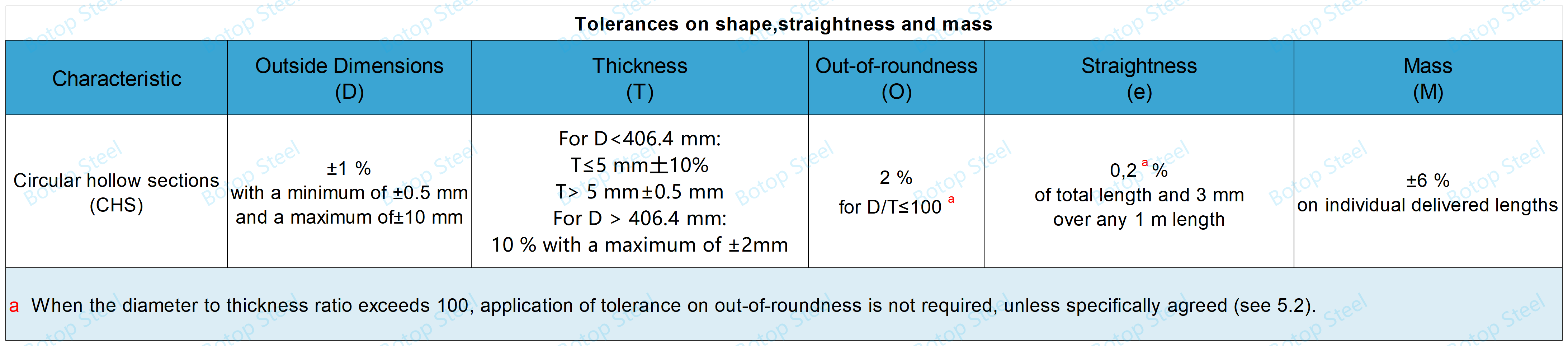

Dimensional Tolerances

Dimensional kushivirira kuchave zvinoenderana nezvinodiwa zve EN 10219-2 uye kutarisisa kuchapihwa kune chimiro chechikamu chemuchinjikwa.

Kushivirira paChimiro, Kururama uye Misa

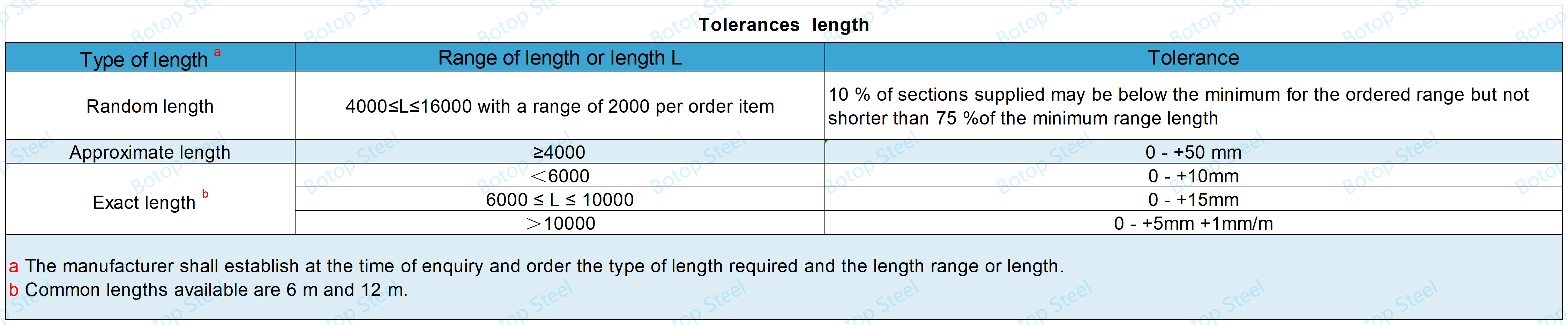

Kushivirira Kwekureba

Seam Kureba kweSAW Weld

Kushivirira pakureba kwemukati nekunze weld musono kune yakanyura arc welded hollow zvikamu.

| Ukobvu, T | Maximum weld bead urefu, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Galvanized

BS EN 10219 Hollow tubing inogona kupisa-dip galvanized kuti iwedzere hupenyu hwesevhisi.

Machubhu maburi anoiswa mubhavhu rinenge riine 98% zinc content kuti iite galvanized layer.

BS EN 10219 Kumaka

Zviri mukati mesimbi pombi yekumaka zvinofanirwa kuve ne:

Zita resimbi, semuenzaniso EN 10219-S275J0H.

Zita kana chiratidzo chemugadziri.

Kodhi yekuzivikanwa, semuenzaniso nhamba yekuodha.

TS EN 10219 machubhu esimbi anogona kucherechedzwa nenzira dzakasiyana siyana kuti ave nechokwadi chekuzivikanwa uye kuteedzera kuve nyore, kungave nekupenda, kutsika, kunamatira mavara, kana mamwe mavara anogona kushandiswa ega kana musanganiswa.

Applications

Iko kushandiswa kweBS EN 0219 yakajairika inovhara nzvimbo dzese dzezvimiro zvesimbi zvinodiwa.

Kuvaka:TS EN 10219 kutsanangurwa kwesimbi mapaipi anoshandiswa zvakanyanya mumapurojekiti ekuvaka, akadai sekuvaka mabhiriji, tsigiro yezvivakwa, nezvimwe.

Kuvaka zvivakwa: anoshandiswa mumapurojekiti ekuchengetedza mvura, kuvaka migwagwa, masisitimu epombi, uye mamwe mapurojekiti ekuvaka zvivakwa, senge pombi dzemvura, mapaipi emvura, zvichingodaro.

Manufacturing: Aya mapombi esimbi anoshandiswawo mukugadzira michina michina, conveyor masisitimu, uye mamwe maindasitiri ekushandisa.

Municipal engineering: Mumadhorobha mainjiniya einjiniya, BS EN 10219 yakajairwa simbi pombi inogona kushandiswa kugadzira njanji, njanji, zvipingamupinyi zvemugwagwa, zvichingodaro.

Architectural decoration: Iyo inoyevedza dhizaini uye kusimba kwemachubhu esimbi inoita kuti ive chinhu chakajairika chinoshandiswa mukushongedza kwekuvaka, senge stair railings, balustrades, ekushongedza mabhuraketi, nezvimwe.

Zvigadzirwa zvedu zvinoenderana

Kubva payakavambwa muna 2014, Botop Steel yave inotungamira kabhoni simbi pombi mutengesi kuChamhembe kweChina, inozivikanwa nebasa rayo repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana. Iyo kambani yakakura yezvigadzirwa zvemhando inosanganisiraisina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe nepombi fittings, flanges, uye specialty simbi.

Nekuzvipira kwakasimba kune mhando, Botop Steel inoshandisa zvakaomesesa zvidzoreso uye bvunzo kuti ive nechokwadi chekuvimbika kwezvigadzirwa zvayo. Chikwata chayo chine ruzivo chinopa zvigadziriso zvemunhu uye rutsigiro rwenyanzvi, nekutarisa kugutsikana kwevatengi.

Tags: bs en 10219, en 10219, chs, cfchs, s355j0h, s275j0h.

Nguva yekutumira: Kubvumbi-26-2024