JIS G 3456 simbi Mapaipimachubhu ecarbon steel anonyanya kukodzera kushandiswa munzvimbo dzebasa dzine madhayamita ekunze ari pakati pe10.5 mm ne660.4 mm patembiricha inopfuura 350 ℃.

Navigation Buttons

JIS G 3456 Giredhi Classification

Raw Materials

JIS G 3456 Manufacturing Processs

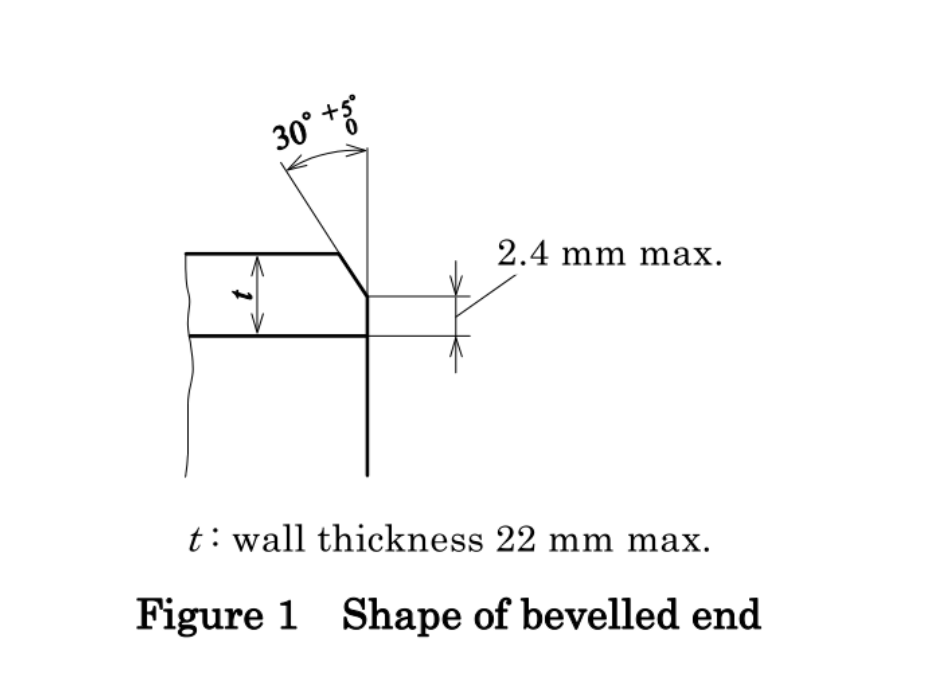

Pipe End

Hot Treatment

Kemikari Zvikamu zveJIS G 3456

Tensile Muedzo weJIS G 3456

Flattening Kuedza

Bendability Test

Hydraulic Test kana Nondestructive Test (NDT)

Pipe Weight Chati uye Pipe Zvirongwa zveJIS G 3456

Dimensional Tolerances

Chitarisiko

JIS G 3456 Kumaka

JIS G 3456 Steel Pipe Applications

Zviyero zvinoenderana neJIS G 3456

Zvigadzirwa zvedu zvinoenderana

JIS G 3456 Giredhi Classification

Iyo JIS G 3456 yakajairwa ine mamakisi matatu zvichienderana nekusimba kwekusimba kwepombi.

STPT370,STPT410 uye STPT480

Iwo anomiririra machubhu ane hushoma tensile simba re370, 410, uye 480 N/mm² (MPa) zvichiteerana.

Raw Materials

Mapombi anofanira kugadzirwa nesimbi yakafa.

Simbi yakaurayiwa imhando yakakosha yesimbi inoratidzwa nekuwedzerwa kwezvinhu zvakanangana, sealuminium nesilicon, panguva yekunyunguduka kunotora uye kusunga okisijeni uye zvimwe zvinokuvadza musimbi.

Iyi nzira inobudirira inobvisa magasi uye tsvina, nokudaro inovandudza kuchena uye kufanana kwesimbi.

JIS G 3456 Manufacturing Processs

Yakagadzirwa uchishandisa musanganiswa wakakodzera wechubhu yekugadzira maitiro uye yekupedzisa nzira.

| Chiratidzo chegiredhi | Chiratidzo chekugadzira nzira | ||

| Pombi yekugadzira nzira | Kupedzisa nzira | Kumaka | |

| STPT370 STPT410 STPT480 | Seamless:S | Kupisa-kupedzwa:H Kutonhora-kupedzwa:C | Sezvapihwa mu13 b). |

| Electric resistance akaiswa welded:E Butt welded:B | Kupisa-kupedzwa:H Kutonhora-kupedzwa:C Sezvo magetsi kuramba welded:G | ||

ForSTPT 480pombi yegiredhi, pombi yesimbi isina musono chete ndiyo ichashandiswa.

Kana kupikisa welding inoshandiswa, ma welds ari mukati uye kunze kwepamusoro pepombi achabviswa kuti awane weld yakatsetseka.

Pipe End

Iyo pombi inofanira kuvaflat end.

Kana iyo pombi ichidikanwa kuti igadziriswe kusvika kumagumo akakomberedzwa, kune ukobvu hwemadziro ≤ 22mm simbi pombi, kona yebevel ndeye 30-35 °, bevel upamhi hwepaipi yesimbi mupendero: ndeye max 2.4mm.

Ukobvu hwemadziro hwakakura kupfuura 22mm simbi pombi inotsvedza kumagumo, inowanzogadziriswa seyakabatanidzwa bevel, kuitiswa kwemazinga kunogona kureva kune zvinodiwa zvinodiwa zveASME B36.19.

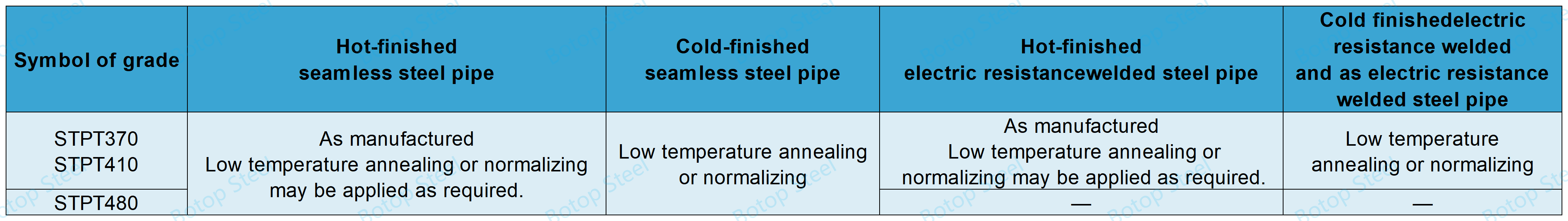

Hot Treatment

Sarudza nzira yakakodzera yekurapa kupisa maererano negiredhi uye maitiro ekugadzira.

Kemikari Zvikamu zveJIS G 3456

Chemical Composition Testing

Iyo nzira yekuongorora kupisa ichave inoenderana neJIS G 0320.

Iyo nzira yekuongorora chigadzirwa ichave inoenderana neJIS G 0321.

| Chiratidzo chegiredhi | C(Kabhoni) | Si(Silicon) | Mn(Manganese) | P(Phosphorus) | S(Sulfur) |

| max | max | max | |||

| STPT370 | 0.25% | 0.10-0.35% | 0.30-0.90% | 0.035% | 0.035% |

| STPT410 | 0.30% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

| STPT480 | 0.33% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

Kushivirira kweKemikari Kuumbwa

Mapombi esimbi asina musono achave ari pasi pekushivirira kuri muTafura 3 yeJIS G 0321.

Resistance-welded simbi mapaipi achave ari pasi pekushivirira muTafura 2 yeJIS G 0321.

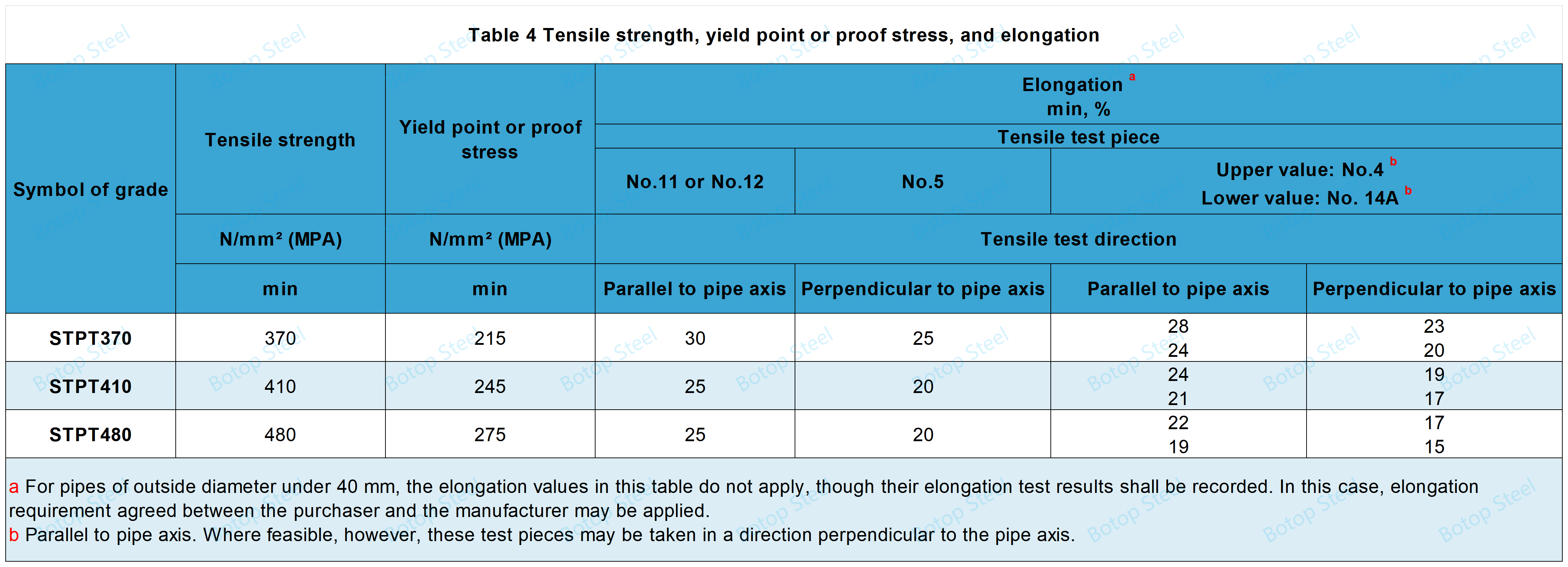

Tensile Muedzo weJIS G 3456

Nzira dzekuedza: Nzira dzekuedza dzichaenderana nemaitiro eJIS Z.2241.

Iyo pombi inosangana nezvinodiwa zvakapihwa muTafura 4 yekusimba kwekusimba, kusimba kwegoho, uye kurebesa.

Chiyero chinoshandiswa chichava cheNhamba 11, Nhamba 12 (No. 12A, No. 12B, kana Nha. 12C), Nha.

Iyo dhayamita yeTest piece Nha. 4 ichave 14 mm (gauge kureba 50 mm).

Zvidimbu zvekuedza Nhamba 11 neNo. 12 zvichatorwa zvakaenzana kune axis yepombi,

Zvimedu zvekuyedza Nha. 14A uye Nha.

uye Test chidimbu Nha. 5, mune perpendicular kune pombi axis.

Test chidimbu Nhamba 12 kana Nha.

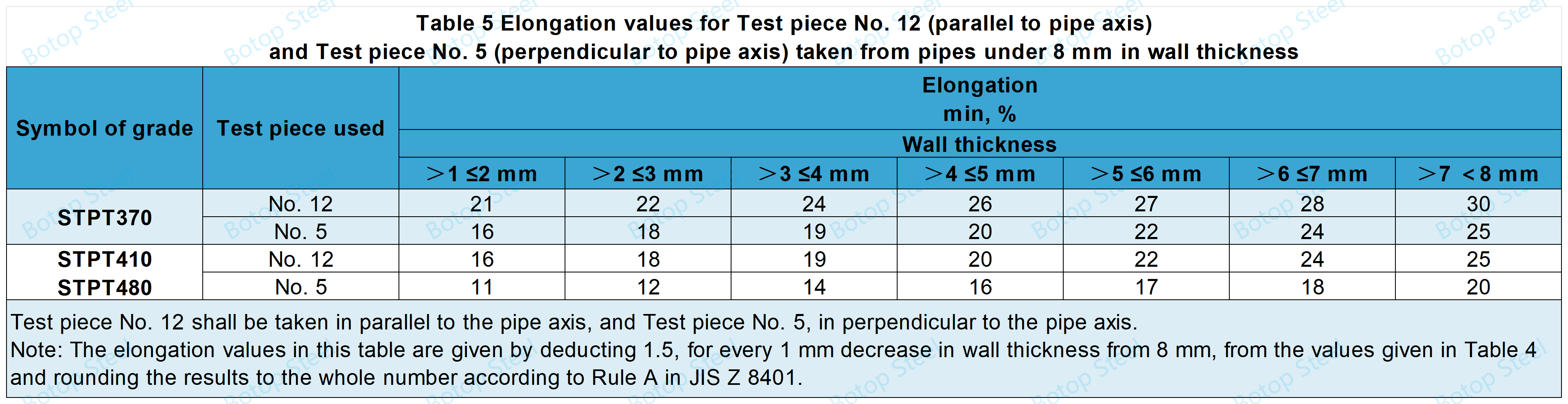

Pakuyedzwa kwemapombi ari pasi pe8 mm muukobvu akaitwa uchishandisa Test piece Nha. 12 kana Test chidimbu Nha.

Flattening Kuedza

Pamukamuri tembiricha (5 ° C - 35 ° C), furatira muenzaniso pakati pemapuratifomu maviri kusvikachinhambwe (H) pakati pazvo chinosvika kukosha kwakatarwa uyezve tarisa kune makatsemuka.

H=(1+e)t/(e+t/D)

н: chinhambwe pakati peplatens (mm)

t: kukora kwemadziro epombi (mm)

D: kunze dhayamita yepombi (mm)

е: zvinogara zvichitsanangurwa kune yega giredhi repombi:

0.08 ye STPT370,

0.07 ye STPT410 uye STPT480

Bendability Test

Bendability inoshandiswa kune mapaipi ane kunze kwedhayamita ye60.5 mm kana pasi.

Nzira yekuedza Patembiricha yekamuri (5 ° C kusvika 35 ° C), kotamisa chidimbu chebvunzo uchitenderedza mandrel kusvika mukati meradius yakapetwa ka6 kubva kunze kwedhayamita yepombi uye tarisa pakatsemuka. Mumuedzo uyu, weld inofanira kunge iri inenge 90 ° kubva kunze kwechikamu chekubhenda.

Iyo Bendability bvunzo inogona zvakare kuitwa zvinoenderana nezvinodiwa kuti radius yemukati kakapetwa kana dhayamita yekunze kwepombi uye kona yekubhenda i180 °.

Hydraulic Test kana Nondestructive Test (NDT)

Muedzo we hydraulic kana bvunzo isiri yekuparadza ichaitwa papombi yega yega.

Hydraulic Test

Bata pombi padiki padiki hydraulic test pressure yakataurwa kweinenge 5 seconds uye cherechedza kuti pombi inokwanisa kumira nekumanikidza pasina kubuda.

Nguva yeHydraulic inotsanangurwa maererano nesimbi pombi Purogiramu.

| Tafura 6 Minimum hydraulic test pressure | ||||||||||

| Nominal rusvingo ukobvu | Nhamba yepurogiramu: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Minimum hydraulic test pressure, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Nondestructive Test

Kana ultrasonic inspection yakashandiswa, zviratidzo kubva kune zvinyorwa zvinyorwa zvine UD-type reference standards, sezvinotsanangurwa muJIS G 0582, ichashandiswa searamu mazinga; chero chiratidzo chinobva papombi chakaenzana kana chikuru kupfuura chiyero chearamu chicharambwa. Uye zvakare, hudiki hudzika hwemakona enzvimbo dzekuyedza pombi, kunze kwekutonhora kupera, huchave 0.3 mm.

Kana eddy ikozvino yekuongorora ikashandiswa, masaini kubva kune EY mhando referensi mwero sekutsanangurwa kwazvino muJIS G 0583 ichashandiswa seyero yearamu; chero chiratidzo chinobva papombi chakaenzana kana chikuru kupfuura chiyero chearamu chichava chikonzero chekurambwa.

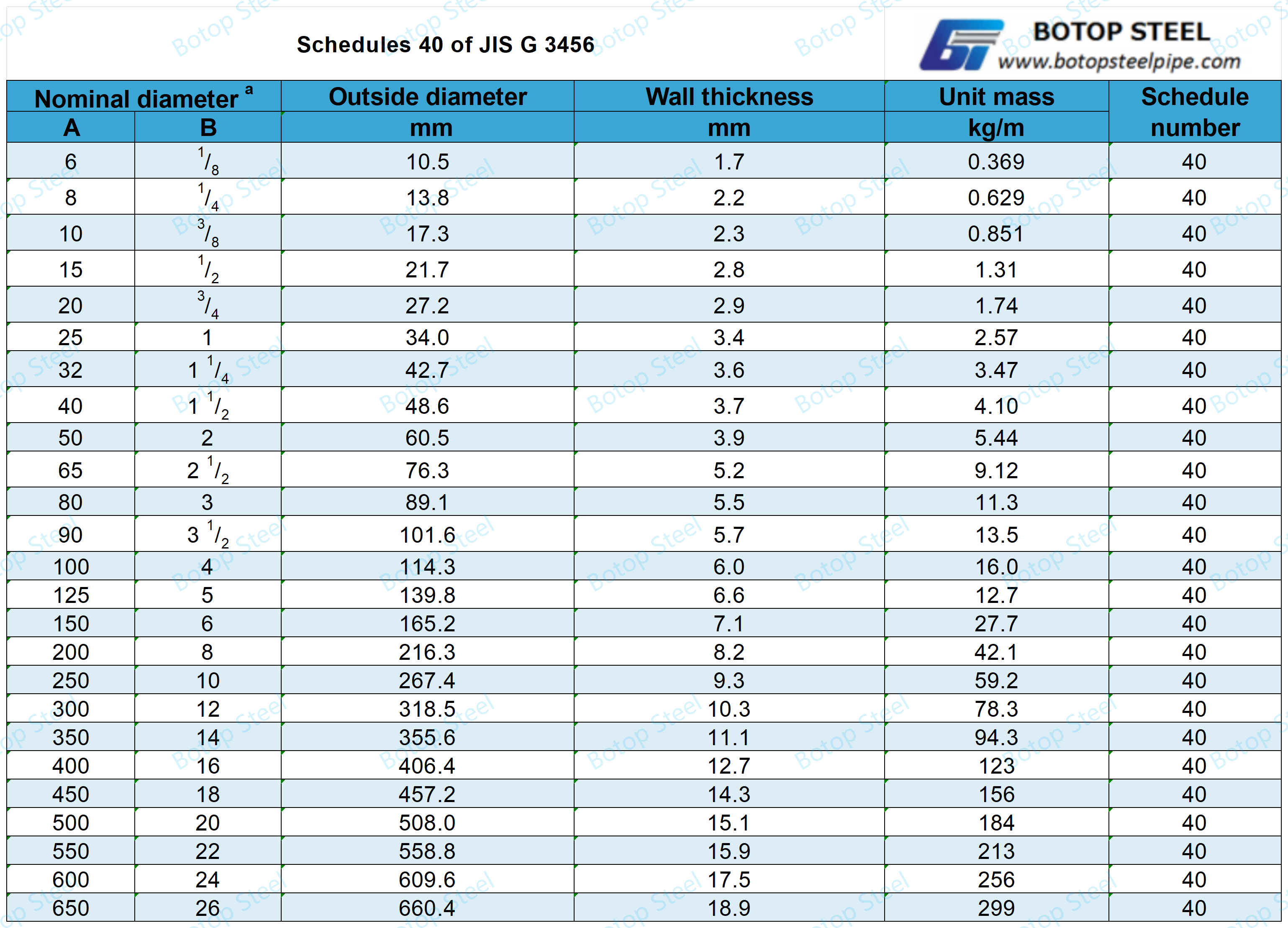

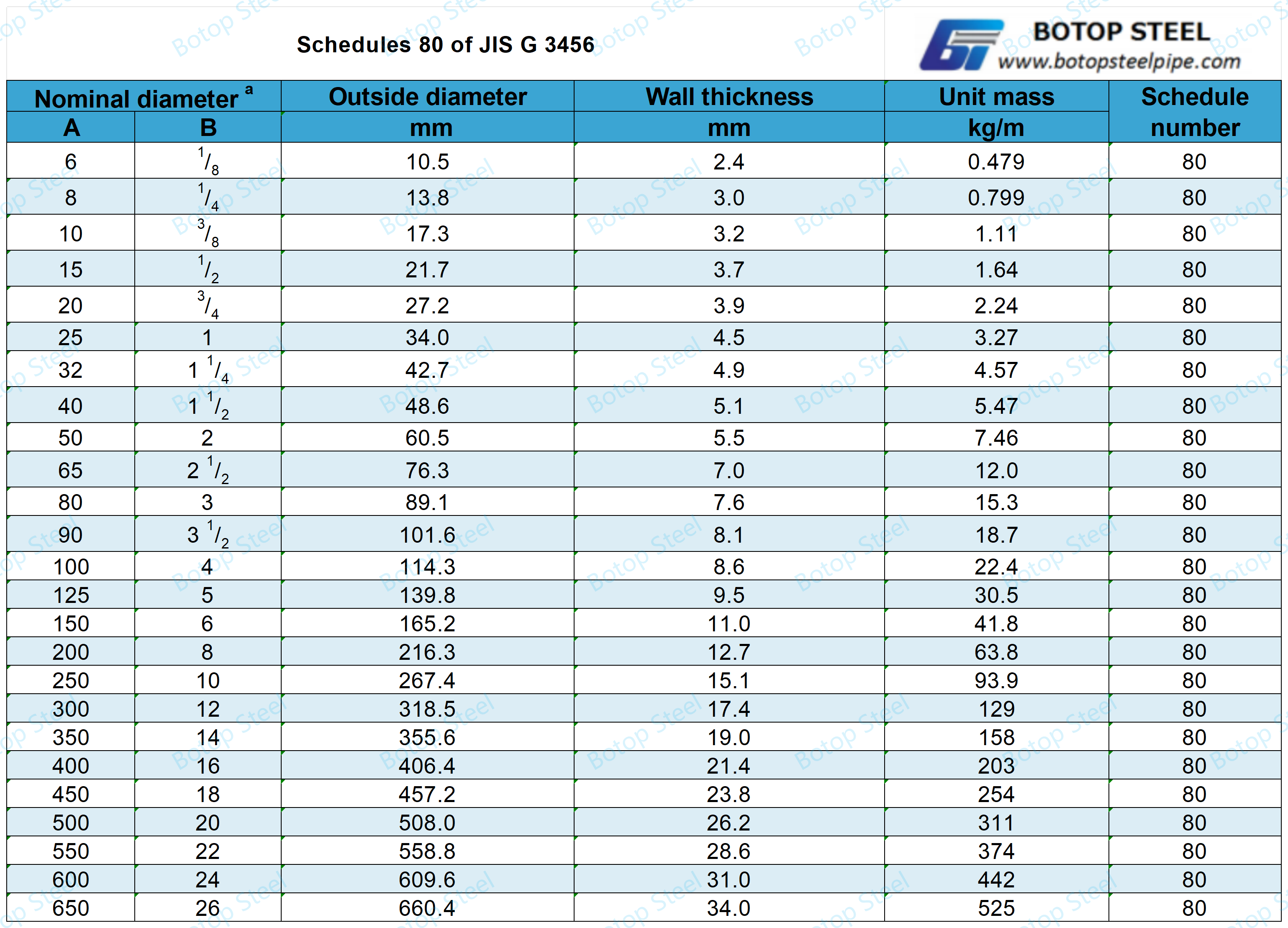

Pipe Weight Chati uye Pipe Zvirongwa zveJIS G 3456

Simbi Pipe Weight Calculation Formula

Tora density ye7.85 g/cm³ yechubhu yesimbi uye tenderedza mhedzisiro kune matatu akakosha manhamba.

W=0.02466t(Dt)

W: huremu hwepombi (kg/m)

t: kukora kwemadziro epombi (mm)

D: kunze dhayamita yepombi (mm)

0.02466: shanduko yekuwana W

Pipe Weight Chati

Pipe uremu matafura uye masheti akakosha mareferenzi ayo anowanzo shandiswa muinjiniya yepombi.

Pipe Zvirongwa

Chirongwa musanganiswa wakamisikidzwa wekukora kwemadziro uye dhayamita rezita repombi.

Purogiramu 40 uye Schedule 80 machubhu esimbi anoshandiswa zvakanyanya muindasitiri nekuvaka. Iwo akajairwa pombi saizi ane akasiyana madziro ukobvu uye kugona kune akasiyana maapplication mamiriro.

Kana iwe uchida kuziva zvakawanda nezvepombi uremu tafura uye pombi purogiramumune chiyero, unogona kudzvanya kuti utarise!

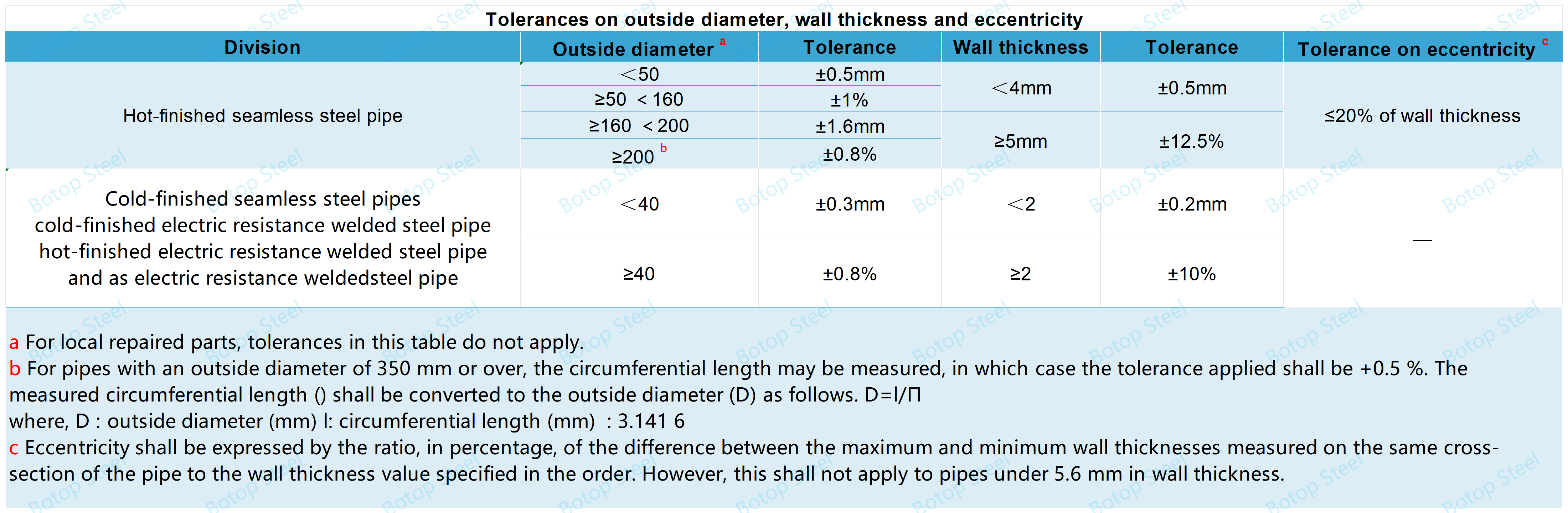

Dimensional Tolerances

Chitarisiko

Iyo yemukati uye yekunze nzvimbo yepombi ichave yakatsetseka uye isina zvikanganiso zvisina kunaka kushandisa.

Iyo pombi ichave yakatwasuka, nemigumo iri pamakona akarurama kune axis yepombi.

Mapaipi anogona kugadziriswa nekukuya, machining kana dzimwe nzira, asi iyo yakagadziriswa madziro ukobvu hucharamba huri mukati mekushivirira kwakatsanangurwa uye iyo yakagadziriswa nzvimbo ichave yakatsetseka muprofile.

Ukobvu hwemadziro epombi yakagadziridzwa huchachengetwa mukati mezvibvumirano zvakatsanangurwa uye pamusoro pepombi yakagadziriswa ichave yakatsetseka muprofile.

JIS G 3456 Kumaka

Pombi imwe neimwe inopfuura nekuongorora inofanira kunyorwa nemashoko anotevera. Mazita anogona kushandiswa pamasumbu epombi madiki-diameter.

a) Chiratidzo chegiredhi

b) Chiratidzo chekugadzira nzira

Chiratidzo chekugadzira nzira yekugadzira ichave inotevera. Madheshi anogona kutsiviwa nema blanks.

Kupisa-kupedzwa seamless simbi pombi: -SH

Kutonhora-kupedzwa seamless simbi pombi: -SC

Semagetsi kuramba welded simbi pombi: -EG

Kupisa-kupedzwa kwemagetsi kupikisa welded simbi pombi: -EH

Kutonhora-kupedzwa kwemagetsi kupikisa welded simbi pombi: -EC

c) Dimensions, inoratidzwa nemazita dhayamita × zita remadziro ukobvu, kana kunze dhayamita × madziro ukobvu.

d) Zita remugadziri kana chiziviso

Muenzaniso:BOTOP JIS G 3456 SH STPT370 50A×SHC40 HEAT NO.00001

JIS G 3456 Steel Pipe Applications

JIS G 3456 simbi pombi inowanzoshandiswa midziyo uye pombi masisitimu munzvimbo yakakwirira-tembiricha uye yakakwirira-kudzvanywa nharaunda, senge mumaboilers, zvinopisa zvinopisa, high-pressure steam piping, thermal power plant, chemical plant, and paper mills.

Zviyero zvinoenderana neJIS G 3456

Aya anotevera zviyero zvese zvinoshanda papombi munzvimbo dzepamusoro-tembiricha uye yakanyanya-kudzvanywa nharaunda uye inogona kushandiswa seimwe nzira yeJIS G 3456.

ASTM A335/A335M: inoshanda kune alloy simbi mapaipi

DIN 17175: yemapombi esimbi asina musono

TS EN 10216-2 mapaipi esimbi asina musono

GB 5310: inoshanda kune isina musono simbi pombi

ASTM A106/A106M: Seamless kabhoni simbi machubhu

ASTM A213/A213M: Machubhu asina musono uye pombi dzesimbi alloy nesimbi isina tsvina.

EN 10217-2 Inokodzera machubhu akaiswa welded uye pombi

TS ISO 9329-2: Seamless kabhoni uye alloy simbi machubhu nemapombi

NFA 49-211: yesimbi isina musono machubhu nemapombi

BS 3602-2: isina musono kabhoni simbi mapaipi uye mafittings

Zvigadzirwa zvedu zvinoenderana

Isu tiri yepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe yakawanda yesimbi pombi mhinduro! Kana iwe uchida kuziva rumwe ruzivo nezve simbi pombi zvigadzirwa, unogona kutibata nesu.

Tags: JIS G 3456, SPTP370, STPT410, STPT480, STPT, vatengesi, vagadziri, mafekitari, masheya, makambani, tengesa, kutenga, mutengo, quotation, zvakawanda, kutengesa, mutengo.

Nguva yekutumira: Kubvumbi-29-2024