ASTM A106 Giredhi B isimbi isina kabhoni simbi pombi yakavakirwa paASTM A106 yakajairwa uye yakagadzirirwa kushingirira tembiricha yepamusoro uye kumanikidza nharaunda.

Inonyanya kushandiswa mumafuta, gasi, uye makemikari maindasitiri ekuvaka mapombi masisitimu uye ane hukama zvivakwa.

Navigation Buttons

ASTM A106 Giredhi

ASTM A106 ndeye yakajairwa dhizaini isina musono kabhoni simbi pombi yeakakwira-tembiricha maapplication akagadzirwa neASTM International. Tsanangudzo inotsanangura magiredhi matatu e seamless carbon steel pipe, Grade A, Grade B, uye Grade C. Pane izvi, Grade B ndiyo inonyanya kushandiswa.

Giredhi "B" inomiririra chaiyo makemikari kuumbwa uye mechanic pfuma nhanho yezvinhu zvekushandisa pane mamwe tembiricha uye kumanikidza.

Kana iwe uchida kuziva zvakawanda nezve ASTM A106 unogona kudzvanya:Chii Chinorevei ASTM A106?

Key Features

Seamless Manufacturing

ASTM A106 Giredhi B tubing inogadzirwa kuburikidza isina musono kugadzira iyo inova nechokwadi chekufanana uye simba rekushandisa munzvimbo dziri pasi pekunetseka kwakanyanya.

High-temperature Performance

Iyi pombi inonyanya kukodzera kushanda munzvimbo dzekupisa kwepamusoro, senge mumapombi masisitimu mune zviteshi zvemagetsi, zvinonatsa, uye zvidyarwa zvemakemikari.

Kuumbwa Kwemakemikari

Iyo kemikari yeGiredhi B yakagadzirirwa kuipa yakanaka kupisa kupisa uye processability. Iyo inowanzo ine yakaderera kabhoni yemukati uye ine mwero huwandu hwemanganese, phosphorus, sarufa, uye silicon.

Mechanical Properties

ASTM A106 Giredhi B simbi pombi inopa yakanakisa tensile simba uye yakanaka goho simba kune maapplication anoda yakanaka makina zvivakwa.

Wide Range of Applications

Nekuda kwekupikiswa kwayo nekupisa uye michina yemagetsi, ASTM A106 Giredhi B tubing inoshandiswa mumhando dzakasiyana dzekushandisa senge oiri negasi, petrochemicals, boilers, uye kupisa kunopisa.

Kuumbwa Kwemakemikari

| Composition | C (Kabhoni) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) | Si (Silicon) | Cr (Chromium) | Cu (Mhangura) | Mo (Molybdenum) | Ni (Nickel) | V (Vanadium) |

| max | - | max | max | min | max | max | max | max | max | |

| uwandu huripo | 0.30 % | 0.29 - 1.06 % | 0.035 % | 0.035 % | 0.10 % | 0.40 % | 0.40 % | 0.15 % | 0.40 % | 0.08 % |

Kunze kwekunge zvatsanangurwa neimwe nzira nemutengi, pakudzikisira kwega kwega kwe0.01% pazasi peiyo kabhoni yakanyanya kutaurwa, kuwedzera kwe0.06% yemanganese pamusoro peiyo yakanyanya kutaurwa ichabvumidzwa kusvika pakukwirira kwe1.65%.

Cr, Cu, Mo, Ni, uye V: huwandu hwezvinhu zvishanu izvi hazvingapfuure 1%.

Mechanical Properties

| List | Kusimba simba, min | Goho simba, min | ||

| classification | psi | MPa | psi | MPa |

| ASTM A106 Giredhi b | 60,000 | 415 | 35,000 | 240 |

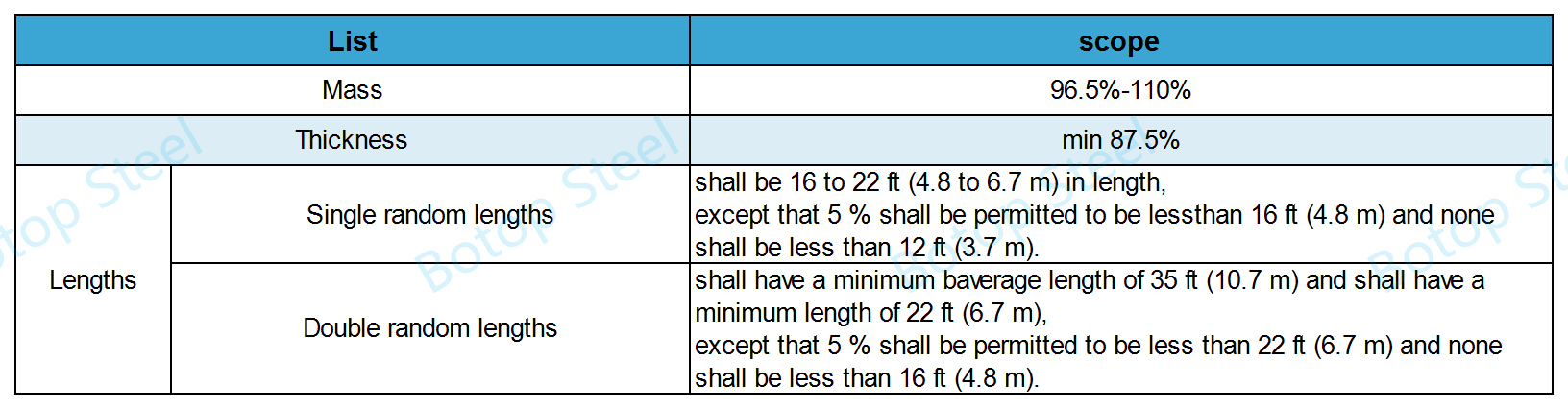

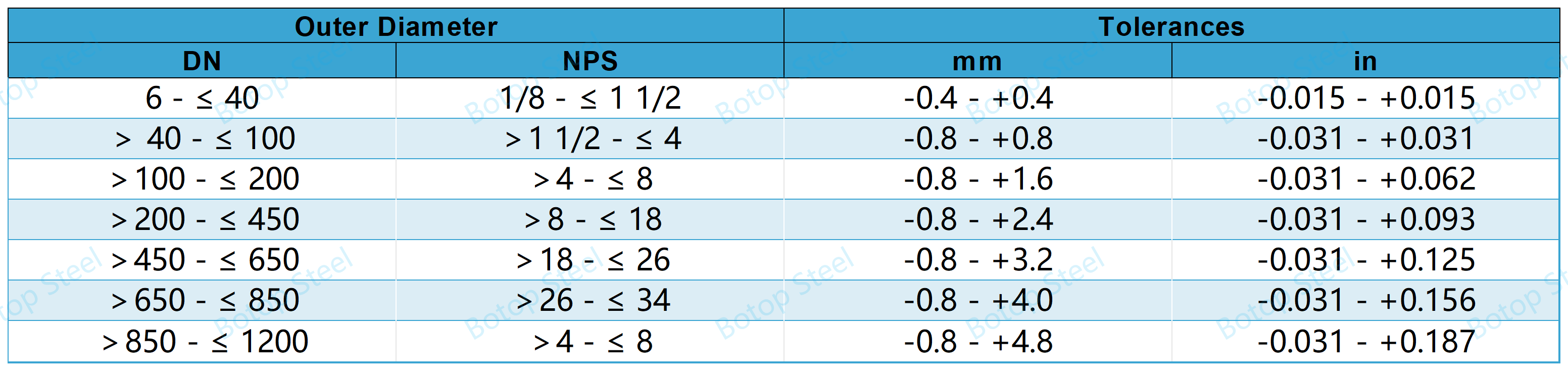

Dimensional Tolerances

Misa, Ukobvu, uye Urefu

Outer Diameter

Testing uye Certification

Chemical Composition Analysis

Sarudza kuumbwa kwekemikari yepombi, kusanganisira kabhoni, manganese, phosphorus, sarufa, uye silicon kuve nechokwadi chekuti zvinhu zvinosangana nezvinodiwa zvemakemikari zvinotsanangurwa muchiyero.

Tensile Testing

Edza kusimba kwesimba, goho simba, uye kureba kwepombi yesimbi. Iyi bvunzo inobatsira kuongorora mashandiro echinyorwa uye kuomarara pasi pekunetseka kwekunetseka.

Bending Test

Kubhenda bvunzo kunoitwa pane yakasungwa uye isina musono pombi yekuongorora yayo epurasitiki deformation kugona uye kutendeseka kwemajoini akasungwa.

Flattening Test

Miedzo yekufuratira inoitwa pamachubhu kuti iongorore deformation yavo uye kuputika maitiro pasi pekumanikidzwa.

Hardness Testing

Kuoma kwechinhu kunoongororwa nenzira yeBrinell kana Rockwell kuomarara bvunzo. Muedzo uyu wakakosha pakuona magadzirirwo uye mashandisirwo echinyorwa.

Hydrotesting

Pombi yega yega inofanirwa kuongororwa hydrostatically kuti ione kuti haina kubvinza pakudzvanywa kwakatarwa kuti ive nechokwadi chekusimba uye kuchengetedzeka kwepombi system.

Non-destructive Testing

Inosanganisira Ultrasonic Testing (UT), Magnetic Particle Testing (MT) uye / kana Radiographic Testing (RT) yekuona zvikanganiso zvemukati nepamusoro zvakadai sekuputika, inclusions uye porosity.

Impact Testing (pakukumbira)

Mune zvimwe zviitiko, kuyedzwa kwemhedzisiro (semuenzaniso, Charpy V-notch bvunzo) inogona kudikanwa kuti uongorore kuomarara kwekupwanyika kwezvinhu patembiricha yakaderera.

Zvikumbiro Zvikuru zveASTM A106 Giredhi B

Kutakura mafuta uye gasi: kune yakakwirira-kumanikidza uye yakakwirira-tembiricha nharaunda.

Chemical processing: yeCorrosion uye yakakwirira-tembiricha inodzivirira pombi masisitimu.

Zviteshi zvemagetsi: kune mitsara yeutsi uye zvitoro zveboiler.

Industrial Manufacturing: yekumanikidza pombi uye yakakwirira-kumanikidza midziyo.

Kuvaka uye kuvaka ngarava: yekuvaka kudziyisa uye kutonhora masisitimu uye boiler uye masystem ezvikepe.

Indasitiri yemotokari: yekugadzirwa kwezvikamu zvemotokari zvinopokana nekupisa kwakanyanya uye kumanikidza.

Imwe nzira kune ASTM A106 GR.B

Paunenge uchisarudza zvimwe zvekushandisa, kutariswa kunofanirwa kupihwa kune iyo mechaniki zvivakwa, tembiricha kuramba, kumanikidza kuramba, uye corrosion kuramba kwezvinhu kuti ive nechokwadi chekutevedzwa kwezvinodiwa zvekushandisa uye mirau uye zviyero.

| Standard Name | Chikamu chekushandisa |

| ASTM A53 Giredhi B | Kuderera kwakaderera uye Mechanical Structural Applications |

| API 5L Giredhi B | Mapaipi emafuta uye gasi |

| ASTM A333 Grade 6 | Yebasa rekudzikira |

| ASTM A335 P11 或 P22 | Kune tembiricha yakakwira senge boilers mumagetsi zviteshi |

| ASTM A312 TP304 或 TP316 | Zvishandiso zvinoda high corrosion resistance |

| ASME SA106 | High-tembiricha uye yakakwirira-kumanikidza nharaunda |

| AS/NZS 1163 C350L0 | Zvinangwa uye zvemagetsi zvinangwa |

| GB 3087 | Seamless simbi machubhu kune yakaderera uye yepakati-kumanikidza boilers |

| GB 5310 | Seamless simbi machubhu e-high-pressure boilers |

| GB 9948 | Seamless simbi machubhu ekutsemukira oiri |

Dziviriro Kupfeka kweASTM A106 GR.B

Galvanized

Galvanizing inzira yekupa kudzivirirwa kwekuora nekuisa zinc coating pamusoro pesimbi.

Nzira inonyanyozivikanwa yokuita galvanizing idip dip galvanizing, umo pombi yesimbi inonyudzwa muzinc yakanyungudutswa kuita denderedzwa rezingi pamusoro payo.

Iyi zinc haingodziviriri chete simbi substrate kubva kumhepo nemvura, kudzivirira oxidation, asi zvakare inoderedza mwero wekuora kwesimbi kuburikidza nechibayiro chekudzivirira anodic (zinc inoshanda kupfuura iron).

Hot-dip galvanized treatment simbi pombi yakakodzera kushandiswa kunze kana munzvimbo dzakanyorova, senge zvivakwa zvekuchenesa mvura uye zvivakwa zvekunze zvekuvaka.

Coating

Coating inzira yekudzivirira ngura nekuisa rimwe kana mamwe layers eimwe anti-corrosion coating pamusoro pepombi yesimbi.

Aya machira anogona kuve epoxy, polyurethane, polyethylene, kana zvimwe zvekugadzira zvinhu.

Epoxy coatings anoshandiswa zvakanyanya mumaindasitiri pombi nekuda kweakanakisa kugadzikana kwemakemikari uye kunamatira.

Basa guru rekuputira nderokuvhara unyoro uye makemikari anoparadza, kudzivirira kuti vasasangana zvakananga nesimbi. Mushonga wekuputira wakakodzera nzvimbo dzakasiyana-siyana dzakadai semiti yemakemikari, nzvimbo dzegungwa uye urban pipe network.

Lining Coating

Mushonga weLining ndewekuisa layer yeanti-corrosive material, senge epoxy resin, ceramics, kana rabha, mukati mepombi yesimbi kudzivirira kukora kwesvikiro inotakura pamadziro emukati mepombi yesimbi.

Iyi nzira inonyanya kukodzera kutakura zvinwiwa zvinoparadza (eg acids, alkalis, munyu, nezvimwewo).

Epoxy resin lining inopa yakasimba anti-corrosion layer iyo inogona kumira imwe dhigirii rekurwisa kemikari uye kuputika kwemuviri.

Iyo lining haingowedzere hupenyu hwepombi asiwo inochengetedza kuchena kwemvura uye inodzivirira kusvibiswa.

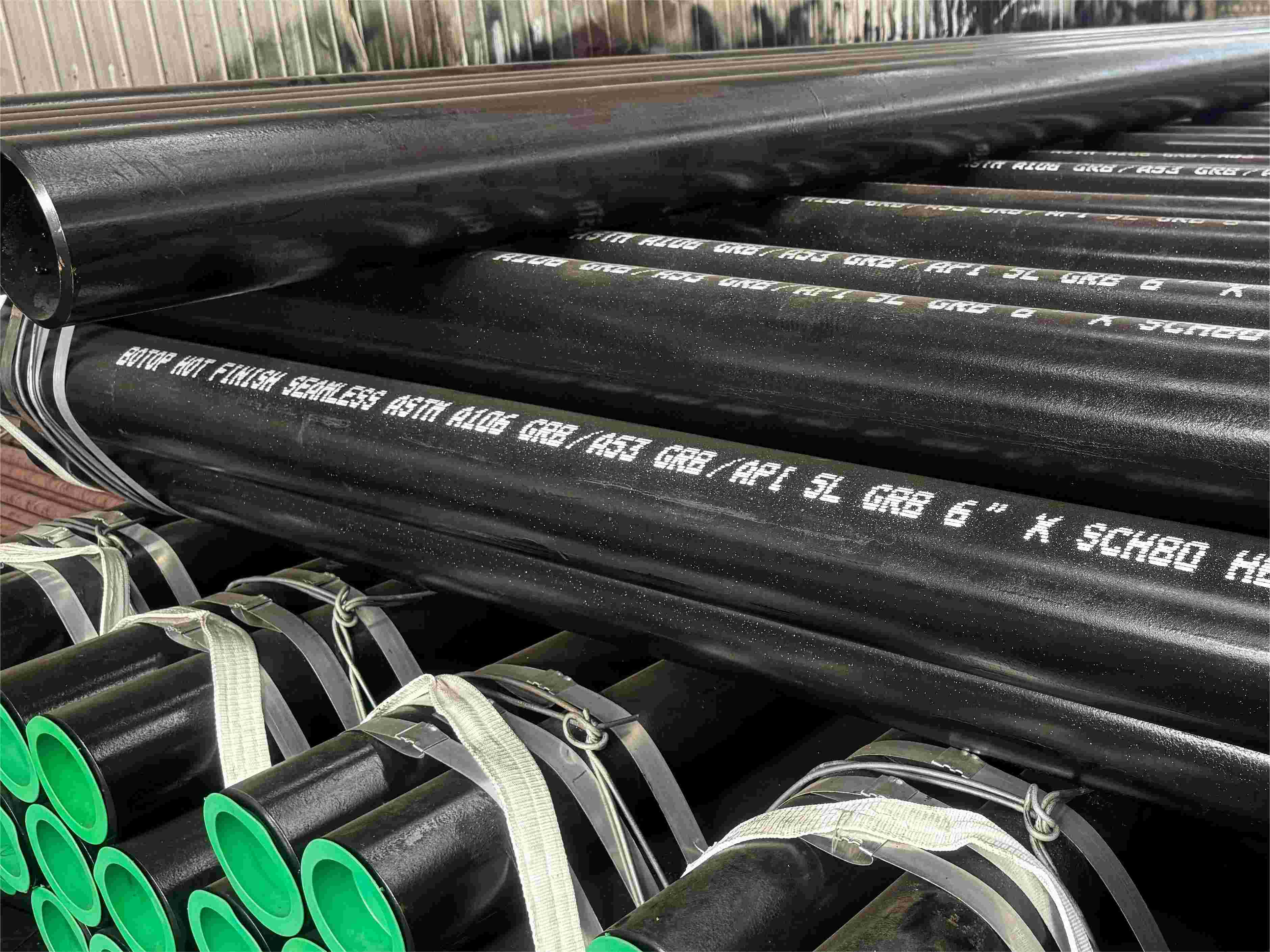

Zvigadzirwa zvedu zvinoenderana

Isu tiri mumwe weanotungamira welded welded kabhoni simbi pombi uye isina musono simbi pombi vagadziri uye vatengesi kubva kuChina, nehupamhi hwemhando yepamusoro simbi pombi mu stock, isu takazvipira kukupa iwe uzere huzere hwesimbi pombi mhinduro. Kuti uwane rumwe ruzivo rwechigadzirwa, ndapota inzwa wakasununguka kutibata nesu, isu tinotarisira kukubatsira iwe kuwana yakanakisa simbi pombi sarudzo pane zvaunoda!

tags:a106 giredhi b, a106, isina musono, vatengesi, vagadziri, mafekitori, masheya, makambani, wholesale, kutenga, mutengo, quotation, zvakawanda, kutengeswa, mutengo.

Nguva yekutumira: Mar-01-2024