Type E simbi pombiinogadzirwa zvinoenderana neASTM A53uye inogadzirwa uchishandisa Electric-Resistance-Welding (ERW) process.

Iyi pombi inonyanya kushandiswa kumakanika uye kudzvanywa maapplications asi yakakodzerawo kushandiswa seyakajairika pombi yekufambisa chiutsi, mvura, gasi, uye mweya.

Saizi yemhando yeASYM A53 iri DN 6-650.

Mhando yekugadzira yeRudzi E nderinoti DN 20-650 DN.

Madhayamita epombi ari pasi peDN 20 idiki kuRudzi E. Nezvikonzero zvehunyanzvi hapana nzira yekuagadzira, saka Type S, inovanzira yekugadzira isina musono, inowanzoshandiswa.

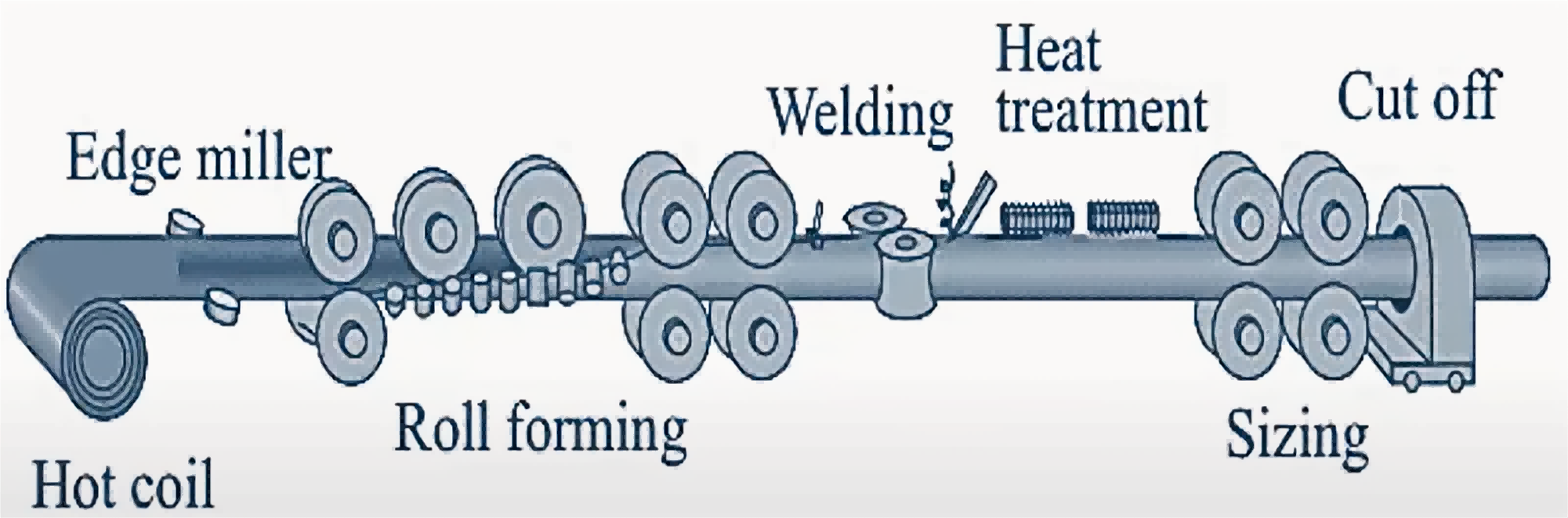

Kugadzira Maitiro eASTM A53 Type E

Maitiro ekugadzira anosanganisira kugadzira simbi coils kuburikidza nema rolls, welding edges nekudziisa kupisa, deburring welds, uye saizi uye kutwasanudza kugadzira machubhu.

Hunhu hweASTM A53 Rudzi E Steel Pipe

Iine maviri longitudinal butt welds mukati nekunze.Micheto yemahwendefa esimbi yakashongedzwa mukati nekunze kwepombi panguva yekugadzira kuti ive nechokwadi chekusimba uye chisimbiso.

Iyo yemukati neyekunze welds haisi kuoneka.Iyo yemukati neyekunze welds inocheneswa kusvika pahurefu hwakafanana neyepombi pamusoro panguva yekugadzirwa, izvo zvinobatsira pakuonekwa kwese uye zvinogoneka hydrodynamic zvimiro zvepombi.

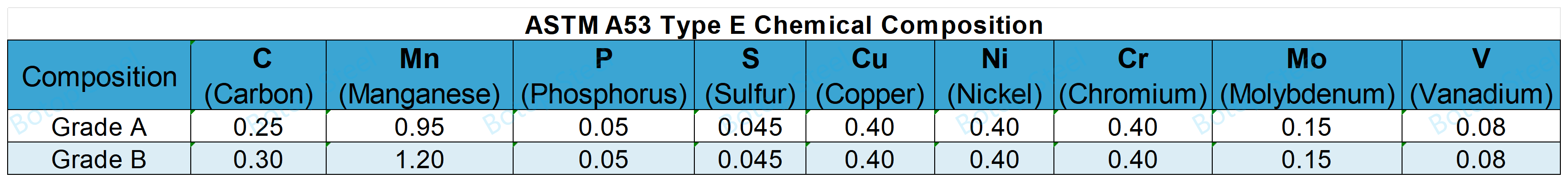

ASTM A53 Rudzi E Chemical Zvikamu

Pakudzikiswa kwega kwega kwe0.01% pazasi pekabhoni yakataurwa, kuwedzera kwe0.06% yemanganese pamusoro peiyo yakataurwa kunobvumidzwa kusvika pa1.65%.

Cu, Ni, Cr, Mo, uye V, zvinhu zvishanu pamwe chete zvisingapfuure 1.00%.

ASTM A53 Rudzi E Mechanical Properties

Tension Test

Resistance welded pombi DN ≥ 200 ichaedzwa uchishandisa maviri akachinjika emhando, imwe yakayambuka weld uye imwe yakatarisana neweld.

| List | classification | Giredhi A | Giredhi B |

| Kusimba simba, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Goho simba, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation mu50 mm (2 mukati) | Cherechedza | A, B | A, B |

Cherechedza A: Hurefu hwehurefu mu2 mu[50 mm] huchave hwakatemwa neinotevera equation:

e = 625000 [1940] A0.2/U0.9

e = kureba kwakaderera mu2 mukati kana 50 mm muzana, yakatenderedzwa kusvika muzana iri pedyo

A = idiki ye0.75 mukati2[500 mm2] uye chikamu chepakati-chepakati chechiratidzo chetension test, yakaverengerwa pachishandiswa dhayamita yekunze yepombi, kana hupamhi hwezita rechiratidzo chetension test uye kukora kwemadziro kwepombi, ine kukosha kwakaverengerwa kwakatenderedzwa kusvika padyo 0.01 mukati.2 [1 mm2].

U=yakatarwa simba shoma rekusimba, psi [MPa].

Cherechedza B: Ona Tafura X4.1 kana Tafura X4.2, chero ipi inoshanda, pahushoma hwehurefu hwekurebesa hunodiwa pamisanganiswa yakasiyana-siyana yetension test specimen size uye yakataurwa shoma yekusimba simba.

Bend Test

Papombi, DN ≤50, hurefu hwakakwana hwepombi huchakwanisa kukotama kutonhora kuburikidza ne90 ° kutenderedza cylindrical mandrel, iyo dhayamita yakapetwa kagumi nembiri yakataurwa kunze kwedhayamita yepombi, pasina kugadzira mitswe pane chero chikamu uye pasina kuvhura weld.

Kaviri-yakawedzera-yakasimba pombi pamusoro peDN 32 haidi kuiswa pasi pekuyedzwa kwekubhenda.

"Double-extra-strong", inowanzonzi XXSipombi ine mudhuri wakasimbiswa zvakanyanya, inowanzoshandiswa mumaindasitiri ekushandisa kutsungirira kudzvinyirirwa kwepamusoro uye nharaunda dzakaomarara. Ukobvu hwemadziro epombi iyi yakanyanya kukora kupfuura pombi yakajairika, saka inopa simba rakawanda uye kusimba kuri nani.

Flattening Test

Muedzo wekubata kumeso uchaitwa papombi yakasungwa pamusoro peDN 50 muhuremu hwakasimba (XS) kana kureruka.

Iyi inotevera nzira yekuyedza inoshanda kune Type E, Magiredhi A uye B.

Munguva yekutsikirira yakatsetseka, iyo weld inofanirwa kuiswa pa 0 ° kana 90 ° kune mutsara wekutungamira kwesimba, zvichienderana nezvinodiwa chaizvo.

Danho 1: Edzai ductility ye weld. Panofanira kunge pasina kuputika kana kuputsika mukati memukati kana kunze kwekunze kwe weld kusvikira chinhambwe pakati pemahwendefa akafuratira chiri pasi pezvikamu zviviri kubva muzvitatu zvekunze kwepaipi.

Danho rechipiri: Ramba uchidzvanya flat uye kuyedza ye ductility munzvimbo iri kunze kwe weld. Panofanira kunge pasina kutsemuka kana kutsemuka mukati kana kunze kwenzvimbo dzepombi kupfuura weld kusvika kureba pakati pemahwendefa akafuratira kuri pasi pechikamu chimwe chete muzvitatu chekunze kwedhayamita yepombi, asi kwete pasi pekashanu ukobvu hwemadziro epombi.

Danho rechitatu: Edzai kutendeseka kwechinhu nekuenderera mberi nekudzvanya pasi kusvika bvunzo yemuenzaniso yatyoka kana madziro epombi asangana. Izvi zvinoshandiswa kuyedza zvinhu zvematambudziko akadai seakatsemuka maseru, kusasimba, kana asina kukwana welds.

Hydrostatic Test

Iyo hydrostatic bvunzo ichaiswa, pasina kuvuza kuburikidza nemusono we weld kana muviri wepombi.

Plain-end pombi ichayedzwa hydrostatically kune iyo inoshanda yakapihwa muTable X2.2,

pombi yakarukwa-uye-yakabatana ichaongororwa hydrostatically kune kumanikidzwa kunoshanda kwakapihwa muTebhu X2.3.

Kune mapaipi esimbi ane DN ≤ 80, kudzvanywa kwekuyedza hakufaniri kudarika 17.2MPa;

Pamapombi esimbi ane DN ~80, kudzvanywa kwekuyedza hakufanire kudarika 19.3MPa;

Nondestructive Electric Test

Kune Type E uye Type F Kirasi B mapaipi DN ≥ 50, ma welds anofanirwa kuisirwa kuongororwa kusingaparadze magetsi.

Kuongororwa kwemagetsi kusingaparadzi kuchaitwa zvinoenderana neSpecifications E213, E273, E309 kana E570.

Kana kuyedza kusingaparadze magetsi kwaitwa, pombi ichaiswa chiratidzo "NDE".

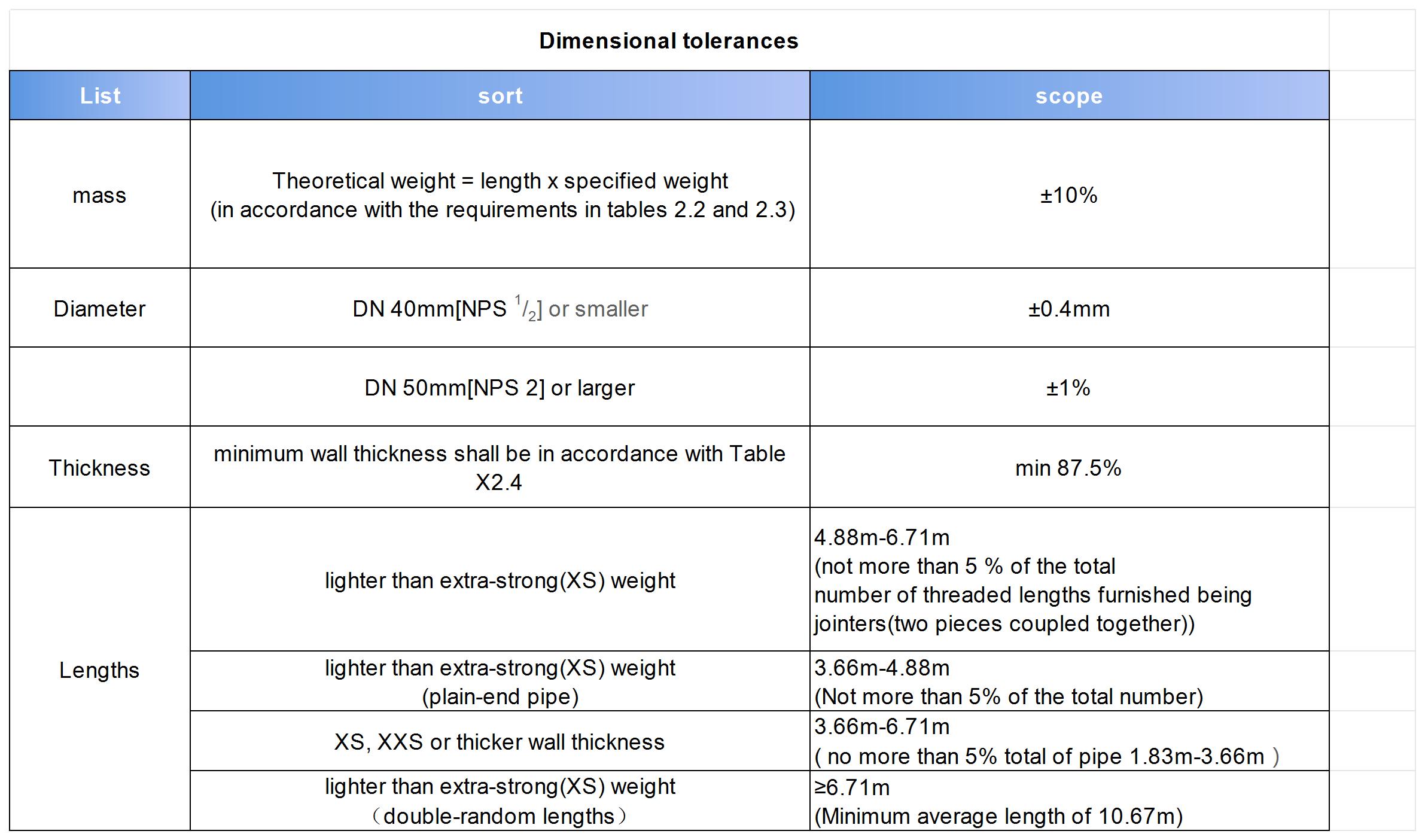

ASTM A53 Dimensional Kushivirira

Pipe Weight Charts uye Pipe Schedules

Zvakanakira zveASTM A53 Type E Pipe

Resistance welding inzira ine mutengo wakaderera welding, zvichiita kuti Type E machubhu ive isingadhure kugadzira uye yakakodzera kugadzirwa kwehuwandu.

Iyo yekudzivirira welding process inokurumidza uye inogona kugadzirwa nguva dzose, iyo inowedzera kugadzirwa uye inoderedza nguva dzekutungamira.

Nekuda kwemaitiro ayo akanaka emuchina uye kushorwa, rudzi urwu rwepombi rinoshandiswa zvakanyanya mumhando dzakasiyana siyana dzekutakura zvinwiwa zvakaita semvura, gasi, uye chiutsi.

Iyo welds inogona kuitwa inenge isingaonekwe kuburikidza nekurapa kwakanaka kwema welds, izvo zvisingangogadziri kutaridzika kwepombi asi zvinogona zvakare kuderedza kushorwa kwekuyerera kwemvura kunokonzerwa ne welds..

Zvikumbiro zveASTM A53 Rudzi E Simbi Pipe

Kushandiswa kwemaitiro: Mukuvaka, A53 Type E simbi pombi inoshandiswa sezvikamu zvechimiro senge zvitsigiro zvekuvaka uye truss masisitimu.

Pombi yemvura: Inoshandiswa mumasisitimu ekupa mvura yezvivakwa, zvinosanganisira moto sprinkler masisitimu.

Steam systems: Muzvivakwa zveindasitiri, iyi pombi yesimbi inowanzoshandiswa mumasitimu ekutumira mhepo, kunyanya mukushandiswa kwakaderera.

Gasi kutapurirana: Inoshandiswa kutakura echisikigo kana mamwe magasi, kunyanya mumasisita uye ekugara gasi masisitimu ekupa.

Mishonga yemakemikari: yekufambisa yakaderera-kudzvanywa chiutsi, mvura, uye mamwe makemikari.

Mapepa uye shuga zvigayo: kuendesa zvigadzirwa uye zvigadzirwa zvakapedzwa, pamwe nekurasa marara ekugadzirisa.

Kudziisa uye kutonhora masisitimu: Inoshandiswa zvakanyanya kupomba mukudziya, kufefetedza, uye air conditioning (HVAC) masisitimu.

Kugadziriswa kwemvura yakasviba: Yekufambisa mvura yetsvina kana mvura yakacheneswa.

Zvirongwa zvekudiridza: Pombi dzemvura dzinoshandiswa kudiridza ivhu rekurima.

Mining: Inoshandiswa pakufambisa mvura uye gasi mumigodhi.

Zvigadzirwa zvedu zvinoenderana

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa akasiyana kabhoni simbi mapaipi uye zvine hukama zvigadzirwa,

zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.

Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

Tags: ASTM a53, mhando e, giredhi a, giredhi b, erw.

Nguva yekutumira: May-12-2024