JIS G 3444 simbi pombichiumbwa kabhoni simbi pombi inogadzirwa nemusono kana welded process, inonyanya kushandiswa muinjiniya nekuvaka.

Navigation Buttons

Size Range

Grade Classification

JIS G 3444 Manufacturing Maitiro

Tube End Type

Kemikari Inoumbwa yeJIS G 3444

Mechanical Property yeJIS G 3444

Flattening Resistance

Bend Test

Mimwe Miedzo

Pipe Weight Tafura yeJIS G 3444

Dimensional Kushivirira kweJIS G 3444

Zvitarisiko

Kumaka

JIS G 3444 Application

Related Standards

Zvatiri Zvakanakira

Size Range

General chinangwa Outer dhayamita: 21.7-1016.0mm;

Nheyo dzenheyo uye mirwi yekudzvinyirirwa kwevhu OD: pazasi 318.5mm.

Grade Classification

Machubhu akakamurwa kuita 5 mamakisi.

STK 290,STK 400, STK 490, STK 500, STK 540.

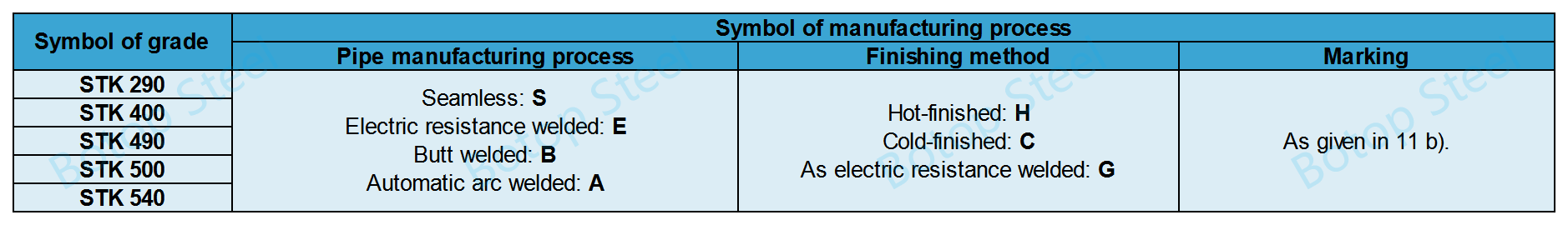

JIS G 3444 Manufacturing Maitiro

Iyo machubhu ichagadzirwa nekubatanidzwa kwechubhu yekugadzira nzira uye nzira yekupedzisa iyo inoratidzwa.

Machubhu anogona kunyatsogadziriswa kupisa kana achida.

Kana zvichidiwa neMutengi, pombi inogona kugadzirwa kubva pashizha resimbi rakavharwa kana simbi yakavharwa. Muchiitiko ichi, rudzi rwekuputira uye kunaka kwekuputira kunofanira kuenderana nezvinodiwa zveJIS G 3444, Appendix A.

Mhando dzehuputi dzinogona kuiswa dzinopisa-dip zinc coating, electrolytic zinc coating, inopisa-dip aluminium coating, inopisa-dip zinc-5% aluminium alloy coating, inopisa-dip 55% aluminium-zinc alloy coating, kana inopisa-dip zinc-aluminium-magnesium alloy coating.

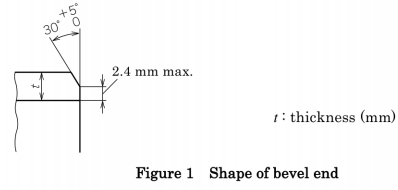

Tube End Type

Migumo yepombi yesimbi inofanira kuti sandara.

Kana iyo pombi ichidikanwa kuti igadziriswe kusvika kumagumo akakomberedzwa, kona yebevel ndeye 30-35 °, bevel upamhi hwesimbi pombi edge: ndeye max 2.4mm.

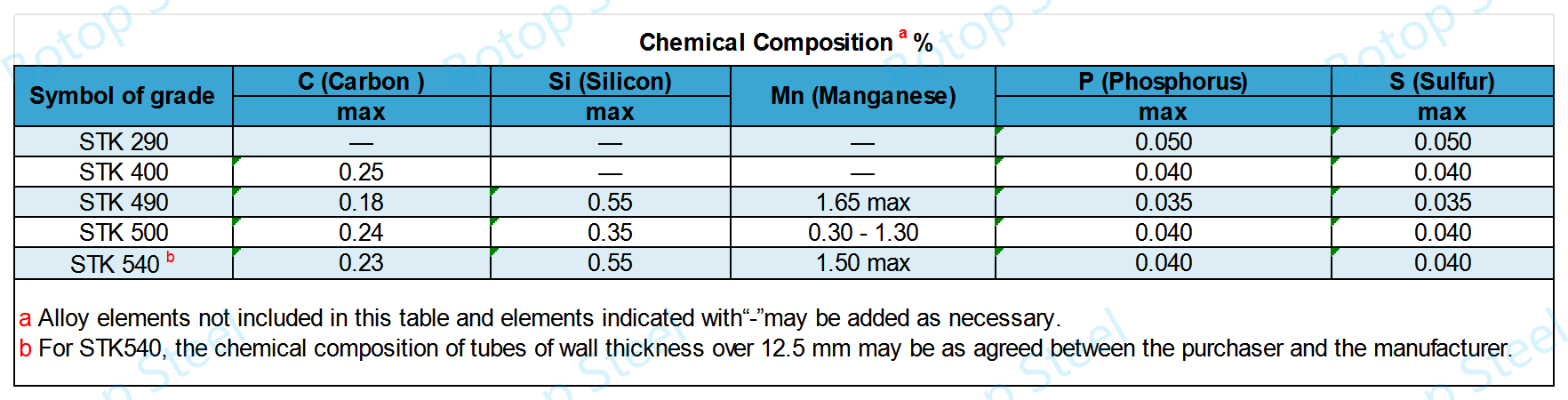

Kemikari Inoumbwa yeJIS G 3444

Nzira dzekuongorora dzekupisa dzichaenderana nezvinodiwa muJIS G 0320.

Iyo nzira yekuongorora chigadzirwa ichave inoenderana nezvinodiwa muJIS G 0321.

Mechanical Property yeJIS G 3444

Izvo zvinodikanwa zvemuchina bvunzo zvichave zvinoenderana neSection 7 uye 9 yeJIS G 0404.

Nekudaro, iyo sampling nzira yebvunzo dzemakanika ichaenderana nezvinodiwa zveKirasi A zviga muChikamu 7.6 cheJIS G 0404.

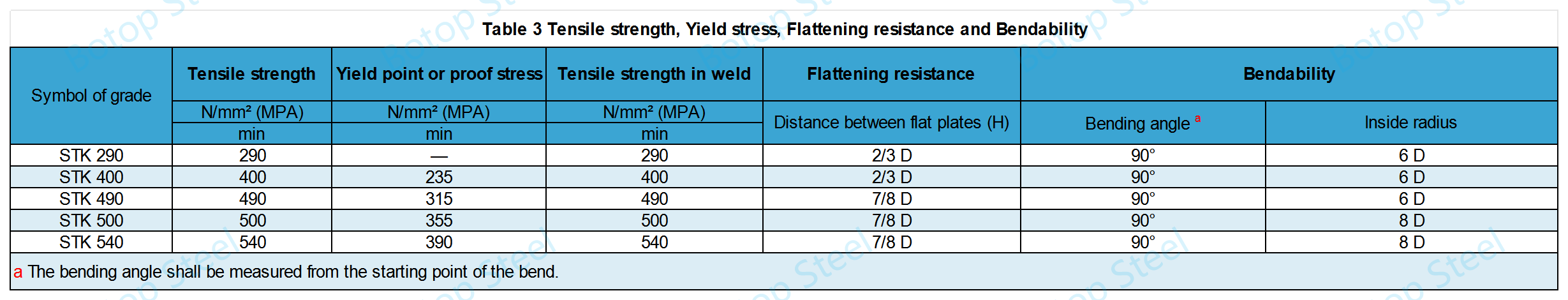

Tensile Simba uye Goho Poindi kana Humbowo Stress

Kusimba kwesimba uye goho poindi kana chiratidzo chekusimbisa pamwe nekusimba kwesimba paweld kunogutsa kukosha kwakatsanangurwa muTafura 3.

Kusimba kwekusimba kweweld kunoshanda kune otomatiki arc welded machubhu.

Simba re weld rakafanana neinodiwa kumuviri wepombi. Iyo welded chikamu chinowanzova chisina kusimba chinongedzo muchimiro, saka kuve neyakafanana kusimba kwesimba kunovimbisa kuvimbika kweiyo welded chimiro.

Tafura 3 zvakare ine chinhambwe chinodiwa cheFlattening kuramba uye zvinodikanwa zvebhend angle uye bend radius pamagumo ekubhenda.

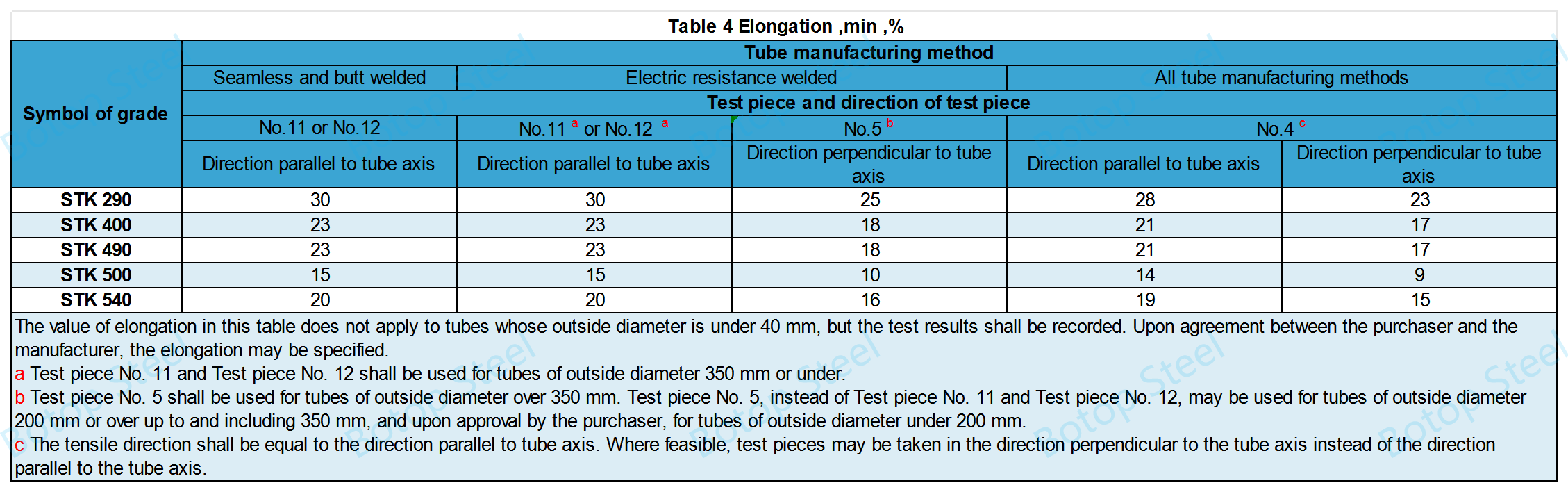

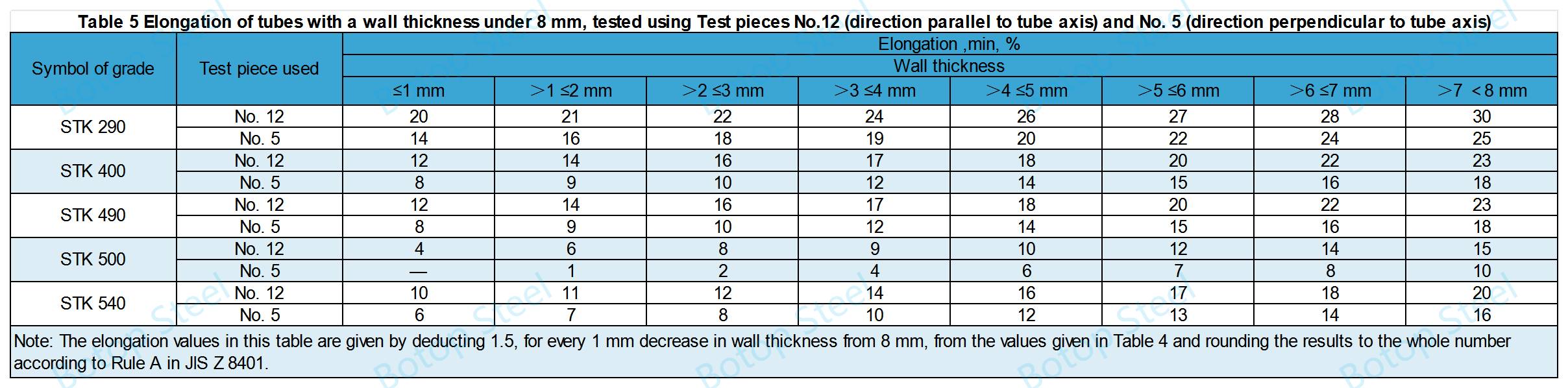

Elongation

Iyo elongation inoenderana neiyo chubhu yekugadzira nzira inoratidzwa muTafura 4.

Zvisineyi, kana bvunzo dzekusimba dzichiitwa paTest Piece No. 12 kana Test Piece No.5 yakatorwa kubva muchubhu iri pasi pe8 mm muhukobvu hwemadziro, kureba kuchaenderana neTafura 5.

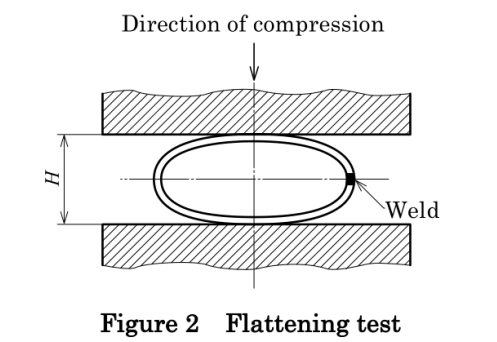

Flattening Resistance

Isa chidimbu chekuyedza pane yakajairika tembiricha (5 ° C kusvika 35 ° C) pakati pemahwendefa maviri akafuratira uye compress kuti igadzikane kusvika chinhambwe chiri pakati pemahwendefa H chave chakaenzana kana chidiki pane kukosha kwakataurwa muTebhu 3, wozoongorora kune makatsemuka pachidimbu chebvunzo.

Isai welds yekupikisa welded simbi mutopota uye butt welded simbi mutopota kuitira kuti mutsetse pakati pepakati pombi uye weld iri perpendicular kune nhungamiro compression.

Bend Test

Penda chidimbu chekuyedza kutenderedza silinda pane yakajairika tembiricha (5 ° C kusvika 35 ° C) pakona yekukotama isiri pasi peiyo shoma yekukombama angle inotsanangurwa muTafura 3, uye nemukati meradius isingapfuure yakakura mukati meradius inotsanangurwa muTafura 3, uye ongorora chidimbu chekuyedza kune makatsemuka.

Kuti uedze kupikisa kwemagetsi welded simbi chubhu uye butt-weld simbi chubhu, isa chidimbu chebvunzo zvekuti weld i90 °C kubva kunze kwenzvimbo yekubhenda.

Mimwe Miedzo

Hydrostatic bvunzo, isingaparadze bvunzo dze welds, kana mamwe maedzo anozobvumiranwa pachine nguva pane zvinoenderana nezvinodiwa.

Pipe Weight Tafura yeJIS G 3444

Simbi pombi uremu calculation formula

W=0.02466 t (Dt)

W: chiyero chechubhu (kg/m)

t: kukora kwemadziro echubhu (mm)

D: kunze kwedhayamita yechubhu (mm)

0.02466: unit inoshandura chinhu chekutora W

Iyo formula yakavakirwa pakuti density yesimbi i7.85 g/cm³.

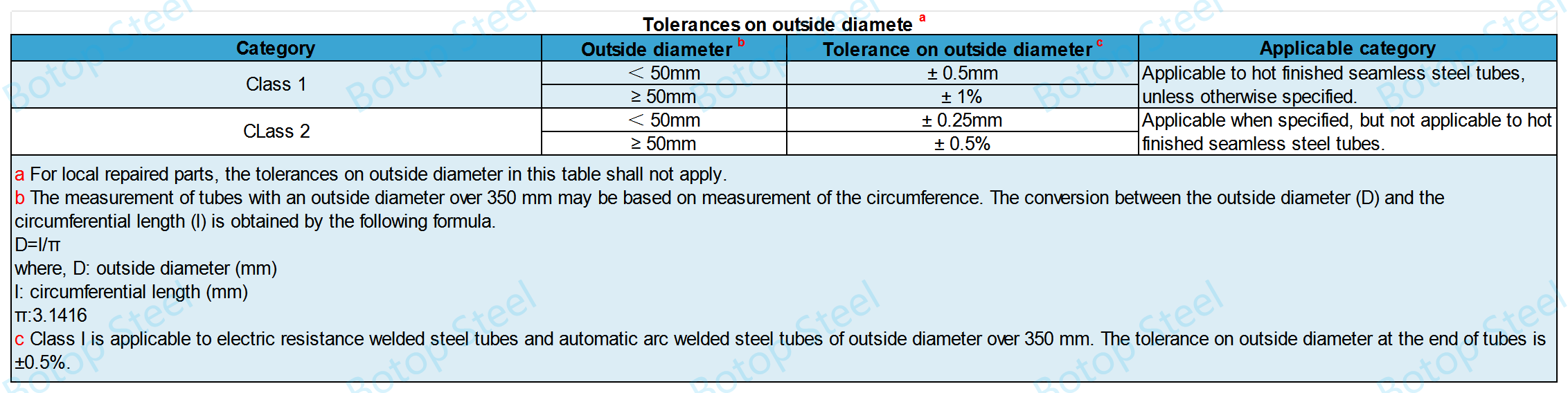

Dimensional Kushivirira kweJIS G 3444

Kunze Diameter Kushivirira

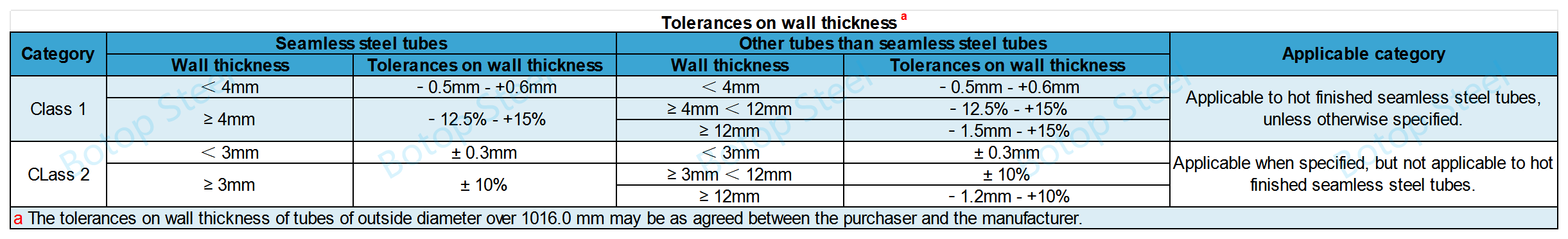

Wall Thickness Tolerance

Kureba Kushivirira

Kushivirira kwehurefu hwepombi yesimbi, kushivirira kwakashata ndeye zero, kushivirira kwakanaka hakusi kudiwa zvakajeka, mutengi uye mugadziri kusarudza nekubvumirana.

Zvitarisiko

Iyo mukati uye kunze kwekunze kwepombi yesimbi ichave yakatsetseka uye isina zvikanganiso zvisina kunaka kushandisa.

Anti-corrosion coatings senge zinc-rich coatings, epoxy coatings, pendi coating, etc. inogona kuiswa kune ekunze kana mukati.

Kumaka

Pombi imwe neimwe yesimbi ichanyorwa nemashoko anotevera.

a)Chiratidzo chegiredhi.

b) Chiratidzo chekugadzira nzira.Chiratidzo chekugadzira nzira yekugadzira ichave inotevera. Dashi rinogona kutsiviwa nechinhu chisina chinhu.

1) Kupisa-kupedza seamless simbi chubhu: -SH

2) Cold-yakapera seamless simbi chubhu: -SC

3) Semagetsi kuramba welded simbi chubhu: -EG

4) Kupisa-kupedzwa kwemagetsi kuramba welded simbi chubhu: -EH

5) Kutonhora-kupedzwa kwemagetsi kuramba welded simbi chubhu: -EC

6) Butt-welded simbi machubhu -B

7) Automatic arc welded simbi machubhu -A

c) Dimensions.Iyo dhayamita yekunze uye ukobvu hwemadziro hucharatidzwa.

d) Zita kana chidimbu chemugadziri.

Kana kumaka pachubhu kwakaoma nekuti dhayamita yekunze idiki kana kuti kana zvakumbirwa nemutengi, chiratidzo chinogona kupihwa pabundle rega rega remachubhu nenzira yakakodzera.

Nzira dzakadai sekushandiswa kwemavara, nezvimwewo.

JIS G 3444 Application

Iwo anoshandiswa kuhuinjiniya hwemagariro uye zvivakwa zvakaita seshongwe dzesimbi, scaffoldings, mirwi yekutsika, nheyo, uye mirwi yekudzvinyirirwa kwepasi.

Related Standards

JIS G 3452: Inotsanangura kabhoni simbi mapaipi kune zvakajairwa zvinangwa (zvakasiyana nezvinangwa zvekuumbwa uye zvakanyanya kutariswa pakufambisa kwezvinwiwa kana magasi).

JIS G 3454: Inotsanangura zviyero zvekabhoni simbi mapaipi ekumanikidza pombi.

ASTM A500: inovhara inotonhora-yakaumbwa welded uye isina musono kabhoni simbi yekumisikidza machubhu uye yakafanana neJIS G 3444 mune zvimwe zvayo zvinodiwa.

EN 10219: Inovhara inotonhora-yakaumbwa yakashongedzerwa makomba zvikamu zvezvimiro, zvinosanganisira denderedzwa, sikweya, uye rectangular profiles.

Zvatiri Zvakanakira

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.

Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

Tags: jis g 3444, kabhoni simbi pombi, stk, simbi chubhu, chimiro pombi.

Nguva yekutumira: May-10-2024