JIS G 3455 simbi pombiinogadzirwa nemusono simbi pombikugadzira nzira, inonyanya kushandiswa kabhoni simbi pombi nekushanda tembiricha iri pasi pe350 ℃ nharaunda, inonyanya kushandiswa kune michina zvikamu.

Navigation Buttons

Size Range

Grade Classification

Manufacturing Processs

Kupisa Kurapa

Pipe End Type

Kemikari Zvikamu zveJIS G 3455

Mechanical Property yeJIS G 3455

Hydrostatic Test kana Nondestructive Test

JIS G 3455 Steel Pipe Weight Chart uye Pipe Schedules

JIS G 3455 Dimensional Tolerances

Zvitarisiko

Kumaka

Zvishandiso zveJIS G 3455 Steel Pipe

JIS G 3455 Equivalent Standards

Zvigadzirwa zvedu zvinoenderana

Size Range

Pombi kunze dhayamita: 10.5-660.4mm (6-650A) (1/8-26B)

A=DN;B=NPS.

Grade Classification

JIS G 3455 ine magiredhi matatu zvichienderana nehudiki hwekusimba kwepombi, kurevaSTS370, STS410,uyeSTS480.

Manufacturing Processs

Mapombi anogadzirwa zvisina musono kubva kusimbi yakafa.

Kuumbwa kwekupedzisira kwakakamurwa kuva marudzi maviri, kupisa-kupedzwa uye kutonhora-kupedzwa, zvichienderana nehupamhi hwekunze uye rusvingo.

| Chiratidzo chegiredhi | Chiratidzo chekugadzira nzira | |

| Pombi yekugadzira nzira | Kupedzisa nzira | |

| STS370 STS410 STS480 | Pasina musono: S | Kupisa-kupedzwa: H Kutonhora-kupedzwa: C |

Kupisa Kurapa

| Chiratidzo chegiredhi | Kupisa-kwapera musono simbi pombi | Kutonhora-kupedza musono simbi pombi |

| STS370 STS410 | Sezvakagadzirwa. Nekudaro, yakaderera-tembiricha annealing kana normalizing inogona kuiswa sezvinodiwa. | Low tembiricha annealed kana normalized |

| STS480 | Low tembiricha annealed kana normalized | |

Mishonga yekupisa kunze kweiyo yakapihwa patafura inogona kuitwa nechibvumirano pakati pemutengi nemugadziri.

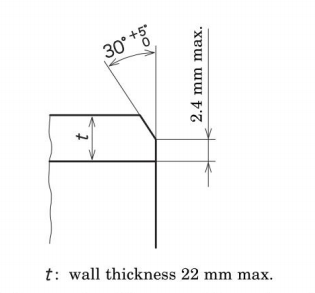

Pipe End Type

Mapombi achapedzwa nemagumo akatsetseka.

Kana magumo akakomberedzwa akatsanangurwa, iyo tapered yekupedzisira chimiro chepombi nemadziro ukobvu ≤ 22 mm ichaenderana ne 30-35 °, uye bevel upamhi hwepaipi yesimbi mupendero ndeye max 2.4mm.

Kemikari Zvikamu zveJIS G 3455

Kuongororwa kwekupisa kuchave maererano neJIS G 0320. Kuongorora kwechigadzirwa kuchave maererano neJIS G 0321.

Thermal kuongororwa kukosha kunoenderana nezvinodiwa zvinotevera:

| Chiratidzo chegiredhi | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | |||

| STS370 | 0.25% | 0.10-0.35% | 0.30-1.10% | 0.35% | 0.35% |

| STS410 | 0.30% | 0.10-0.35% | 0.30-1.40% | 0.35% | 0.35% |

| STS480 | 0.33% | 0.10-0.35% | 0.30-1.50% | 0.35% | 0.35% |

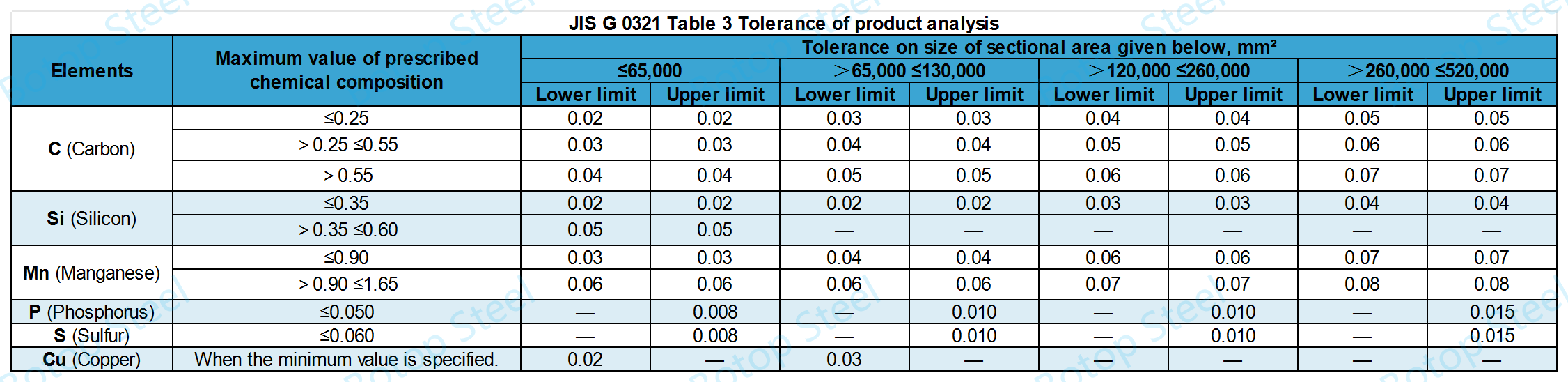

Izvo zvakaongororwa zvakakosha zvechigadzirwa hazvifanirwe kungosangana nehukoshi huri patafura, asi kushivirira kwakasiyana kwechimwe nechimwe chinhu kunofanirwa kuenderana nezvinodiwa zveTafura 3 yeJIS G 3021.

Mechanical Property yeJIS G 3455

Zvinodiwa zvakajairika pabvunzo dzemuchina zvichaenderana nezvikamu 7 ne9 zveJIS G 0404. Nzira dzesampling dzebvunzo dzemuchina dzichaenderana neKirasi A yeJIS G 0404, Chikamu 7.6.

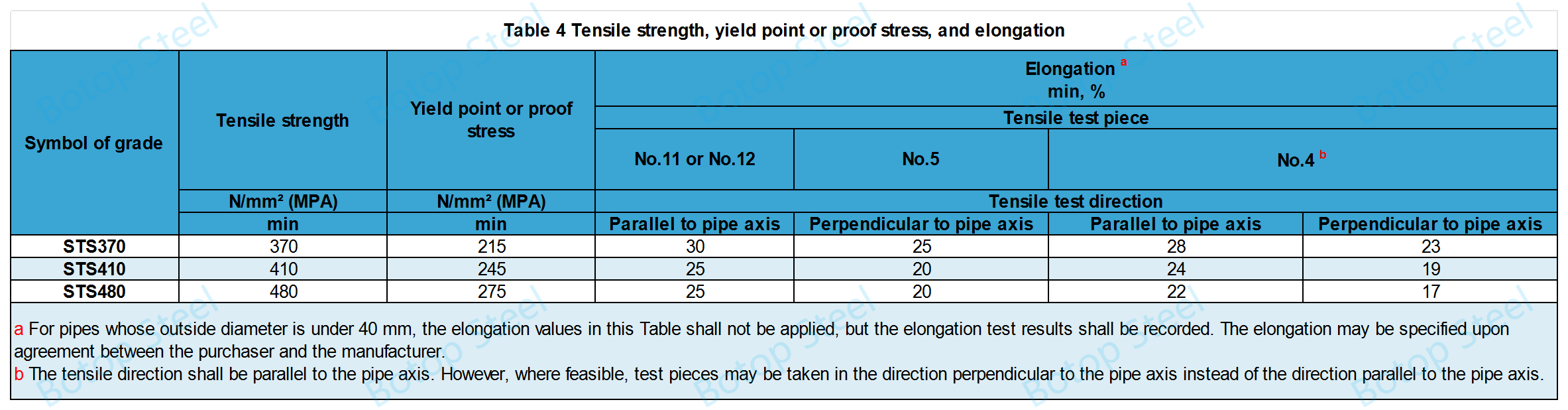

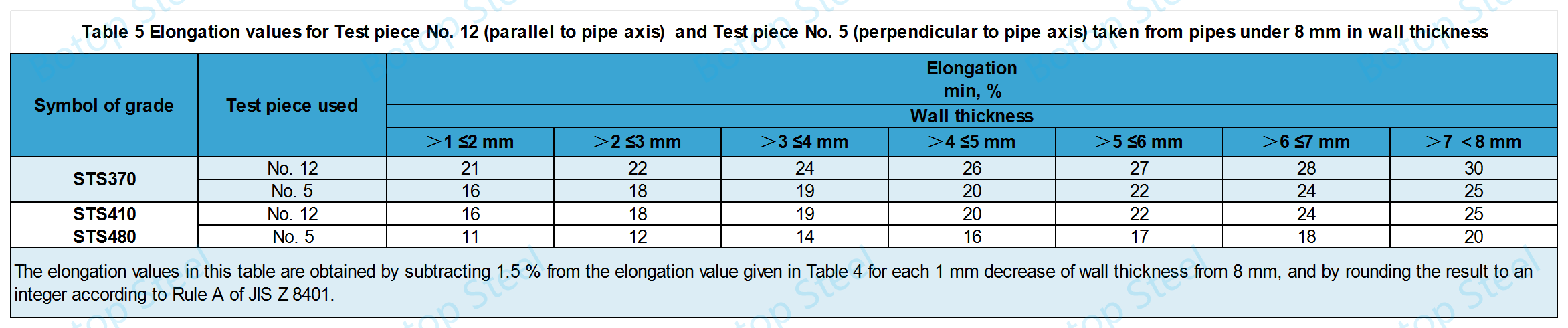

Kusimba Kwesimba, Goho Poindi kana Humbowo Stress, uye Elongation

Iyo nzira yekuyedza ichave inoenderana nezviyero muJIS Z 2241.

Pamapombi akaiswa mukuyedzwa kwekusimba uchishandisa muenzaniso Nha. 12 kana Nha.

Flattening Resistance

Muedzo unogona kusiiwa pakufunga kwemugadziri chero bedzi mapaipi achigutsa yakataurwa flattening kuramba.

Muenzaniso unoiswa pakati pemapuratifomu maviri uye wakatsetseka mukutsikirira kusvika chinhambwe H pakati pemapuratifomu chasvika kukosha kwakatarwa.Muenzaniso wacho unobva watariswa kana pakatsemuka.

H=(1+e)t/(e+t/D)

H: chinhambwe pakati peplatens (mm)

t: kukora kwemadziro epombi (mm)

D: kunze dhayamita yepombi (mm)

е: nguva dzose inotsanangurwa yegiredhi rega rega repombi: 0.08 yeSTS370, 0.07 yeSTS410 uye STS480.

Bendability Test

Inoshanda kune mapaipi ane dhayamita yekunze ≤50 mm sezvakatsanangurwa nemutengi.

Mucherechedzo ngauve usina kuputika kana wakakotama pakona ye90 ° nepakati pedhayamita katanhatu kubva kunze kwepaipi.Kona yekukotama ichayerwa pakutanga kwekubhenda.

Hydrostatic Test kana Nondestructive Test

Muedzo we hydrostatic kana usinga paradza uchaitwa papombi imwe neimwe.

Hydrostatic Test

Bata pombi isingasviki pane yakataurwa yakaderera hydrostatic test pressure kweinenge 5 seconds uye tarisa kuti pombi inogona kumirisana nekudzvanywa pasina kubuda.

Kana Mutengi akasatsanangura kudzvanywa kwekuyedza, uye pombi painoiswa pasi peiyo shoma hydrostatic test pressure yakapihwa, pombi inokwanisa kumira nayo pasina kuvuza.

| Nominal rusvingo ukobvu | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Minimum hydraulic test pressure, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Kana iyo madziro emadziro ekunze kwekunze kwepombi yesimbi isiri iyo yakakosha kukosha mutafura yehuremu hwepombi yesimbi, zvinodikanwa kushandisa fomuro kuverenga kukosha kwekumanikidza.

P=2st/D

P: test pressure (MPa)

t: kukora kwemadziro epombi (mm)

D: kunze dhayamita yepombi (mm)

s: 60 % yehushoma kukosha kwegoho poindi kana chiratidzo chekusimbisa chakapihwa.

Kana iyo yakaderera hydrostatic bvunzo yekumanikidza yenhamba yechirongwa chakasarudzwa ichipfuura bvunzo yekumanikidza P yakawanikwa neformula, iyo yekumanikidza P ichashandiswa seyakaderera hydrostatic test pressure pachinzvimbo chekusarudza iyo shoma hydrostatic test pressure mutafura iri pamusoro.

Nondestructive Test

Iyo pombi ichaongororwa ne ultrasonic kuonekwa kana eddy ikozvino kuonekwa.

Kune ma ultrasonic ekuonekwa maitiro, masaini ereferenzi samples ane UD kirasi referensi zviyero zvakatsanangurwa muJIS G 0582 ichaonekwa seyero yearamu, uye hapana chiratidzo chakaenzana kana chikuru kupfuura chiyero chealarm chichavepo.

Kune eddy ikozvino yekuona maitiro, chiratidzo chereferenzi sampuli ine referensi chiyero chekirasi EY sezvakatsanangurwa muJIS G 0583 ichaonekwa searamu level, uye hapana chiratidzo chakaenzana kana chikuru kupfuura alarm level ichave iripo.

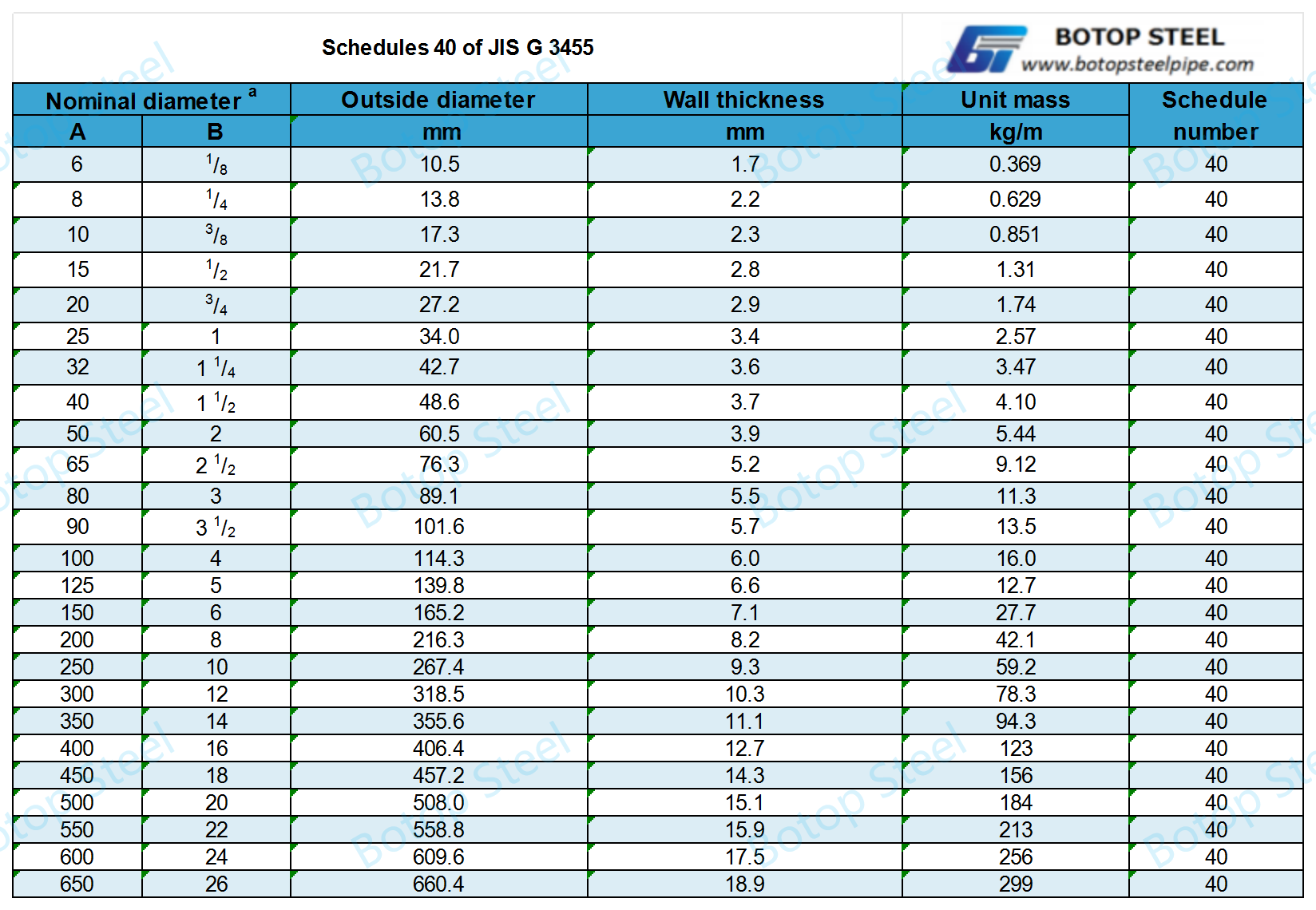

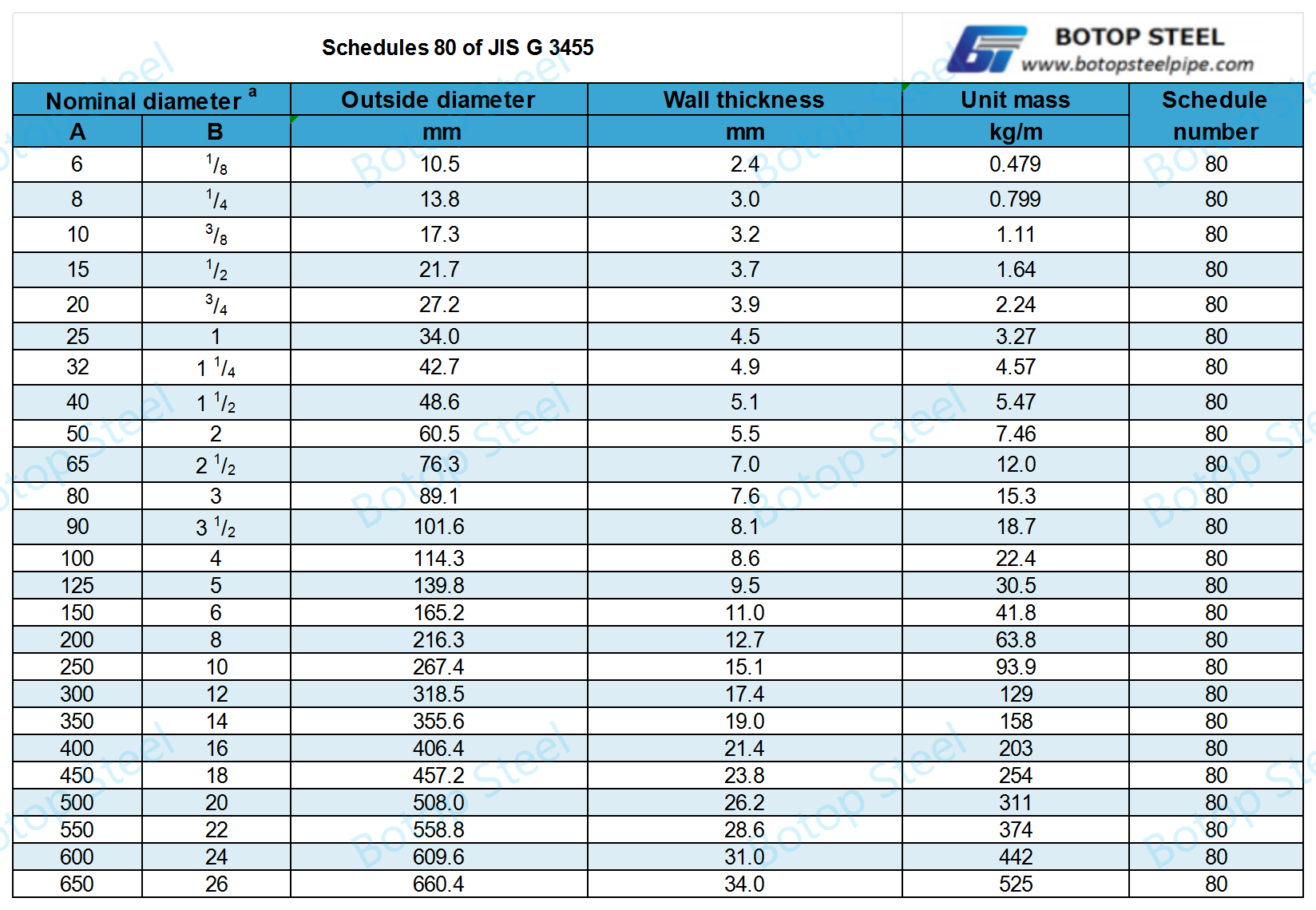

JIS G 3455 Steel Pipe Weight Chart uye Pipe Schedules

Simbi Pipe Weight Chati

Panyaya yezviyero zvisina kutaurwa mumatafura ehuremu hwepombi, fomula inogona kushandiswa kuzviverenga.

W=0.02466t(Dt)

W: huremu hwepombi (kg/m)

t: kukora kwemadziro epombi (mm)

D: kunze dhayamita yepombi (mm)

0.02466: shanduko yekuwana W

Tora density ye7.85 g/cm³ yechubhu yesimbi uye tenderedza mhedzisiro kune matatu akakosha manhamba.

Pipe Zvirongwa

Chiyero chinotsanangudza zviyero zvishanu zveSchedule 40, 60, 80, 100, 120, uye 160.

Kuti zvive nyore kwauri, heino ndiyo inonyanya kushandiswa purogiramu 40 uye purogiramu 80.

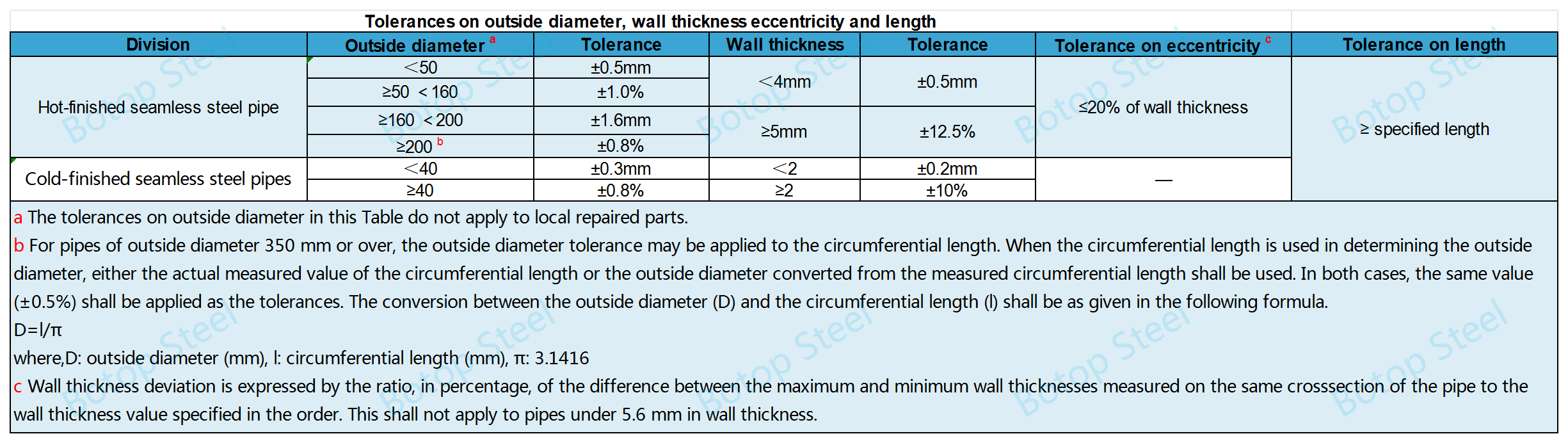

JIS G 3455 Dimensional Tolerances

Zvitarisiko

Iyo yemukati uye yekunze nzvimbo yepombi ichave yakatsetseka uye isina zvikanganiso zvisina kunaka kushandisa.

Migumo yepombi yesimbi ichave pamakona akarurama kune axis yepombi.

Kumaka

Imwe neimwe chubhu ichanyorwa nemashoko anotevera.

a) Chiratidzo chegiredhi;

b) Chiratidzo chekugadzira nzira;

Kupisa-kupedzwa seamless simbi pombi: -SH

Kutonhora-kupedzwa seamless simbi pombi: -SC

c) DimensionsMuenzaniso 50AxSch80 kana 60.5x5.5;

d) Zita remugadziri kana chiziviso.

Kana dhayamita rekunze rechubhu imwe neimwe riri diki uye zvakaoma kumaka chubhu imwe neimwe, kana kuti mutengi paanoda kuti tsanga imwe neimwe yemachubhu yamaka, sumbu rega rega rinogona kumakwa nenzira yakakodzera.

Zvishandiso zveJIS G 3455 Steel Pipe

Mechanical kugadzira: Nekuda kwesimba rayo rakakwirira uye kukwirira-kupisa kwekudzivirira, inoshandiswa mukugadzirwa kwezvikamu zvakasiyana-siyana zvemagetsi, zvakadai sezvikamu zve hydraulic systems uye high-pressure fuel injection systems.

Industrial piping systems: Inoshandiswa zvakanyanya mumaindasitiri maapplication ayo anoda yakakwirira-kumanikidza kutakura simba, senge pombi mumakemikari zvidyarwa, zvinonatsa, uye zvimwe zvinogadzirisa zvidyarwa.Ivo vanokwanisa kutakura zvakachengetedzeka high-pressure steam, mvura, oiri, uye mamwe makemikari.

Simba zvinomera: Inoshandiswa muzvikamu zvakakosha zvakadai semabhoilers uye superheaters izvo zviri pasi pekushisa kwepamusoro uye high-pressure operating conditions.

Kuvaka uye kuvaka: Anogona kushandiswa kutsigira zvimiro kana sekumanikidza pombi, kunyanya panodiwa simba rakawedzerwa uye kusimba.

JIS G 3455 Equivalent Standards

ASTM A106 / ASME SA106: Yakajairwa-inotsanangura seamless kabhoni simbi machubhu epamusoro-tembiricha sevhisi, anowanzo shandiswa mukunatsa, boilers, uye kupisa kunopisa.

DIN 17175: Inovhara seamless simbi machubhu uye pombi kuti ishandiswe munzvimbo yepamusoro-tembiricha uye inoshanda kune yakakwirira-tembiricha inodzivirira-inodzivirira application senge indasitiri yeboiler.

EN 10216-2: Inovhara machubhu asina musono uye mapaipi asina-alloyed uye alloyed simbi kuti ishandiswe mumamiriro ekupisa kwepamusoro.

GB 5310: Yakajairwa seamless simbi machubhu uye mapaipi e-high-pressure boilers, ane zvinodiwa zvehunyanzvi zvakafanana neaya eJIS G 3455, anoshandawo kune yakakwirira-tembiricha uye yakanyanya-kudzvanywa nharaunda.

API 5L: Inonyanya kushandiswa kuoiri uye gasi kutapurirana mitsara, zvinhu zvayo zvinodiwa, uye kushandiswa kwepombi isina musono pasi pemamwe mamiriro akafanana.

Zvigadzirwa zvedu zvinoenderana

Kubva payakavambwa muna 2014, Botop Steel yave mutengesi anotungamira wekabhoni simbi pombi kuChamhembe kweChina, inozivikanwa nebasa repamusoro, zvigadzirwa zvemhando yepamusoro, uye mhinduro dzakakwana.

Iyo kambani inopa dzakasiyana siyana dzekabhoni simbi mapaipi uye zvigadzirwa zvine hukama, zvinosanganisira isina musono, ERW, LSAW, uye SSAW simbi pombi, pamwe neyakakwana mutsara wepombi fittings uye flanges.

Zvigadzirwa zvayo zvehunyanzvi zvinosanganisira alloys epamusoro-giredhi uye austenitic simbi isina tsvina, yakagadzirirwa kusangana nezvinodiwa zveakasiyana mapurojekiti epombi.

Tags: JIS G 3455, kabhoni simbi pombi, STS, isina musono.

Nguva yekutumira: May-14-2024