Submerged arc welding yakanakira mapaipi, midziyo yekumanikidza uye matangi, kugadzirwa kwenjanji uye makuru ekuvaka mashandisirwo, ine yakapusa monofilament fomu, kaviri waya chimiro, tandem mbiri waya chimiro uye akawanda-filament chimiro.

Yakanyura arc welding inogona kubatsira vashandisi mune akawanda welding application. Kubva pakuwedzera kubereka, kusvika pakuvandudza nharaunda yekushanda, kuve nechokwadi chekuenderana uye nezvimwe. Metal processing fabricators vari kufunga nezvekuchinja mune yakadzika arc welding process vanofanira kunge vakafunga kuti vanogona kuwana mabhenefiti akawanda kubva mukuita uku.

Ruzivo rwekutanga rwe submerged arc welding

Iyo yakanyura arc welding process inodikanwa yakakodzera kune inorema maindasitiri kunyorera semapombi, midziyo yekumanikidza uye matangi, kuvaka locomotive, inorema kuvaka / kuchera. Yakanakira maindasitiri anoda kugadzirwa kwepamusoro, kunyanya kana zvasvika pakukwenenzvera zvinhu zvakakora kwazvo, pane zvakawanda zvakanaka zvinowanikwa kubva kune yakanyudzwa arc welding process.

Yayo yakakwirira deposition mwero uye kumhanya kwekufamba kunogona kuve nemhedzisiro yakakura pakubudirira kwevashandi, kunyatsoita uye mutengo wekugadzira, inova imwe yemabhenefiti akakosha eiyo yakanyudzwa arc welding process.

Zvimwe zvinobatsira zvinosanganisira: yakanakisa kuumbwa kwemakemikari uye michina zvimiro zve weld, kushoma arc kuoneka uye yakaderera welding utsi, yakagadziridzwa nharaunda yekushanda kunyaradza, uye yakanaka weld chimiro uye chigunwe mutsara.

Submerged arc welding inzira yekudyisa waya inoshandisa granular flux kuti iparadzanise arc kubva kumhepo, sezita rinoratidza, iyo arc inovigwa mukuyerera, izvo zvinoreva kuti kana maparamendi akaiswa, iyo arc haionekwe nekubuda kweiyo layer ye flux. Waya yewelding inodyiswa nguva dzose netochi inofamba ichitevedza weld.

Kupisa kweArc kunonyungudutsa chikamu chewaya, chikamu chekuyerera uye chigadziko chesimbi, ichigadzira dziva rakanyungudutswa, rinoita kuti riite weld yakafukidzwa nedhiri yewelding slag. Ukobvu hwemhando yewelding zvinhu ndeye 1/16 "-3/4", inogona kuva 100% yekupinda welding nekamwe welding, kana ukobvu hwemadziro husina kuganhurirwa, multi-pass welding inogona kuitwa, uye weld yakanyatso pretreated uye yakasarudzwa, uye iyo yakakodzera welding waya flux musanganiswa inosarudzwa.

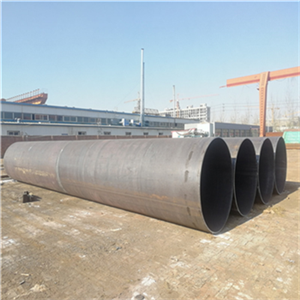

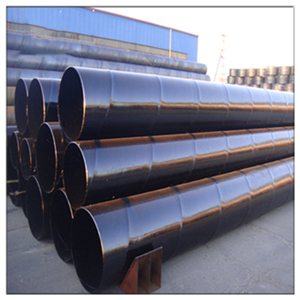

LSAW

ERW

SSAW

Kusarudzwa kwe flux uye welding wire

Kusarudza iyo chaiyo flux uye waya kune imwe yakanyura arc welding process kwakakosha kuti uwane mhedzisiro yakanaka uchishandisa maitiro. Nepo akanyudzwa arc welding maitirwo ega achibudirira, kugadzirwa uye kugona kunogona kuwedzerwa kunyangwe zvichibva pane welding waya uye flux inoshandiswa.

Iyo flux haingodziviriri dziva re weld, asi inobatsirawo pakuvandudzwa kweiyo mechanical properties uye kubereka kwe weld. Iko kuumbwa kwe fluxes kune kukanganisa kukuru pane izvi zvinhu, zvichikanganisa ikozvino kutakura simba uye slag kusunungurwa.

Ikozvino kutakura kugona kunoreva kuti iyo yepamusoro inogoneka deposition kunyatsoshanda uye yepamusoro-mhando weld mbiri inogona kuwanikwa.

Slag kuburitswa kubva kune imwe flux inokanganisa kusarudzwa kwe flux nekuti mamwe fluxes akakodzera kune mamwe madhizaini ekutengesa kupfuura mamwe.

Flux sarudzo dzekusarudza dzakanyudzwa arc soldering dzinosanganisira inoshanda uye isina kwayakarerekera mhando dzewelds. Musiyano wakakosha ndewekuti iyo inoshanda flux inoshandura chemistry ye weld, nepo kusarerekera kusingaite.

Active fluxes inoratidzirwa nekubatanidzwa kwesilicon uye manganese. Zvinhu izvi zvinobatsira kuchengetedza kusimba kweiyo weld pakupisa kwekupisa, kubatsira kuchengetedza weld yakatsetseka uye yakatsetseka pakumhanya kukuru kwekufamba uye kupa yakanaka slag kuburitswa. Pakazere, kushingaira kunoyerera kunogona kubatsira kuderedza njodzi yehurombo solder quality, pamwe neinodhura post-weld kuchenesa uye rework. Ramba uchifunga, zvisinei, kuti mashandiro anoita fluxes anowanzo kukodzera kune imwechete- kana kaviri-pass soldering.

Neutral fluxes zviri nani kune mahombe multipass solder nekuti anobatsira kudzivirira kuumbwa kwebrittle, crack-sensitive welds.

Kune akawanda marudzi ewelding waya sarudzo maererano neakanyura arc welding, imwe neimwe iine zvakanakira uye zvayakaipira. Dzimwe waya dzakagadzirirwa welding pakupisa kwepamusoro pekuisa, nepo dzimwe dzakanyatsogadzirirwa kuti dzive nealloys anobatsira flux kuita welding kuchenesa.

Ziva kuti makemikari zvivakwa uye kupisa kupindirana kupindirana kwewaya welding kunokanganisa ma mechanical properties ye weld. Kugadzirwa kunogona zvakare kuwedzerwa zvakanyanya nekuzadza simbi kusarudzwa.

Semuyenzaniso, kushandisa simbi yepakati waya ine yakanyura arc welding process inogona kuwedzera deposition kunyatsoshanda ne15% kusvika 30% zvichienzaniswa nekushandisa waya yakasimba, uku ichipa yakafara uye isina kudzika yekupinda mbiri.

Nekuda kwekumhanya kwayo kukuru kwekufamba, waya dzesimbi dzepakati zvakare dzinoderedza kupisa kwekuisa kudzikisa njodzi yewelding deformation uye kupera simba.

Pamasimbi ese, austenitic Stainless steels ane yakaderera goho poindi. Nokudaro, maererano nemagetsi emagetsi, austenitic simbi isina tsvina haisi iyo yakanakisa zvinhu zvevhavha yehunde, nokuti kuve nechokwadi cheimwe simba, dhayamita yevhavha yevhavha ichawedzera. Nzvimbo yegoho haigone kuwedzerwa nekurapa kwekupisa, asi inogona kuwedzerwa nekutonhora kuumba.

Isu tiri stockist yekabhoni uye isina musono simbi pombi, tinogamuchira chero kubvunza, isu tichapa kekutanga!

Nguva yekutumira: Jan-30-2023