ASTM A672ipombi yesimbi yakagadzirwa kubva mundiro yekumanikidza yemhando yeplate,Magetsi-Fusion-Welded (EFW)yebasa repamusoro-soro pane tembiricha iri pakati nepakati.

Navigation Buttons

ASTM A672 Giredhi Classification

ASTM A672 Kirasi Classification

ASTM A672 Size Range

Welding Precautions

Kupisa Kurapa

Chemical Components

Tension Test

Transverse-Guided-Weld-Bend Tests

Pressure Test

Radiographic Examination

Dimensional kushivirira kweASTM A672

ASTM A672 Chitarisiko

Kukanganisa uye Kugadzirisa

ASTM A672 Kumaka

Kushandiswa kweASTM A672 Steel Pipe

Zvigadzirwa zvedu zvinoenderana

ASTM A672 Giredhi Classification

Yakakamurwa zvichienderana nerudzi rwendiro inoshandiswa kugadzira machubhu esimbi.

Magiredhi akasiyana anomiririra akasiyana maumbirwo emakemikari uye ma mechanical zvimiro zvekumanikidza kwakasiyana uye tembiricha mamiriro.

| Pipe Grade | Rudzi rweSimbi | Kutsanangurwa kweASTM | |

| Aihwa. | Giredhi | ||

| A45 | plain carbon | A285 / A285M | A |

| A50 | plain carbon | A285 / A285M | B |

| A55 | plain carbon | A285 / A285M | C |

| B 60 | plain carbon, vakaurawa | A515 / A515M | 60 |

| B 65 | plain carbon, vakaurawa | A515 / A515M | 65 |

| B70 | plain carbon, vakaurawa | A515 / A515M | 70 |

| C 55 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516 / A516M | 55 |

| C 60 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516 / A516M | 60 |

| C 65 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516 / A516M | 65 |

| C 70 | kabhoni isina chinhu, yakaurawa, zviyo zvakanaka | A516 / A516M | 70 |

| D 70 | manganese-silicon, yakajairika | A537 / A537M | 1 |

| D80 | manganese-silicon, Q&TA | A537 / A537M | 2 |

| H 75 | manganese-molybdenum, yakajairika | A302 / A302M | A |

| H80 | manganese-molybdenum, yakajairika | A302 / A302M | B, C, kana D |

| J 80 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-1B |

| J 90 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-3B |

| L 65 | molybdenum | A204 / A204M | A |

| L 70 | molybdenum | A204 / A204M | B |

| L 75 | molybdenum | A204 / A204M | C |

| N 75 | manganese-silicon | A299 / A299M | A |

AQ&T = kudzimwa uye kushatirwa.

ВChero giredhi rinogona kupihwa.

Tinogona kutanga kuona rudzi rwepombi yesimbi nemabhii ari mugiredhi.

Magiredhi anotanga nemabhii A, B, uye C anowanzoratidzakabhoni simbi pombi.

Magiredhi anotanga nemabhii D, H, J, L, naN anoratidzaalloy simbi pombi.

ASTM A672 Kirasi Classification

Iwo machubhu akaiswa mumapoka zvichienderana nerudzi rwekurapa kwekupisa kwaanogamuchira panguva yekugadzira uye kuti kana kwete iwo akaongororwa radiographical uye kudzvanywa kwakaedzwa.

| Kirasi | Kurapa kwekupisa papombi | Radiography, ona chinyorwa: | Pressure test, ona chinyorwa: |

| 10 | hapana | hapana | hapana |

| 11 | hapana | 9 | hapana |

| 12 | hapana | 9 | 8.3 |

| 13 | hapana | hapana | 8.3 |

| 20 | kushushikana kwakadzikira, ona 5.3.1 | hapana | hapana |

| 21 | kushushikana kwakadzikira, ona 5.3.1 | 9 | hapana |

| 22 | kushushikana kwakadzikira, ona 5.3.1 | 9 | 8.3 |

| 23 | kushushikana kwakadzikira, ona 5.3.1 | hapana | 8.3 |

| 30 | normalized, ona 5.3.2 | hapana | hapana |

| 31 | normalized, ona 5.3.2 | 9 | hapana |

| 32 | normalized, ona 5.3.2 | 9 | 8.3 |

| 33 | normalized, ona 5.3.2 | hapana | 8.3 |

| 40 | normalized uye hasha, ona 5.3.3 | hapana | hapana |

| 41 | normalized uye hasha, ona 5.3.3 | 9 | hapana |

| 42 | normalized uye hasha, ona 5.3.3 | 9 | 8.3 |

| 43 | normalized uye hasha, ona 5.3.3 | hapana | 8.3 |

| 50 | kudzimwa uye kushatirwa, ona 5.3.4 | hapana | hapana |

| 51 | kudzimwa uye kushatirwa, ona 5.3.4 | 9 | hapana |

| 52 | kudzimwa uye kushatirwa, ona 5.3.4 | 9 | 8.3 |

| 53 | kudzimwa uye kushatirwa, ona 5.3.4 | hapana | 8.3 |

Kunyanya kutarisisa kunofanirwa kubhadharwa kune inotarisirwa tembiricha yebasa pakusarudza yakakodzera kirasi yezvinhu.Tarisa kune yakatarwa ASTM A20/A20M.

ASTM A672 Size Range

Yakakurudzirwa saizi renji: DN≥400mm[16 mukati] uye WT≤75mm[3 mukati].

Kune mamwe saizi yepombi, chero inosangana nezvimwe zvese zvinodiwa zveiyi tsanangudzo, inogona zvakare kushandiswa.

Welding Precautions

Mishonga ichave yakapetwa kaviri, yakazara-inopinda-yakaiswa welded.

Mawelds anozoitwa nemaoko kana otomatiki nemagetsi maitiro anosanganisira kuiswa kwesimbi yekuzadza.

Welds inogona kuongororwa pachishandiswa radiography uye inofanirwa kutevedzera zvinopihwa muChikamu VII UW-51 yeASME Boiler uye Pressure Vessel Code.

Kureba kweweld hakufaniri kudarika 3 mm [1/8 mukati].

Kupisa Kurapa

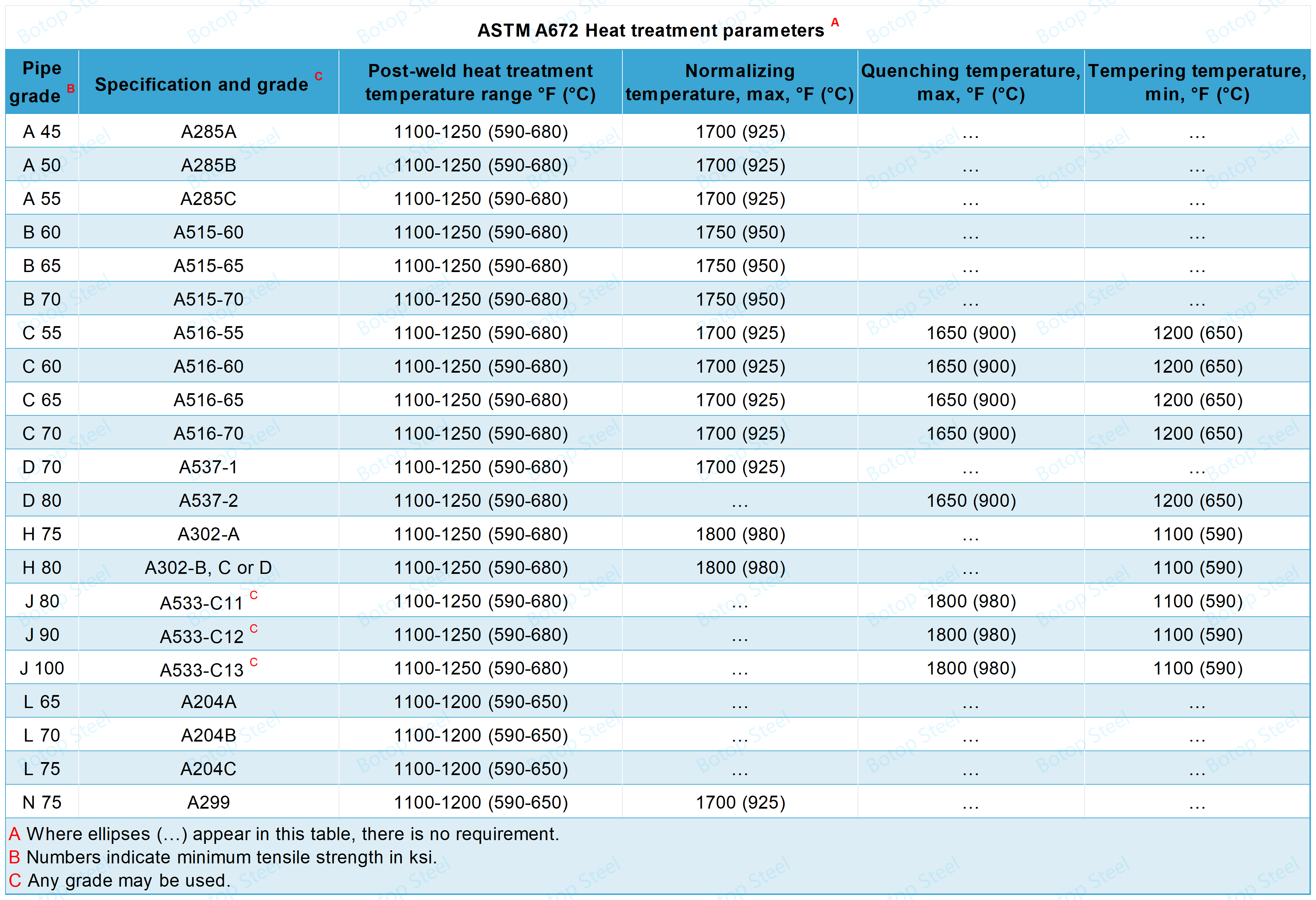

Makirasi ese kunze kwe10, 11, 12, uye13 achabatwa kupisa muchoto kunodzorwa kusvika ± 25 ° F [± 15 ° C]:

Makirasi 20, 21, 22, uye 23

Iyo pombi inofanira kupiswa zvakafanana mukati memashure-weld kupisa-kupisa tembiricha yakaratidzwa muTebhurari 2 kwehushoma hwe1 h/in.[0.4 h/cm] yeukobvu kana kuti 1 h, chero chikuru.

Makirasi 30, 31, 32, uye 33

Iyo pombi inofanira kupiswa zvakafanana kune tembiricha mu austenitizing renji uye isingapfuure iyo yakanyanya normalizing tembiricha inoratidzwa muTebhurari 2 uye yozotonhodzwa mumhepo pakamuri tembiricha.

Makirasi 40, 41, 42, uye 43

Iyo pombi ichave yakajairika.

Iyo pombi ichadziyirwa zvakare kune tembiricha yekudziya inoratidzwa muTebhurari 2 sediki uye inochengetwa patembiricha isingaite 0.5 h/in.[0.2 h/cm] yeukobvu kana kuti ye.1/2h, chero chikuru, uye mhepo-yakatonhodzwa.

Makirasi 50, 51, 52, uye 53

Iyo pombi ichapiswa zvakafanana kune tembiricha mukati meiyo austenitizing renji uye isingapfuure yakanyanya kudzima tembiricha inoratidzwa muTafura 2.

Zvadaro, bvisa mumvura kana mafuta.Mushure mekudzima, pombi ichadzoserwa kune yakaderera tembiricha yekushisa inoratidzwa muTable 2 uye inobatwa ipapo.

tembiricha yepasi pe0,5 h/inch yeukobvu kana kuti 0,5 h, chero yakakura, uye yakatonhodzwa nemhepo.

Chemical Components

Ichava basa remugadziri kuti aedze kemikari yendiro uye welds kuti aite maererano nezvinodiwa zveplate tsanangudzo yezvinhu zvakarairwa uye nzira yewelding yekuisa iyo weld metal, zvichiteerana.

Tension Test

Experimental frequency: sampuli imwe pane mujenya.

Test Method: Mienzaniso yebvunzo ichaitwa zvinoenderana neQW-150 muChikamu IX cheASME Boiler uye Pressure Vessel Code.Mienzaniso ichaedzwa pakamuri tembiricha zvinoenderana neTest Methods uye Tsanangudzo A370.

Pamusoro peMagiredhi Dxx, Hxx, Jxx, uye Nxx muClass 3x, 4x, uye 5x transverse tensile zvimiro zveplate yepasi, ichatemwa pazvienzaniso zvakachekwa kubva papombi inodziya.

Zvinodiwa pamibairo: Transverse tensile zvimiro zvejoint yakasungwa zvinosangana nezvinodiwa zvishoma zvesimba rekupedzisira rekusimba reiyo yakatsanangurwa ndiro zvinhu.

Transverse-Guided-Weld-Bend Tests

Nhamba Yemiedzo: Kuedza frequency: kamwe pabatch, maviri emuenzaniso

Nzira yekuedza: Zvinodiwa zvekuedzwa kweTest Methods uye Definitions A370, ndima A2.5.1.7 ichasangana.

Zvemadziro ukobvu pamusoro3/ 8mukati. [10 mm] asi pasi pe3/4in. [19 mm] Miedzo yeSide-bend inogona kuitwa pachinzvimbo chemeso uye midzi-bend bvunzo.

Zvemadziro makobvu3/4mukati. [19 mm] uye pamusoro pezvienzaniso zvose zvichaiswa pasi pemuedzo we-side-bend.

Zvinodiwa pamibairo: The bend test ichave inogamuchirwa kana pasina kuputika kana kumwe kukanganisa kunopfuura1/8mukati. [mamirimita matatu] mune chero nzira iripo musimbi inopinza kana pakati peiyo weld nehwaro simbi mushure mekukotama.

Mitswe inotangira kumucheto kwemuenzaniso panguva yekuedzwa, uye ishoma pane1/4mukati. [6 mm] kuyerwa munzira ipi neipi hazvitariswe.

Pressure Test

Makirasi X2 uye X3 pombi ichaedzwa zvinoenderana neSpecification A530/A530M, Hydrostatic Test Zvinodiwa.

Radiographic Examination

Hurefu hwakazara hweweld yega yega yeClass X1 neX2 ichaongororwa neradiographical zvinoenderana nekuzadzisa zvinodiwa zveASME Boiler uye Pressure Vessel Code, Chikamu VIII, Paragraph UW-51.

Kuongororwa kweradiographic kunogona kuitwa kusati kwaitwa kupisa.

Dimensional kushivirira kweASTM A672

| Sports | Kushivirira Kukosha | Cherechedza |

| Kunze Diameter | ±0.5% | Kubva pachiyero che circumferential |

| Kunze-kwe-Roundness | 1%. | Musiyano pakati pemadhayamita makuru uye madiki ekunze |

| Alignment | 1/8 mukati. [3 mm] | Kushandisa mupendero wakatwasuka wemamita 10 wakaiswa kuitira kuti migumo yose ibatane nepombi |

| Ukobvu | 0.01 mukati. [0.3 mm] | Ukobvu hwemadziro hudiki hudiki pane hwataurwa nezita |

| Urefu | 0-+0.5in [0-+13mm] | magumo asina kugadzirwa |

ASTM A672 Chitarisiko

Pombi yakapedzwa haifaniri kuva nezvinokuvadza uye ichava nemagumo akafanana neanoshanda.

Izvo zvinodikanwa zvakafanana mune yakatarwa ASTM A20/A20M yekupedza pamusoro pemarata esimbi.

Kukanganisa uye Kugadzirisa

Defect Kutsunga

Iyo ASTM A672 chiyero haitsanangure mazinga anogamuchirika ehurema uye maitiro ekumisikidza epombi uye kazhinji anoreva akakodzera einjiniya zviyero uye maitiro eindasitiri.

Kukanganisa kwemukati: Kukanganisa kwemukati kunogona kusanganisira porosity, slag, inclusions, nezvimwe.

Kukanganisa kwekunze: Hurema hwekunze hunogona kusanganisira kutsemuka, dents, kukwenya, nezvimwe.

Kubviswa neRegrinding

Kuremara kwepamusoro kunogona kubviswa nekuwandisa kana kugadzira nekusarira ukobvu husingasviki 0.3 mm pazasi pehukobvu hwakajairwa.

Iyo regrind depression inofanira kusanganiswa zvakafanana munzvimbo yakapoteredza.

Welding Repair

Hurema huchabviswa nenzira dzakakodzera dzemuchina kana kupisa kana dicing nzira uye kugadzirira kugadzirisa makomba akaiswa.

uye neradiologically kuongororwa maererano neASME Boiler uye Pressure Vessel Code, Chikamu VIII, Ndima UW-51.

Hurefu hwakazara hwepombi yakagadziridzwa ichave yakagadziriswa kupisa mushure mekugadzirisa maererano neyakatsanangurwa piping giredhi zvinodiwa.

ASTM A672 Kumaka

Kumaka kunofanirwa kuve nezvinotevera:

Chiziviso chemugadziri, senge mucherechedzo kana logo.

Tsanangudzo yepombi (saizi, ukobvu hwemadziro, nezvimwewo).

Material giredhi kana rudzi rwepombi.Muenzaniso: C60-22 (kupfupisa kwegiredhi: C60 uye kirasi 22).

Iyo yekugadzira chiyero chepombi ndeye ASTM A672.

Zuva rekugadzira kana nhamba yemugove wekugadzira.

Kushandiswa kweASTM A672 Steel Pipe

Muindasitiri yemagetsi emagetsi, ASTM A672 Electric Welded Steel Pipe inowanzo shandiswa kuendesa chiutsi muma boiler masisitimu.

Muindasitiri yemakemikari, ASTM A672 welded simbi pombi inowanzo shandiswa kutakura akasiyana makemikari, asidhi, uye alkali mhinduro, uye mamwe midhiya.

Muindasitiri yemafuta negasi, ASTM A672 welded simbi pombi inowanzoshandiswa kutakura mafuta asina kuchena, gasi rechisikigo, uye zvimwe zvinwiwa kana magasi.

Isu tiri yepamusoro-soro welded kabhoni simbi pombi inogadzira uye mutengesi kubva kuChina, uye zvakare isina musono simbi pombi stockist, inokupa iwe yakawanda yesimbi pombi mhinduro!

Tags: ASTM a672, efw, kabhoni simbi pombi, giredhi.

Nguva yekutumira: Kubvumbi-23-2024