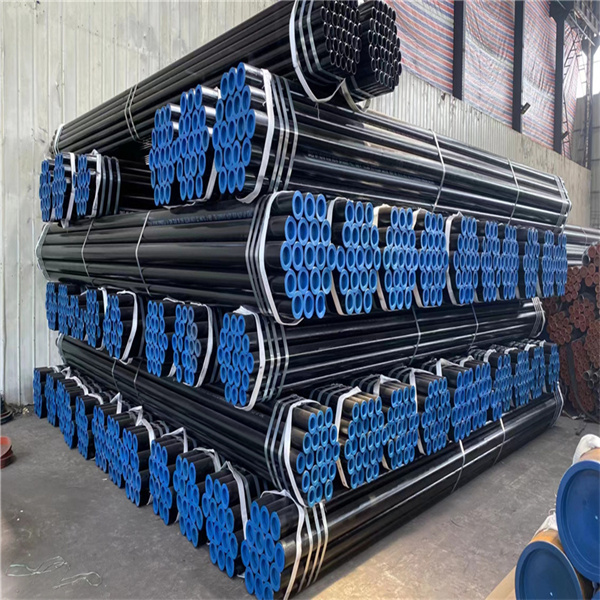

| Magaca Alaabta | Dhuumaha Birta Kaarboon/Kuuliyaha birta |

| Qalab | A53 GrB,A36,ST52,ST35,ST42,ST45,X42,X46,X52,X60,X65,X70 |

| Heerka | API 5L,ASTM A106 Gr.B,ASTM A53 Gr.B,ASTMA179/A192,ASTM A335 P9,ASTM A210,ASTM A333 |

| Shahaadooyinka | API 5L,ISO9001,SGS,BV,CCIC |

| Dhexroorka dibadda | 13.7mm-762mm |

| Dhumucda darbiga | SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160,XS,XXS |

| Dhererka | 1m,4m,6m,8m,12m sida ku cad codsiga iibsadaha |

| Daaweynta Dusha sare | rinji madow, Varnish, Saliid, galvanized, ka-hortagga daxalka |

| Calaamadayn | Calaamadaynta caadiga ah,ama si waafaqsan codsigaaga. Habka Calaamadaynta: Ku buufin rinjiga cad |

| Dhamaystirka Daaweynta | Dhammaadka/dhamaadka fidsan ee dhamaadka/dhamaadka fidsan ee leh koofiyadaha caaga ah |

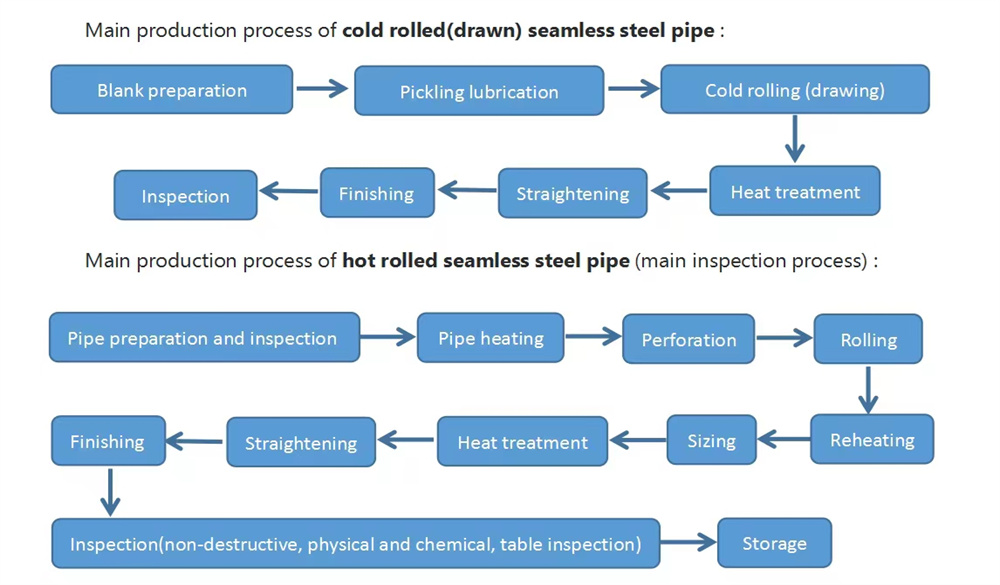

| Farsamada | Kulul duuban ama Qabow duuban ERW |

| Xidhmada | Baakad dabacsan; Ku baakadsan xidhmooyin (2Ton Max); tuubooyin xidhxidhan oo leh dharbaaxo labada dhamaadkasi sahlan loo rari karo oo loo dajin karo, alwaaxKiisaska; Bac-xidhka-xidhka ah oo aan biyuhu lahayn |

| Tijaabi | Falanqaynta Qaybaha Kiimikada, Guryaha Makaanikada, Guryaha Farsamada, Cabirka Dibadda Baaritaanka, Baaritaanka Haydarooliga, Baaritaanka X-ray |

| Codsiga | Gaadhida dareeraha ah, tuubooyinka qaab dhismeedka, dhismaha, dildilaaca batroolka, tuubooyinka saliidda, dhuumaha gaasta |

API 5L X42-X80, PSL1&PSL2 Saliida iyo GaaskaDhuumaha Birta ee Kaarboon-ka aan Xidhiidhka Lahaynwaxaa loo isticmaalaa gudbinta gaaska, biyaha, iyo batroolka ee labada warshadood ee saliidda iyo gaaska dabiiciga ah.

API 5L X42-X80, PSL1&PSL2 Saliida iyo Gaaska Kaarboonka birta ah ee aan xidhnayn waxa lagu sameeyaa mid qabow la jiido ama duuban kulul, sida ay u baahan yihiin macaamiishu.

API 5L X52 PSL1&PSL2 Saliida iyo Gaaska Kaarboonka birta ah ee aan xidhnayn waxa lagu sameeyaa mid qabow-jiiday ama duuban kulul, caadi ahaan cabbirro yar yar oo qabow-sawir ah iyo cabbirro waaweyn iyadoo la duubayo kulul.

Darajada iyo Kiimikada (%)Loogu talagalay API 5L PSL1

| Heerka |

Darajo | Halabuurka kiimikada(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.28 | ≤1.30 | ≤0.030 | ≤0.030 |

| X46,X52,X56 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X60,X65 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X70 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X52 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

Darajada iyo Kiimikada (%)Loogu talagalay API 5L PSL2

| Heerka |

Darajo | Halabuurka kiimikada(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.24 | ≤1.30 | ≤0.025 | ≤0.015 |

| X46,X52,X56 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X60,X65 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X70,X80 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X52 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

Qalabka Makaanikada ee API 5L GR.B X42-X80/X52(PSL1):

| Darajo | Xoogga Wax-soo-saarka(MPa) | Xoogga Jilicsan(MPa) | Dheeraynta A% | ||

|

| psi | MPa | psi | MPa | Dheeraynta (min) |

| X42 | 42,000 | 290 | 60,000 | 414 | 21 ~ 27 |

| X46 | 46,000 | 317 | 63,000 | 434 | 20 ~ 26 |

| X52 | 52,000 | 359 | 66,000 | 455 | 20 ~ 24 |

| X56 | 56,000 | 386 | 71,000 | 490 |

|

| X60 | 60,000 | 414 | 75,000 | 517 |

|

| X65 | 65,000 | 448 | 77,000 | 531 |

|

| X70 | 70,000 | 483 | 82,000 | 565 |

|

| X52 | 52,000 | 359 | 66,000 | 455 | 20 ~ 24 |

Qalabka Farsamada ee API 5L/X52GR.B Dhuumaha Khadka Tooska ah (PSL2):

| Darajo | Xoogga Wax-soo-saarka(MPa) | Xoogga Jilicsan(MPa) | Dheeraynta A% | Saamaynta (J) | ||

|

| psi | MPa | psi | MPa | Dheeraynta (min) | Min |

| X42 | 290 | 496 | 414 | 758 | 21 ~ 27 | 41 (27) |

| X46 | 317 | 524 | 434 | 758 | 20 ~ 26 | 41 (27) |

| X52 | 359 | 531 | 455 | 758 | 20 ~ 24 | 41 (27) |

| X56 | 386 | 544 | 490 | 758 |

|

|

| X60 | 414 | 565 | 517 | 758 |

|

|

| X65 | 448 | 600 | 531 | 758 |

|

|

| X70 | 483 | 621 | 565 | 758 |

|

|

| X80 | 552 | 690 | 621 | 827 |

| |

| X52 | 359 | 531 | 455 | 758 | 20 ~ 24 | 41 (27) |

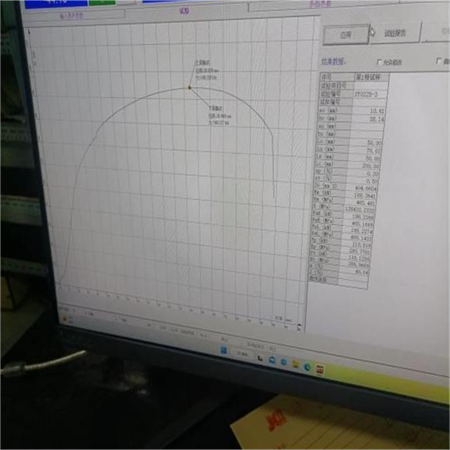

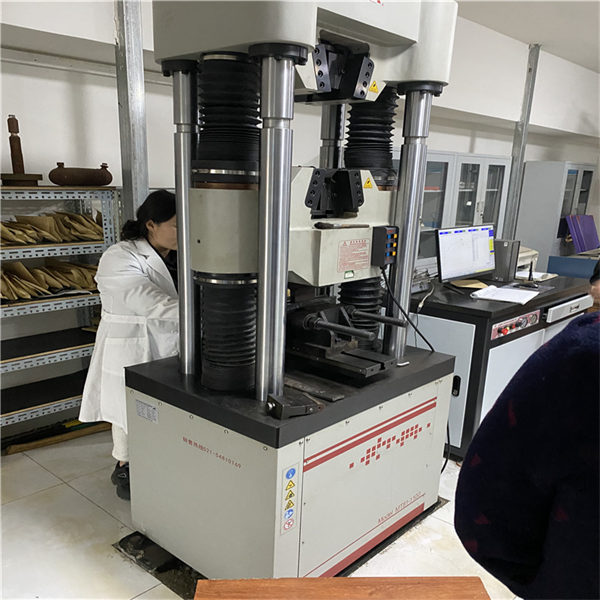

Tijaabada Makaanikada

Tijaabada Adag

Qallooca Tijaabada

Tijaabada xajinta ee jidhka biibiile-Tijaabadu waa in lagu sameeyaa si waafaqsan ISO6892 ama ASTM A370

Tijaabada fidsan—Hal tijaabo ah ayaa lagu samayn doonaa muunado laga soo qaaday dabadhid kasta oo ka mid ah laba tuubbo oo laga soo xulay qayb kasta

Imtixaanka saamaynta CVN-Tijaabada Charpy waa in lagu fuliyaa si waafaqsan ASTM A370. Laba jeer unug kasta oo tijaabo ah oo aan ka badnayn 100 dherer oo tuubo ah oo leh isla saamiga fidinta qabow ee abd

Tijaabada Adag-Marka lagu ogaado dhibco adag oo looga shakisan yahay kormeer muuqaal ah, tijaabooyinka adkaanta waa in lagu sameeyaa si waafaqsan ISO 6506, ISO 6507, ISO 6508 ama ASTM A 370 iyadoo la adeegsanayo qalabka tijaabada adkaanta la qaadan karo iyo hababka waafaqsan ASTM A 956, ASTM A 1038 ama ASTM E 110 siday u kala horreeyaan.

Tijaabada Hydro-static-Tuubo kasta waa in la mariyaa tijaabada cadaadiska hydrostatic

Qallooca Tijaabada - dherer ku filan oo tuubo ah waa in ay istaagtaa iyadoo qabow ilaa 90 ° agagaarka mandrel cylindrical ah.

100% Tijaabada raajo ee tollaynta alxanka

Baaritaanka ultrasonic

Imtixaanka eddy hadda

Dhuumaha qaawan ama dahaarka madow / Varnish (sida waafaqsan shuruudaha macaamiisha);

6" iyo in ka hooseeya oo xidhmo ah oo leh laba dharbaaxo suuf ah;

Labaduba waxay ku dhammaadaan ilaaliyeyaasha dhamaadka;

Dhammaadka cad, dhammaadka gogol-dhaafka ah (2 "iyo wixii ka sarreeya oo leh darafyada goysyada, darajada: 30 ~ 35°), dunta iyo isku-xidhka;

Calaamadayn

| Cabbirka | Dulqaad (oo leh ixtiraamt to dibadda cayimandhexroorka) |

| <2 3/8 | + 0.016 inji, - 0.031 inji (+ 0.41 mm, - 0.79 mm) |

| > 2 3/8 iyo ≤4 1/2, alxanka joogtada ah | ± 1.00% |

| > 2 3/8 iyo <20 | ± 0.75% |

| > 20. aan toosnayn | ± 1.00% |

| >20 iyo <36, welded | + 0.75%.-0.25% |

| > 36, welded | + 1/4 inji .. - 1/8 inji (+ 6.35 mm, -3.20 mm) |

Marka la eego kiiska tuubada hydro-statically lagu tijaabiyay cadaadiska ka badan cadaadiska caadiga ah, dulqaadyada kale ayaa laga yaabaa in ay ku heshiiyaan soo saaraha iyo iibsadaha.

| Wareega ka baxsan | |||||

| Cabbirka | Dulqaadka laga jaray | Dulqaadka Dheeraadka ah | Dulqaadka dhamaadka-ilaa-dhamaadka | Dhexroor, Dulqaadka dhidibka (Boqolkiiba OD cayiman) | Farqiga ugu badan ee u dhexeeya dhexrooryada ugu yar iyo kan ugu badan (Waxay khusaysaa oo keliya tuubooyinka D/t≤75) |

| ≤10 3/4 l&V4 | 1/64 (0.40mm) | 1/16 (1.59mm) | - | - | |

| >10 3/4 iyo ≤20 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | - | - | - |

| > 20 iyo ≤ 42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | <0.500 in. (12,7 mm) |

| >42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | £625 gudaha. (15.9 mm) |

Dulqaadyada ka baxsan wareega waxay khuseeyaan ugu badnaan iyo dhexrooryada ugu yar sida lagu cabbiro cabbirka bar, caliper, ama qalab cabbiraya ugu badnaan iyo dhexrooryada ugu yar ee dhabta ah.

Dhexroorka celceliska (sida lagu qiyaasay cajalad dhexroor ah) ee hal daraf ee tuubada waa in aanu ka duwanayn in ka badan 3/32 inji (2.38 mm) marka loo eego dhinaca kale.

| Cabbirka | Nooca Dhuumaha | Dulqaadka1 (Boqolkiiba Dhumucda gidaarka ee la cayimay} | |

| Fasalka B ama Hoose | Fasalka X42 ama ka sare | ||

| <2 7/8 | Dhammaan | +20.- 12.5 | + 15.0.-12.5 |

| >2 7/8iyo<20 | Dhammaan | + 15,0,-12.5 | + 15-I2.5 |

| >20 | Alxan | + 17.5.-12.5 | + 19.5.-8.0 |

| >20 | Xumaan la'aan | + 15.0.-12.5 | + 17.5.-10,0 |

Marka dulqaadka taban ee ka yar kuwa liiska ku qoran uu cayimay iibsaduhu, dulqaadka togan waa in lagu kordhiyaa tirada guud ee dulqaadka lagu dabaqi karo boqolkiiba in ka yar dhumucda darbiga dulqaadka taban.

| Tirada | Tolerance (boqolkiiba) |

| Dhererka kelida ah, tuubo-dhammaadka gaarka ah ama tuubo A25Dhererka kelida ah, tuubo kaleCarloads.GradeA25,40,000lb(18 144kg) ama ka badanCarloads, oo aan ahayn Fasalka A25,40.0001b (18 144 kg) ama ka badanCarloads, dhammaan darajooyinka ka yar 40000 lb (18 144 kg) Dalbo alaabta Fasalka A25. 40.000 lb (18 144 kg) ama ka badan Dalbo alaab, oo aan ahayn Fasalka A25,40,000 lb (18 144 kg) ama ka badan Dalbo alaab, dhammaan darajooyinka, in ka yar 40.000 lb (18 144 kg) | + 10.-5.0 + 10,- 35 -2.5 -1.75 -15 -3.5 -1.75 -3.5 |

Xusuusin:

1. U dulqaadashada miisaanka ayaa lagu dabaqaa miisaanka la xisaabiyay ee tuubada dunta iyo isku xidhan iyo miisaanka la xisaabiyay ama la xisaabiyay ee tuubada dhamaadka-dhamaadka ah. Haddii dulqaadka dhumucda derbiga taban ee ka yar kuwa ku taxan shaxda sare uu cayimay iibsadaha, dulqaadka miisaanka oo lagu daray ee dhererka kelida ah waa in la kordhiyaa 22.5 boqolkiiba in ka yar dulqaadka taban ee baroorta.

2.Baabuurta xamuulka ah ee ka kooban tuubooyinka wax ka badan hal shay, dulqaadashada baabuurka waa in lagu dabaqaa si gooni ah shay dalbo.

3. Dulqaadka alaabta dalbashada waxay khusaysaa tirada guud ee tubada loo soo raray shayga dalabka.