ASTM A519tubbada waa in lagu soo saaraa hab-socodka aan kala go'a lahayn oo waa inay noqdaan kuwo kuleyl ah ama la dhammeeyey qabow sida lagu cayimay.

Tuubooyinka wareegsan ee leh dhexroorka dibadda oo aan ka badnayn 12 3/4 inji (325 mm).

Tuubooyinka birta sidoo kale waxaa lagu soo saari karaa afar gees, leydi, ama qaabab kale sida loo baahdo.

ASTM A519 waxaa loo kala saari karaa iyadoo loo eegayo walxaha birta:Birta Kaarboonkaiyo Alloy Steel.

Birta kaarboonwaxaa loo qaybiyaaKaarboon hoose MT(Tubooyinka Makaanikada),Birta Kaarboonka SareiyoDesulfurized ama dib-u-phosphorised, ama labadabaBirta Kaarboonka, si loo waafajiyo baahiyaha warshadaha kala duwan iyo xaaladaha codsiga.

Marka aan darajo la cayimin, soosaarayaashu waxay leeyihiin ikhtiyaarka ah inay bixiyaanMT1015 ama MTX1020buundooyinka

Dhexroor ka baxsan: 13.7 - 325 mm;

Dhumucda gidaarka: 2-100mm.

Birta waxaa lagu samayn karaa hab kasta.

Waxaa laga yaabaa in birta lagu shubo godad ama waxa laga yaabaa in lagu shubo xadhig.

Tuubooyinka waa in ay sameeyaan ahab aan kala go 'lahaynwaana inuu ahaadaa mid kuleyl ah ama la dhammeeyay qabow, sida lagu cayimay.

Tuubooyinka birta ah ee aan fiicneyn waa tuubooyinka aan lahayn tolmo alxan oo dhan.

Tuubooyinka qabow-dhammeeyaywaxaa lagu talinayaa baahida sare ee saxnaanta cabbirka iyo tayada dusha sare.

Welwelka ugu weyni waa waxtarka-wax-ku-oolnimada iyo adkaanta alaabta,tuubo bir ah oo kululwaxay noqon kartaa doorasho ku habboon.

Marka xigta waa habka wax soo saarka ee tuubada birta ah ee kulul ee duuban.

Soo saaraha birta waa in uu baari doonaa kulaylka birta kasta si loo go'aamiyo boqolkiiba walxaha la cayimay.

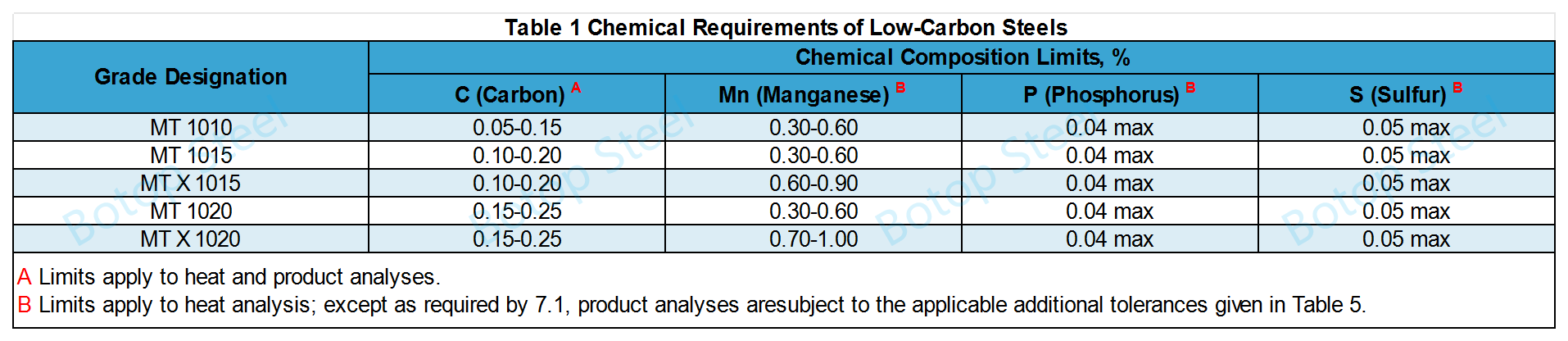

Shaxda 1 Shuruudaha Kiimikada ee Biraha Kaarboon-yar

Birta fudud waa bir ka kooban kaarboon inta badan aan ka badnayn 0.25%. Sababo la xiriira kaarboonka ku jira ee hoose, birtani waxay leedahay ductility iyo maleability ka wanaagsan waana ka adag tahay kana xoog badan tahay marka la barbar dhigo birta karbon-sare.

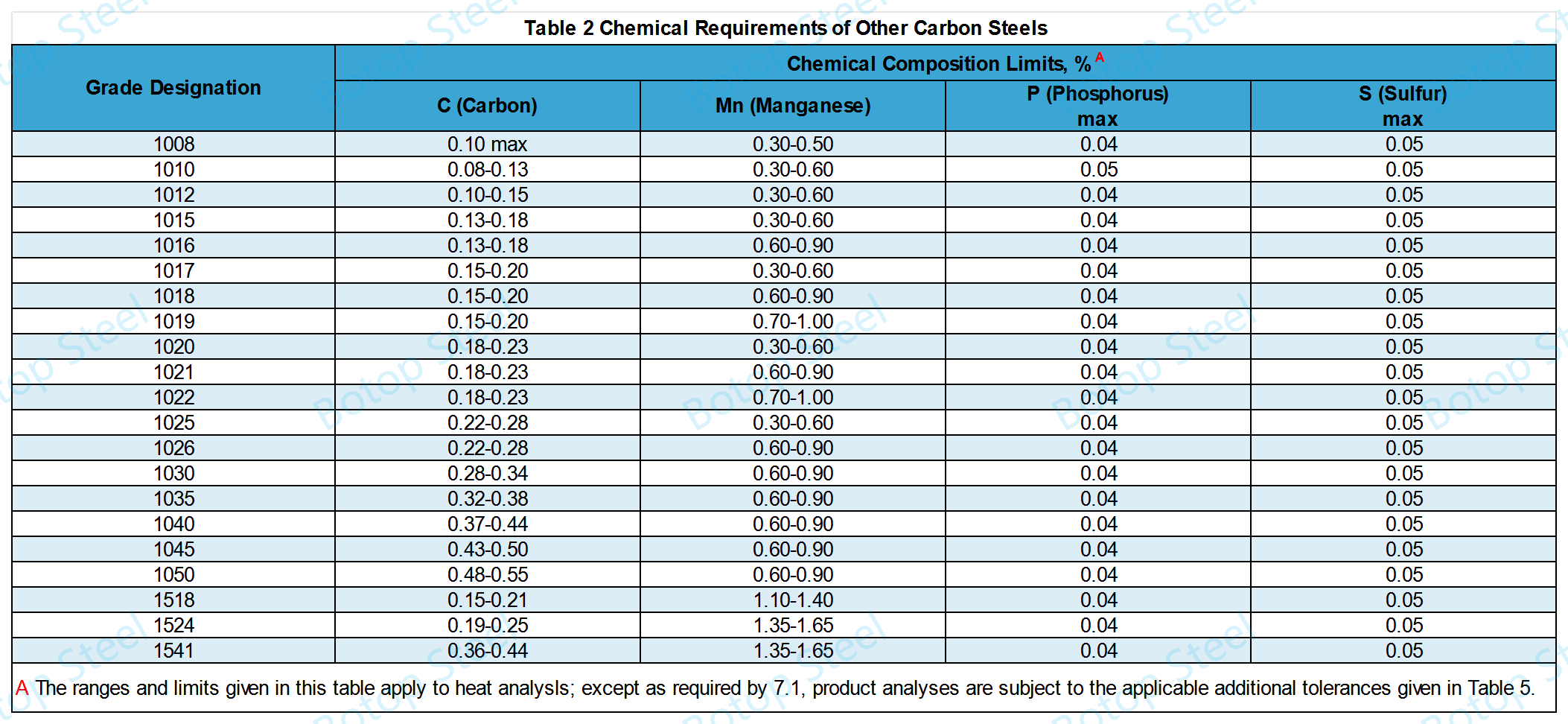

Shaxda 2 Shuruudaha Kiimikada ee Biraha kale ee Kaarboon

Biraha kaarboonka dhexdhexaadka ah: Ka kooban inta u dhaxaysa 0.25% iyo 0.60% kaarboon, waxay bixiyaan adayg sare iyo xoog waxayna u baahan yihiin daaweyn kulayl si loo hagaajiyo guryaha.

Bir kaarboon sare leh: Waxa ku jira inta u dhaxaysa 0.60% iyo 1.0% ama ka badan oo kaarboon ah, oo waxay siisaa qallafsanaan aad u sarreeya iyo xoog, laakiin adagaanta hoose.

Shaxda 3 Shuruudaha Kiimikada ee Biraha Alloy

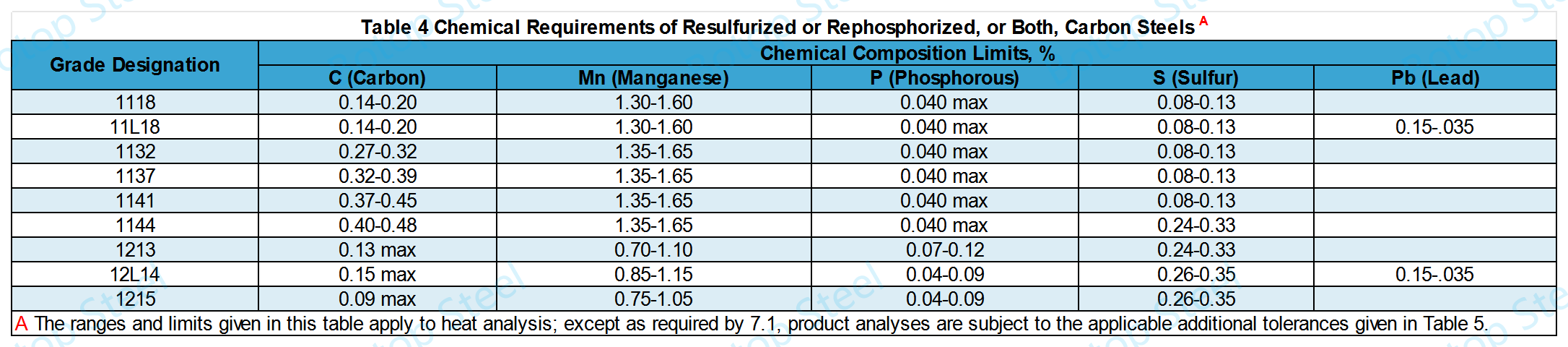

Shaxda 4 Shuruudaha Kiimikada ee la Resulfurized ama Dib-u-Foosforized, ama Labada, Birta Kaarboon

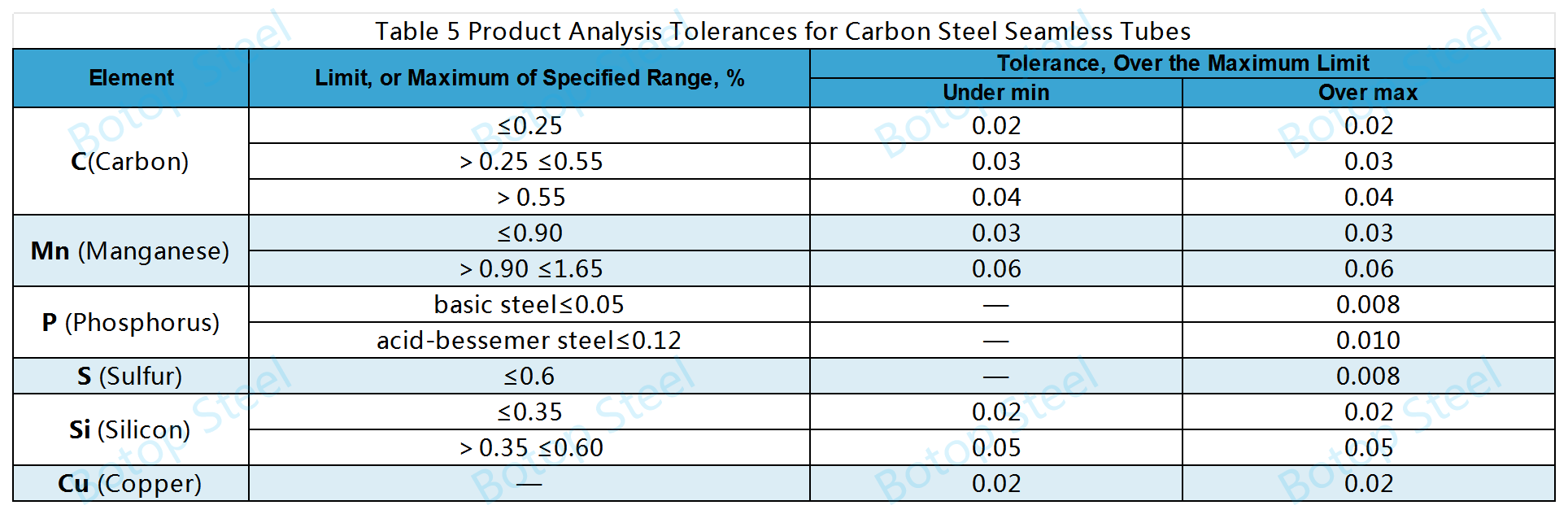

Shaxda 5 Dulqaadyada Falanqaynta Alaabta Ka badan ama ka hooseeya Xadka ama Xadka la cayimay

Soo-saaraha waa in la waydiiyaa oo kaliya inuu falanqeeyo badeecada haddii loo baahdo.

ASTM A519 waxay dabooshaa walxaha tijaabada ah ee soo socda:

Imtixaan Adag; Imtixaannada kacsanaanta; Tijaabada aan burburin; Imtixaanka Dabciga; Nadaafadda birta iyo adkaanta.

| Magacaabidda Darajada | Nooca Dhuumaha | Xaalad | Xoog wax ku ool ah | Xoogga Wax-soo-saarka | Kordhinta 2in.[50mm],% | Rockwell, Miisaanka Adag B | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Birta Kaarboonka | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Birta Kaarboonka | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Birta Kaarboonka | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Birta Kaarboonka | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Birta Kaarboonka | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized ama dib loo qaabeeyey, ama labadaba, Biraha Kaarboonka | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized ama dib loo qaabeeyey, ama labadaba, Biraha Kaarboonka | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Alloy Steels | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Alloy Steels | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Hot Rolled, CW-qabow Shaqeynayay, SR-Stress la yareeyay, A-Annealed iyo N-caadiyan.

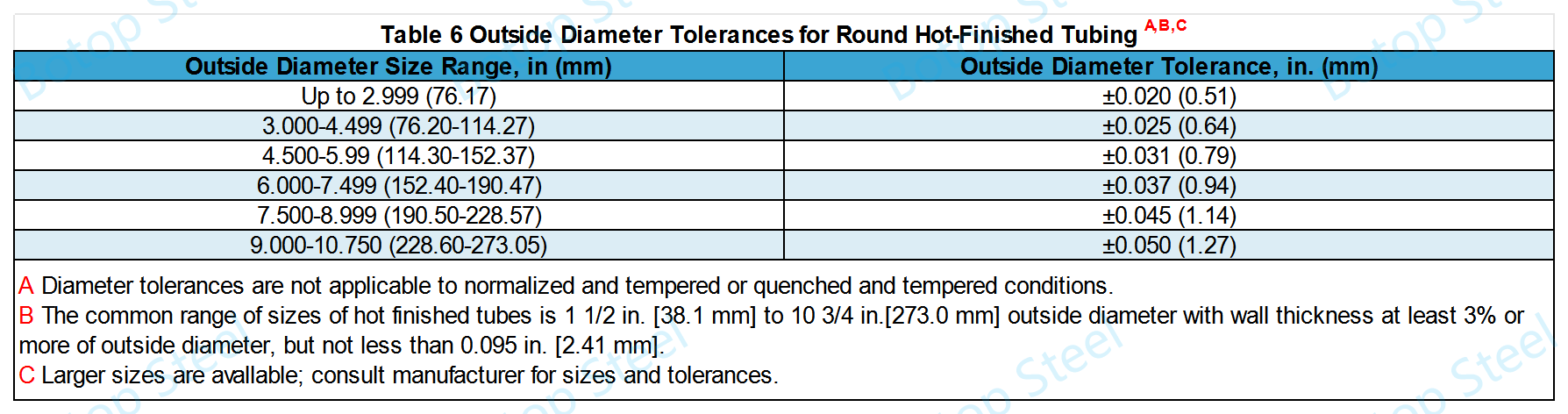

Dulqaadka Dhexroorka Dibadda

Shaxda 6 Dulqaadyada Dhexroorka Dibadeedloogu talagalay Tuubooyinka Kulul ee Wareega

Shaxda 12 Dulqaadyada Dhexroorka Dibadeed eeTubooyin aan Xumaan lahayn oo Dhulka ah

| Cabbirka Dhexroorka Ka baxsan, gudaha [mm] | Dulqaadyada Dhexroorka Dibadeed ee Cabirka iyo Dhererka La Siiyey, gudaha. [mm] | |||

| Dhamaaday | Hoosta | Dhamaaday | Hoosta | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] marka L≤16ft[4.9m] | 0.000 | 0.004 [0.10] marka L >16ft[4.9m] | 0.000 |

| 1 1/4 [31.8] OD ≤2 [50.8] | 0.005 [0.13] marka L≤16ft[4.9m] | 0.000 | 0.006 [0.15] marka L >16ft[4.9m] | 0.000 |

| 2 [50.8] OD ≤3 [76.2] | 0.005 [0.13] marka L≤12ft[3.7m] | 0.000 | 0.006 [0.15] marka L≤16ft[4.9m] | 0.000 |

| 3 [76.2] OD ≤4 [101.6] | 0.006 [0.15] marka L≤12ft[3.7m] | 0.000 | 0.006 [0.15] marka L≤16ft[4.9m] | 0.000 |

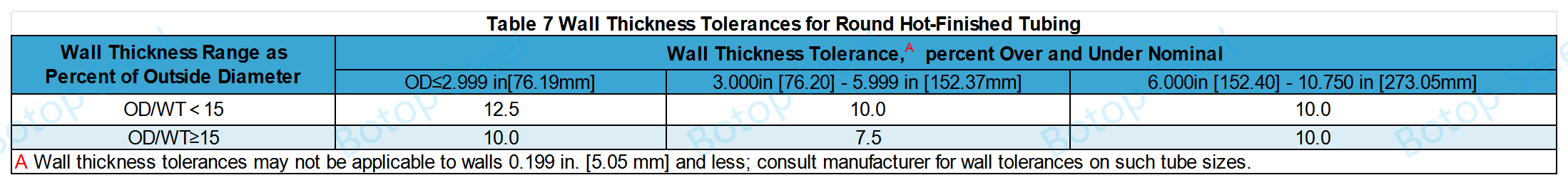

Dulqaadka Dhumucda gidaarka

Shaxda 7 Dulqaadyada Dhumucda Darbigaloogu talagalay Tuubooyinka Kulul ee Wareega

Shaxda 10 Dulqaadyada Dhumucda Darbigaloogu talagalay Tuubooyinka Qabow-wareega ah ee Wareegga ah

| Dhumucdiisuna waxay u kala duwan tahay sida Boqolkiiba dhexroorka ka baxsan | Dulqaadka Dhumucda gidaarka ee ka hooseeya ama ka hooseeya magaca % | |

| OD≤1.499in[38.07mm] | OD≥1.500 gudaha [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT:25 | 12.5 | 10.0 |

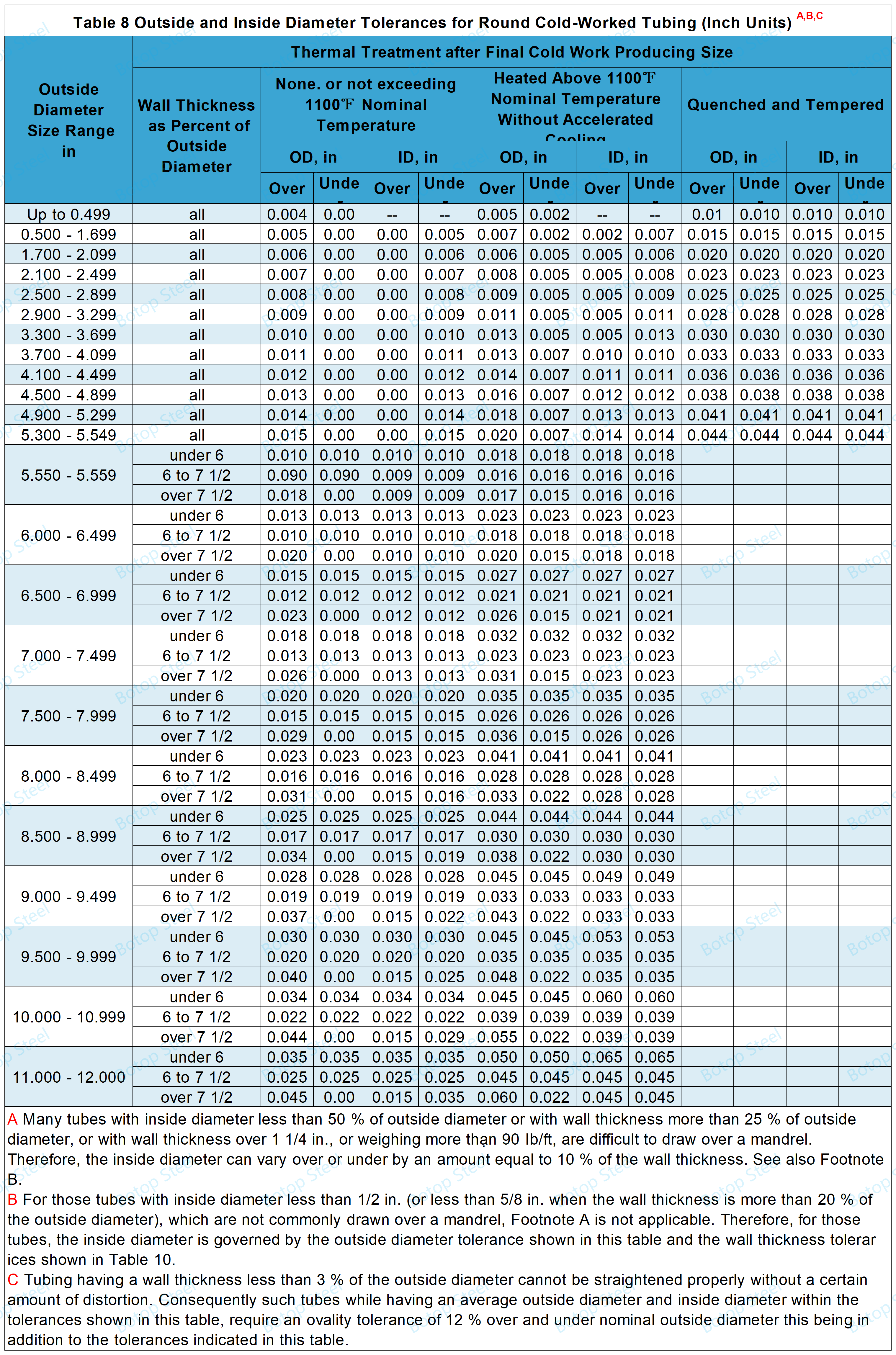

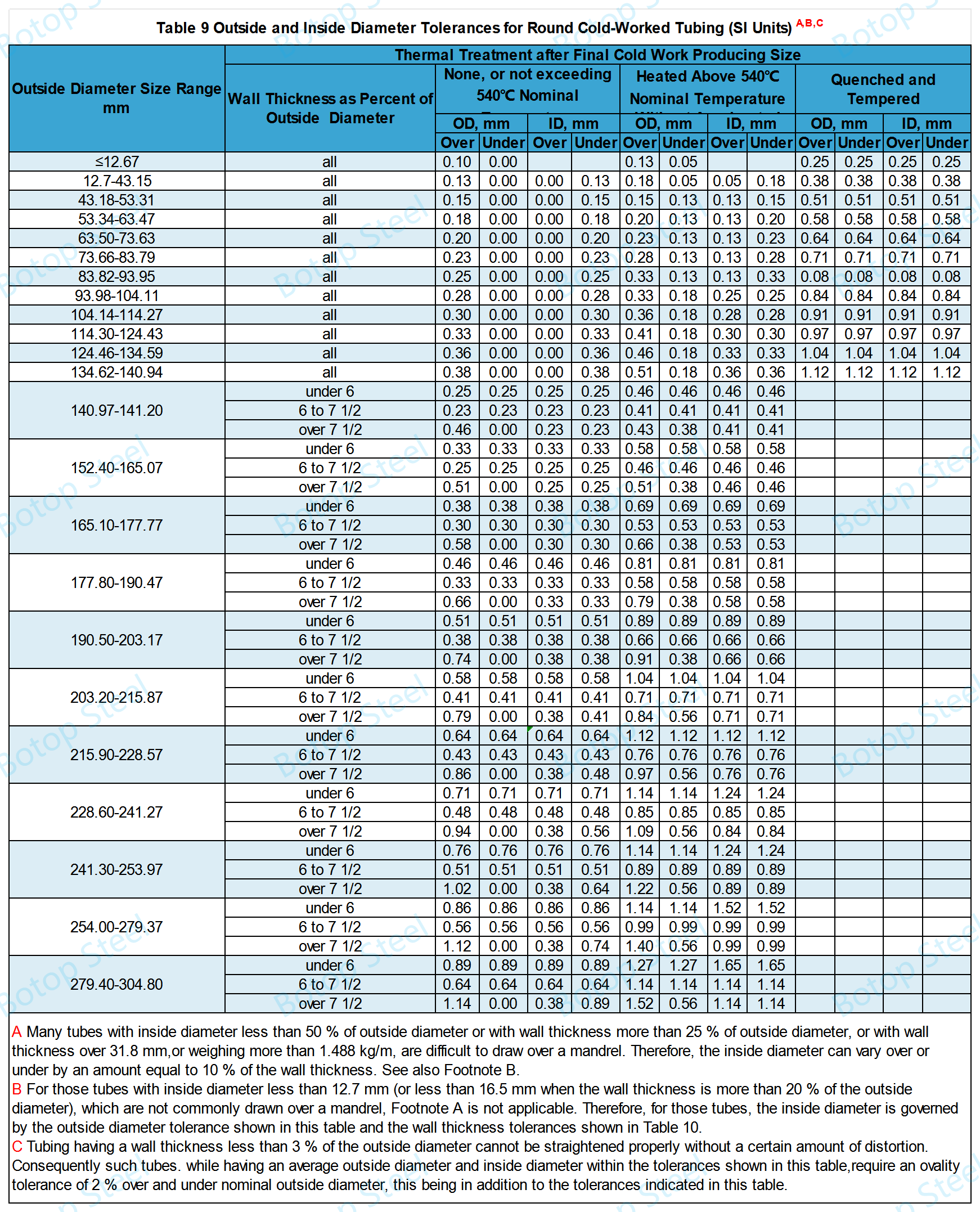

Dulka iyo Guddaha Dulqaadka Dhexroorka

Shaxda 8 Dibadeed iyo Guddaha Dulqaadyada Dhexroorka eeTuubooyinka Qabow-wareega ah ee Wareegga ah (cutubyo inch)

Shaxda 9 Dubka iyo Guddaha Dulqaadyada Dhexroorkaloogu talagalay Tuubooyinka Qabow-wareega ah ee Wareegga ah (Utubyada SI)

Dhexroorka ka baxsan iyo Dulqaadka Dhumucda gidaarka

Shaxda 11 Dhexroorka Dibadeed iyo Dulqaadyada Darbigaee loogu talagalay Tubbooyinka Biraha ee Qalafsan

| Cabbirka la cayimay ee ka baxsan dhexroorka, gudaha [mm] | Dhexroor ka baxsan, gudaha [mm] | Dhumucda gidaarka, % |

| 6 3/4 [171.4] | ±0.005 [0.13] | ± 12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ± 12.5 |

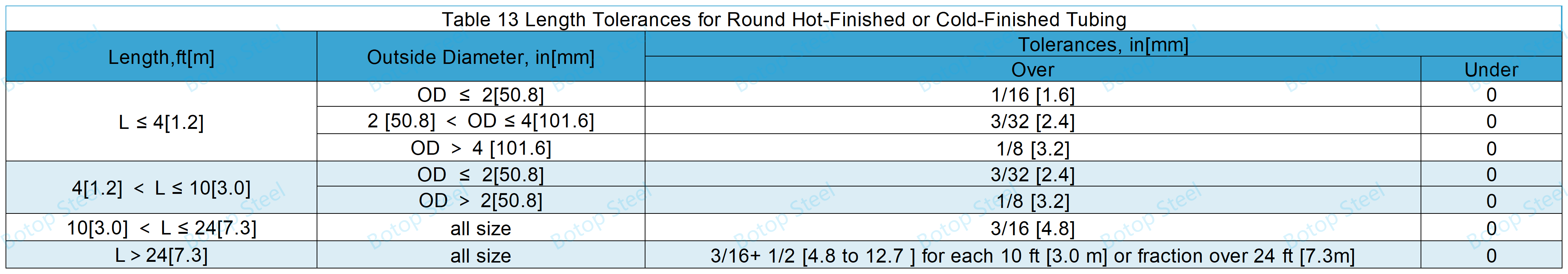

Dulqaadka dhererka

Shaxda 13 Dulqaadyada Dhererkaloogu talagalay Tuubooyinka Kulul-Dhamayseed ama Qabow-Dhamayseed

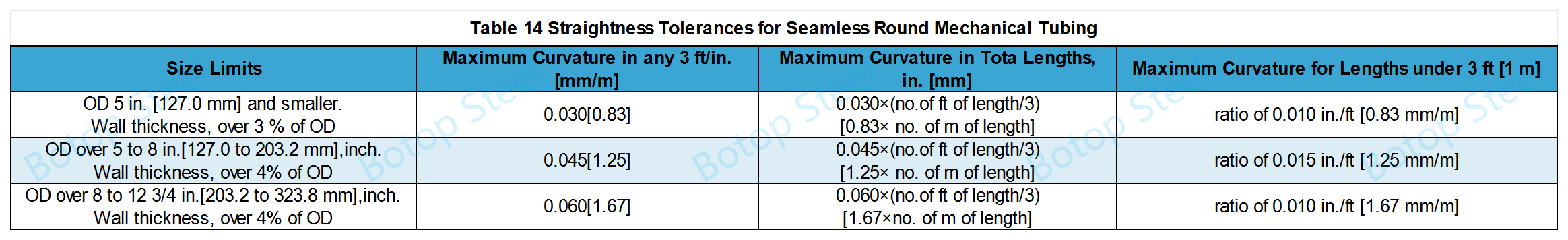

Dulqaadka Toosan

Shaxda 14 Dulqaadashada Toosanloogu talagalay Tuubooyinka Makaanikada Wareegga ah ee aan Xumaan lahayn

Tuubada waa in lagu daboolaa filim saliid ah ka hor inta aan la dhejin si looga hortago miridhku.

Saliida ka hortagga miridhku waxa kale oo laga yaabaa in lagu mariyo gudaha iyo bannaanka ee tuubada.

Duulimaadka iyo hawada sare: soo saarista qaybaha muhiimka ah sida matoorada diyaaradaha iyo hababka taageerada hawada sare.

Warshadaha tamartaQalabka qodista iyo soo saarista tuubooyinka kuleyliyaha cadaadiska sare leh.

Mashiinnada iyo qalabka wax soo saarka: Qaybaha asaasiga ah ee ka kooban mashiinada iyo qalabka warshadaha ee kala duwan.

Qalabka ciyaaraha: Soo saarista xargaha baaskiillada ee waxqabadka sarreeya iyo goobaha kale ee ciyaaraha.

Dhismaha iyo dhismahaWaxyaalaha taageerada qaabdhismeed ee dhismayaasha iyo codsiyada jawiga cadaadiska sare leh.

TS EN 10297-1: E355, 25CrMo4, 42CrMo4, iwm. Qalabkan waxaa loo arki karaa inay u dhigmaan qaar ka mid ah kaarboonka iyo birta daawaha ee ASTM A519.

2. DIN 1629: St52, St37.4, iwm. Sida caadiga ah loo isticmaalo ujeedooyinka farsamada iyo dhismaha, kuwani waxay la mid yihiin darajooyinka birta fudud ee ASTM A519.

3. JIS G3445: STKM13A, STKM13B, iwm. Kuwani waa tuubooyinka birta kaarboon ee loo isticmaalo ujeedooyinka farsamada iyo dhismaha.

4. BS 6323: CFS 3, CFS 4, CFS 8, iwm. Kuwani waa tuubooyinka birta ah ee aan xidhnayn iyo kuwa alxanka leh ee baabuurta, farsamada iyo injineernimada guud.

5. GB/T 8162: 20#, 45#, 40Cr, 20CrMo, iwm. Tuubooyinka birta ah ee aan kala go'a lahayn iyo tuubooyinka dhismaha guud iyo qaabdhismeedka farsamada.

6. ISO 683-17: 100Cr6, iwm, oo caadi ahaan loo isticmaalo soo saarista wax soo saarka, waxay sidoo kale ka heli kartaa codsiga injineernimada makaanikada waxayna leedahay codsiyo la mid ah biraha daawaha qaarkood ee ASTM A519.

Markaad dooranayso walxo u dhigma, waxaa muhiim ah in la tixraaco qaabka kiimikada ee faahfaahsan iyo sifooyinka hantida farsamada si loo hubiyo in alaabta la doortay ay buuxinayso shuruudaha waxqabadka ee codsiga gaarka ah.

Tan iyo markii la aasaasay 2014, Botop Steel waxay noqotay shirkad hormuud ka ah tuubooyinka birta kaarboon ee Waqooyiga Shiinaha, oo loo yaqaan adeeg aad u wanaagsan, alaab tayo sare leh, iyo xalal dhammaystiran. Shirkaddu waxay bixisaa noocyo kala duwan oo ah tuubooyinka birta kaarboonka iyo alaabada la xidhiidha, oo ay ku jiraan kuwa aan fiicneyn, ERW, LSAW, iyo tuubada birta ee SSAW, iyo sidoo kale saf buuxa oo ah xirmooyinka tuubooyinka iyo flanges.

Alaabooyinkeeda gaarka ah waxa kale oo ka mid ah alloys-ga sare iyo biraha austenitic ahama, oo loogu talagalay in lagu daboolo baahiyaha mashaariicda dhuumaha ee kala duwan.