API (Heerarka Machadka Batroolka Mareykanka) 5L waa halbeegga caalamiga ah ee tuubooyinka birta ee loo isticmaalo nidaamyada gaadiidka dhuumaha.

API 5L waxay dabooshaa dhuumaha birta ee codsiyada kala duwan ee gaadiidka gaaska dabiiciga ah, saliidda, iyo dareerayaasha kale.Taariikhda dhaqangalka ah ee daabacaadda 46aad: dhaqangal Noofambar 1, 2018.

Haddii aad rabto inaad hesho fikrad guud API 5L, fadlan gujiAPI 5L Faahfaahinta Tubta Guudmarka.

Badhamada navigation

Maxaa Lagu Cusboonaaday API 5L 46th

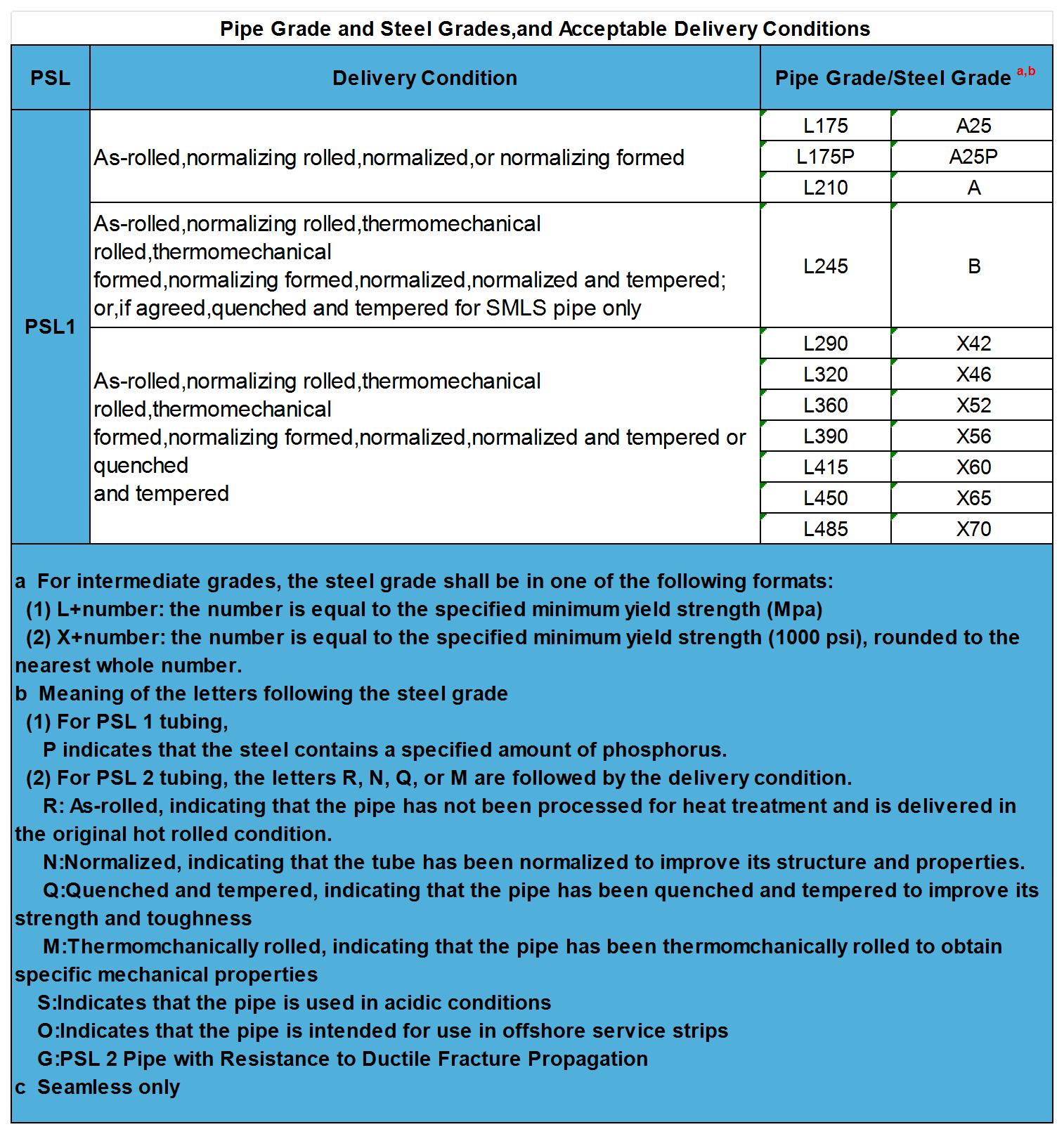

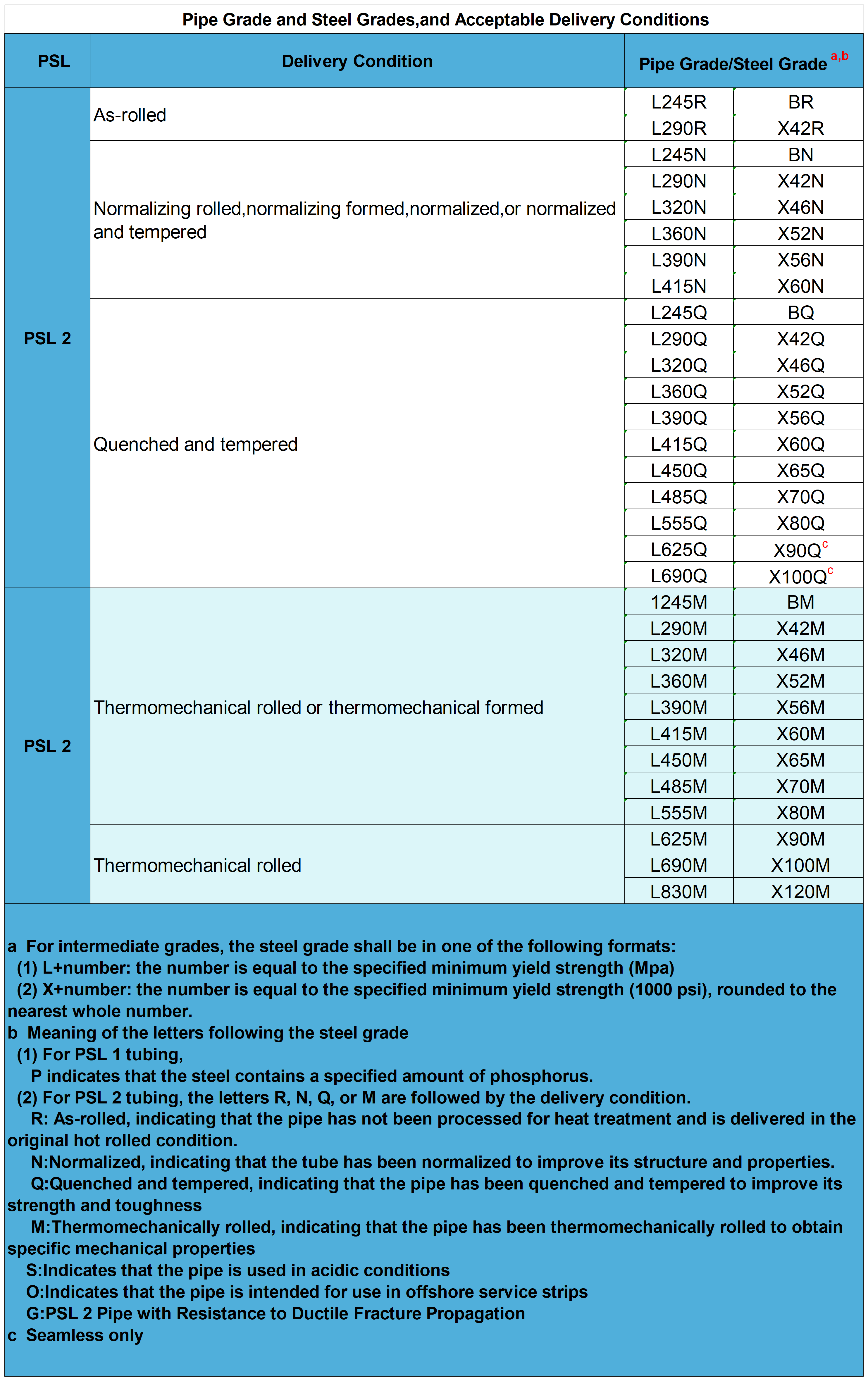

Asalka API 5L PSL

Kala soocida darajooyinka birta iyo buundooyinka

Dawladaha Bixinta La Aqbali Karo

Qalabka Ceyriinka ah ee Tuubooyinka Birta

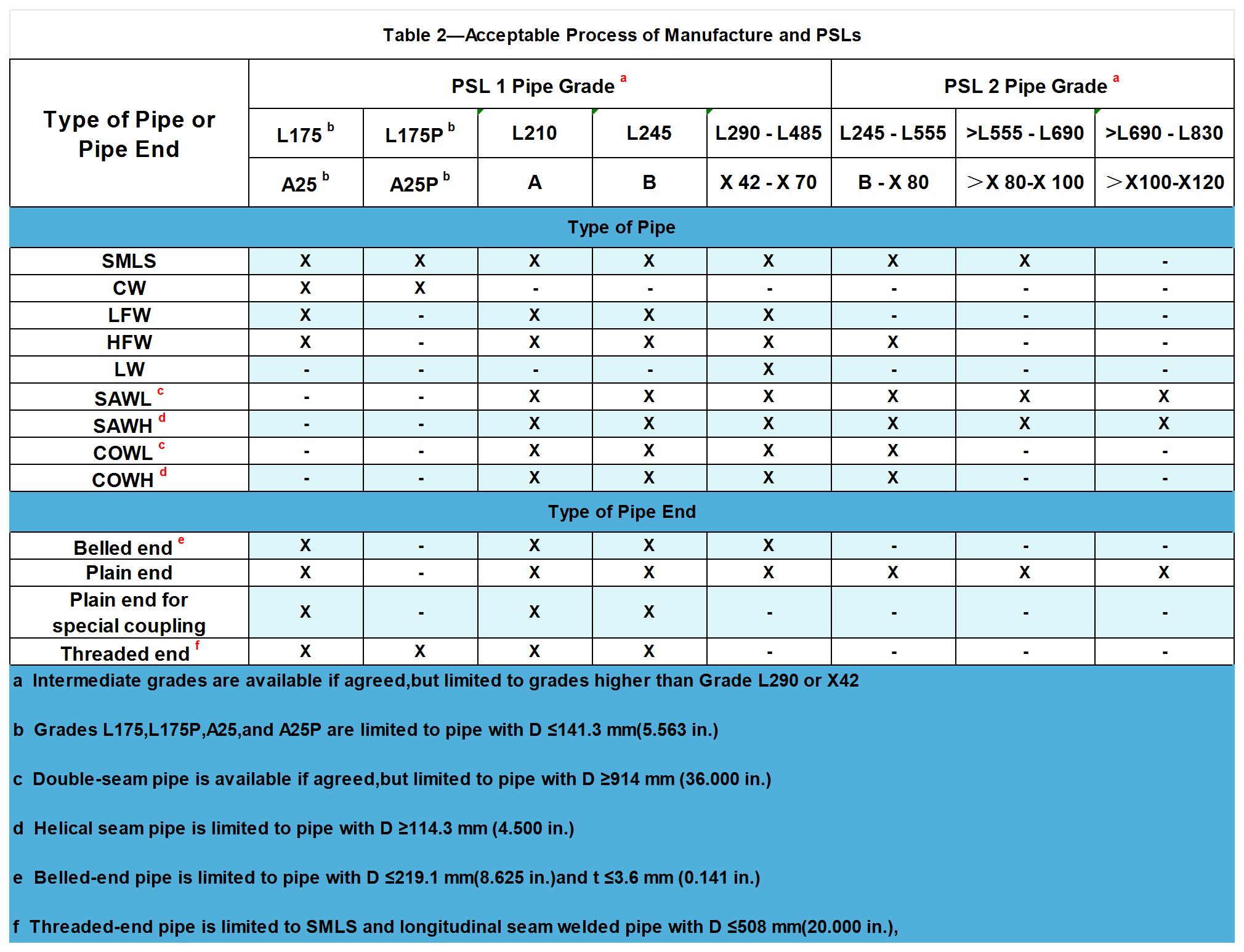

Noocyada Dhuumaha Birta iyo Dhamaadka Tubooyinka Waxaa Dabooshay API 5L

Hannaanka wax-soo-saarka ee la aqbali karo ee Tuubooyinka Birta ee PSL2

Kormeerka muuqaalka iyo cilladaha guud ee API 5L

Kormeerka Cabbirka (Dhaqdhaqaaqa cabbirka)

API 5L Walxaha Tijaabada

Calaamadaynta Dhuumaha iyo Goobta

Heerka u dhigma

Alaabtayada laxidhiidha

Maxaa Lagu Cusboonaaday API 5L 46th

Cusbooneysii

Shuruudaha la cusboonaysiiyay oo la ballaariyay ee kala-goysyada shiididda;

Shuruudaha la cusboonaysiiyay ee ku habboonaanta dhammaadka tuubbada;

Shuruudaha tijaabinta adkaanta ee la cusboonaysiiyay ee tuubooyinka API 5LPSL 2 ee deegaanka dhanaan iyo API 5L PSL 2 tuubooyinka deegaanka xeebaha;

Cusub

API 5L PSL 2 tuubo loogu talagalay codsiyada u baahan awoodda cadaadis caag ah oo dheer.

Asalka API 5L PSL

PSL: Soo gaabinta Heerka Tilmaamida Dhuumaha;

U qaybsan: API 5L PSL 1 iyo API 5L PSL 2.

Kala soocida darajooyinka birta iyo buundooyinka

L + nambarka( xarafka L waxaa raacaya awoodda wax-soo-saarka ugu yar ee MPa):

L175,L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485,L555,L625,L683,L690

X + nambar(lambarka soo socda xarafka X ayaa qeexaya awoodda wax-soosaarka ugu yar ee 1000 psi):

X42,X46,X52,X56,X60,X65,X70,X80,X90,X100,X120.

Iyo fasalka a iyo fasalka b.Fasalka A=L210 Fasalka B=L 2459

Gobolada gaarsiinta la aqbali karo

Fiiro gaar ah: L415/X60 ama darajooyinka ka sareeya waa in aan loo isticmaalin booska L360/X52 ama ka hooseeya iyada oo aan la helin heshiiska iibsadaha.

Qalabka Ceyriinka ah ee Tuubooyinka Birta

Ingot, billet, billet, strip (gariiradda) ama saxan.

Fiiro gaar ah:

1. Qalabka ceeriin ee loogu talagalayAPI 5L PSL2Dhuumaha birta ahi waa inay ahaadaan bir wasakhaysan.

2. Xarigga birta ah (gariiradda) ama saxanka loo isticmaalo samaynta API 5L PSL2 tuubooyinka birta waa in aanay qaadin wax alxanka ah.

Noocyada Dhuumaha Birta iyo Dhamaadka Tubooyinka Waxaa Dabooshay API 5L

Dhuumaha Bir alxanka leh

Dhuumaha CW:Habka samaynta tollaynta iyadoo lagu kululeynayo falinka foornada oo si farsamaysan loo cadaadiyo cidhifka la sameeyay, halkaas oo gariiradaha is-daba-joogga ah ee xariijinta la isku daray si loo helo qulqul joogto ah oo loogu talagalay warshadda alxanka.

COWHPipe:Alaabta tubbada oo leh hal tol oo helical ah oo ay soo saartay isku-darka birta gaaska iyo alxanka qulqulka, kaas oo birta gaaska alxanka aan si buuxda looga saarin baasasyada alxanka arc ee hoos jira.

Lo'da DhuumahaAlaabta tubbada oo leh hal ama laba toleed oo dhaadheer oo ay soo saartay isku-darka birta gaaska iyo alxanka dhulka hoostiisa, kaas oo gaaska birta alxanka aan si buuxda looga saarin baasasyada alxanka ee quuska ah.

EW Dhuumaha:Alaabta tubbada leh oo leh hal tol oo dherer ah oo ay soo saartay alxanka koronto ee hooseeya ama sarreeya.

Dhuumaha HFW:EWpipe oo la soo saaray alxanka inta jeer ee hadda la mid ah ama ka weyn 70 kHz.

Dhuumaha LFW:Dhuumaha EW waxaa lagu soo saaraa alxanka inta jeer ee hadda jirta oo ka yar 70 kHz.

Dhuumaha LW:Alaabta tubbada oo leh hal tol oo dherer ah oo ay soo saartay alxanka laysarka.

Dhuumaha SAWH:Alaabta tubbada leh oo leh hal tol oo helical ah oo ay soo saartay habka alxanka arc quuska ah.

SAWLDhuumaha:Alaabta tubbada leh oo leh hal ama laba tolmood oo dhaadheer oo ay soo saartay alxanka arc hoostiisa.

Dhuumaha birta ah ee aan cillad lahayn

Dhuumaha SMLS:Tuubo bir ah oo kulul oo duuban iyo tuubo bir ah oo qabow oo duuban, waxaa jira qaar ka mid ah hababka kale ee farsamaynta, sida sawir qabow, sawir qabow, foorno, iwm.

API 5L PSL2 Noocyada Dhuumaha ee codsiyada gaarka ah

U adkaysiga Faafinta Jajabka Ductile (G)

Dhuumaha Xaaladda Adeegga Dhadhanka (S)

Xaaladda Dhuumaha Adeegga Badda (O)

U Baahan Dhuumaha Awooda Cadaadiska Caagaga Dheer

Noocyada Dhamaadka Tubooyinka

Dhamaadka Socket, Flat End, Gaarka Isku Xidhka Daboolka, Dhammaadka Xadhkaha Leh.

Fiiro gaar ah:

1. Dhamaadka godka, cidhifyada tuubooyinka xirmooyinka gaarka ah, iyo darafyada tuubooyinka dunta leh ayaa loogu talagalay API 5L PSL1 oo keliya.

2. L175 P/A25 P birta darajada API 5L PSL1 tuubooyinka birta waa in lagu farsameeyaa cidhifyada dunta leh, iyo API 5L PSL1 tuubooyinka birta ee darajooyinka kale ee birta waa in lagu farsameeyaa cidhifyo siman.

3. API 5L PSL 2 tuubooyinka waa in lagu keenaa cidhifyo fidsan.

Hannaanka wax-soo-saarka ee la aqbali karo ee Tuubooyinka Birta ee PSL2

| Shaxda 3-Wadooyinka wax soo saarka ee la aqbali karo ee PSL 2 Pipe | ||||

| Nooca Dhuumaha | Materiyada bilawga ah | Samaynta Dhuumaha | Kuleylka Dhuumaha Daawaynta | gaarsiin Xaalad |

| SMLS | Dhalo, ubaxu, ama billet | Sida-duuban | - | R |

| Caadiyan samaynta | - | N | ||

| Samaynta kulul | Caadiyan | N | ||

| Deminta iyo xanaaqa | Q | |||

| Samaynta kulul iyo qabow dhammayn | Caadiyan | N | ||

| Deminta iyo xanaaqa | Q | |||

| HFW | Gariiradda duuban ee caadiga ah | Qabow samaynta | Daawaynta kulaylkaa ee aagga alxanka kaliya | N |

| Thermomechanical-rogid gariiradda | Qabow samaynta | Daawaynta kulaylkaa ee aagga alxanka kaliya | M | |

| Daawaynta kulaylkaa ee aagga alxanka iyo yaraynta walbahaarka ee tuubooyinka oo dhan | M | |||

| Sida-duuban ama gariiradda thermomechanical-rogid | Qabow samaynta | Caadiyan | N | |

| Deminta iyo xanaaqsanaan | Q | |||

| Qabowga oo uu daba socdo kulayl hoos u dhigista xakamaynta heerkulka ka dhasha xaalad caadi ah | - | N | ||

| Qabow samaynta waxaa ku xiga samaynta thermomechanical tuubooyinka | - | M | ||

| SAW ama Lo'da | Caadiyan ama caadi- gariiradda duuban ama saxan | Qabow samaynta | - | N |

| Sida-duuban thermomechanical-rogid Caadiye-rogid, ama caadi laga dhigay | Qabow samaynta | Caadiyan | N | |

| Thermomechanical-rogid gariiradda ama saxan | Qabow samaynta | - | M | |

| Demiyey oo xanaaqsan saxan | Qabow samaynta | - | Q | |

| Sida-duuban thermomechanical-rogid Caadiye-rogid, ama gariiradda caadiga ah ama saxan | Qabow samaynta | Deminta iyo xanaaqsanaan | Q | |

| Sida-duuban thermomechanical-rogid Caadiye-duuban,ama gariiradda caadiga ah ama saxan | Caadiyan samaynta | - | N | |

| aFiiri ISO 5L 8.8 daawaynta kulaylka lagu dabaqi karo | ||||

Kormeerka muuqaalka iyo cilladaha guud ee API 5L

Muuqashada

Dusha sare ee tuubbadu waa inay ahaataa mid siman oo ka madax bannaan cillado saameeya xoogga iyo sifooyinka tuubada.

Cilladaha waaweyn

Cidhifyada Nibbled:Cidhifyada nibble waxay sida ugu fiican u heli karaan kormeer muuqaal ah.

Arc gubashada:Gubashada Arc waa in lagu qiimeeyaa mid cilladaysan.

Gubashooyinka arc waa tiro cillado ah oo meel maxalli ah oo ka dhasha dhalaalidda birta oogada oo ay keento qaansada u dhaxaysa korantada ama korantada dhulka hoostiisa iyo dusha tuubada birta.

Baraha la taabto waa baro kala go'a oo u dhow xariiqda alxanka ee tuubada EW, oo ay sababto taabashada u dhaxaysa korantada bixisa hadda alxanka iyo dusha tuubada.

Dejinta:Kala saarid kasta ama ka mid ahaansho kasta oo ku fidsan dusha tuubada ama wejiga rogman oo> 6.4 mm (0.250 in) dherer ahaan ah marka la eego kormeerka muuqaalku waa in loo tixgeliyaa cilad.

weecsanaan joomatari:Weecsanaan joomatari ah (tusaale, baloog fidsan ama boodh, iwm.), oo aan ka ahayn god hoosaad, oo ay sababto habka samaynta tuubada ama hawlgalka wax soo saarka.Fogaanta u dhaxaysa barta ugu ba'an iyo kordhinta konturrada caadiga ah ee tuubada, ie, qoto dheer oo ka weyn 3.2 mm (0.125 in), waa in loo tixgeliyaa cillad.

Godadku waa inay ahaadaan ≤ 0.5 D jiho kasta.

AdagMarka baadhista aragga ay muujiso adkaanshiyaha la tuhunsan yahay, tijaabiye adkaanta la qaadan karo waa in la isticmaalaa si loo tijaabiyo adkaanta, iyo galinta hal-dhibcood oo qiimaheedu ka sarreeyo 35 HRC, 345 HV10, ama 327 HBW waa in loo tixgeliyaa mid cilladaysan marka cabbirku yahay gelinta ayaa ka weyn 50 mm (2.0 in) jiho kasta.

Wax ka qabashada cillad

Fadlan tixraac shuruudaha la xiriira API 5L Lifaaqa C ee wax ka qabashada.

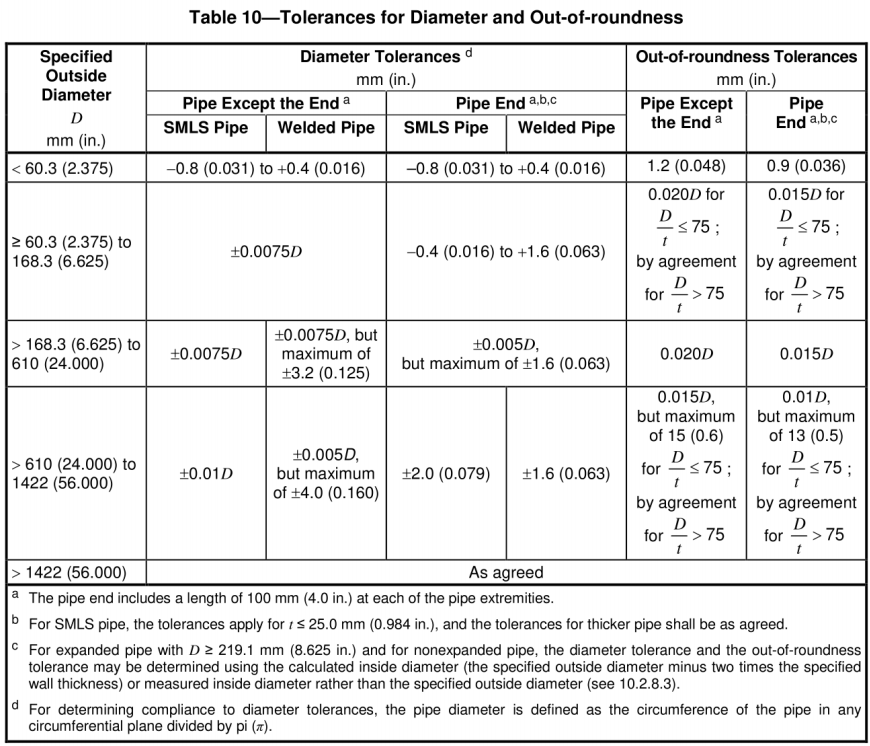

Kormeerka Cabbirka (Dhaqdhaqaaqa cabbirka)

Jaantuska Miisaanka Beebka iyo Weelashada Miisaanka

Foomka miisaanka

M=(DT)×T×C

M waa cufka halkii cutubkiiba;

D waa dhexroorka dibadda ee la cayimay, oo lagu muujiyey millimitir (inji);

T waa dhumucda gidaarka ee la cayimay, oo lagu muujiyey millimitir (inji);

C waa 0.02466 xisaabinta cutubyada SI iyo 10.69 xisaabinta cutubyada USC.

SHAXDA MIISAANKA TUBEE IYO JADWALKA

Miisaska tuubada ee API 5L ayaa la tixraacaaISO 4200iyoASME B36.10M, kaas oo siinaya qiyamka caadiga ah ee tuubada leh dhexroor ka baxsan oo cayiman iyo dhumucdiisuna waxay cayiman tahay.

Jadwalka 40 iyo Jadwalka 80aadHoos ku lifaaqan, haddii aad jeclaan lahayd inaad aragto jadwalka tuubada oo buuxa,fadlan halkan ku dhufo!

Weelnaanta Miisaanka

Tayada tuubo kasta marka loo eego aragtida: miisaanka: 95% ≤ miisaanka aragtida ≤ 110;

leexashada iyo tuubooyinka qeexida khafiifka ah: 5% ≤ 110% miisaanka aragtida;

L175, L175P, A25, iyo A25P darajooyinka birta: 95% ≤ 110% miisaanka aragtida.

Dhexroorka Dibadeed iyo Xaddiga Dhumucda gidaarka

| Shaxda 9-La oggol yahay ee lagu cayimay dhexroorka bannaanka iyo dhumucda gidaarka ee cayiman | ||

| Dhexdhexaad ka baxsan oo cayiman D mm (gud) | Dhumucda gidaarka ee cayiman t mm (gud) | |

| Qiyaasaha Iftiinka Gaarka aha | Cabbirrada Joogtada ah | |

| ≥10.3 (0.405) ilaa <13.7 (0.540) | - | ≥1.7 (0.068) ilaa≤2.4 (0.094) |

| ≥13.7 (0.540) ilaa <17.1 (0.675) | - | ≥2.2 (0.088) ilaa≤3.0 (0.118) |

| ≥17.1 (0.675) ilaa <21.3 (0.840) | - | ≥2.3 (0.091) ilaa≤3.2 (0.125 |

| ≥21.3 (0.840) ilaa <26.7 (1.050) | - | ≥2.1 (0.083) ilaa≤7.5 (0.294) |

| ≥26.7 (1.050) ilaa <33.4 (1.315) | - | ≥2.1 (0.083) ilaa≤7.8 (0.308) |

| ≥33.4 (1311}5) ilaa <48.3 (1.900) | - | ≥2.1 (0.083) ilaa ≤10.0 (0.394) |

| ≥48.3 (1.900) ilaa <60.3 (2.375) | - | ≥2.1 (0.083) ilaa≤12.5 (0.492) |

| ≥60.3 (2.375) ilaa <73.0 (2.875) | ≥2.1 (0.083) ilaa≤3.6 (0.141) | >3.6 (0.141) ilaa ≤14.2 (0.559) |

| ≥73.0 (2.875) ilaa <88.9 (3.500) | ≥2.1 (0.083) ilaa≤3.6 (0.141) | >3.6 (0.141) ilaa≤20.0 (0.787) |

| ≥88.9 (3.500) ilaa <101.6 (4.000) | ≥2.1 (0.083) ilaa≤4.0 (0.156) | >4.0 (0.156) ilaa ≤22.0 (0.866) |

| ≥101.6 (4.000) ilaa <168.3 (6.625) | ≥2.1 (0.083) ilaa≤4.0 (0.156) | >4.0 (0.156) ilaa≤25.0 (0.984) |

| ≥168.3 (6.625) ilaa <219.1 (8.625) | ≥2.1 (0.083) ilaa≤4.0 (0.156 | >4.0 (0.156) ilaa ≤40.0 (1.575) |

| ≥219.1 (8.625) ilaa <273.1 (10.750) | ≥3.2 (0.125) ilaa≤4.0 (0.156 | >4.0 (0.156) ilaa≤40.0 (1.575 |

| ≥273.1 (10.750) ilaa <323.9 (12.750) | ≥3.6 (0.141) ilaa≤5.2 (0.203) | >5.2 (0.203) ilaa ≤45.0 (1.771) |

| ≥323.9 (12.750) ilaa <355.6(14.000) | ≥4.0 (0.156) ilaa≤5.6 (0.219) | >5.6 (0.219) ilaa≤45.0 (1.771 |

| ≥355.6 (14.000) ilaa <457(18.000) | ≥4.5 (0.177) ilaa≤7.1 (0.281) | >7.1 (0.281) ilaa≤45.0 (1.771 |

| ≥457 (18.000) ilaa <559 (22.000) | ≥4.8 (0.188) ilaa≤7.1 (0.281) | >7.1 (0.281) ilaa ≤45.0 (1.771) |

| ≥559 (22.000) ilaa <711(28.000) | ≥5.6 (0.219) ilaa≤7.1 (0.281) | >7.1 (0.281) ilaa ≤45.0 (1.771) |

| ≥711 (28.000) ilaa <864(34.000) | ≥5.6 (0.219) ilaa≤7.1 (0.281) | >7.1 (0.281) ilaa ≤52.0 (2.050) |

| ≥864 (34.000) ilaa <965(38.000) | - | ≥5.6 (0.219) ilaa≤52.0 (2.050) |

| ≥965 (38.000) ilaa <1422 (56.000) | - | ≥6.4 (0.250) ilaa≤52.0 (2.050) |

| ≥1422 (56.000) ilaa <1829 (72.000) | - | ≥9.5 (0.375) ilaa≤52.0 (2.050) |

| ≥1829(72.000) ilaa <2134(84.000) | - | ≥10.3 (0.406) ilaa≤52.0 (2.050) |

| aDhuumaha oo leh isku darka dhexroor ka baxsan oo la cayimay iyo dhumucdiisuna tahay gidaarka la cayimay waxaa lagu qeexaa sida tuubo gaar ah oo iftiin leh;isku darka kale ee lagu siiyey shaxdan waxa lagu qeexaa sida tuubada cabbirka caadiga ah. | ||

Dhexroorka iyo leexashada wareega

Weelashada Dhumucda gidaarka

| Shaxda 11-Dulqaadka Dhumucda gidaarka | |

| Dhumucda darbiga t mm (in.) | Dulqaadkaa mm (in.) |

| Dhuumaha SMLSb | |

| ≤4.0 (0.157) | +0.6 (0.024) -0.5 (0.020) |

| >4.0 (0.157) ilaa <25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146)ama+0.1t, hadba kan weyn -3.0 (0.120) ama -0.1t, hadba kan weyn |

| Dhuumaha alxanka lehcd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| >5.0 (0.197) ilaa <15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aHaddii amarka iibsigu caddeeyo dulqaadka laga jaray dhumucda gidaarka oo ka yar qiimaha lagu dabaqi karo shaxdan, dulqaadka lagu daray dhumucda gidaarka waa in lagu kordhiyaa qadar ku filan si loo ilaaliyo xadka dulqaadka lagu dabaqi karo. bTuubbada leh D2 355.6 mm (14.000 in.) iyo 1 2 25.0 mm (0.984 in.), dulqaadka dhumucda gidaarka gudaha waxa laga yaabaa in uu dhaafo dulqaadka lagu daray dhumucda gidaarka 0.05t dheeraad ah, waase haddii dulqaadka lagu daray cufka (eeg 9.14) lama dhaafin. cDulqaadka dheeriga ah ee dhumucda gidaarka ma khusayso aagga alxanka. dEeg 9.13.2 xayiraado dheeraad ah. | |

Length Deviation

Dulqaadyada tuubooyinka dhererkoodu go'an yahay: leexashada dhererku waa inay noqotaa 500 mm (20 inji).

Dulqaadyada dhuumaha dhererka random:

| Shaxda 12-Dulqaadka Tubooyinka Dhererka Random | |||

| Dhererka Random Magacaabidda m (ft) | Dhererka ugu Yar m (ft) | Dhererka Celceliska Ugu Yar Shay kasta oo Dalbo ah m (ft) | Dhererka ugu badan m (ft) |

| Dhuumaha xadhig-iyo-isku-xidhan | |||

| 6 (20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72 (45.0 |

| Dhuumaha-dhamaadka cad | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72 (45.0) |

| 15 (50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

Toosannimada leexleexda

Isugeynta ka leexashada xariiqda toosan ee dhererka tuubada oo dhan waa inay noqotaa <0.2% dhererka tuubada;

Ka leexashada maxalli ah ee xariiq toosan waa in ay ahaataa <3.2 mm (0.125 in) in ka badan 1.5 m (5.0 ft) dhererka tubo kasta.

Xagasha Bevel

Tuubbada leh t> 3.2 mm (0.125 in) cidhifyada fidsan waa in lagu farsameeyaa alxanka xagal 30°-35°.

Ballaca Dusha Xididka La Sameeyey

1.6 mm (0.063 in) oo leh leexsan ± 0.8 mm (0.031 in).

Kala duwanaanshaha xagasha koontada gudaha (kaliya ee tuubada birta aan fiicnayn)

| Shaxda 13-Xagalka ugu badan ee Taper gudaha ee tuubada SMLS | |

| Dhumucda gidaarka ee cayiman t mm (gud) | Xagasha ugu badan ee Taper shahaadooyinka |

| <10.5 (0.413) | 7.0 |

| 10.5 (0.413) ilaa <14.0 (0.551) | 9.5 |

| 14.0 (0.551) ilaa <17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

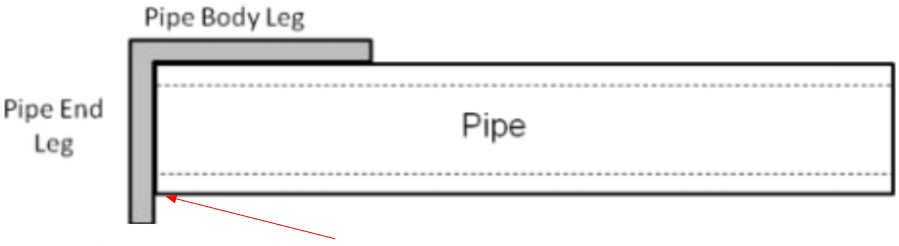

Pipe End squareness (kabaxsan-squareness)

Ka-baxsanaanta-squareness waxaa lagu qiyaasaa sida farqiga u dhexeeya dhamaadka tuubada iyo lugta dhamaadka tuubada, kaas oo noqon doona 1.6 mm (0.063 in.).

Welding Tolleynta

Xarigga/Xaashka Qaldan:

Tuubbooyinka korantada-welded (EW) iyo laysarka-welded (LW), qallafsanaantu waa inaysan ka dhalan dhumuc darbiga haray ee alxanka kaas oo ka yar dhumucda derbiga ugu yar ee la oggol yahay.

Tuubbada Welded Submerged Arc welded (SAW) iyo isku-dhafka welded (COW), is-waafajintu waa inaysan dhaafin qiyamka u dhigma ee lagu sheegay Shaxda 14 ee API 5L.

Burrs (EW) iyo tuubooyinka laysarka-welded (LW):

Burooyinka dibadda waa in laga saaraa si aad u nadiif ah (oo leh walxaha salka).

Burburka guduhu waa in aanu dhaafin 1.5 mm (0.060 in) wixii ka dambeeya dariiqa tuubada, dhumucda gidaarka meesha laga saarayo burka waa in aanu ka yarayn dhumucda gidaarka ugu yar ee la ogolyahay.

Weld Dhererka(Alxanka Arc-ga Hoostiisa (SAW) iyo Tuubbooyinka Isku-dhafka ah (COW)):

Ka saar dhererka hadhay ee alxanka gudaha ugu yaraan 100 mm (4.0 in) ee dhamaadka tuubada ee cidhif kasta oo tuubada, oo shiiddo alxanka si aanu u kicin in ka badan 0.5 mm (0.020 in) oogada sare tuubada ku xigta.

API 5L Walxaha Tijaabada

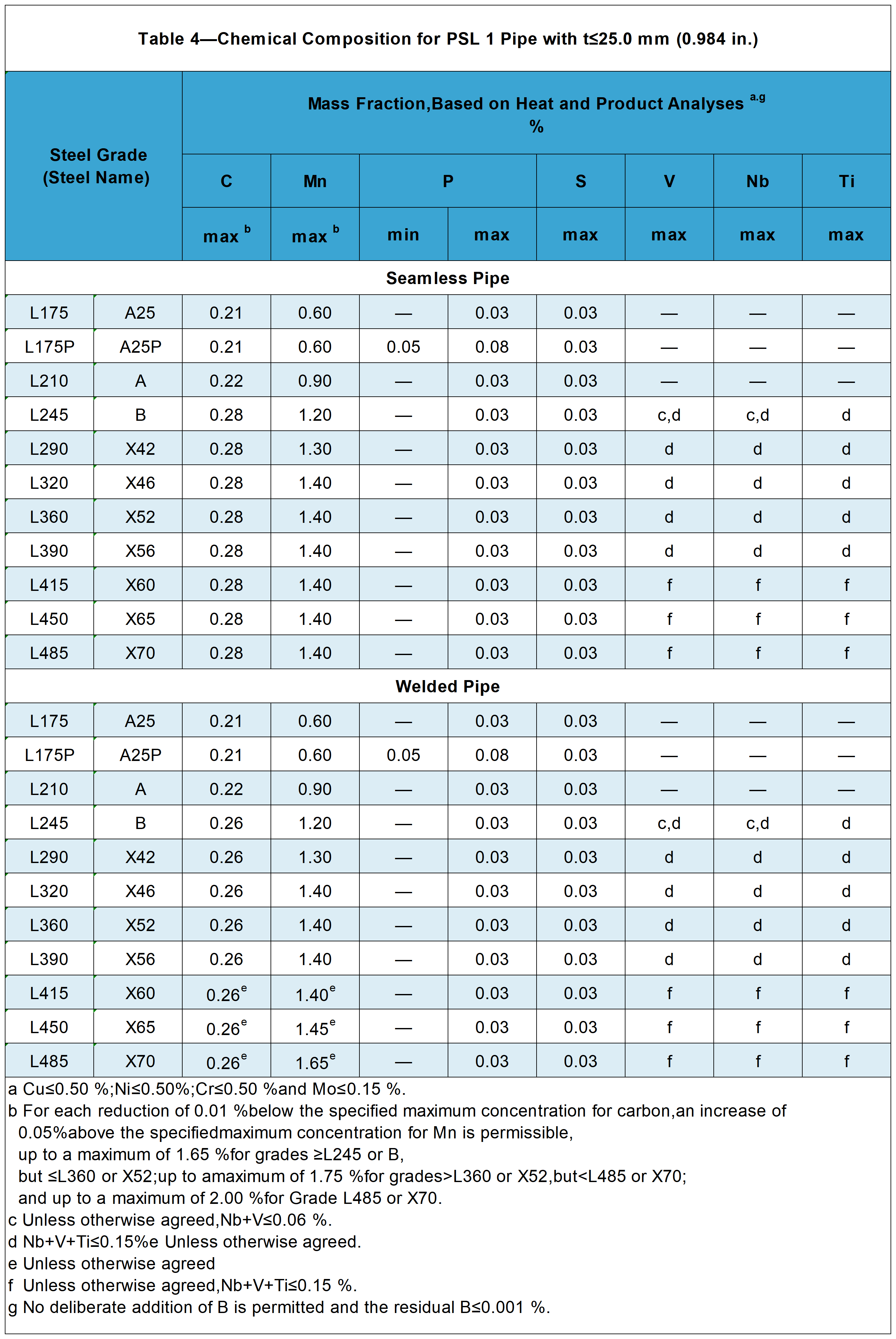

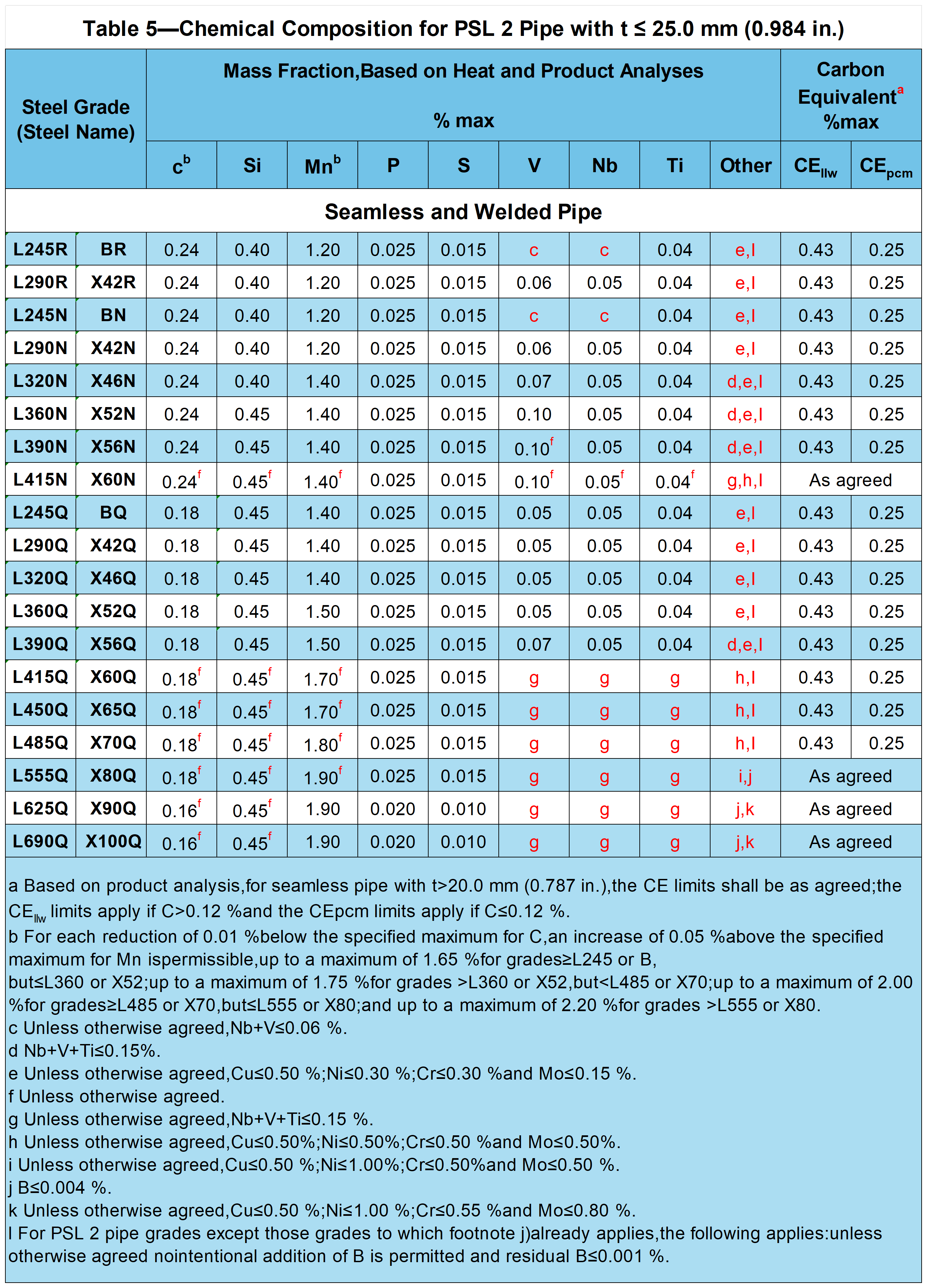

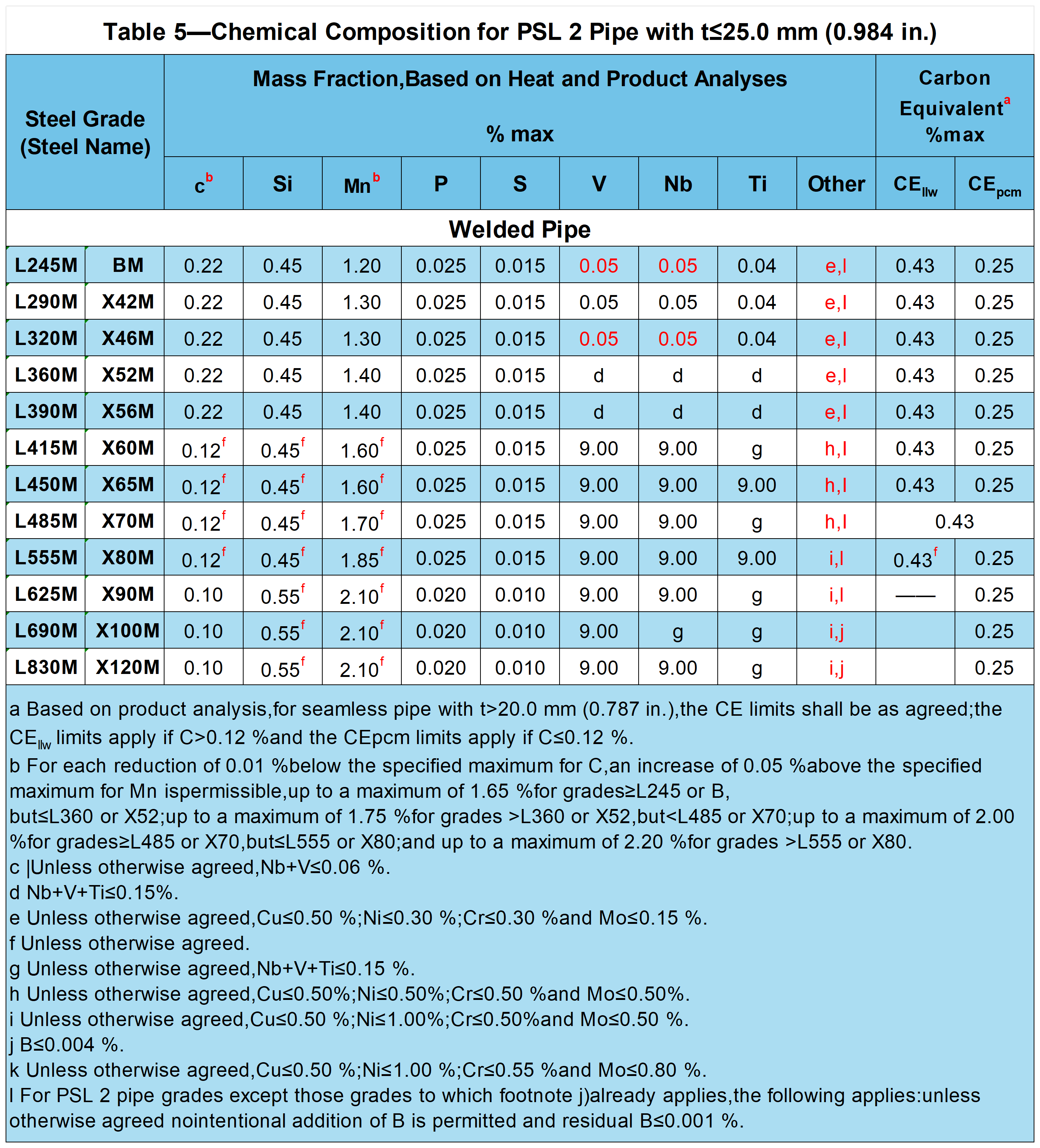

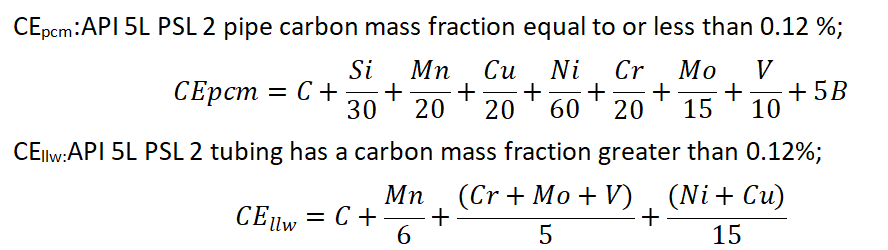

Halabuurka Kiimikada

Habka Tijaabada: Tixraac ISO 9769 ama ASTM A751.

Halabuurka kiimikada API 5L PSL1 iyo API 5L PSL2 birta birta t> 25.0 mm (0.984 in) waa in lagu go'aamiyaa gorgortan ku salaysan halabuurka kiimikaad ee miisaska u dhigma.

Halabuurka Kiimikada ee PSL 1 Dhuumaha leh t≤25.0 mm (0.984 in.)

Halabuurka Kiimikada ee PSL 2 Dhuumaha leh t≤25.0 mm (0.984 in.)

Guryaha Jilicsan

Hababka Imtixaanka: Waa in lagu sameeyaa si waafaqsan ISO 6892-1 ama ASTM A370.

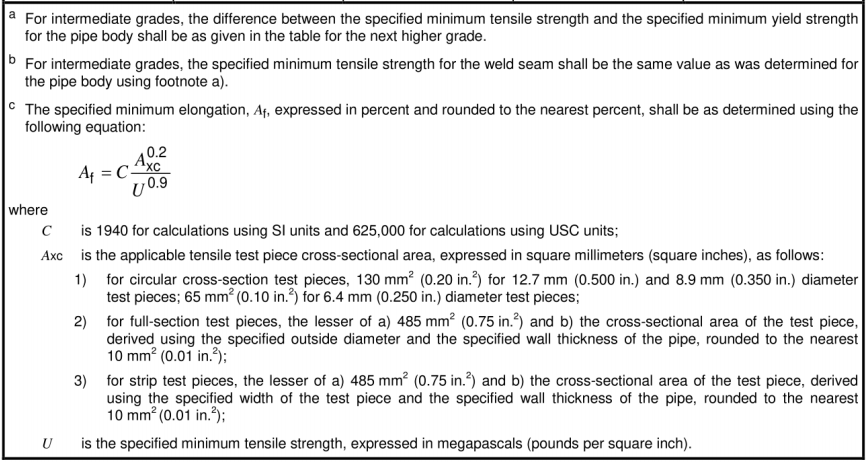

Shuruudaha Natiijooyinka Tijaabooyin Jilicsan oo loogu talagalay PSL 1 Pipe

| Shaxda 6-Shuruudaha Natiijooyinka Tijaabada Jilitaanka ee PSL 1 Pipe | ||||

| Heerka Dhuumaha | Jidhka Dhuumaha ee Dhuumaha Aan Xun iyo Alxan lahayn | Weld Seam ee EW, LW, SAW, iyo Dhuumaha Lo'da | ||

| Xoogga Wax-soo-saarkaa Rku.5 MPa(psi) | Xoogga Jilicsana Rm MPa(psi) | Dheeraynta (oo ku saabsan 50 mm ama 2 in.) Af % | Xoogga Jilicsanb Rm MPa(psi) | |

| min | min | min | min | |

| L175 ama A25 | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L175P ama A25P | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L210 ama A | 210 (30,500) | 335 (48,600) | c | 335 (48,600) |

| L245 ama B | 245 (35,500) | 415 (60,200) | c | 415 (60,200) |

| L290 ama X42 | 290 (42,100) | 415 (60,200) | c | 415 (60,200) |

| L320 ama X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 ama X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) |

| L390 ama X56 | 390 (56,600) | 490 (71,100) | c | 490 (71,100) |

| L415 ama X60 | 415 (60,200) | 520 (75,400) | c | 520 (75,400) |

| L450 ama X65 | 450 (65,300) | 535 (77,600) | c | 535 (77,600) |

| L485 ama X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

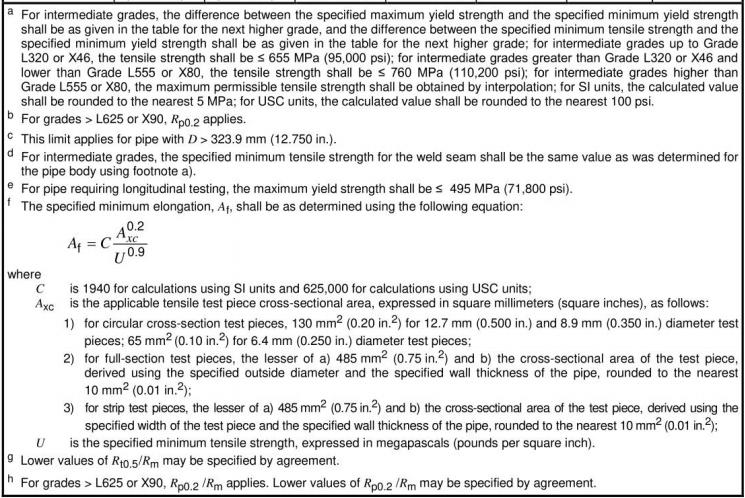

Shuruudaha Natiijooyinka Tijaabooyin Xasillooni ah oo loogu talagalay PSL 2 Pipe

| Shaxda 7-Shuruudaha Natiijooyinka Tijaabada Jilitaanka ee PSL 2 Pipe | |||||||

| Heerka Dhuumaha | Jidhka Dhuumaha ee Dhuumaha Aan Xun iyo Alxan lahayn | Weld tolid ee HFW SAW iyo Dhuumaha CoW | |||||

| Xoogga Wax-soo-saarkaa Rto.5 MPa(psi) | Xoogga Jilicsana Rm MPa (psi) | Saamigaac Rt0.5/Rm | Dheeraynta (ku saabsan 50 mm ama 2 in.) Af % | Jilicsan Xoogd Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R ama BR L245N ama BN L245Q ama BQ L245M ama BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R ama X42R L290N ama X42N L290Q ama X42Q L290M ama X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N ama X46N L320Q ama X46Q L320M ama X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N ama X52N L360Q ama X52Q L360M ama X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N ama X56N L390Q ama X56Q L390M ama X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N ama X56N L390Q ama X56Q L390M ama X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N ama X60N L415Q ama X60Q L415M ama X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q ama X65Q L450M ama X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q ama X70Q L485M ama X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q ama X80Q L555M ama X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M ama X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q ama X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M ama X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q ama X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M ama X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Kordhinta boqolleyda xilliga nasashada waa in lagu soo wargeliyaa shaybaarrada leh dhererka cabbirka 50 mm (2 in).

Tijaabooyin dhererkoodu ka yar yahay 50 mm (2 in) dhererka nasashada waa in loo beddelaa dhererka 50 mm (2 in) sida waafaqsan ISO 2566-1 ama ASTM A370.

Baaritaanka Cadaadiska Hydrostatic

Habka tijaabada: API 5L 10.2.6.

Dhammaan xajmiyada tuubooyinka bilaa-xarafka ah (SMLS) iyo tuubooyinka alxanka leh ee leh D ≤ 457 mm (18.000 in) waa inay lahaadaan wakhtiga xasilinta oo aan ka yarayn 5 ilbiriqsi.Dhuumaha alxanka leh ee leh D> 457 mm (18.000 in) waa in ay lahaadaan waqti xasilin oo aan ka yarayn 10 ilbiriqsi.

Qallooca Tijaabada

Hababka Tijaabada: Imtixaanka foorarsiga waa inuu waafaqaa shuruudaha ISO 8491 ama ASTM A370.

Qayb ka mid ah muunada waa in aan dillaacin alxankuna ma dillaaci doono.

Darajada L175P/A25P waa bir kor u qaaday fosfooraska oo bixisa waxqabadka dunta ka wanaagsan L175/A25 birta laakiin way adagtahay in la leexiyo.

Tijaabada fidsan

Hababka Tijaabada: Tijaabadu waa inay u hoggaansamaan shuruudaha ISO 8492 ama ASTM A370.

Masaafada u dhaxaysa labada taarikada waa inay ahaataa mid aan dillaacin alxanka ilaa inta la cayimay la gaarayo.

Tijaabada qalooca ee la hagayo

Hababka Tijaabada: Imtixaanka foorarsiga ee la hagayo waa inuu u hoggaansamaa shuruudaha ISO 5173 ama ASTM A370.

Imtixaan Adag

Habka Tijaabada: Tijaabada adag sida ISO 6506, ISO 6507, ISO 6508, ama ASTM A370.

Marka tuhun adag laga helo baadhista muuqaalka, tijaabiye adkaanta la qaadan karo waa in loo isticmaalo baadhista adkaanta.

Tijaabada Saamaynta CVN ee API 5L PSL2 Dhuumaha Birta

Hababka Imtixaanka: Imtixaanka saamaynta charpy waa inuu buuxiyaa shuruudaha ASTM A370.

Tijaabada DWT ee API 5L PSL2 Dhuumaha Welded

Habka tijaabada: Imtixaanka DWT waa inuu ahaadaa mid waafaqsan API5L3.

Baaritaanka Macro-Inspection iyo Metallographic Test

Weelashada alxanka gudaha iyo dibadda ee arc alxanka hoostiisa ah (SAW) iyo tuubooyinka isku-welded (COW) waa in lagu eegaa kormeerka maroscopic.

Tuubooyinka u baahan daaweynta kulaylka alxanka, baaritaanka biraha waa in la sameeyaa si loo xaqiijiyo in HAZ oo dhan si fiican loogu daaweeyay jihada dhumucda derbiga oo dhan.

Tuubooyinka aan u baahnayn daawaynta kulaylka alxanka, baadhista biraha waa in la sameeyaa si loo xaqiijiyo in aanay jirin hadhaaga martensite aan dabci lahayn.

Tijaabada Aan Burbursanayn (kaliya saddex ujeedo gaar ah API 5L PSL2 tuubooyinka)

Habka tijaabada: API 5L Annex E.

Calaamadaynta Dhuumaha iyo Goobta

Waxyaabaha calaamadaynta caadiga ah ee tuubooyinka birta:

Magaca ama calaamadaynta soo saaraha tuubooyinka;

Calaamadaynta "API Spec 5L".(Guud ahaan loo soo gaabiyo API 5L.) Alaabooyinka u hoggaansamaya in ka badan hal halbeeg oo ku habboon ayaa laga yaabaa in lagu calaamadiyo magaca halbeeg kasta.

Dhexdhexaad ka baxsan oo cayiman

Dhumucdiisuna waxay cayiman tahay

Heerka tuubada (magaca birta)

Nooca tuubada

Dhererka (dhererka tuubada m ilaa kan ugu dhow 0.01 m (ft ilaa tobnaadka cag ee ugu dhow))

Goobta calaamadaha tuubooyinka birta

D ≤ 48.3 mm (1.900 in) tuubooyin bir ah: Taabooyin si joogto ah loogu sameeyay dhererka tuubada birta ama lagu xidhi karo xidhmada tuubada birta.

Dhuumaha D> 48.3 mm (1.900 in):

Dusha bannaanka: Laga bilaabo barta bannaanka ee tuubada inta u dhaxaysa 450 mm iyo 760 mm (1.5 ft iyo 2.5 ft) laga bilaabo hal daraf ee tuubada.

Dusha gudaha: Bilow calaamadaynta dusha gudaha ee tuubada ugu yaraan 150 mm (6.0 in) ka soo cidhifkeeda.

Heerka u dhigma

Heerarka tuubooyinka caalamiga iyo kuwa goboleed ee API 5L u dhigma ama, xaaladaha qaarkood, ikhtiyaarka beddelka ah, iyo sidoo kale tiro heerar codsi gaar ah:

Heerarka caalamiga ah iyo kuwa gobolka

1. ISO 3183 - Heerka dhuumaha caalamiga ah ee warshadaha saliidda iyo gaaska oo ay daabacday Ururka Caalamiga ah ee Halbeega oo si dhow ula xiriira API 5L.

TS EN 10208 - Heerka Yurub ee tuubooyinka birta ee qaadista gaaska shidaalka iyo dareeraha

3. GB / T 9711 - Heerka qaranka Shiinaha ee nidaamka gaadiidka dhuumaha ee warshadaha saliidda iyo gaaska.

4. CSA Z245.1 - Heerka Kanadiyaanka ee daboolaya dhuumaha khadka ee gaadiidka saliidda iyo gaasta.

5. GOST 20295 - Heerka Ruushka ee tuubada khadka birta ee gaadiidka saliidda iyo saliidda.

6. IPS (Heerarka Shidaalka Iiraan) - Heerarka Shidaalka Iiraan ee dhuumaha khadka ee warshadaha saliidda iyo gaaska.

7. JIS G3454, G3455, G3456 - Heerarka Warshadaha Japan ee tuubooyinka gudbinta ee heerarka cadaadiska kala duwan.

8. DIN EN ISO 3183 - Heerka Warshadaha Jarmalka oo ku saleysan ISO 3183 tuubooyinka khadka.

9. AS 2885 - Heerka Australia ee nidaamyada dhuumaha khadka ee gaadiidka saliidda iyo gaasta.

Codsiga Heerarka Gaarka ah

1. API 5CT - Heerka Machadka Batroolka Mareykanka ee daboolka ceelasha saliidda iyo tubbada, taas oo, in kasta oo ugu horrayn loo isticmaalo ceelasha saliidda, sidoo kale waxay muhiim u tahay warshadaha saliidda iyo gaaska.

2. ASTM A106 - Bulshada Maraykanka ee Tijaabinta iyo Qalabka Halbeegyada tubada birta kaarboonka ee aan xidhnayn iyo alxanka ee adeega heerkulka sare.

3. ASTM A53 - Machadka Qaranka ee Tijaabinta iyo Qalabka Heerka ee tuubada birta kaarboonka ee aan xidhnayn iyo alxanka, sida caadiga ah loo isticmaalo gaadiidka dareeraha heerkulka qolka ama heerkulka hoose.

4. TS ISO 3834 - Ururka Caalamiga ah ee Halbeegga ee shuruudaha tayada, diiradda saaraya nidaamyada hubinta tayada biraha alxanka leh.

5. dnv-os-f101 - Heerka bulshada Norway ee nidaamka tuubooyinka biyaha hoostooda ee dhuumaha gudbinta saliidda iyo gaaska badda.

6. MSS SP-75 - Halbeegyada Halbeegga Soosaarayaasha ee diiradda saaraya xoogga sare, dhexroorka weyn ee xirmooyinka tuubooyinka birta ah ee alxanka leh.

Maareynta Tayada iyo Heerarka Ku Habboonaanta Deegaanka

1. NACE MR0175/ISO 15156 - Shuruudaha agabka loo isticmaalo soo saarista saliidda iyo gaasta ee deegaanka sulfur-ka kooban ee hydrocarbon, kuwaas oo, iyada oo ugu horreyn khusaysa xulashada walxaha, ay muhiim u tahay hubinta iska caabbinta daxalka ee alaabta loo isticmaalo warshadaha saliidda iyo gaaska.

Alaabtayada laxidhiidha

API 5L PSL1&PSL2 GR.B Dhuumaha dhaadheer

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Dhuumaha Birta Kaarboon

API 5L GR.B Dhumucda Derbiga Culus ee Dhuumaha Birta ah ee Farsamada leh

API 5L Gr.X52N PSL 2 Dhuumaha Birta Aan Xun Lahayn ACC.U socda IPS-M-PI-190(3) & NACE MR-01-75 ee adeega dhanaan

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Saliida iyo Gaaska Kaarboonka ee Dhuumaha Biraha ah

API 5L GR.B Dhuumaha Khadka Tooska ah ee Cadaadiska iyo Dhismaha

API 5L/ASTM A106/ASTM A53 Gr.B Dhuumaha Birta Kaarboon-ka

BotopSteel waa khabiir Shiinaha ahSoo saaraha Tubooyinka Kaarboon-Birta Alxanka leh & Soo-saareyaashaIn ka badan 16 Sano oo leh 8000+ Tan oo Tubooyin Khad La'aan ah oo kayd ah bil kasta.Waxaan diyaar u nahay inaan kuugu soo jawaabno 24 saacadood gudahood ka dib markaan helno hal codsi iyo sidoo kale inaan horumarino faa'iidooyinka aan xadidnayn iyo abaabulka labada dhinac ee suurtagalka ah.

tags: API 56 46th, Weedha cabbirka, PSL1, PSL2,alaab-qeybiyeyaal, warshadeeyayaal, warshado, saamiley, shirkado, jumlo, gad, qiimo, xigasho, bulk, iib, kharash.

Waqtiga boostada: Mar-22-2024