AS/NZS 1163qeexaa qabow-sameeyey, caabbinta-alxanka, qaab-dhismeedka birta godan qaybaha tuubooyinka ee codsiyada dhismaha guud iyo injineernimada iyada oo aan daaweyn kulaylka xiga.

Nidaamyada caadiga ah ee lagu dabaqi karo Australia iyo New Zealand.

Badhamada navigation

Kala-soocidda Qaab-Qaybta-isku-tallaabta

AS/NZS 1163 Kala saarida Fasalka Dhexe

Walxaha ceeriin

Habka wax-soo-saarka

AS/NZS 1163 Halabuurka Kiimikada

AS/NZS 1163 Tijaabada Xakamaynta

AS/NZS 1163 Tijaabada Saamaynta

Tijaabada Qabow

Imtixaan aan burburin

Dulqaadyada Qaabka iyo Mass

Dulqaadka Dhererka

AS/NZS 1163 SSHS Liiska Cabbirka Dhuumaha iyo Miisaska Miisaanka ee lagu daray

Dayactirka Cilladaha Dibadda iyo Qurxinta

galvanized

AS/NZS 1163 Calaamadaynta

Codsiyada AS/NZS 1163

Alaabtayada laxidhiidha

Kala-soocidda Qaab-Qaybta-isku-tallaabta

Saddex nooc oo AS/NZS 1163 ah ayaa loo kala saari karaa iyadoo loo eegayo qaabka qaybta iskutallaabtu, kuwaas oo kala ah:

Qaybaha godan ee wareegtada ah (CHS)

Qaybaha godan ee afargeeska ah (RHS)

Qaybaha bannaan ee labajibbaaran (SHS)

Ujeeddada maqaalkani waa in la soo koobo shuruudaha tuubooyinka birta ee leh qaybo godan oo wareeg ah.

AS/NZS 1163 Kala saarida Fasalka Dhexe

Saddex darajo AS/NZS 1163 oo ku salaysan awoodda wax-soosaarka ugu yar (MPA) ee alaabta la dhammeeyey:

C250, C350 iyo C450.

U dhiganta 0 ℃ heerka tijaabada heerkulka hooseeya ee tuubada birta ah ay buuxin karto:

C250L0, C350L0 iyo C450L0.

Heerku waxa kale oo uu dhigayaa in habka saxda ah ee lagu muujinayo heerka tuubada birta ay tahay:

AS/NZS 1163-C250 or AS/NZS 1163-C250L0

Walxaha ceeriin

gariiradda kulul ama gariiradda qabow-duuban

Gariiradda qabow-rogidku waa gariiradda kulul ee duuban oo lagu sameeyay hoos u dhac qabow oo ka badan 15%.Gariiradu waa inay lahaataa wareeg hoosaysa oo dib u qaabaynaysa oo samaysa miro ferrite oo cusub.Waxyaabaha soo baxay waxay la mid yihiin gariiradda kulul ee duuban.

Birta hadhuudhka leh ayaa lagu qeexaa inay tahay alaabta ceeriin ee gariiradda birta.Biraha leh cabbirka hadhuudhka austenitic ee lambarka 6 ama ka fiican marka la tijaabiyo si waafaqsan AS 1733.

Birtan waxaa soo saara habka Ogsajiinta Aasaasiga ah (BOS) ama Farsamada Furnace ee Korontada (EAF) waxaana laga yaabaa in lagu sifeeyo Vacuum Arc Remelting (VAR), Electroslag Remelting (ESR), ama hababka labaad ee birta samaynta sida Vacuum Degassing ama Calcium Injection .

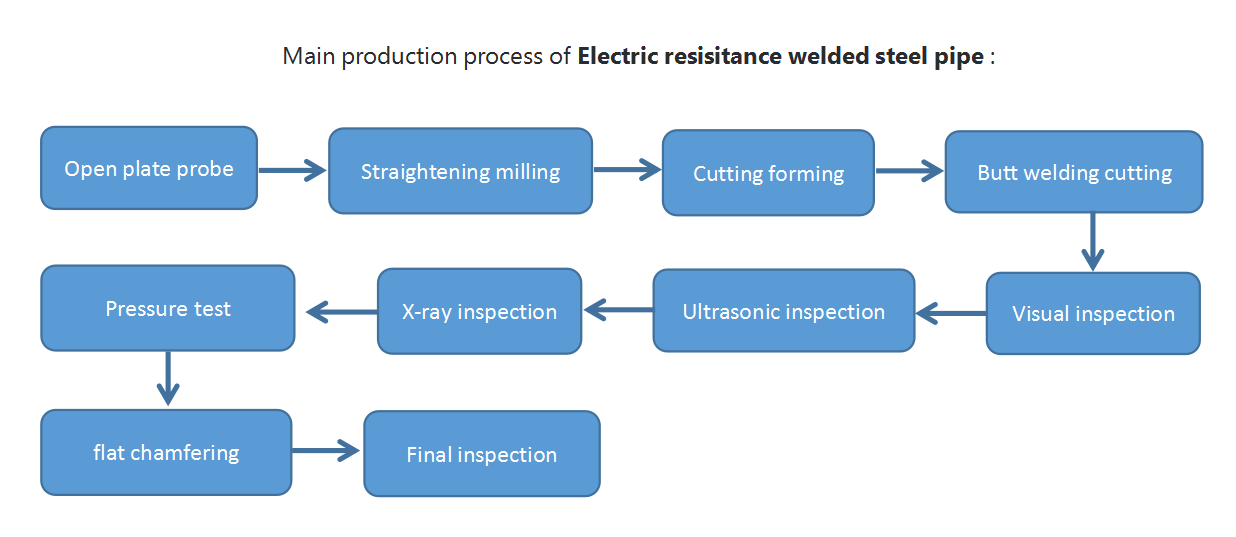

Habka wax-soo-saarka

Badeecada qaybta bannaan ee dhammaatay waa in lagu soo saaraa habka qabow-samaynta iyo isticmaalkaAlxanka caabbinta korantada (ERW)farsamooyinka lagu biiro cidhifyada strip.

Tollaynta alxanka waa in ay noqotaa mid dherer ah oo laga saaro xanaaqa dibadda.

Ma jiri doonto daawaynta kulaylka guud ee soo socota ee alaabta la dhammeeyey.

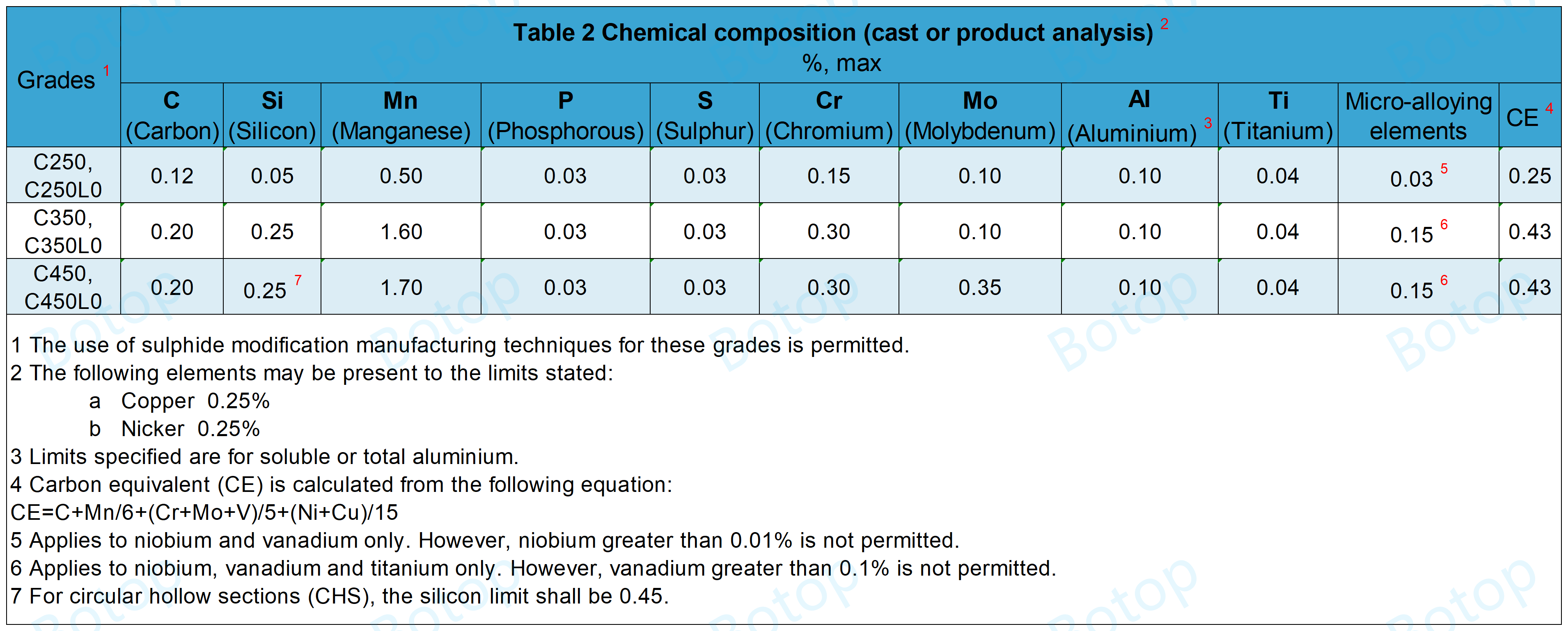

AS/NZS 1163 Halabuurka Kiimikada

AS/NZS 1163 ee tijaabinta halabuurka kiimikada waxa loo qaybiyaa laba xaaladood:

Hal kiis ayaa ah alaabta ceeriin ee baaritaanka isku dhafka kiimikada,

Midda kale waa baaritaanka dhuunta birta ee dhammaatay.

Falanqaynta Casriyeynta ee Birta

Falanqaynta kabka ee birta waa in laga sameeyaa kulayl kasta si loo go'aamiyo saamiga walxaha la cayimay.

Xaaladaha ay tahay wax aan macquul aheyn in laga helo muunado birta dareeraha ah, falanqaynta shaybaarada tijaabada ee la qaaday si waafaqsan AS/NZS 1050.1 ama ISO 14284 ayaa lagu soo warrami karaa inay tahay falanqaynta shubka.

Falanqaynta kabka ee birta waa inay u hoggaansamaan xadka darajada ku habboon ee lagu bixiyoShaxda 2.

Falanqaynta Kiimikada ee Alaabta Dhammaatay

AS/NZS 1163kuma amro in la tijaabiyo ka kooban kiimikaad ee sheyga u dambeeya.

Haddii baaritaanka la sameeyo, waa in ay u hoggaansamaan xadka lagu siiyayShaxda 2iyo dulqaadka la siiyayShaxda 3.

| SHAXDA 3 Dulqaadyada falanqaynta badeecada ee darajooyinka lagu bixiyay shaxda 2 | |

| Curiyaha | Dulqaad ka sarreeya xadka ugu sarreeya |

| C(Kaarboon) | 0.02 |

| Si(Silikoon) | 0.05 |

| Mn(Manganese) | 0.1 |

| P(phosphorous) | 0.005 |

| S(Sulfur) | 0.005 |

| Cr(Chromium) | 0.05 |

| Ni(Nikel) | 0.05 |

| Mo(Molybdenum) | 0.03 |

| Cu(Naxaas) | 0.04 |

| AI(Aluminium) (wadarta) | -0.005 |

| Walxaha alwaaxinta yar yar (niobium iyo vanadium kaliya) ee loogu talagalayFasalada C250, C250L0 | 0.06 oo leh niobium aan ka badnayn 0.020 |

| Walxaha alwaaxinta yar yar (niobium, vanadium, iyo titanium kaliya) ee FasaladaC350, C350L0, C450, C450L0 | 0.19 oo leh vanadium aan ka badnayn 0.12 |

AS/NZS 1163 Tijaabada Xakamaynta

Habka tijaabada: AS 1391.

Kahor tijaabada xajinta, muunada waa in lagu kululeeyaa heerkul aan ka yarayn 15 daqiiqo iyada oo lagu kululeynayo heerkul u dhexeeya 150°C iyo 200°C.

| Darajo | Ugu yar dhalid xoog | Ugu yar adkaysi xoog | Kordhinta ugu yar ee saami ahaan dhererka cabbirka 5.65√S0 | ||

| samee/t | |||||

| ≤ 15 | >15 ≤30 | >30 | |||

| MPA | MPA | % | |||

| C250, C250L0 | 250 | 320 | 18 | 20 | 22 |

| C350, C350L0 | 350 | 430 | 16 | 18 | 20 |

| C450, C450L0 | 450 | 500 | 12 | 14 | 16 |

AS/NZS 1163 Tijaabada Saamaynta

Habka tijaabada: at 0°C marka loo eego AS 1544.2.

Kahor tijaabada saamaynta, muunada waa in lagu kululeeyaa inta u dhaxaysa 150°C iyo 200°C wax aan ka yarayn 15 daqiiqo.

| Darajo | Tijaabi heerkulka | Tamar la nuugo ugu yar, J | |||||

| Cabbirka qaybta tijaabada | |||||||

| 10mm×10mm | 10mm×7.5mm | 10mm × 5mm | |||||

| Celcelis ahaan ee 3 imtixaan | Shakhsi imtixaan | Celcelis ahaan ee 3 imtixaan | Shakhsi imtixaan | Celcelis ahaan ee 3 imtixaan | Shakhsi imtixaan | ||

| C250L0 C350L0 C450L0 | 0℃ | 27 | 20 | 22 | 16 | 18 | 13 |

Tijaabada Qabow

Qaybta tijaabada ah waa in la simi doonaa ilaa masaafada u dhaxaysa sagxadaha ay tahay 0.75 samee ama ka yar.

Waa inayna ka muuqan calaamadaha dildilaaca ama cilladaha.

Imtixaan aan burburin

Shayga aan qasabka ahayn, alxanka qaybaha godan ee dhismayaasha alxanka ah waxa laga yaabaa in lagu sameeyo baadhitaan aan burburin (NDE).

Dulqaadyada Qaabka iyo Mass

| Nooca | Range | Dulqaad |

| Sifada | - | Qaybo bannaan oo wareeg ah |

| Cabirka dibadda (sameeyay) | - | ± 1%, oo leh ugu yaraan ± 0.5 mm iyo ugu badnaan ± 10 mm |

| Dhumucda (t) | do≤406,4 mm | 土10% |

| samee :406.4 mm | ± 10% oo leh ugu badnaan ± 2 mm | |

| Wareega ka baxsan (o) | Dhexroorka dibadda (bo)/ dhumucda gidaarka (t)≤100 | ± 2% |

| Toosanaan | dhererka guud | 0.20% |

| Cuf (m) | miisaan cayiman | ≥96% |

Dhumucda:

Dhumucda (t) waa in lagu cabbiraa meel aan ka yarayn 2t (macnaha dhumucda gidaarka 2x) ama 25 mm, hadba kii ka yar, laga bilaabo tolitaanka alxanka.

wareeg-ka-baxsan:

Ka-baxsanaanta (o) waxa bixiya :o=(domax- sameemin)/do×100

Dulqaadka Dhererka

| Nooca dhererka | Range m | Dulqaad |

| Dhererka random | 4m ilaa 16m leh kala duwan oo ah 2m per shay dalbo | 10% qaybaha la bixiyay waxa laga yaabaa inay ka hooseeyaan ugu yaraan xadka la dalbaday laakiin aan ka yarayn 75% ee ugu yar |

| dherer aan la cayimin | DHAMMAAN | 0-+100mm |

| Dhererka saxda ah | ≤ 6m | 0-+5mm |

| 6m≤10m | 0-+15mm | |

| :10m | 0-+(5+1mm/m)mm |

AS/NZS 1163 SSHS Liiska Cabbirka Dhuumaha iyo Miisaska Miisaanka ee lagu daray

Gudaha AS/NZS 1163, liisaska qaybaha godan qaab dhismeedka qabow-samaysan ee caadiga ah (SSHS) ee Australia iyo New Zealand ayaa lagu bixiyay.

Liisaskani waxay bixiyaan magacyada qaybta, cabbirrada magac-u-yaalka ah, sifooyinka qaybta, iyo tayada.

| Dhexroor ka baxsan | Dhumucda | Dhererka massperunitility | Dibadda bedka dhulka | Saamiga | |

| do | t | dhererka cutubkiiba | halkii cuf | ||

| mm | mm | kg/m | m²/m | m²/t | samee/t |

| 610.0 | 12.7CHS | 187 | 1.92 | 10.2 | 48.0 |

| 610.0 | 9.5CHS | 141 | 1.92 | 13.6 | 64.2 |

| 610.0 | 6.4CHS | 95.3 | 1.92 | 20.1 | 95.3 |

| 508.0 | 12.7CHS | 155 | 1.60 | 10.3 | 40.0 |

| 508.0 | 9.5CHS | 117 | 1.60 | 13.7 | 53.5 |

| 508.0 | 6.4CHS | 79.2 | 1.60 | 20.2 | 79.4 |

| 457.0 | 12.7CHS | 139 | 1.44 | 10.3 | 36.0 |

| 457.0 | 9.5CHS | 105 | 1.44 | 13.7 | 48.1 |

| 457.0 | 6.4CHS | 71.1 | 1.44 | 20.2 | 71.4 |

| 406.4 | 12.7CHS | 123 | 1.28 | 10.4 | 32.0 |

| 406.4 | 9.5CHS | 93.0 | 1.28 | 13.7 | 42.8 |

| 406.4 | 6.4CHS | 63.1 | 1.28 | 20.2 | 63.5 |

| 355.6 | 12.7CHS | 107 | 1.12 | 10.4 | 28.0 |

| 355.6 | 9.5CHS | 81.1 | 1.12 | 13.8 | 37.4 |

| 355.6 | 6.4CHS | 55.1 | 1.12 | 20.3 | 55.6 |

| 323.9 | 2.7CHS | 97.5 | 1.02 | 10.4 | 25.5 |

| 323.9 | 9.5CHS | 73.7 | 1.02 | 13.8 | 34.1 |

| 323.9 | 6.4CHS | 50.1 | 1.02 | 20.3 | 50.6 |

| 273.1 | 9.3CHS | 60.5 | 0.858 | 14.2 | 29.4 |

| 273.1 | 6.4CHS | 42.1 | 0.858 | 20.4 | 42.7 |

| 273.1 | 4.8CHS | 31.8 | 0.858 | 27.0 | 56.9 |

| 219.1 | 8.2CHS | 42.6 | 0.688 | 16.1 | 26.7 |

| 219.1 | 6.4CHS | 33.6 | 0.688 | 20.5 | 34.2 |

| 219.1 | 4.8CHS | 25.4 | 0.688 | 27.1 | 45.6 |

| 168.3 | 71CHS | 28.2 | 0.529 | 18.7 | 23.7 |

| 168.3 | 6.4CHS | 25.6 | 0.529 | 20.7 | 26.3 |

| 168.3 | 4.8CHS | 19.4 | 0.529 | 27.3 | 35.1 |

| 165.1 | 5.4CHS | 21.3 | 0.519 | 24.4 | 30.6 |

| 165.1 | 5.0CHS | 19.7 | 0.519 | 26.3 | 33.0 |

| 165.1 | 3.5CHS | 13.9 | 0.519 | 37.2 | 47.2 |

| 165.1 | 3.0CHS | 12.0 | 0.519 | 43.2 | 55.0 |

| 139.7 | 5.4CHS | 17.9 | 0.439 | 24.5 | 25.9 |

| 139.7 | 5.0CHS | 16.6 | 0.439 | 26.4 | 27.9 |

| 139.7 | 3.5CHS | 11.8 | 0.439 | 37.3 | 39.9 |

| 139.7 | 3.0CHS | 10.1 | 0.439 | 43.4 | 46.6 |

| 114.3 | 6.0CHS | 16.0 | 0.359 | 22.4 | 19.1 |

| 114.3 | 5.4CHS | 14.5 | 0.359 | 24.8 | 21.2 |

| 114.3 | 4.8CHS | 13.0 | 0.359 | 27.7 | 23.8 |

| 114.3 | 4.5CHS | 12.2 | 0.359 | 29.5 | 25.4 |

| 114.3 | 3.6CHS | 9.83 | 0.359 | 36.5 | 31.8 |

| 114.3 | 3.2CHS | 8.77 | 0.359 | 41.0 | 35.7 |

| 101.6 | 5.0CHS | 11.9 | 0.319 | 26.8 | 20.3 |

| 101.6 | 4.0CHS | 9.63 | 0.319 | 33.2 | 25.4 |

| 101.6 | 3.2CHS | 7.77 | 0.319 | 41.1 | 31.8 |

| 101.6 | 2.6CHS | 6.35 | 0.319 | 50.3 | 39.1 |

| 88.9 | 5.9CHS | 12.1 | 0.279 | 23.1 | 15.1 |

| 88.9 | 5.0CHS | 10.3 | 0.279 | 27.0 | 17.8 |

| 88.9 | 5.5CHS | 11.3 | 0.279 | 24.7 | 16.2 |

| 88.9 | 4.8CHS | 9.96 | 0.279 | 28.1 | 18.5 |

| 88.9 | 4.0CHS | 8.38 | 0.279 | 33.3 | 22.2 |

| 88.9 | 3.2CHS | 6.76 | 0.279 | 41.3 | 27.8 |

| 88.9 | 2.6CHS | 5.53 | 0.279 | 50.5 | 34.2 |

| 76.1 | 5.9CHS | 10.2 | 0.239 | 23.4 | 12.9 |

| 76.1 | 4.5CHS | 7.95 | 0.239 | 30.1 | 16.9 |

| 76.1 | 3.6CHS | 6.44 | 0.239 | 37.1 | 21.1 |

| 76.1 | 3.2CHS | 5.75 | 0.239 | 41.6 | 23.8 |

| 76.1 | 2.3CHS | 4.19 | 0.239 | 57.1 | 33.1 |

| 60.3 | 5.4CHS | 7.31 | 0.189 | 25.9 | 11.2 |

| 60.3 | 4.5CHS | 6.19 | 0.189 | 30.6 | 13.4 |

| 60.3 | 3.6CHS | 5.03 | 0.189 | 37.6 | 16.8 |

| 48.3 | 5.4CHS | 5.71 | 0.152 | 26.6 | 8.9 |

| 48.3 | 4.0CHS | 4.37 | 0.152 | 34.7 | 12.1 |

| 48.3 | 3.2CHS | 3.56 | 0.152 | 42.6 | 15.1 |

| 42.4 | 4.9CHS | 4.53 | 0.133 | 29.4 | 8.7 |

| 42.4 | 4.0CHS | 3.79 | 0.133 | 35.2 | 10.6 |

| 42.4 | 3.2CHS | 3.09 | 0.133 | 43.1 | 13.3 |

Dayactirka Cilladaha Dibadda iyo Qurxinta

Muuqashada

Alaabta la dhammeeyey waa bilaash cilladaha wax u dhimaya hufnaanta qaabdhismeedka maaddada.

Ka saarida cilladaha dusha sare

Marka cilladaha dusha sare laga saaro ciid, aagga ciidda leh waa inuu lahaadaa kala-guur wanaagsan.

Dhumucda gidaarka hadhay ee aagga ciiddu waa in aanay ka yarayn 90% dhumucda magaca.

Dayactirka alxanka cilladaha dusha sare

Alxanku waa inuu ahaadaa mid wanaagsan, alxanka oo si fiican loo isku daray iyada oo aan la gooyn ama la is dul saarin.

Birta alxanka ah waa in ay ka sarraysaa ugu yaraan 1.5 mm oogada duuban, birta wax soo saartana waa in laga saaraa iyada oo la shiidi doono oogada duuban.

galvanized

Qaybaha bannaan ee wareegsan ee galvanized oo leh dhexroor ka baxsan ≤ 60.3 mm iyo qaybo kale oo qaabaysan oo godan oo cabbir u dhigma waa in ay u adkeysan karaan 90 ° foorori agagaarka mandrel jeexan.

Dahaarka galvanized waa in uusan muujin calaamado dildilaac ah ama cillad ka dib qalooca shaqada.

AS/NZS 1163 Calaamadaynta

Kuwa soo socdaa waxay ka muuqdaan ugu yaraan hal mar calaamadaynta tuubada birta.

(a) Magaca ama calaamadda soo saaraha, ama labadaba.

(b) Goobta ama aqoonsiga warshadaynta, ama labadaba.

(c) Aqoonsiga qoraalka ee gaarka ah, raadraac kara, kaas oo noqon doona mid ama labada nooc ee soo socda:

(i) Waqtiga iyo taariikhda la soo saaray alaabta.

(ii) Nambar aqoonsi oo taxane ah oo loogu talagalay xakamaynta/xaqiijinta tayada iyo ujeedooyinka raadraaca.

Tusaale:

BOTOP CHINA AS/NZS 1163-C350L0 457×12.7CHS×12000MM TUBE NO.001 kulayl NO.000001

Codsiyada AS/NZS 1163

Dhismayaasha Dhismaha iyo Injineerinka: Waxaa loo adeegsadaa qaab-dhismeedka taageerada dhismayaasha, sida dhismayaasha dhaadheer iyo garoomada.

Goobaha Gaadiidka: Waxaa loo isticmaalaa dhismaha buundooyinka, tunnelyada, iyo kaabayaasha tareenada.

Saliidda, Gaaska, iyo Macdanta: loo isticmaalo dhisidda ceelasha saliidda, qalabka macdanta, iyo hababka gaadiidka qaada ee la xidhiidha.

Warshadaha kale ee culus: oo ay ku jiraan qaab-dhismeedka qaab-dhismeedka dhirta wax-soo-saarka iyo mashiinnada culus.

Alaabtayada laxidhiidha

Waxaan nahay soo saaraha tuubooyinka birta kaarboonka ah ee tayada sare leh iyo alaab-qeybiye ka yimid Shiinaha, iyo sidoo kale kaydiyaha birta birta ah, oo ku siinaya noocyo badan oo ah xalalka tuubooyinka birta!

Tags: as/nzs 1163,chs, structural, erw, alaab-qeybiyeyaal, warshadeeyayaal, warshado, saamiley, shirkado, jumlo, gad, qiimo, oraah, bulk, iib, kharash.

Waqtiga boostada: Abriil-21-2024