ASTM A252Tilmaamaha caadiga ah ee Tusmada Tubooyinka Biraha ee alxanka ah iyo kuwa aan fiicneyn.

Qeexitaanku wuxuu daboolayaa tuubooyinka birta ee magacaaban (celcelis ahaan) ee gidaarada birta ah ee qaabka cylindrical waxayna quseysaa tuubooyinka tuubooyinka taas oo dhululubada birta ay u shaqeyso sidii xubin rareyn joogto ah, ama qolof si ay u sameysato tuulo shub ah oo meel ku yaal.Tusmada tuubooyinka waxaa loo soo saaraa sidii alaab alxan leh iyo mid aan lahayn labadaba.

Badhamada navigation

ASTM A252

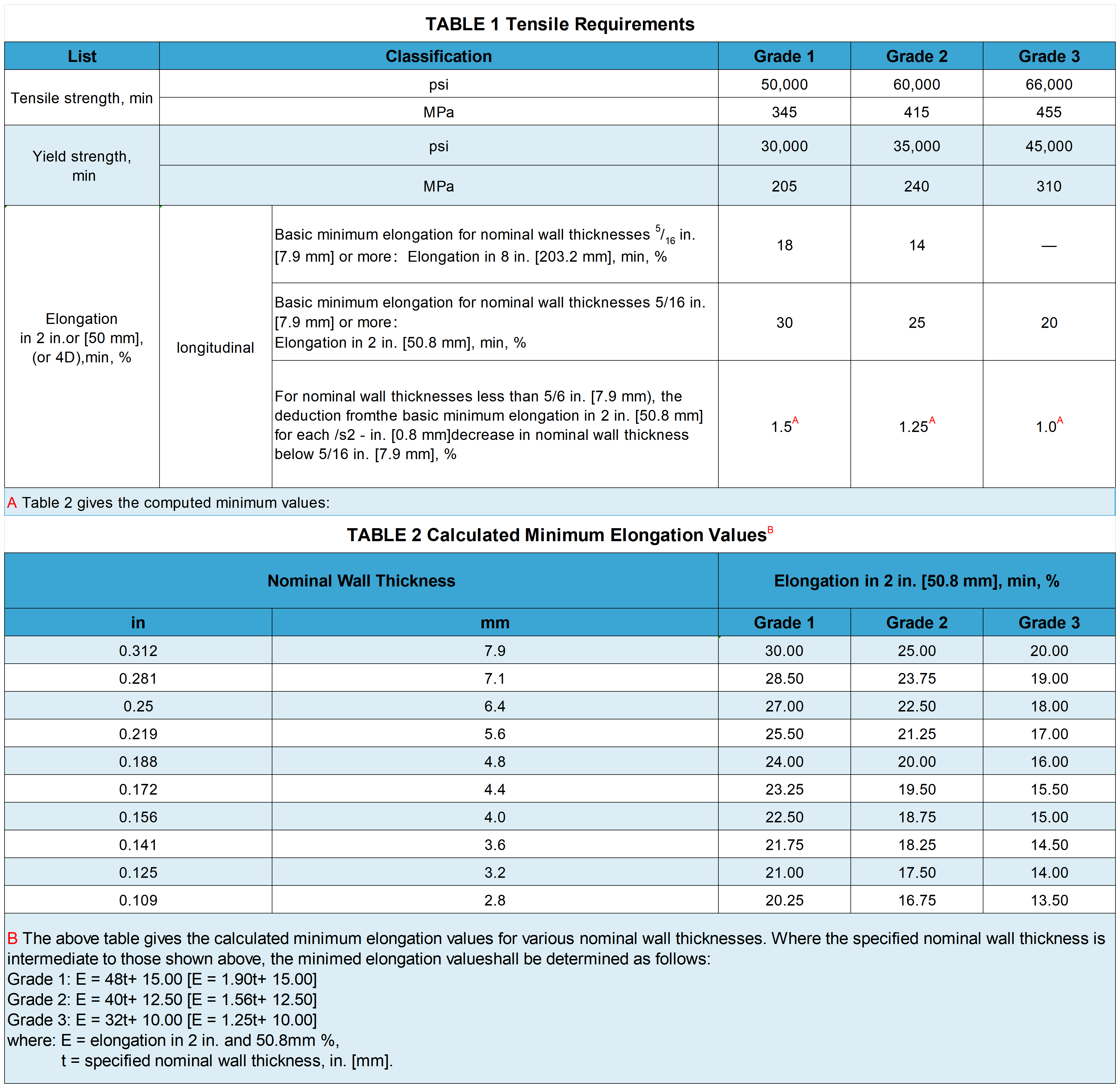

Darajooyinka ASTM A252 waxaa loo kala saaray Fasalka 1 Fasalka 2 iyoFasalka 3.

Habka Wax-soo-saarka Qalabka Ceyriinka

Birta waa in lagu sameeyaa mid ama in ka badan oo ka mid ah hababka soo socda: Qalbi-furan, oksijiin-asaasiga ah, ama foornada korontada.

Qalabka iyo wax-soo-saarka

Tuulooyinka waa in lagu sameeyaa habka alxan la'aanta, caabbinta korantada, alxanka toosan, ama habka alxanka fiyuuska.

Xirmooyinka tuulannada tuubooyinka alxanka leh waa inay ahaadaan kuwo dhaadheer, dabada-dabada, ama dhabta-jilicsan.

ASTM A252 Halabuurka Kiimikada

Habka tijaabada: ASTM A751.

Birtu waa inay ka koobnaato wax ka badan 0.050% fosfooraska.Tani waa sababta oo ah heerarka fosfooraska sare waxay keeni karaan birta inay jajabaan heerkulka hooseeya, taas oo yareyneysa adkaanta walxaha.

Tilmaamaha ASTM A252 waxay leedahay shuruudo xaddidan oo loogu talagalay isku dhafka kiimikada: tani waa sababta oo ah ASTM A252 waxay khuseysaa ugu horrayn codsiyada qaabdhismeedka, gaar ahaan sida walxaha culeyska qaada, halkaasoo astaamaha jireed (sida xoogga dhalidda, xoogga jilicsanaanta, iyo dhererka) ay aad uga muhiimsan yihiin halabuurka kiimikada .Qalabkan jireed waxaa lagu gaari karaa iyada oo loo marayo habka saxda ah ee wax soo saarka iyo daaweynta kulaylka iyada oo aan si adag loo xakameynin kiimikada ka kooban fosfooraska.

ASTM A252 Shuruudaha Xakamaynta

Habka tijaabada: ASTM A370.

Baaritaanka Cadaadiska Hydrostatic

Sababta ASTM A52 aysan u cadeynin baaritaanka hydraulicka ayaa ugu horrayn sabab u ah sifooyinka codsiga iyo shuruudaha naqshadeynta ee tuubooyinkan.

Tuulooyinka tuubooyinka birta ee ASTM A252, ujeeddada naqshadeynta aasaasiga ah waa inay u adkeyso culeysyada axial, ma aha cadaadiska gudaha.Tani waxay ka duwan tahay tuubooyinka gaadiidka dareeraha ama gaaska, sida kuwa hoos yimaada API 5L, kaas oo ay tahay in lagu sameeyo tijaabada tooska ah ee cadaadiska gudaha si loo hubiyo cidhiidhigiisa iyo xooggiisa.

Dulqaadyada cabbirka

| Dulqaadyada cabbirka | ||

| Liiska | kala soocid | baaxadda |

| Miisaanka | Miisaanka Aragtida | 95% -125% |

| Dhexroorka | Dhexdhexaad ka baxsan oo cayiman | ± 1% |

| Dhumucda | dhumucda derbiga magac ahaan la cayimay | min 87.5% |

| Dhererka | Dherer aan kala sooc lahayn oo keli ah | 16 ilaa 25 fuudh [4.88 ilaa 7.62 mitir] |

| Dhererka labanlaaban ee random | in ka badan 25 ft (7.62 m) oo leh celceliska ugu yar ee 35 ft [10.67 m] | |

| Dhererka lebbiska | dhererka sida lagu qeexay kala duwanaanshaha la ogol yahay ee ±1 in. | |

| Gariir | Tuulooyinka tuubooyinka waa in lagu dhejiyaa cidhifyo cad: Marka cidhifyada loo qoondeeyo sidii jeexan | 30°-35° |

Shaxda Miisaanka Dhuumaha

Haddii aad jeclaan lahayd inaad wax badan ka ogaatojaantusyada miisaanka iyo jadwalkaheerka caadiga ah,fadlan halkan ku dhufo!

| Dhexroor ka baxsan | Dhumucda Darbiga Magac ahaan | Miisaanka Dhererka Halbeegga | |||

| IN | MM | IN | MM | IN | MM |

| 6 | 152.4 | 0.134 | 3.40 | 8.40 | 12.50 |

| 6 | 152.4 | 0.141 | 3.58 | 8.83 | 13.10 |

| 6 | 152.4 | 0.156 | 3.96 | 9.75 | 14.50 |

| 6 | 152.4 | 0.164 | 4.17 | 10.23 | 15.20 |

| 6 | 152.4 | 0.172 | 4.37 | 10.72 | 16.00 |

| 8 | 203.2 | 0.141 | 3.58 | 11.85 | 17.60 |

| 8 | 203.2 | 0.172 | 4.37 | 14.39 | 21.40 |

| 8 5/8 | 219.1 | 0.109 | 2.77 | 9.92 | 14.80 |

| 8 5/8 | 219.1 | 0.141 | 3.58 | 12.79 | 19.00 |

| 8 5/8 | 219.1 | 0.172 | 4.37 | 15.54 | 23.10 |

| 8 5/8 | 219.1 | 0.188 | 4.78 | 16.96 | 25.30 |

| 8 5/8 | 219.1 | 0.203 | 5.16 | 18.28 | 27.20 |

| 8 5/8 | 219.1 | 0.219 | 5.56 | 19.68 | 29.30 |

| 8 5/8 | 219.1 | 0.250 | 6.35 | 22.38 | 33.30 |

| 8 5/8 | 219.1 | 0.277 | 7.04 | 24.72 | 36.80 |

| 8 5/8 | 219.1 | 0.312 | 7.92 | 27.73 | 41.20 |

| 8 5/8 | 219.1 | 0.322 | 8.18 | 28.58 | 42.50 |

| 8 5/8 | 219.1 | 0.344 | 8.74 | 30.45 | 45.30 |

| 8 5/8 | 219.1 | 0.375 | 9.53 | 33.07 | 49.30 |

| 8 5/8 | 219.1 | 0.438 | 11.13 | 38.33 | 57.10 |

| 8 5/8 | 219.1 | 0.500 | 12.70 | 43.43 | 64.60 |

| 10 | 254.0 | 0.109 | 2.77 | 11.53 | 17.20 |

| 10 | 254.0 | 0.120 | 3.05 | 12.67 | 18.90 |

| 10 | 254.0 | 0.134 | 3.40 | 14.13 | 21.00 |

| 10 | 254.0 | 0.141 | 3.58 | 14.86 | 22.10 |

| 10 | 254.0 | 0.150 | 3.81 | 15.79 | 23.50 |

| 10 | 254.0 | 0.164 | 4.17 | 17.24 | 25.70 |

| 10 | 254.0 | 0.172 | 4.37 | 18.07 | 26.90 |

| 10 | 254.0 | 0.179 | 4.55 | 18.79 | 28.00 |

| 10 | 254.0 | 0.188 | 4.78 | 19.72 | 29.40 |

| 10 | 254.0 | 0.203 | 5.16 | 21.26 | 31.70 |

| 10 | 254.0 | 0.219 | 5.56 | 22.90 | 34.10 |

| 10 | 254.0 | 0.230 | 5.84 | 24.02 | 35.70 |

| 10 | 254.0 | 0.250 | 6.35 | 26.06 | 38.80 |

| 10 3/4 | 273.1 | 0.109 | 2.77 | 12.40 | 18.50 |

| 10 3/4 | 273.1 | 0.120 | 3.05 | 13.64 | 20.30 |

| 10 3/4 | 273.1 | 0.134 | 3.40 | 15.21 | 22.60 |

| 10 3/4 | 273.1 | 0.141 | 3.58 | 15.99 | 23.80 |

| 10 3/4 | 273.1 | 0.150 | 3.81 | 17.00 | 25.30 |

| 10 3/4 | 273.1 | 0.164 | 4.17 | 18.56 | 27.70 |

| 10 3/4 | 273.1 | 0.172 | 4.37 | 19.45 | 29.00 |

| 10 3/4 | 273.1 | 0.179 | 4.55 | 20.23 | 30.10 |

| 10 3/4 | 273.1 | 0.188 | 4.78 | 21.23 | 31.60 |

| 10 3/4 | 273.1 | 0.203 | 5.16 | 22.89 | 34.10 |

| 10 3/4 | 273.1 | 0.219 | 5.56 | 24.65 | 36.70 |

| 10 3/4 | 273.1 | 0.230 | 5.84 | 25.87 | 38.50 |

| 10 3/4 | 273.1 | 0.250 | 6.35 | 28.06 | 41.80 |

| 10 3/4 | 273.1 | 0.279 | 7.09 | 31.23 | 46.50 |

| 10 3/4 | 273.1 | 0.307 | 7.80 | 34.27 | 51.00 |

| 10 3/4 | 273.1 | 0.344 | 8.74 | 38.27 | 57.00 |

| 10 3/4 | 273.1 | 0.365 | 9.27 | 40.52 | 60.30 |

| 10 3/4 | 273.1 | 0.438 | 11.13 | 48.28 | 71.90 |

| 10 3/4 | 273.1 | 0.500 | 12.70 | 54.79 | 81.60 |

| 12 | 304.8 | 0.134 | 3.40 | 17.00 | 25.30 |

| 12 | 304.8 | 0.141 | 3.58 | 17.87 | 26.60 |

| 12 | 304.8 | 0.150 | 3.81 | 19.00 | 28.30 |

| 12 | 304.8 | 0.164 | 4.17 | 20.75 | 30.90 |

| 12 | 304.8 | 0.172 | 4.37 | 21.75 | 32.40 |

| 12 | 304.8 | 0.179 | 4.55 | 22.62 | 33.70 |

| 12 | 304.8 | 0.188 | 4.78 | 23.74 | 35.40 |

| 12 | 304.8 | 0.203 | 5.16 | 25.60 | 38.10 |

| 12 | 304.8 | 0.219 | 5.56 | 27.58 | 41.00 |

| 12 | 304.8 | 0.230 | 5.84 | 28.94 | 43.10 |

| 12 | 304.8 | 0.250 | 6.35 | 31.40 | 46.70 |

| 12 | 304.8 | 0.281 | 7.14 | 35.20 | 52.40 |

| 12 | 304.8 | 0.312 | 7.92 | 38.98 | 58.00 |

| 12 3/4 | 323.9 | 0.109 | 2.77 | 14.73 | 21.90 |

| 12 3/4 | 323.9 | 0.134 | 3.40 | 18.07 | 26.90 |

| 12 3/4 | 323.9 | 0.141 | 3.58 | 19.01 | 28.30 |

| 12 3/4 | 323.9 | 0.150 | 3.81 | 20.20 | 30.10 |

| 12 3/4 | 323.9 | 0.164 | 4.17 | 22.07 | 32.90 |

| 12 3/4 | 323.9 | 0.172 | 4.37 | 23.13 | 34.40 |

| 12 3/4 | 323.9 | 0.179 | 4.55 | 24.05 | 35.80 |

| 12 3/4 | 323.9 | 0.188 | 4.78 | 25.25 | 37.60 |

| 12 3/4 | 323.9 | 0.203 | 5.16 | 27.23 | 40.60 |

| 12 3/4 | 323.9 | 0.219 | 5.56 | 29.34 | 43.70 |

| 12 3/4 | 323.9 | 0.230 | 5.84 | 30.78 | 45.80 |

| 12 3/4 | 323.9 | 0.250 | 6.35 | 33.41 | 49.70 |

| 12 3/4 | 323.9 | 0.281 | 7.14 | 37.46 | 55.80 |

| 12 3/4 | 323.9 | 0.312 | 7.93 | 41.48 | 61.80 |

| 12 3/4 | 323.9 | 0.330 | 8.38 | 43.81 | 65.20 |

| 12 3/4 | 323.9 | 0.344 | 8.74 | 45.62 | 67.90 |

| 12 3/4 | 323.9 | 0.375 | 9.53 | 49.61 | 73.90 |

| 12 3/4 | 323.9 | 0.438 | 11.13 | 57.65 | 85.80 |

| 12 3/4 | 323.9 | 0.500 | 12.70 | 65.48 | 97.50 |

| 14 | 355.6 | 0.134 | 3.40 | 19.86 | 29.50 |

| 14 | 355.6 | 0.141 | 3.58 | 20.89 | 31.10 |

| 14 | 355.6 | 0.150 | 3.81 | 22.21 | 33.10 |

| 14 | 355.6 | 0.164 | 4.17 | 24.26 | 36.10 |

| 14 | 355.6 | 0.172 | 4.37 | 25.43 | 37.90 |

| 14 | 355.6 | 0.179 | 4.55 | 26.45 | 39.40 |

| 14 | 355.6 | 0.188 | 4.78 | 27.76 | 41.40 |

| 14 | 355.6 | 0.203 | 5.16 | 29.94 | 44.60 |

| 14 | 355.6 | 0.219 | 5.56 | 32.26 | 48.00 |

| 14 | 355.6 | 0.230 | 5.84 | 33.86 | 50.40 |

| 14 | 355.6 | 0.250 | 6.35 | 36.75 | 54.70 |

| 14 | 355.6 | 0.281 | 7.14 | 41.21 | 61.40 |

| 14 | 355.6 | 0.312 | 7.93 | 45.65 | 68.00 |

| 14 | 355.6 | 0.344 | 8.87 | 50.22 | 74.80 |

| 14 | 355.6 | 0.375 | 9.53 | 54.62 | 81.30 |

| 14 | 355.6 | 0.438 | 11.13 | 63.50 | 94.60 |

| 14 | 355.6 | 0.469 | 11.91 | 67.84 | 100.90 |

| 14 | 355.6 | 0.500 | 12.70 | 72.16 | 107.50 |

| 16 | 406.4 | 0.134 | 3.40 | 22.73 | 33.80 |

| 16 | 406.4 | 0.141 | 3.58 | 23.90 | 35.60 |

| 16 | 406.4 | 0.150 | 3.81 | 25.42 | 37.80 |

| 16 | 406.4 | 0.164 | 4.17 | 27.76 | 41.40 |

| 16 | 406.4 | 0.172 | 4.37 | 29.10 | 43.30 |

| 16 | 406.4 | 0.179 | 4.55 | 30.27 | 45.10 |

| 16 | 406.4 | 0.188 | 4.78 | 31.78 | 47.30 |

| 16 | 406.4 | 0.203 | 5.16 | 34.28 | 51.10 |

| 16 | 406.4 | 0.219 | 5.56 | 36.95 | 55.00 |

| 16 | 406.4 | 0.230 | 5.84 | 38.77 | 57.70 |

| 16 | 406.4 | 0.250 | 6.35 | 42.09 | 62.60 |

| 16 | 406.4 | 0.281 | 7.14 | 47.22 | 70.30 |

| 16 | 406.4 | 0.312 | 7.93 | 52.32 | 77.90 |

| 16 | 406.4 | 0.344 | 8.87 | 57.57 | 87.00 |

| 16 | 406.4 | 0.375 | 9.53 | 62.64 | 93.50 |

| 16 | 406.4 | 0.438 | 11.13 | 72.86 | 108.50 |

| 16 | 406.4 | 0.469 | 11.91 | 77.87 | 115.90 |

| 16 | 406.4 | 0.500 | 12.70 | 82.85 | 123.30 |

| 18 | 457.2 | 0.141 | 3.58 | 26.92 | 40.00 |

| 18 | 457.2 | 0.172 | 4.37 | 32.78 | 48.80 |

| 18 | 457.2 | 0.188 | 4.78 | 35.80 | 53.30 |

| 18 | 457.2 | 0.219 | 5.56 | 41.63 | 61.90 |

| 18 | 457.2 | 0.230 | 5.84 | 43.69 | 65.00 |

| 18 | 457.2 | 0.250 | 6.35 | 47.44 | 70.60 |

| 18 | 457.2 | 0.281 | 7.14 | 53.23 | 79.20 |

| 18 | 457.2 | 0.312 | 7.93 | 58.99 | 87.90 |

| 18 | 457.2 | 0.344 | 8.74 | 64.93 | 96.70 |

| 18 | 457.2 | 0.375 | 9.53 | 70.65 | 105.20 |

| 18 | 457.2 | 0.438 | 11.13 | 82.23 | 122.40 |

| 18 | 457.2 | 0.469 | 11.91 | 87.89 | 130.80 |

| 18 | 457.2 | 0.500 | 12.70 | 93.54 | 139.20 |

| 20 | 508.0 | 0.141 | 3.58 | 29.93 | 44.50 |

| 20 | 508.0 | 0.172 | 4.37 | 36.46 | 54.30 |

| 20 | 508.0 | 0.188 | 4.78 | 39.82 | 59.30 |

| 20 | 508.0 | 0.219 | 5.56 | 46.31 | 68.90 |

| 20 | 508.0 | 0.250 | 6.35 | 52.78 | 78.60 |

| 20 | 508.0 | 0.281 | 7.14 | 59.23 | 88.20 |

| 20 | 508.0 | 0.312 | 7.93 | 65.66 | 97.80 |

| 20 | 508.0 | 0.344 | 8.87 | 72.28 | 107.60 |

| 20 | 508.0 | 0.375 | 9.53 | 78.67 | 117.20 |

| 20 | 508.0 | 0.438 | 11.13 | 91.59 | 136.40 |

| 20 | 508.0 | 0.469 | 11.91 | 97.92 | 145.70 |

| 20 | 508.0 | 0.500 | 12.70 | 104.23 | 155.10 |

| 22 | 558.8 | 0.172 | 4.37 | 40.13 | 59.80 |

| 22 | 558.8 | 0.188 | 4.78 | 43.84 | 65.30 |

| 22 | 558.8 | 0.219 | 5.56 | 50.99 | 75.90 |

| 22 | 558.8 | 0.250 | 6.35 | 58.13 | 86.50 |

| 22 | 558.8 | 0.281 | 7.14 | 65.24 | 97.10 |

| 22 | 558.8 | 0.312 | 7.93 | 72.34 | 107.70 |

| 22 | 558.8 | 0.375 | 9.53 | 86.69 | 129.10 |

| 22 | 558.8 | 0.438 | 11.13 | 100.96 | 150.30 |

| 22 | 558.8 | 0.469 | 11.91 | 107.95 | 160.60 |

| 22 | 558.8 | 0.500 | 12.70 | 114.92 | 171.00 |

| 24 | 609.6 | 0.172 | 4.37 | 43.81 | 65.20 |

| 24 | 609.6 | 0.188 | 4.78 | 47.86 | 71.30 |

| 24 | 609.6 | 0.219 | 5.56 | 55.67 | 82.80 |

| 24 | 609.6 | 0.250 | 6.35 | 63.47 | 94.50 |

| 24 | 609.6 | 0.281 | 7.14 | 71.25 | 106.10 |

| 24 | 609.6 | 0.312 | 7.93 | 79.01 | 117.70 |

| 24 | 609.6 | 0.375 | 9.53 | 94.71 | 141.00 |

| 24 | 609.6 | 0.438 | 11.13 | 110.32 | 164.30 |

| 24 | 609.6 | 0.469 | 11.91 | 117.98 | 175.60 |

| 24 | 609.6 | 0.500 | 12.70 | 125.62 | 186.90 |

Cilladaha Dusha Tubooyinka

1. Cilladaha dusha sare ee leh qoto dheer oo aan ka badnayn 12.5 % dhumucdiisuna waxay tahay in la aqbalo.

Waa la ogolyahay in la caddeeyo qoto-dheeraanta cilladahaas iyadoo la shiidi karo ama xerayn karo.

2. Cilladaha dusha sare leh oo qoto dheer oo ka badan 12.5% dhumucda darbiga magac ahaan la cayimay waa in loo arkaa cillad.

Waa in loo oggolaadaa cilladaha aan ka hoosayn 33.3 % ee dhumucda derbiga magacaaban in lagu hagaajiyo alxanka, waase haddii cilada gebi ahaanba meesha laga saaro alxanka ka hor.

Qalabka

ASTM A252 Fasalka 1 Codsiyada

Mashaariic fudud oo lagu raro xaaladaha guud ee ciidda, sida aasaaska dhismayaasha yaryar ama dhismayaasha.

Aasaaska dhismayaasha ku meel gaarka ah sida taageerooyinka dhismaha ama buundooyinka ku meel gaarka ah.

Mashaariicda dib-u-hagaajinta deegaanka ee xaaladaha ciidda wanaagsan ee aan loo baahnayn culaysyo xad-dhaaf ah.

ASTM A252 Fasalka 2 Codsiyada:

Mashaariicda injineernimada oo leh shuruudo rarista dhexdhexaad ah, oo ay ku jiraan aasaaska dhismayaal dabaqyo badan ah ama tas-hiilaad.

Buundooyinka, tiirarka, iyo mashaariicda xeebaha ee xaaladaha ciidda dhexdhexaadka ah.

Isticmaal xaalado leh heer ka mid ah halista daxalka kiimikada ama nabaad guurka.

ASTM A252 Fasalka 3 Codsiyada:

Mashruucyo muhiim ah oo si heer sare ah loo raray, xaaladaha ciidda adag sida buundooyinka waaweyn, dhismayaal dhaadheer, iyo tas-hiilaad warshadeed oo waaweyn.

Degaannada khatarta sare leh, sida dhismayaal ay ku jiraan nabaad-guur daran, daxal kiimikaad, ama xaalado cimilo oo aad u daran.

Mashruucyo waaweyn oo xeebaha ka baxsan, sida aasaaska jetties-biyo-dheer, biyo-goysyo waaweyn, iyo goobo saliid iyo gaas ah.

Heerarka La Xiriira

ASTM A252 fasalka 1

TS EN 10219 S235JRH - Tuubooyinka qaab dhismeedka alxanka leh ee qabow

TS EN 10219 S235JRH - Tuubooyinka birta ah ee alxanka leh iyo tuubooyinka qabow-sameeyay ee ujeeddooyin dhismeed

CSA G40.21 300W - Bir tayada qaab-dhismeedka.

AS/NZS 1163 C250L0 - Tubooyinka qaab-dhismeed ee qabow.

GB/T 3091 Q235B - Dhuumaha birta alxanka leh ee gaadiidka dareeraha cadaadiska hooseeya.

JIS G3444 STK400 - Dhuumaha birta kaarboon ee isticmaalka qaabdhismeedka.

IS 4923 YST 210 - Tuubooyinka birta ee godan ee ujeedooyinka dhismaha.

GOST 10704-91 - Tuubooyinka birta ah ee korontada ku xiran.

TS EN ISO 11960 - Tuubooyinka birta ee warshadaha saliidda iyo gaaska

ASTM A36 - Qaab-dhismeedka Birta Carbon ee Codsiyada Aan Caadiga ahayn.

ASTM A252 Fasalka 2

TS EN 10219 S275J0H - tuubo qaabaysan oo alxan leh oo qabow

CSA G40.21 350W - Bir tayada qaab-dhismeedka.

AS/NZS 1163 C350L0 - Dhuumaha qaab-dhismeed qabow.

GB/T 3091 Q345B - Dhuumaha birta alxanka leh ee gaadiidka dareeraha cadaadiska hooseeya.

JIS G3444 STK490 - Dhuumaha birta kaarboon ee isticmaalka qaabdhismeedka.

IS 4923 YST 310 - Dhuumaha birta banaan ee ujeedooyinka qaabdhismeedka.

ASTM A252 Fasalka 3

TS EN 10219 S355J2H - Tuubooyinka qaab dhismeedka alxanka ee qabow-sameeyay

CSA G40.21 350W - Birta tayada qaab-dhismeedka, qaabaynta gaarka ah ayaa laga yaabaa inay buuxiso shuruudaha Fasalka 3.

AS/NZS 1163 C450L0 - Tuubooyinka iyo tuubooyinka qaab dhismeedka qabow-sameeyay, darajada xoogga sare ee taxanaha.

GB/T 3091 Q460C - Dhuumaha birta welded ee gaadiidka dareeraha cadaadiska hooseeya ee codsiyada u baahan xoog sare.

JIS G3444 STK540 - Dhuumaha birta kaarboon ee isticmaalka qaab dhismeedka, oo lagu heli karo xulashooyin awood sare leh.

Alaabtayada laxidhiidha

Botop Steel waa Soosaaraha Tubooyinka Kaarboonka ee Xirfadleyda Alxanka leh & Alaab-qeybiyeyaal ka badan 16 Sano oo wata 8000+ Tons oo ah dhuumo khadka ah oo aan cillad lahayn oo kayd ah bil kasta.Ku siiya alaab tayo sare leh oo qiimo jaban leh, haddii aad u baahan tahay fadlan nala soo xiriir, waxaanu ku siin doonaa noocyo badan oo ah xalalka tuubooyinka birta.

tags: astm a252, astm a252 fasalka 2, astm a252 fasalka 3, tuubooyinka tuubooyinka, tuubada dhismaha,alaab-qeybiyeyaal, warshadeeyayaal, warshado, saamiley, shirkado, jumlo, gad, qiimo, xigasho, bulk, iib, kharash.

Waqtiga boostada: Mar-29-2024