ASTM A671 waa tuubo bir ah oo laga sameeyay saxan tayada markabka cadaadiska,Korantada-Fusion-welded (EFW)jawiga cadaadiska sare leh ee jawiga iyo heerkulka hoose.

Waxay si gaar ah ugu habboon tahay codsiyada u baahan xasilloonida cadaadiska sare iyo sifooyinka heerkulka hoose ee gaarka ah.

Badhamada navigation

Qiyaasta ASTM A671

Calaamadeynta ASTM A671

Kala saarista darajada

Kala soocidda

Alaabta ceeriin

Qodobbada muhiimka ah ee alxanka

Daawaynta kulaylka ee Fasalo kala duwan

ASTM A671 Mashaariicda Tijaabada

ASTM A671 muuqaalka

Weelashada La Ogolyahay ee Xajmiga

Codsiyada ASTM A671 Tuubooyinka Birta

Alaabtayada laxidhiidha

Qiyaasta ASTM A671

Kala duwanaanshaha lagu taliyay: tuubooyinka birta ee leh DN ≥ 400 mm [16 in] iyo WT ≥ 6 mm [1/4].

Waxa kale oo loo isticmaali karaa cabbirrada kale ee tuubooyinka, waase haddii ay buuxisay dhammaan shuruudaha kale ee qeexitaankan.

Calaamadeynta ASTM A671

Si aan si wanagsan ugu fahanno ASTM A671, aan marka hore fahano waxa ku jira calaamadaynta. Tani waxay kaa caawinaysaa in la caddeeyo baaxadda codsiga iyo sifooyinka heerkan.

Tusaalaha Buufiska Calaamadaynta:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 kulaylka NO.4589716

BOTOPMagaca soo saaraha.

EFW: Habka wax soo saarka tubbada birta.

ASTM A671: Heerka Fulinta ee Tuubooyinka Birta.

CC60-22Soo gaabinta darajada:cc60 iyo fasalka 22.

16" x SCH80: Dhexroorka iyo Dhumucda gidaarka.

KULUL NO. 4589716: Kulul maya. wax soo saarka tuubooyinka birta.

Kani waa qaabka caadiga ah ee calaamadaynta buufinta ASTM A671.

Ma adka in la helo ASTM A671 fasalka iyo fasalka labaad, markaa labadan qaybood ayaa u taagan macnaha macnaha.

Kala saarista darajada

Lagu kala soocaa iyadoo loo eegayo nooca saxanka loo isticmaalo soo saarista tubooyinka birta.

Darajooyin kala duwani waxay u taagan yihiin ka kooban kiimikooyin kala duwan iyo sifooyinka farsamada ee cadaadiska iyo xaaladaha heerkulka kala duwan.

Tusaale ahaan, darajooyinka qaarkood waa birta kaarboonka ee cad, halka kuwa kalena ay yihiin birta leh walxo daawaynta lagu daray, sida birta nikkel.

| Heerka Dhuumaha | Nooca Birta | Tilmaamaha ASTM | |

| Maya | Fasalka/fasalka/nooca | ||

| CA 55 | kaarboon caadi ah | A285/A285M | Gr C |

| CB 60 | Kaarboon caadi ah, la dilay | A515/A515M | Gr 60 |

| CB 65 | Kaarboon caadi ah, la dilay | A515/A515M | Gr 65 |

| CB 70 | Kaarboon caadi ah, la dilay | A515/A515M | Gr 70 |

| CC 60 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516/A516M | Gr 60 |

| CC 65 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516/A516M | Gr 65 |

| CC 70 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516/A516M | Gr 70 |

| CD 70 | manganese-silikon, caadiga ah | A537/A537M | Cl 1 |

| CD 80 | manganese-silikon, la demiyay oo xanaaqsan | A537/A537M | Cl 2 |

| CFA 65 | birta nikkel | A203/A203M | Gr A |

| CFB 70 | birta nikkel | A203/A203M | Gr B |

| CFD 65 | birta nikkel | A203/A203M | Gr D |

| CFE 70 | birta nikkel | A203/A203M | Gr E |

| CG 100 | 9% nikkel | A353/A353M | |

| CH 115 | 9% nikkel | A553/A553M | Nooca 1 |

| CJA 115 | bir daawaha ah, la demiyay oo dabcay | A517/A517M | Gr A |

| CJB 115 | bir daawaha ah, la demiyay oo dabcay | A517/A517M | Gr B |

| CJE 115 | bir daawaha ah, la demiyay oo dabcay | A517/A517M | Gr E |

| CJF 115 | bir daawaha ah, la demiyay oo dabcay | A517/A517M | Gr F |

| CJH 115 | bir daawaha ah, la demiyay oo dabcay | A517/A517M | Gr H |

| CJP 115 | bir daawaha ah, la demiyay oo dabcay | A517/A517M | Gr P |

| CK 75 | kaarboon-manganese-silicon | A299/A299M | Gr A |

| CP 85 | birta daawaha ah, adkaynta da'da, damay iyo kulaylka roobka ee la daweeyay | A736/A736M | Gr A, Fasalka 3 |

Kala soocidda

Tuubooyinka waxaa loo kala soocaa iyadoo loo eegayo nooca daaweynta kulaylka ee ay helaan inta lagu jiro habka wax soo saarka iyo haddii si shucaac ah loo baaro iyo in la tijaabiyo cadaadiska.

Qaybaha kala duwani waxay ka tarjumayaan sifooyinka daaweynta kulaylka ee kala duwan ee tuubooyinka.

Tusaalooyinka waxaa ka mid ah wax-ka-dhigista, ka-reebista walbahaarka, deminta, iyo xanaaqa.

| Fasalka | Daaweynta kulaylka ee tuubada | Raadiyaha, fiiri qoraalka: | Tijaabada cadaadiska, fiiri qoraalka: |

| 10 | midna | midna | midna |

| 11 | midna | 9 | midna |

| 12 | midna | 9 | 8.3 |

| 13 | midna | midna | 8.3 |

| 20 | diiqada la yareeyay, eeg 5.3.1 | midna | midna |

| 21 | diiqada la yareeyay, eeg 5.3.1 | 9 | midna |

| 22 | diiqada la yareeyay, eeg 5.3.1 | 9 | 8.3 |

| 23 | diiqada la yareeyay, eeg 5.3.1 | midna | 8.3 |

| 30 | caadiga ah, eeg 5.3.2 | midna | midna |

| 31 | caadiga ah, eeg 5.3.2 | 9 | midna |

| 32 | caadiga ah, eeg 5.3.2 | 9 | 8.3 |

| 33 | caadiga ah, eeg 5.3.2 | midna | 8.3 |

| 40 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | midna | midna |

| 41 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | 9 | midna |

| 42 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | 9 | 8.3 |

| 43 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | midna | 8.3 |

| 50 | Demisay oo xanaaqsan, eeg 5.3.4 | midna | midna |

| 51 | Demisay oo xanaaqsan, eeg 5.3.4 | 9 | midna |

| 52 | Demisay oo xanaaqsan, eeg 5.3.4 | 9 | 8.3 |

| 53 | Demisay oo xanaaqsan, eeg 5.3.4 | midna | 8.3 |

| 70 | kulayl demiyay iyo roob da'ay | midna | midna |

| 71 | kulayl demiyay iyo roob da'ay | 9 | midna |

| 72 | kulayl demiyay iyo roob da'ay | 9 | 8.3 |

| 73 | kulayl demiyay iyo roob da'ay | midna | 8.3 |

Heerkulka isticmaalka waa in la ogaadaa marka la dooranayo alaabta. Tixraaca waxaa lagu sameyn karaa qeexida ASTM A20/A20M.

Alaabta ceeriin

Taarikada tayada sare leh ee maraakiibta cadaadiska, faahfaahinta noocyada, iyo heerarka fulinta ayaa laga heli karaa shaxda gudahaKala saarista darajadasare.

Qodobbada muhiimka ah ee alxanka

Alxanka: Tolmodu waa inay noqdaan laba-alxanka, oo alxanka buuxa.

Alxanka waa in loo fuliyaa si waafaqsan habraacyada lagu qeexay Qaybta IX ee Xeerka Kuleyliyaha ASME iyo Xeerka Markabka Cadaadiska.

Alxanka waa in lagu sameeyaa gacanta ama si toos ah iyada oo loo marayo habka korantada ee ku lug leh dhigista birta buuxinta.

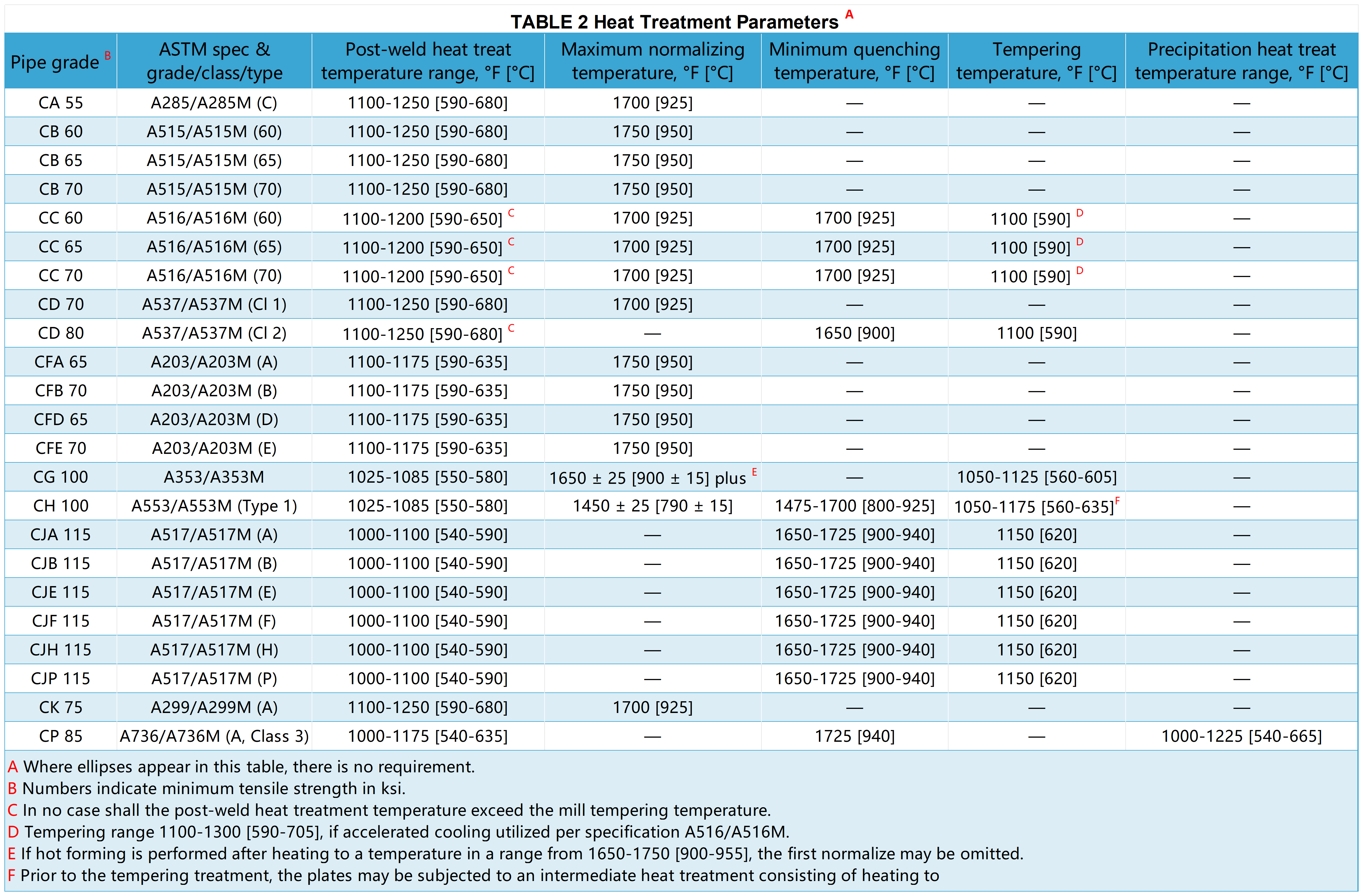

Daawaynta kulaylka ee Fasalo kala duwan

Dhammaan fasallada aan ka ahayn 10, 11, 12, iyo 13 waa in lagu daaweeyaa kulaylka foornada lagu kontoroolo ±25 °F[± 15°C].

Fasalada 20, 21, 22, iyo 23

Waa in si isku mid ah loo kululeeyo gudaha heerkulka daawaynta kulaylka kadib ee lagu tilmaamay shaxda 2 ugu yaraan 1 saac/in. [0.4 h/cm] dhumucdiisuna tahay ama 1 saac, hadba kii ka weyn.

Fasalada 30, 31, 32, iyo 33

Waa in si isku mid ah loogu kulayliyaa heer kul cabbirka tafatirka oo aan ka badnayn heerkulka caadiga ah ee lagu tilmaamay shaxda 2 ka dibna lagu qaboojiyo hawada heerkulka qolka.

Fasalada 40, 41, 42, iyo 43

Dhuumaha waa in la caadiyeeyaa.

Dhuumaha waa in lagu kululeeyaa heerkulka heerkulka lagu tilmaamay shaxda 2 ugu yaraan waxaana lagu hayaa heerkul ugu yaraan 0.5 h/in.

Fasalada 50, 51, 52, iyo 53

Dhuumaha waa in si isku mid ah loogu kululeeyaa heerkul ku dhex jira cabbirka tafatirka oo aan ka badnayn heerkulka ugu sarreeya ee lagu muujiyey shaxda 2.

Ka dib, ku dami biyo ama saliid. Deminta ka dib, tuubada waa in lagu kululeeyaa heerkulka heerkulka ugu yar ee lagu muujiyay shaxda 2 waxaana lagu hayaa halkaas.

heerkulka ugu yaraan 0.5 h/inch [0.2 h/cm] dhumucdiisuna tahay 0.5 saac, hadba kii weyn, oo hawo qaboojisay.

Fasalada 70, 71, 72, iyo 73

Tuubooyinka waa inin si isku mid ah loogu kululeeyo heer kulka cabbirka hagaajinta, oo aan ka badnayn heerkulka ugu sarreeya ee lagu tilmaamay shaxda 2, ka dibna lagu damiyo biyo ama saliid.

Ka dib marka la demiyo tuubada waa in lagu kululeeyaa qiyaasta daawaynta kulaylka roobabka ee lagu tilmaamay shaxda 2 ilaa wakhti ay go'aaminayso soo saaraha.

ASTM A671 Mashaariicda Tijaabada

Halabuurka Kiimikada

Marka loo eego shuruudaha u dhigma ee heerarka fulinta ee alaabta ceeriin, falanqaynta halabuurka kiimikada, natiijooyinka tijaabada si loo buuxiyo shuruudaha caadiga ah.

Baaritaanka Kacsanaanta

Dhammaan tuubooyinka alxanka ah ee lagu soo sammeeyay qeexitaankan waa inay lahaadaan tijaabinta xajinta alxanka ka dib daawaynta kulaylka ugu dambeeya, iyo natiijadu waa inay la jaanqaadaan shuruudaha walxaha aasaasiga ah ee xoogga ugu dambeeya ee qalabka saxanka la cayimay.

Intaa waxaa dheer, Fasalada CD XX iyo CJ XXX, marka kuwani yihiin Fasalka 3x, 4x, ama 5x, iyo Fasalka CP ee 6x iyo 7x waa in ay lahaadaan tijaabada xajinta birta ee ka gudubta ee lagu sameeyay muunado laga gooyay tuubada dhammaatay. Natiijooyinka imtixaannadani waa inay buuxiyaan shuruudaha tijaabada farsamada ugu yar ee qeexitaanka saxanka.

Tijaabada Qalloocinta Weld Hanuunsan ee Transverse

Tijaabada qalooca waa in la aqbalo haddii aysan dillaacin ama cillado kale oo dhaafsiisan1/8in. [3 mm] jiho kasta ayaa ku jira biraha alxanka ama inta u dhaxaysa alxanka iyo birta salka ka dib foorarsiga.

Dildilaaca ka yimaada cidhifyada muunada inta lagu jiro tijaabada, oo ka yar1/4in. [6 mm] lagu cabbiro jiho kasta lama tixgelin doono.

Tijaabada Cadaadiska

Fasalada X2 iyo tubbada X3 waa in lagu tijaabiyaa si waafaqsan Tilmaamaha A530/A530M, Shuruudaha Imtixaanka Hydrostatic.

Baaritaanka Shucaaca

Dhererka buuxa ee alxan kasta oo ah Fasalada X1 iyo X2 waa in si shucaac ah loo baaro si waafaqsan oo la kulmo shuruudaha kuleyliyaha ASME iyo Xeerka Markabka Cadaadiska, Qaybta VIII, Baaragaraaf UW-51.

Baaritaanka shucaaca waxaa la samayn karaa ka hor daaweynta kulaylka.

ASTM A671 muuqaalka

Tuubada dhammaatay waa in aanay lahayn cillado dhaawici ah oo waxay yeelan doontaa dhammayn shaqo oo kale ah.

Weelashada La Ogolyahay ee Xajmiga

| Ciyaaraha | Qiimaha dulqaadka | Ogow |

| Dhexroor ka baxsan | ± 0.5% | Iyada oo ku saleysan cabbirka wareegga |

| Wareega ka baxsan | 1%. | Farqiga u dhexeeya dhexrooryada waaweyn iyo kuwa yar ee dibadda |

| Toosin | 1/8 gudaha [3 mm] | Isticmaalka cidhif toosan oo dhererkeedu yahay 10 ft (3 mitir) oo la dhigay si labada daraf ay ula xiriiraan tuubada |

| Dhumucda | 0.01 gudaha [0.3 mm] | Dhumucda derbiga ugu yar ayaa ka yar dhumucda magaca ee la cayimay |

| Dhererka | 0 - +0.5in [0 - +13mm] | dhammaad aan mashiin |

Codsiyada ASTM A671 Tuubooyinka Birta

Warshadaha tamarta

Loo isticmaalo in lagu qaado dareerayaasha cryogenic ee dhirta daawaynta gaaska dabiiciga ah, wershadaha sifaynta, iyo tas-hiilaadka warshadaynta kiimikada.

Nidaamyada Qaboojiyaha Warshadaha

Isticmaalka qaybta cryogenic ee hababka qaboojinta iyo qaboojinta si loo hubiyo xasilloonida nidaamka iyo badbaadada.

Utility

Kaydinta iyo tas-hiilaadka gaadiidka ee gaaska dareeraha ah.

Dhismaha iyo Dhismaha

Lagu dabaqo mashaariicda kaabayaasha heerkulka hooseeya ama xaaladaha deegaanka ee aadka u daran, sida dhismaha kaydinta qabowga.

Waxaan nahay mid ka mid ah kuwa ugu horreeya ee birta birta ah ee alxanka leh iyo soosaarayaasha tuubooyinka birta ah ee birta ah iyo alaab-qeybiyeyaasha Shiinaha, oo leh noocyo badan oo birta birta ah oo tayo sare leh oo kayd ah, waxaa naga go'an inaan ku siinno noocyo badan oo ah xalalka tuubooyinka birta. Faahfaahin dheeraad ah oo ku saabsan badeecada, fadlan xor u noqo inaad nala soo xiriirto, waxaan rajeyneynaa inaan kaa caawino inaad hesho fursadaha ugu fiican ee tuubada birta ee baahidaada!

Tags: ASTM a671, efw, cc 60, fasalka 22, alaab-qeybiyeyaal, warshadeeyayaal, warshado, saamiley, shirkado, jumlo, gad, qiimo, oraah, bulk, iib, kharash.

Waqtiga boostada: Abriil-19-2024