ASTM A672waa tuubo bir ah oo laga sameeyay saxan tayada markabka cadaadiska,Korantada-Fusion-welded (EFW)adeega cadaadiska sare ee heerkulka dhexdhexaadka ah.

Badhamada navigation

ASTM A672 Kala soocidda

Kala soocidda ASTM A672

Heerka cabbirka ASTM A672

Taxadirka alxanka

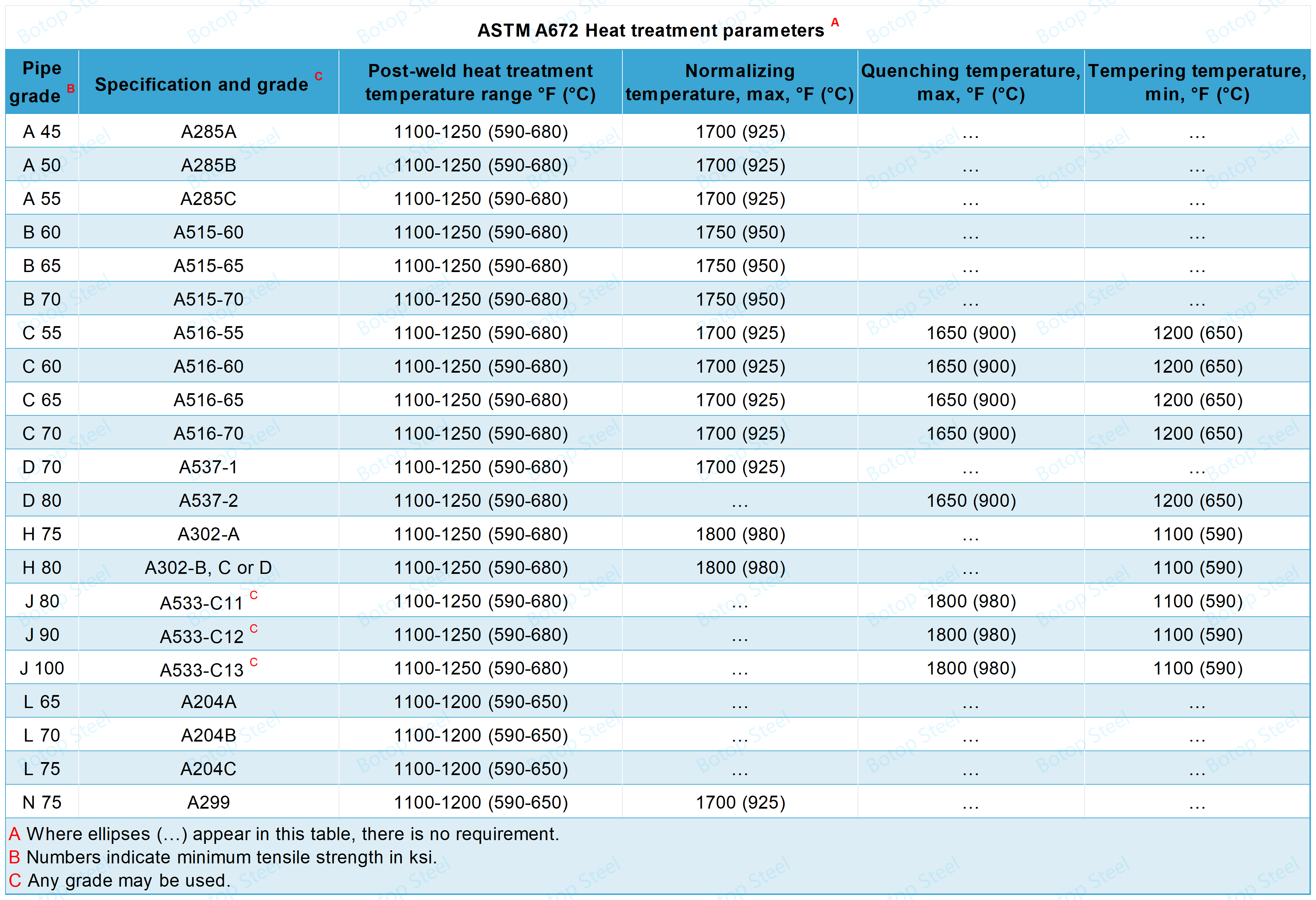

Daawaynta kulaylka

Qaybaha Kiimikada

Baaritaanka Kacsanaanta

Tijaabooyin-kala-duwan-Haga-Weld-qaloocin

Tijaabada Cadaadiska

Baaritaanka Shucaaca

Dulqaadyada cabbirka ee ASTM A672

ASTM A672 muuqaalka

Cilladaha iyo Dayactirka

Calaamadeynta ASTM A672

Codsiga ASTM A672 Steel Pipe

Alaabtayada laxidhiidha

ASTM A672 Kala soocidda

Lagu kala soocaa iyadoo loo eegayo nooca saxanka loo isticmaalo soo saarista tubooyinka birta.

Darajooyin kala duwani waxay u taagan yihiin isku-dhafka kiimikada kala duwan iyo sifooyinka farsamada ee cadaadiska iyo xaaladaha heerkulka kala duwan.

| Heerka Dhuumaha | Nooca Birta | Tilmaamaha ASTM | |

| Maya | Darajo | ||

| A 45 | kaarboon caadi ah | A285 / A285M | A |

| A50 | kaarboon caadi ah | A285 / A285M | B |

| A 55 | kaarboon caadi ah | A285 / A285M | C |

| B 60 | Kaarboon caadi ah, la dilay | A515 / A515M | 60 |

| B 65 | Kaarboon caadi ah, la dilay | A515 / A515M | 65 |

| B 70 | Kaarboon caadi ah, la dilay | A515 / A515M | 70 |

| C 55 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516 / A516M | 55 |

| C 60 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516 / A516M | 60 |

| C 65 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516 / A516M | 65 |

| C 70 | Kaarboon caadi ah, la dilay, hadhuudh fiican | A516 / A516M | 70 |

| D 70 | manganese-silikon, caadiga ah | A537 / A537M | 1 |

| D 80 | manganese-silikon, Q&TA | A537 / A537M | 2 |

| H 75 | manganese-molybdenum, caadiga ah | A302 / A302M | A |

| H 80 | manganese-molybdenum, caadiga ah | A302 / A302M | B, C, ama D |

| J 80 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-1B |

| J 90 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-3B |

| L 65 | molybdenum | A204 / A204M | A |

| L 70 | molybdenum | A204 / A204M | B |

| L 75 | molybdenum | A204 / A204M | C |

| N 75 | manganese-silicon | A299 / A299M | A |

AQ&T = demiyay oo xanaaqsan.

ВDarajo kasta waa la goyn karaa.

Waxaan marka hore go'aamin karnaa nooca dhuumaha birta xarfaha fasalka.

Fasalada ka bilaabma xarfaha A, B, iyo C waxay badanaa muujiyaandhuunta birta kaarboon.

Fasalada ka bilaabma xarfaha D, H, J, L, iyo N ayaa tilmaamayaDhuumaha birta daawaha ah.

Kala soocidda ASTM A672

Tuubooyinka waxaa loo kala saaraa iyadoo loo eegayo nooca daaweynta kulaylka ee ay helaan inta lagu jiro habka wax soo saarka iyo haddii si shucaac ah loo baaro oo cadaadis la tijaabiyo.

| Fasalka | Daaweynta kulaylka ee tuubada | Raadiyaha, eeg qoraalka: | Tijaabada cadaadiska, eeg qoraalka: |

| 10 | midna | midna | midna |

| 11 | midna | 9 | midna |

| 12 | midna | 9 | 8.3 |

| 13 | midna | midna | 8.3 |

| 20 | diiqada la yareeyay, eeg 5.3.1 | midna | midna |

| 21 | diiqada la yareeyay, eeg 5.3.1 | 9 | midna |

| 22 | diiqada la yareeyay, eeg 5.3.1 | 9 | 8.3 |

| 23 | diiqada la yareeyay, eeg 5.3.1 | midna | 8.3 |

| 30 | caadiga ah, eeg 5.3.2 | midna | midna |

| 31 | caadiga ah, eeg 5.3.2 | 9 | midna |

| 32 | caadiga ah, eeg 5.3.2 | 9 | 8.3 |

| 33 | caadiga ah, eeg 5.3.2 | midna | 8.3 |

| 40 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | midna | midna |

| 41 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | 9 | midna |

| 42 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | 9 | 8.3 |

| 43 | caadiyeysan oo xanaaqsan, eeg 5.3.3 | midna | 8.3 |

| 50 | Demisay oo xanaaqsan, eeg 5.3.4 | midna | midna |

| 51 | Demisay oo xanaaqsan, eeg 5.3.4 | 9 | midna |

| 52 | Demisay oo xanaaqsan, eeg 5.3.4 | 9 | 8.3 |

| 53 | Demisay oo xanaaqsan, eeg 5.3.4 | midna | 8.3 |

Fiiro gaar ah waa in la siiyaa heerkulka adeegga ee la filayo marka la dooranayo fasalka alaabta ku habboon.Tixraac qeexidda ASTM A20/A20M.

Heerka cabbirka ASTM A672

cabbirka lagu taliyay:DN≥400mm[16 in] iyo WT≤75mm[3 in].

Cabbirrada kale ee tuubooyinka, waase haddii ay buuxiso dhammaan shuruudaha kale ee qeexitaankan, sidoo kale waa la isticmaali karaa.

Taxadirka alxanka

Tolmodu waa inay noqdaan kuwo laba-laaban, oo si buuxda loo alxanayo.

Alxanka waa in lagu sameeyaa gacanta ama si toos ah iyada oo loo marayo habka korantada ee ku lug leh dhigista birta buuxinta.

Alxanka waxaa lagu baari karaa iyadoo la isticmaalayo shucaaca waana in la raaco qodobbada Qeybta VII UW-51 ee Xeerka Kuleyliyaha ASME iyo Qalabka Cadaadiska.

Dhererka alxanka waa inuusan dhaafin 3 mm [1/8 in].

Daawaynta kulaylka

Dhammaan fasallada aan ka ahayn 10, 11, 12, iyo13 waa in lagu daaweeyaa kulaylka foornada lagu xakameynayo ±25 °F[± 15°C]:

Fasalada 20, 21, 22, iyo 23

Tuubada waa in si isku mid ah loo kululeeyo gudaha daawaynta kulaylka ka dib ee lagu tilmaamay shaxda 2 ugu yaraan 1 saac/in.[0.4 h/cm] dhumucdiisuna tahay ama 1 saac, hadba kii ka weyn.

Fasalada 30, 31, 32, iyo 33

Tuubbadu waa in si isku mid ah loogu kululeeyaa heerkul ku jira cabbirka wax-qabadka oo aan ka badnayn heerkulka caadiga ah ee lagu tilmaamay Jadwalka 2 oo ka dibna lagu qaboojiyo hawada heerkulka qolka.

Fasalada 40, 41, 42, iyo 43

Dhuumaha waa in la caadiyeeyaa.

Dhuumaha waa in lagu kululeeyaa heerkulka heerkulka lagu tilmaamay shaxda 2 ugu yaraan waxaana lagu hayaa heerkul ugu yaraan 0.5 h/in.[0.2 h/cm] oo dhumucdiisuna tahay1/2h, hadba kii weyn, oo hawo qaboojiye.

Fasalada 50, 51, 52, iyo 53

Dhuumaha waa in si isku mid ah loogu kululeeyaa heerkul ku dhex jira cabbirka tafatirka oo aan ka badnayn heerkulka ugu sarreeya ee lagu muujiyey shaxda 2.

Ka dib, ku dami biyo ama saliid.Deminta ka dib, tuubada waa in lagu kululeeyaa heerkulka heerkulka ugu yar ee lagu muujiyay shaxda 2 waxaana lagu hayaa halkaas.

heerkulka ugu yaraan 0.5 h/inch [0.2 h/cm] dhumucdiisuna tahay 0.5 saac, hadba kii weyn, oo hawo qaboojisay.

Qaybaha Kiimikada

Waxay noqon doontaa mas'uuliyadda soo saaraha si ay u tijaabiso ka kooban kiimikada saxanka iyo alxanka si ay ugu hoggaansanto shuruudaha qeexida saxanka ee walxaha la dalbaday iyo habka alxanka ee dhigista birta alxanka, siday u kala horreeyaan.

Baaritaanka Kacsanaanta

Inta jeer ee tijaabada ah: hal muunad halkiiba.

Habka ImtixaankaTijaabada tijaabada ah waa in lagu sameeyaa si waafaqsan QW-150 ee Qaybta IX ee kululeeyaha ASME iyo Xeerka markabka cadaadiska.Muunada waa in lagu tijaabiyaa heerkulka qolka iyadoo la raacayo Hababka Tijaabada iyo Qeexida A370.

Marka lagu daro Darajooyinka Dxx, Hxx, Jxx, iyo Nxx ee Fasalada 3x, 4x, iyo 5x sifooyinka xajinta ee saxanka salka, waa in lagu go'aamiyaa shaybaarka laga jaray tuubada kulaylka lagu daweeyay.

Shuruudaha natiijada: Sifooyinka jilicsan ee kala-duwan ee isku-dhafka alxanka ah waa inay buuxiyaan shuruudaha ugu yar ee xoogga ugu dambeeya ee alaabta saxanka ee la cayimay.

Tijaabooyin-kala-duwan-Haga-Weld-qaloocin

Tirada imtixaanada: Inta jeer ee tijaabada ah: hal mar dufcaddii, laba nooc

Habka tijaabada ahShuruudaha imtixaanka ee Hababka Imtixaanka iyo Qeexitaannada A370, cutubka A2.5.1.7 waa in la buuxiyaa.

Waayo dhumucdii darbiga ayaa dhaaftay3/ 8gudaha [10 mm] laakiin ka yar3/4in

Dhumucyada darbiga3/4in. [19 mm] iyo in ka badan labada shayba waa in la mariyaa tijaabada dhinaca leexinta.

Shuruudaha natiijada: Tijaabada qalooca waa in la aqbalaa haddii aysan jirin dildilaacyo ama cillado kale oo ka badan1/8in. [3 mm] jiho kasta ayaa ku jira biraha alxanka ama inta u dhaxaysa alxanka iyo birta salka ka dib foorarsiga.

Dildilaaca ka yimaada cidhifyada muunada inta lagu jiro tijaabada, oo ka yar1/4in. [6 mm] lagu cabbiro jiho kasta lama tixgelin doono.

Tijaabada Cadaadiska

Fasalada X2 iyo tubbada X3 waa in lagu tijaabiyaa si waafaqsan Tilmaamaha A530/A530M, Shuruudaha Imtixaanka Hydrostatic.

Baaritaanka Shucaaca

Dhererka buuxa ee alxan kasta oo ah Fasalada X1 iyo X2 waa in si shucaac ah loo baaro si waafaqsan oo la kulmo shuruudaha kuleyliyaha ASME iyo Xeerka Markabka Cadaadiska, Qaybta VIII, Baaragaraaf UW-51.

Baaritaanka shucaaca waxaa la samayn karaa ka hor daaweynta kulaylka.

Dulqaadyada cabbirka ee ASTM A672

| Ciyaaraha | Qiimaha dulqaadka | Ogow |

| Dhexroor ka baxsan | ± 0.5% | Iyada oo ku saleysan cabbirka wareegga |

| Wareega ka baxsan | 1%. | Farqiga u dhexeeya dhexrooryada waaweyn iyo kuwa yar ee dibadda |

| Toosin | 1/8 inji [3 mm] | Isticmaalka cidhif toosan oo dhererkeedu yahay 10 ft (3 mitir) oo la dhigay si labada daraf ay ula xiriiraan tuubada |

| Dhumucda | 0.01 inji [0.3 mm] | Dhumucda derbiga ugu yar ayaa ka yar dhumucda magaca ee la cayimay |

| Dhererka | 0-+0.5in [0-+13mm] | dhammaad aan mashiin |

ASTM A672 muuqaalka

Tuubada dhammaatay waa in aanay lahayn cillado dhaawici ah oo waxay yeelan doontaa dhammayn shaqo oo kale ah.

Shuruudaha la midka ah sida ku qeexan ASTM A20/A20M ee dhammaystirka dusha sare ee taarikada birta.

Cilladaha iyo Dayactirka

Go'aaminta Cilad

Heerka ASTM A672 ma qeexayo heerarka la aqbali karo ee cilladaha iyo shuruudaha go'aaminta tuubooyinka oo badanaa waxay tixraacaan heerarka injineernimada ee khuseeya iyo dhaqamada warshadaha.

Cilladaha gudaha: Cilladaha gudaha waxaa ka mid noqon kara porosity, slag, ka mid ahaanshaha, iwm.

Cilladaha dibadda: Cilladaha dibadda waxaa ka mid noqon kara dildilaaca, jeexjeexyada, xagashada, iwm.

Ka saarida iyadoo dib loo eegayo

Cilladaha dusha sare waxaa lagaga saari karaa si xad dhaaf ah oo loo shiilo ama makiinado leh dhumuc haraaga ah oo aan ka yarayn 0.3 mm oo ka hooseeya dhumucda caadiga ah.

Niyad-jabka dib-u-kicinta waa in si isku mid ah loogu dhex daraa dusha ku wareegsan.

Dayactirka alxanka

Cilladaha waa in lagu baabi'iyaa hab ku habboon makaanik ama kuleyl goynta ama hababka jeexjeexa oo loo diyaariyo in lagu hagaajiyo godadka alxanka ah.

iyo shucaac ahaan loo baadhay iyadoo la raacayo ASME Boiler and Pressure Code, Qaybta VIII, Faqrada UW-51.

Dhererka buuxa ee tuubada la hagaajiyay waa in lagu daaweeyaa kuleyl ka dib dayactirka iyadoo la raacayo shuruudaha heerka tuubooyinka ee la cayimay.

Calaamadeynta ASTM A672

Calaamadaynta waa inay ka kooban tahay kuwan soo socda:

Aqoonsiga soo saaraha, sida summada ganacsiga ama astaanta.

Cadaynta tuubada (xajmiga, dhumucda gidaarka, iwm.).

Heerka maadada ama nooca tuubada.Tusaale: C60-22 (soo gaabinta darajada: C60 iyo fasalka 22).

Heerka wax soo saarka ee tuubada waa ASTM A672.

Taariikhda wax-soo-saarka ama tirada badan ee wax-soo-saarka.

Codsiga ASTM A672 Steel Pipe

Warshadaha korantada, ASTM A672 Electric Welded Steel Pipe waxaa caadi ahaan loo isticmaalaa in lagu gudbiyo uumiga nidaamyada kuleyliyaha.

Warshadaha kiimikada, ASTM A672 tubbada birta welded waxaa inta badan loo isticmaalaa in lagu qaado kiimikooyin kala duwan, acid, iyo xalalka alkali, iyo warbaahinta kale.

Warshadaha saliidda iyo gaaska, ASTM A672 tuubooyinka birta alxanka leh ayaa caadi ahaan loo isticmaalaa in lagu qaado saliid ceyriin, gaaska dabiiciga ah, iyo dareerayaasha kale ama gaaska.

Waxaan nahay soo saaraha tuubooyinka birta kaarboonka ah ee tayada sare leh iyo alaab-qeybiye ka yimid Shiinaha, iyo sidoo kale kaydiyaha birta birta ah, oo ku siinaya noocyo badan oo ah xalalka tuubooyinka birta!

Tags: ASTM a672, efw, tuubada birta kaarboon, darajada.

Waqtiga boostada: Abriil-23-2024