API 5L X42, eo hape e tsejoang e le L290, ke mofuta oa pipe ea mohala o sebelisoang indastering ea oli le khase.

Lintho tse bonahalang ke abonyane ba lihlahisoa matla a 42,100 psi(290 MPa) le amatla a fokolang a 60,200 psi(415 MPa). Ke mophato o le mong ho feta API 5L Kereiti ya B mme e loketse dikopo tsa matla a mahareng.

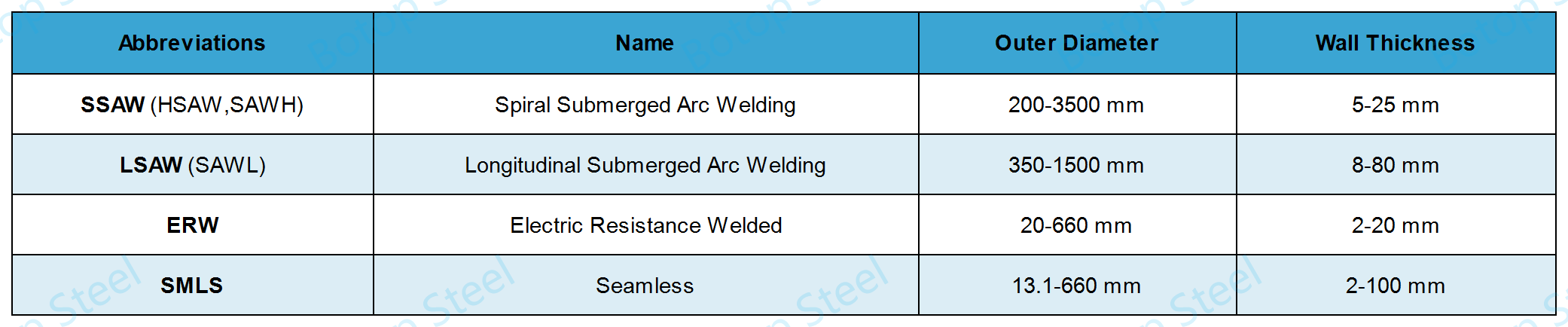

X42 e atisa ho etsoa ka Seamless, SSAW, LSAW, le ERW. Li-coatings le li-finishing li fumaneha ho fihlela litlhoko tse khethehileng tsa kopo.

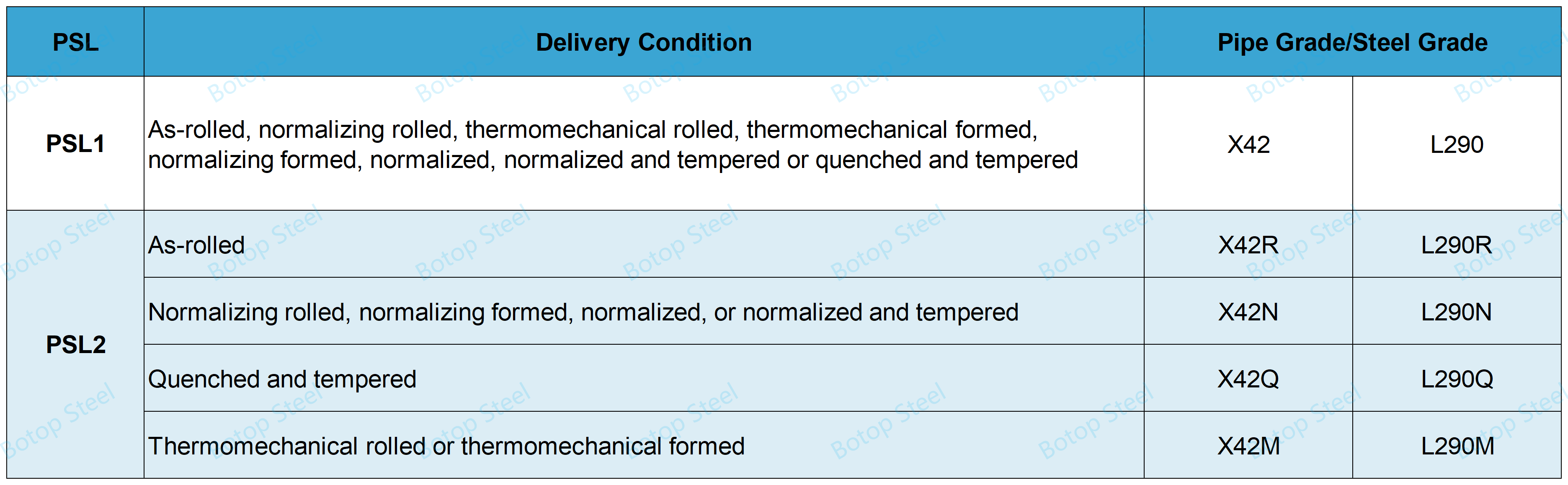

Maemo a Phano

Ho ipapisitsoe le maemo a phano le boemo ba PSL, e ka aroloa ka tsela e latelang:

PSL1: X42 kapa L290;

PSL2: X42R, X42N, X42Q, X42M kapa L290R, L290N, L290Q, L290M;

Litlhaku tsa sehlomathi sa PSL2 ka 'ngoe li emela phekolo e fapaneng ea mocheso.

R: Qholotsoe;

N: Ho tloaelehile;

Q: E timisitsoe ebile e halefile;

M: Phekolo ea Thermo-mechanical.

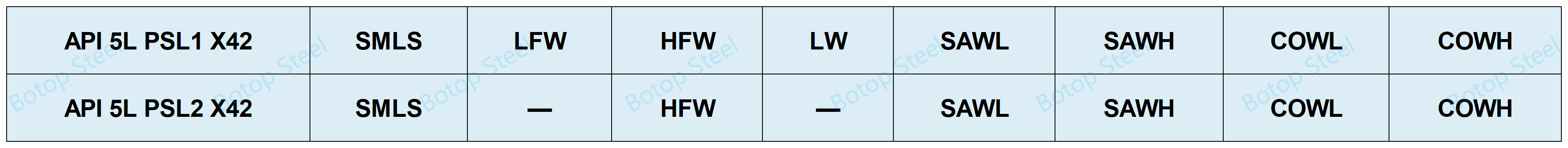

Mokhoa oa Tlhahiso

X42 e lumella ts'ebetso e latelang ea tlhahiso:

Haeba u fumana ho le thata ho utloisisa likhutsufatso tsena, sheba pokello ea rona ea lingoliloeng holikhutsufatso tse tloaelehileng bakeng sa liphaephe tsa tšepe.

Botop Steel e ka u fa mefuta e mengata ea boholo ba liphaephe joalokaha ho bontšitsoe tafoleng e ka tlaase.

Thepa ea rona e fapaneng

E tloaelehileng: API 5L (ISO 3183);

PSL1: X42 kapa L290;

PSL2: X42R, X42N, X42Q, X42M kapa L290R, L290N, L290Q, L290M;

Peipi ea tšepe e cheselitsoeng:LSAW(SAWL), SSAW (HSAW), DSAW, ERW;

Peipi ea tšepe e se nang seam:SMLS;

Lits'ebetso tsa Pipe: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 le SCH160.

Boitsebiso: STD (E Tloaelehileng), XS (E Eketsehileng e Matla), XXS (Double Extra Strong);

Ho roala: pente, varnish,3LPE, FBE, 3LPP, HDPE, galvanized, epoxy zinc-rich, samente e boima, joalo-joalo.

Packing: Lesela le sa keneleng metsi, mokotla oa lepolanka, lebanta la tšepe kapa ho kopanya terata ea tšepe, mosireletsi oa ho qetela oa phala ea polasetiki kapa ea tšepe, joalo-joalo.

Lihlahisoa tse tsamaellanang: Bends,flanges, lisebelisoa tsa liphaephe, le lihlahisoa tse ling tse tšoanang li teng.

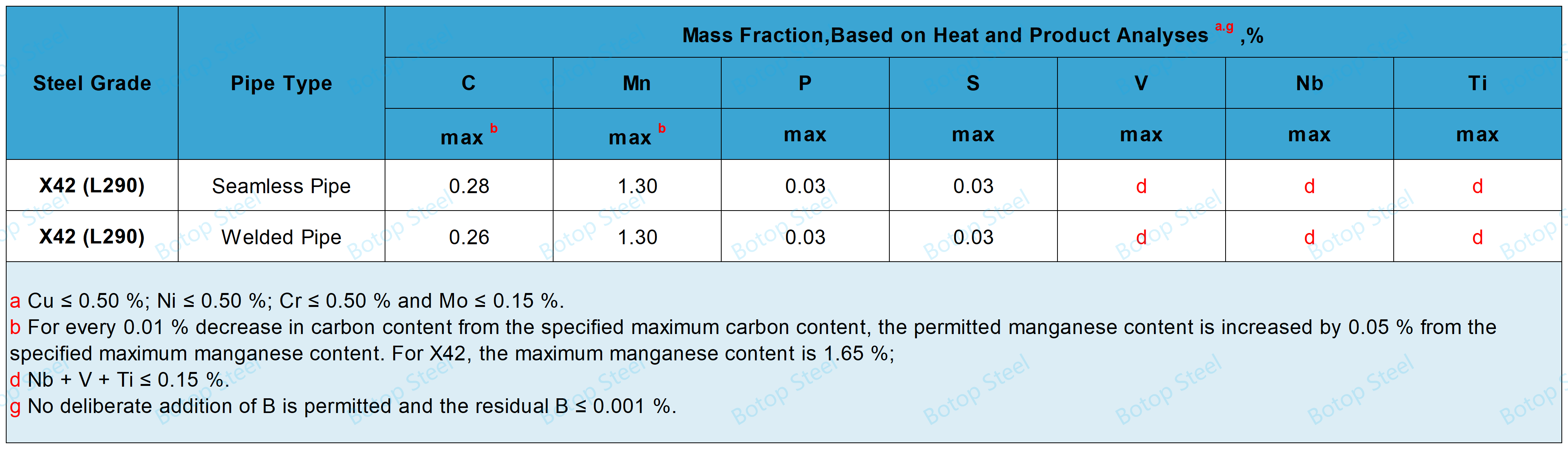

API 5L X42 Sebopeho sa Lik'hemik'hale

Sebopeho sa Lik'hemik'hale bakeng sa PSL 1 Pipe e nang le t ≤ 25.0 mm (0.984 in.)

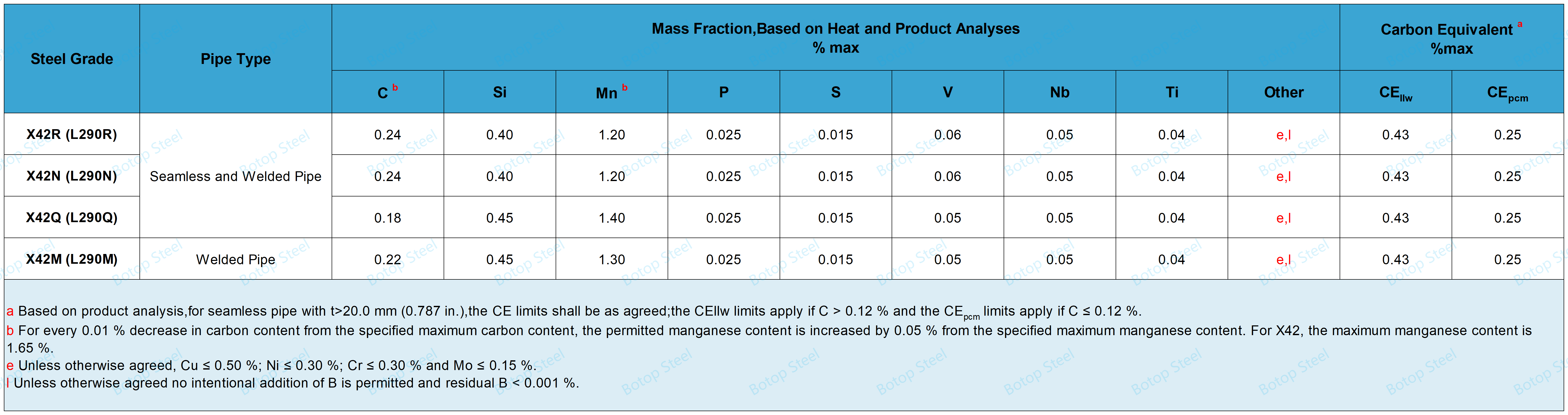

Sebopeho sa Lik'hemik'hale bakeng sa PSL 2 Pipe e nang le t ≤ 25.0 mm (0.984 in.)

Bakeng sa lihlahisoa tsa lipeipi tsa tšepe tsa PSL2 tse hlahlobiloeng kakhabone ea ≤0.12%, k'habone e lekanang le CEpcme ka baloa ho sebelisoa foromo e latelang:

CEpcm= C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

Bakeng sa lihlahisoa tsa lipeipi tsa tšepe tsa PSL2 tse hlahlobiloeng kakhabone > 0.12%, k'habone e lekanang le CEllwe ka baloa ho sebelisoa foromo e ka tlase:

CEllw= C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

Sebopeho sa Lik'hemik'hale se nang le t > 25.0 mm (0.984 in.)

Sena se ka buisanoa ka ho bua ka sebopeho sa lik'hemik'hale ka holimo.

API 5L X42 Mechanical Properties

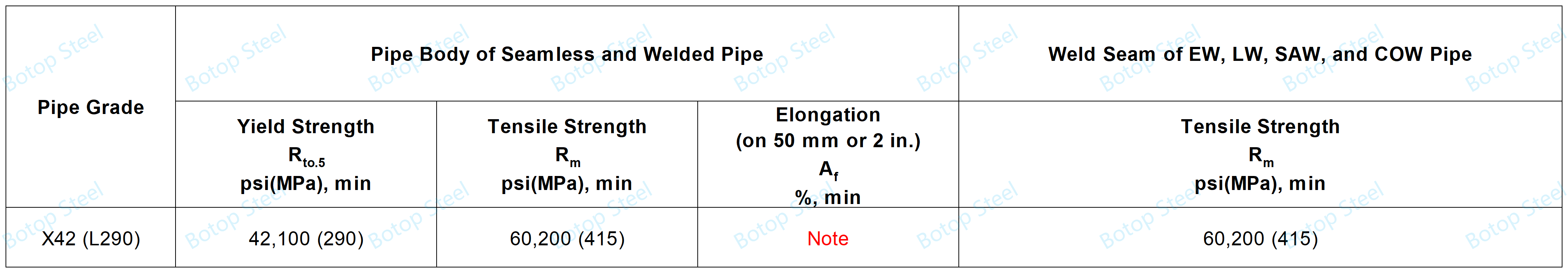

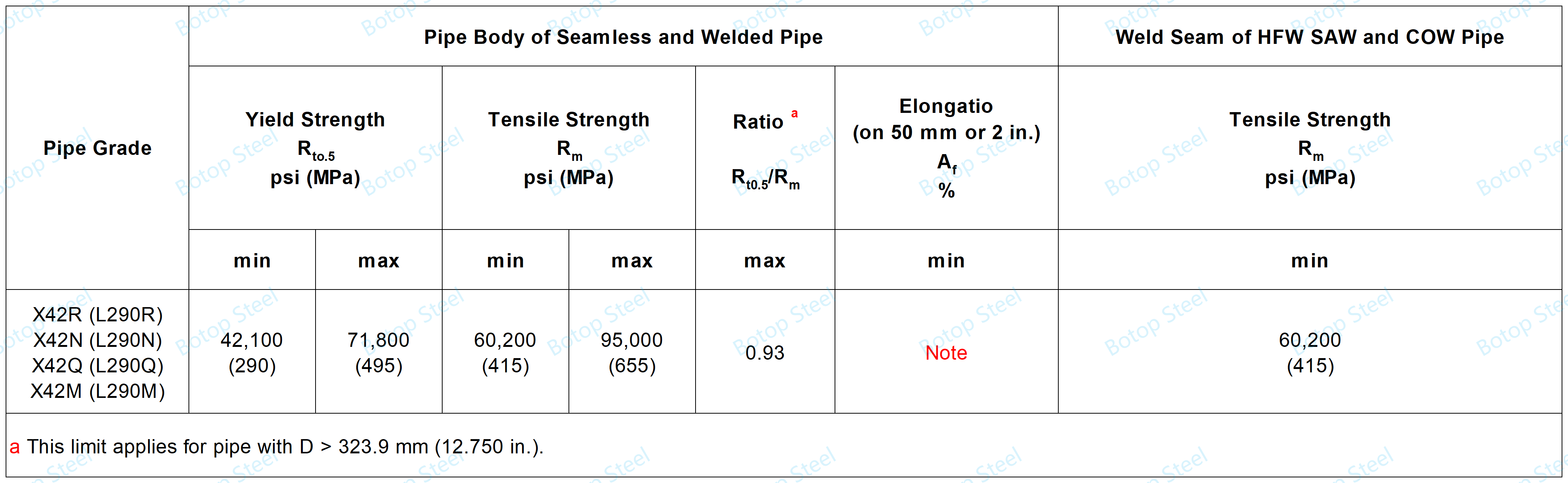

Tensile Properties

Teko ea tensile ke teko ea bohlokoa bakeng sa thepa ea mochini ea li-tubes tsa tšepe, tse khonang ho lekanya matla a chai, matla a ho tsitsa, le likarolo tsa bohlokoa tsa bolelele.

Matla a tlhahiso ea X42 ke 42,100 psi kapa 290 MPa.

Matla a tensile ea X42 ke 60,200 psi kapa 415 MPa.

PSL1 X42 Thepa ea Tensile

Thepa ea PSL2 X42 Tensile

Hlokomela: Litlhokahalo li hlalositsoe ka botlalo karolong ea Mechanical Properties eaAPI 5L X52, e ka bonoang ka ho tobetsa fonte e putsoa haeba u thahasella.

Liteko tse ling tsa Mechini

Bend Test

Teko e bataletseng

Tataiso e kobehang Teko

CVN Impact Test bakeng sa PSL 2 Pipe

Teko ea DWT bakeng sa PSL 2 Pipe e Welded

Ha e le hantle, ha se li-tubes tsohle tse lokelang ho hlahlojoa bakeng sa lisebelisoa tse feletseng tsa mechine, empa ho e-na le hoo, liteko li khethoa ho latela mofuta oa tube. Litlhoko tse khethehileng li ka fumanoa ho Tafole 17 le 18 ea API 5L standard.

U ka boela ua ikopanya le rona bakeng sa tlhahisoleseding ena.

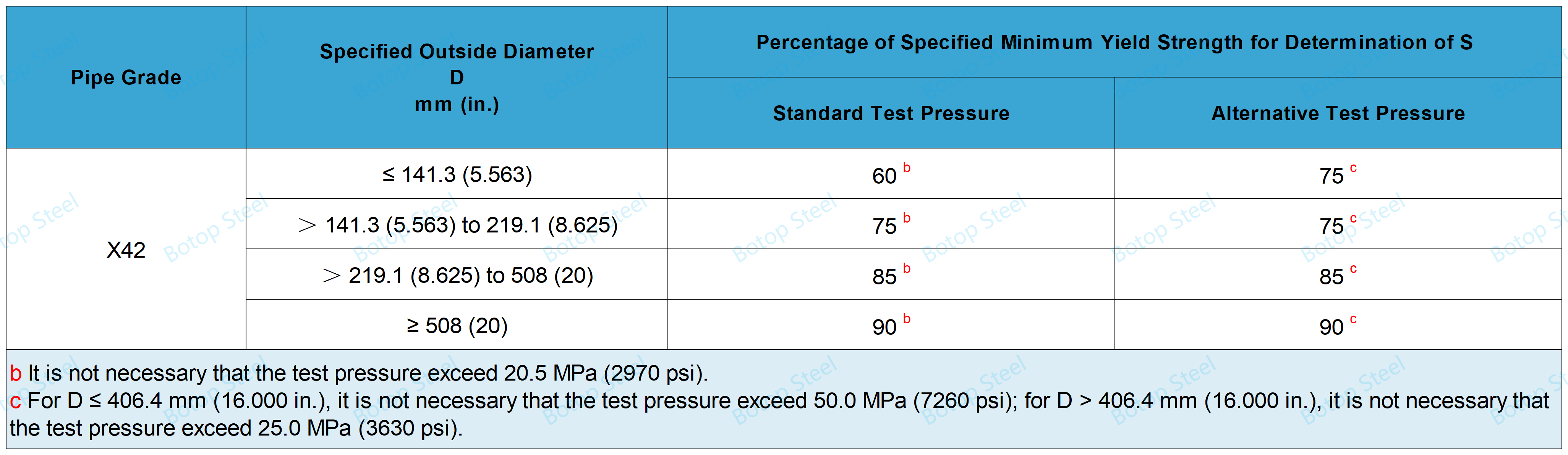

Teko ea Hydrostatic

Nako ea Teko

Mefuta eohle ea li-tubes tsa tšepe tse se nang moroallo le tse cheselitsoeng tse nang le D ≤ 457 mm (18 in.):nako ea teko ≥ 5s;

Peipi ea tšepe e cheselitsoeng D > 457 mm (18 in.):nako ea teko ≥ 10s.

Maqhubu a Teko

Pipe e 'ngoe le e' ngoe ea tšepemme ho ke ke ha ba le ho dutla ho tswa ho weld kapa mmele wa pipe nakong ya teko.

Likhatello tsa teko

Khatello ea teko ea hydrostatic P ea apeipi ea tšepe e se nang lethoe ka baloa ka ho sebelisa foromo.

P = 2St/D

Ske khatello ea maikutlo. boleng bo lekana le matla a fokolang a tlhahiso a fokolang a peresente ea pipe xa peresente, ho MPa (psi);

tke botenya ba lebota bo boletsoeng, bo hlahisoang ka limilimithara (lisenthimithara);

Dke bophara bo ka ntle bo boletsoeng, bo hlahisoang ka limilimithara (inchi).

Tlhahlobo e sa Senyeheng

Bakeng sa li-tubes tsa SAWmekhoa e 'meli,UT(tlhahlobo ea ultrasonic) kapaRT(tlhahlobo ea radiographic), hangata e sebelisoa.

ET(tlhahlobo ea motlakase) ha e sebetse ho li-tubes tsa SAW.

Li-welded seams liphaepheng tse cheselitsoeng tsa lihlopha ≥ L210/A le bophara ba ≥ 60.3 mm (2.375 ka) li tla hlahlojoa ka mokhoa o sa tsitsang bakeng sa botenya le bolelele bo feletseng (100 %) joalokaha ho boletsoe.

Tlhahlobo ea UT e sa senyeheng

Tlhahlobo ea RT e sa senyeheng

Li-tubes tsohle tse se nang moroallo tsa PSL 2, le li-tubes tse tingoeng le tse halefileng tsa PSL1 Grade B, li tla etsoa liteko tse sa senyeheng tsa bolelele bo felletseng (100%).

E le 'ngoe kapa motsoako oa ET (Electromagnetic Testing), UT (Ultrasonic Testing), le MT (Magnetic Particle Testing) e ka sebelisoa bakeng sa NDT.

Dimensional Tolerances

Litlhoko tsa API 5L bakeng sa mamello ea boholo li hlalositsoe ka botlalo hoAPI 5L Sehlopha sa B. Ho qoba ho pheta-pheta, o ka tobetsa fonte e putsoa ho bona lintlha tse amehang.

Chate ea Kemiso ea Pipe ea API 5L

Bakeng sa ho shebella le ho sebelisoa habonolo, re hlophisitse kemiso e nepahetseng ea lifaele tsa PDF. U ka khoasolla le ho sheba litokomane tsena ha ho hlokahala.

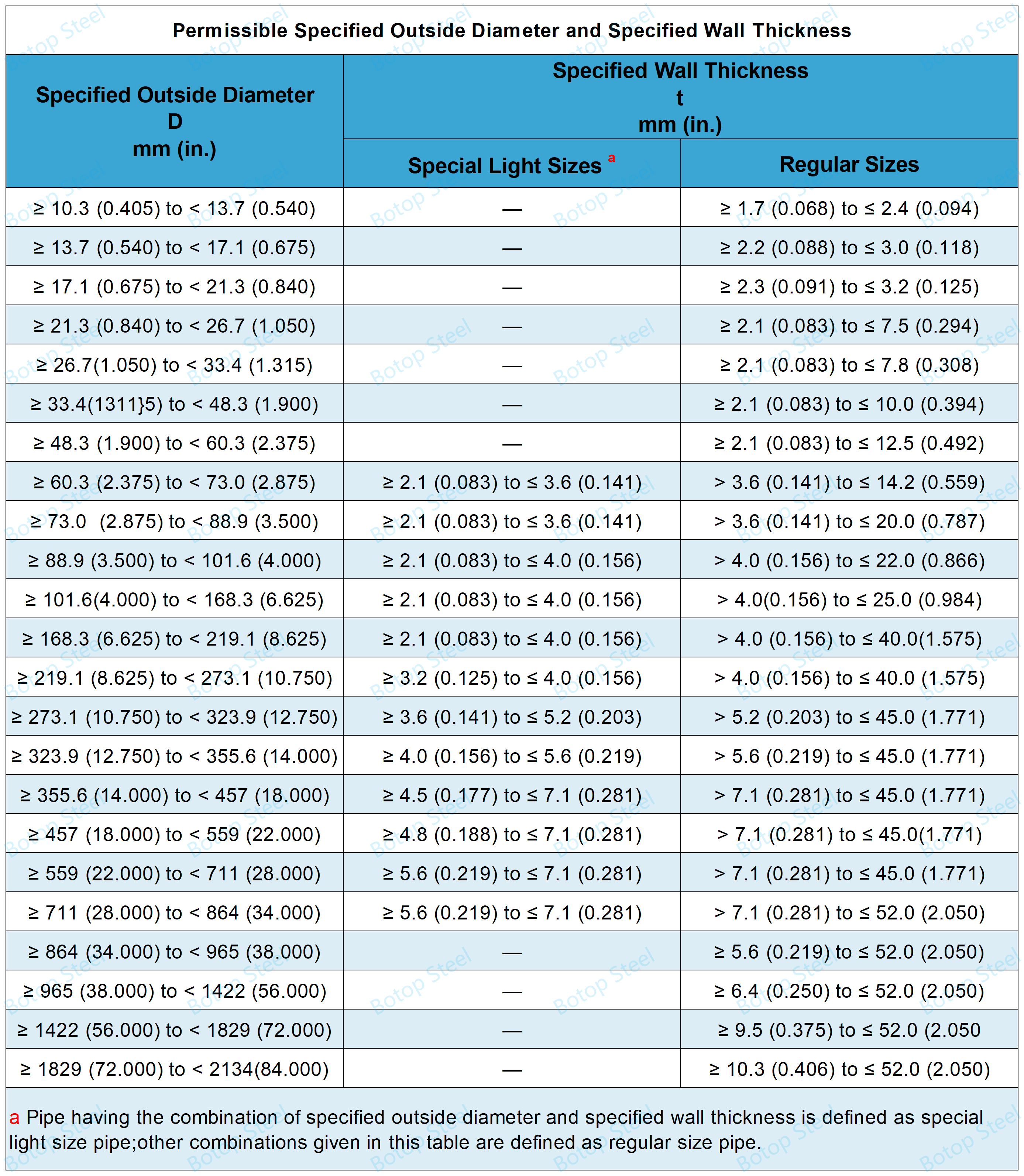

Ntle le moo, API 5L e totobatsa tumello e boletsoeng ka ntle ho bophara le botenya ba lebota bo boletsoeng.

Dimensional Tolerances

Litlhoko tsa API 5L bakeng sa mamello ea boholo li hlalositsoe ka botlalo hoAPI 5L Sehlopha sa B. Ho qoba ho pheta-pheta, o ka tobetsa fonte e putsoa ho bona lintlha tse amehang.

Lihlahisoa tsa rona tse Amanang

Ho tloha ha e thehoa ka 2014,Botop Steele fetohile morekisi ea ka sehloohong oa pipe ea tšepe ea carbon e ka Leboea ea Chaena, e tsejoang ka tšebeletso e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse pharaletseng.

Khampani e fana ka mefuta e sa tšoaneng ea liphaephe tsa tšepe ea carbon le lihlahisoa tse amanang le tsona, tse kenyelletsang seamless, ERW, LSAW, le phala ea tšepe ea SSAW, hammoho le lethathamo le feletseng la liphaephe le li-flanges. Lihlahisoa tsa eona tse khethehileng li boetse li kenyelletsa li-alloys tsa boemo bo phahameng le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho finyella litlhoko tsa merero e fapaneng ea liphaephe.