API 5L X60 (L415) ke phala ea molae nang le matla a bonyane a tlhahiso ea 60,200 (415 MPa) bakeng sa ho sebelisoa lits'ebetsong tsa lipeipi tsa lipeipi indastering ea oli le khase.

X60e ka ba e se nang seam kapa mefuta e mengata ea li-tubing tsa tšepe tse cheselitsoeng, hangata LSAW (SAWL), SSAW (SAWH), le ERW.

Ka lebaka la matla a eona a phahameng le ho tšoarella ha nako e telele, pipeline ea X60 e atisa ho sebelisoa bakeng sa lipeipi tsa libaka tse telele kapa mesebetsi ea lipalangoang libakeng tse rarahaneng le libaka tse ling tse boima.

Botop Steelke moetsi ea hloahloa oa phala e teteaneng e nang le marako a maholo a bophara ba mahlakore a mabeli a kentsoeng ka metsing a LSAW a tšepe a fumanehang China.

·Sebaka: Motse oa Cangzhou, Profinseng ea Hebei, Chaena;

·Kakaretso ea Matsete: RMB e limilione tse 500;

·Sebaka sa fektheri: 60,000 square metres;

·Matla a tlhahiso ea selemo: lithane tse 200,000 tsa liphaephe tsa tšepe tsa JCOE LSAW;

·Thepa: Lisebelisoa tse tsoetseng pele tsa tlhahiso le tlhahlobo;

·Tse khethehileng: tlhahiso ea lipeipi tsa tšepe tsa LSAW;

·Setifikeiti: API 5L e netefalitsoe.

Maemo a Phano

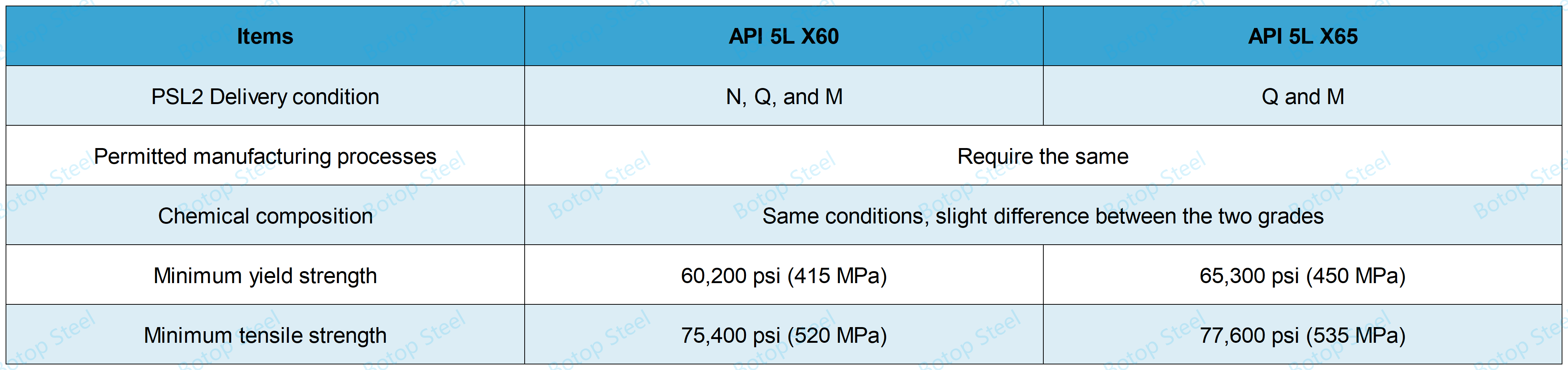

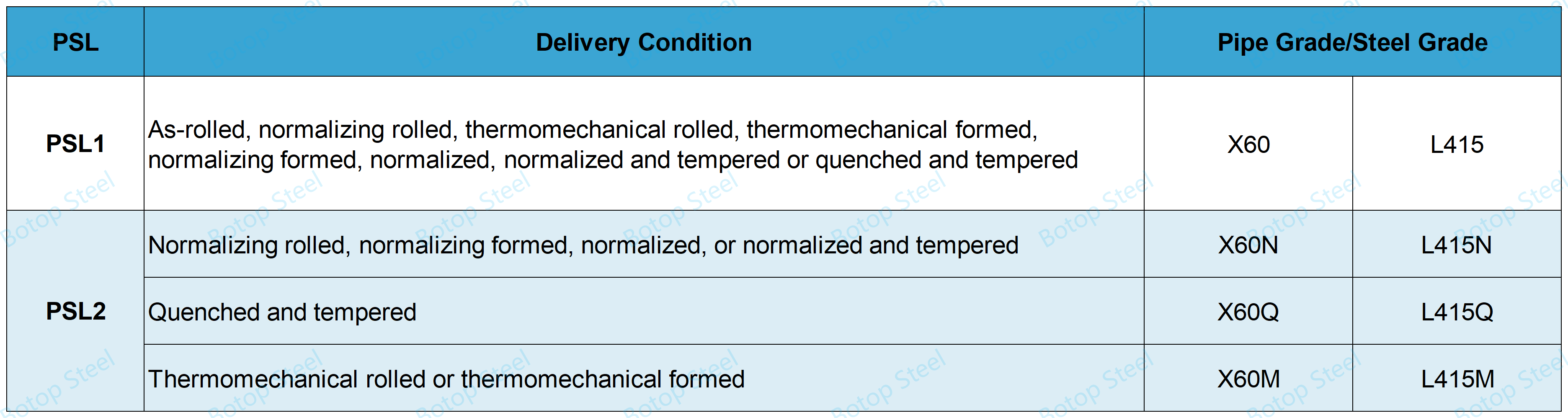

Ho ipapisitsoe le maemo a phano le boemo ba PSL, X60 e ka aroloa ka tsela e latelang:

PSL1: x60 kapa L415;

PSL2: X60N, X60Q, X60M kapa L415N, L415Q, L415M.

N: E bontša ho tloaeleha ha thepa. Ka ho futhumatsa tšepe mochesong o itseng o lateloa ke ho pholisa moea. Ho ntlafatsa microstructure le thepa ea mechine ea tšepe le ho eketsa toughness ea eona le ho tsitsana.

Q: E eme bakeng sa ho tima le ho halefisa. Ho futhumatsa tšepe ka ho e futhumatsa mocheso o itseng, ho e pholisa ka potlako, ebe o e futhumatsa hape mochesong o tlaase. Ho fumana ho leka-lekana ha thepa e khethehileng ea mochine, joalo ka matla a phahameng le ho tiea.

M: E bontša phekolo ea thermo-mechanical. Motsoako oa kalafo mocheso le machining ho optimize microstructure le thepa ea tšepe. Hoa khoneha ho eketsa matla le ho tiea ha tšepe ha u ntse u boloka thepa e ntle ea welding.

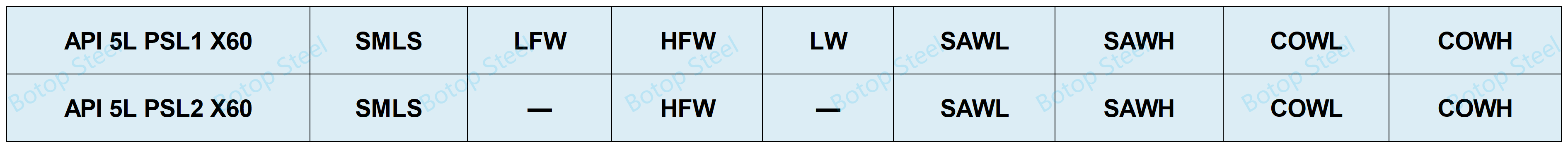

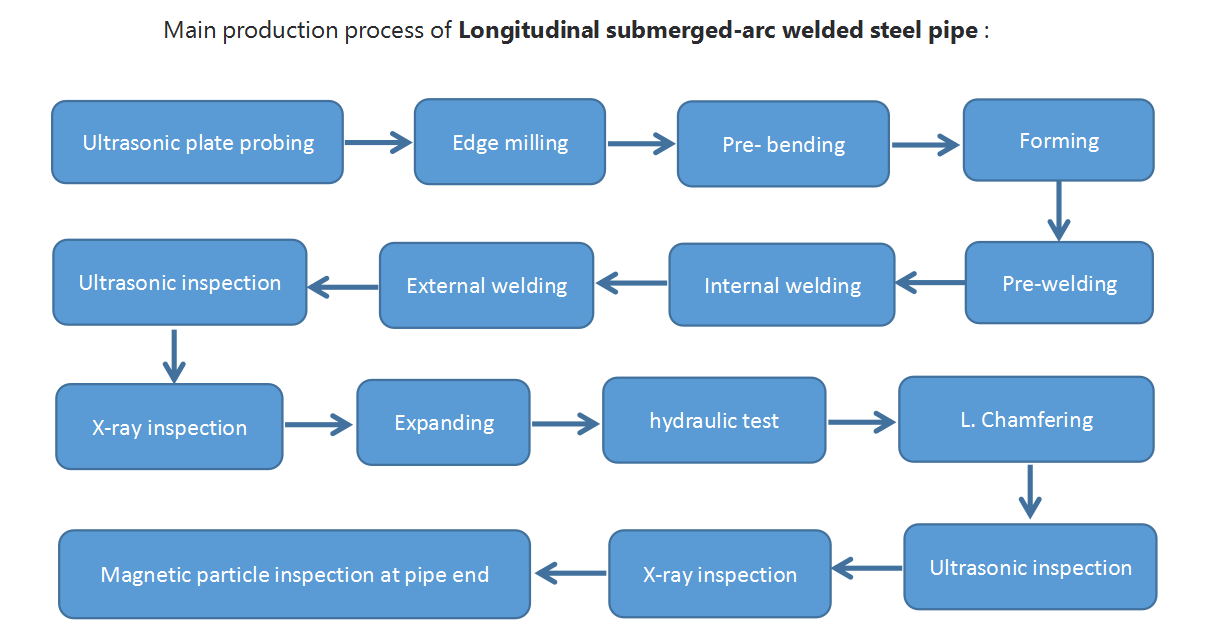

API 5L X60 Manufacturing Process

Mokhoa o amohelehang oa ho etsa li-tube tsa tšepe bakeng sa X60

Haeba u fumana ho le thata ho utloisisa likhutsufatso tsena, sheba pokello ea rona ea lingoliloeng holikhutsufatso tse tloaelehileng bakeng sa liphaephe tsa tšepe.

Melemo ea SAWL (LSAW)

Haeba o hloka phala e kholo ea bophara bo botenya ba tšepe, khetho ea pele keSAWL (LSAW) pipe ea tšepe.Pipe ea tšepe ea LSAW e ka hlahisoa ka boholo bo fihlang ho 1500mm ka bophara le 80mm ka botenya ba lebota, e khonang ka ho feletseng ho finyella litlhoko tsa lipeipi tsa libaka tse telele bakeng sa merero e meholo.

Ntle le moo, nakong ea ts'ebetso ea tlhahiso, phala ea tšepe ea LSAW e amohela litšepe tse nang le mahlakore a mabeli a ka tlas'a metsi.DSAW) ts'ebetso, e netefatsang boleng ba seam weld.

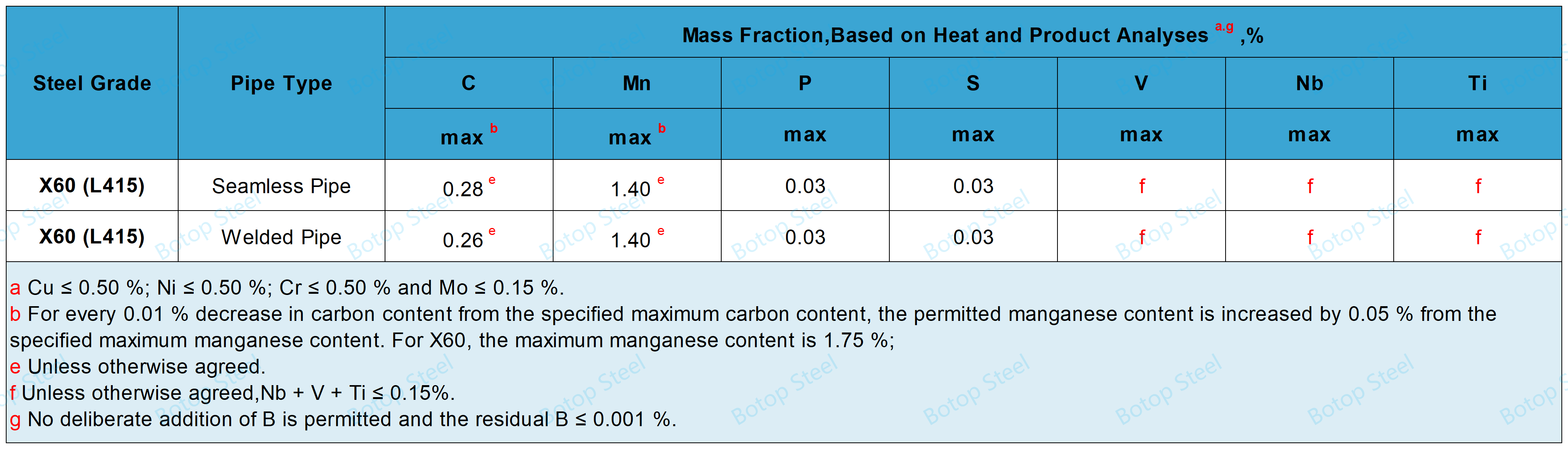

API 5L X60 Sebopeho sa Lik'hemik'hale

PSL1 e bonolo ho feta PSL2 mabapi le sebopeho sa lik'hemik'hale, thepa ea mochini, le litlhoko tse ling.

Sena ke hobanePSL1emela boemo bo tloaelehileng ba boleng ba pipeline tšepe phala, ha a ntse aPSL2e ka bonoa e le mofuta o ntlafalitsoeng oa PSL1, o fanang ka litlhaloso tse tsoetseng pele le taolo e thata ea boleng.

Sebopeho sa Lik'hemik'hale bakeng sa PSL 1 Pipe e nang le t ≤ 25.0 mm (0.984 in.)

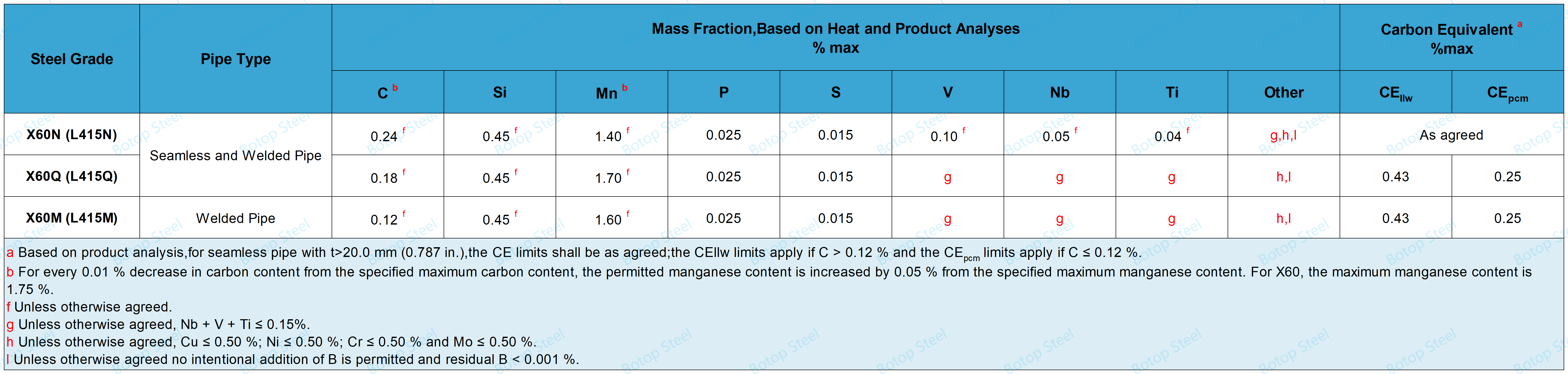

Sebopeho sa Lik'hemik'hale bakeng sa PSL 2 Pipe e nang le t ≤ 25.0 mm (0.984 in.)

Bakeng sa lihlahisoa tsa lipeipi tsa tšepe tsa PSL2 tse hlahlobiloeng kakhabone ea ≤0.12%, k'habone e lekanang le CEpcme ka baloa ho sebelisoa foromo e latelang:

CEpcm= C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

Bakeng sa lihlahisoa tsa lipeipi tsa tšepe tsa PSL2 tse hlahlobiloeng kakhabone > 0.12%, k'habone e lekanang le CEllwe ka baloa ho sebelisoa foromo e ka tlase:

CEllw= C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

Sebopeho sa Lik'hemik'hale se nang le t > 25.0 mm (0.984 in.)

E tla khethoa ka lipuisano le ho fetoloa hore e be sebopeho se loketseng ho latela litlhoko tsa motsoako oa lik'hemik'hale tse ka holimo.

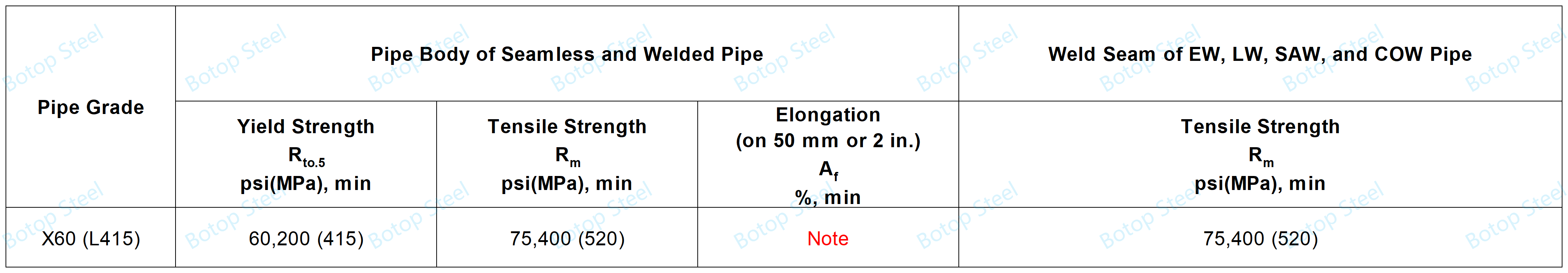

API 5L X60 Mechanical Properties

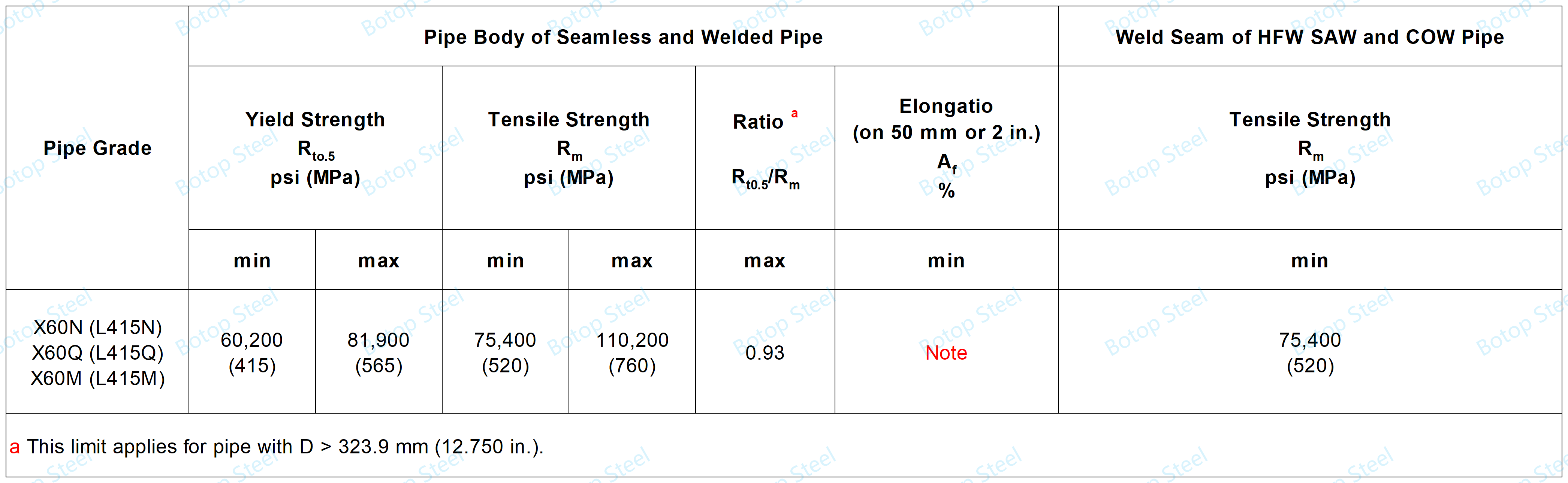

Tensile Properties

Teko ea tensile ke lenaneo la bohlokoa la liteko bakeng sa ho lekola litšobotsi tsa mochini oa li-tubes tsa tšepe. Teko ena e lumella ho etsa qeto ea litekanyo tsa bohlokoa tsa thepa, ho kenyelletsafana ka matla, matla a tšepe, le etjantjello.

Thepa ea PSL1 X60 Tensile

Thepa ea PSL2 X60 Tensile

Hlokomela: Litlhokahalo li hlalositsoe ka botlalo karolong ea Mechanical Properties eaAPI 5L X52, e ka bonoang ka ho tobetsa fonte e putsoa haeba u thahasella.

Liteko tse ling tsa Mechini

Lenaneo le latelang la litekoe sebetsa ho mefuta ea lipeipi tsa tšepe tsa SAW feela.

Weld guide kobang teko;

Teko ea boima ba phala e entsoeng ka serame;

Tlhahlobo ea macro ea seam welded;

mme feela bakeng sa phala ea tšepe ea PSL2: Teko ea phello ea CVN le tlhahlobo ea DWT.

Lintho tsa liteko le maqhubu a liteko tsa mefuta e meng ea lipeipi li ka fumanoa ho Tafole 17 le 18 ea API 5L e tloaelehileng.

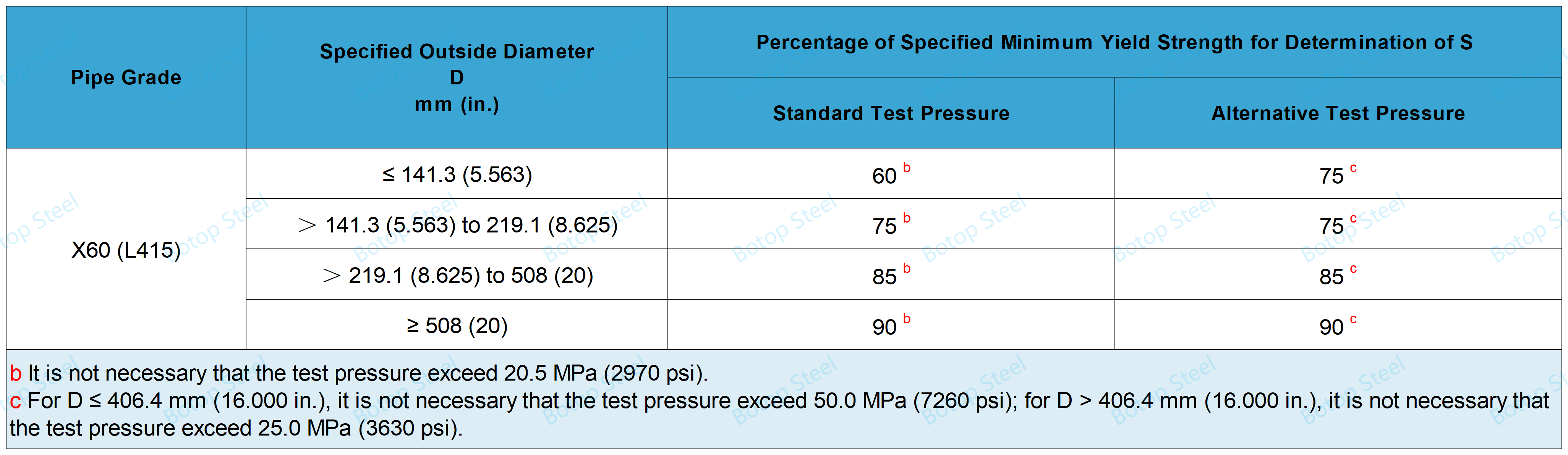

Teko ea Hydrostatic

Nako ea Teko

Mefuta eohle ea li-tubes tsa tšepe tse se nang moroallo le tse cheselitsoeng tse nang le D ≤ 457 mm (18 in.):nako ea teko ≥ 5s;

Peipi ea tšepe e cheselitsoeng D > 457 mm (18 in.):nako ea teko ≥ 10s.

Maqhubu a Teko

Pipe e 'ngoe le e' ngoe ea tšepemme ho ke ke ha ba le ho dutla ho tswa ho weld kapa mmele wa pipe nakong ya teko.

Likhatello tsa teko

Khatello ea teko ea hydrostatic P ea apeipi ea tšepe e se nang lethoe ka baloa ka ho sebelisa foromo.

P = 2St/D

Ske khatello ea maikutlo. boleng bo lekana le matla a fokolang a tlhahiso a fokolang a peresente ea pipe xa peresente, ho MPa (psi);

tke botenya ba lebota bo boletsoeng, bo hlahisoang ka limilimithara (lisenthimithara);

Dke bophara bo ka ntle bo boletsoeng, bo hlahisoang ka limilimithara (inchi).

Tlhahlobo e sa Senyeheng

Bakeng sa li-tubes tsa SAWmekhoa e 'meli,UT(tlhahlobo ea ultrasonic) kapaRT(tlhahlobo ea radiographic), hangata e sebelisoa.

ET(tlhahlobo ea motlakase) ha e sebetse ho li-tubes tsa SAW.

Li-welded seams liphaepheng tse cheselitsoeng tsa lihlopha ≥ L210/A le bophara ba ≥ 60.3 mm (2.375 ka) li tla hlahlojoa ka mokhoa o sa tsitsang bakeng sa botenya le bolelele bo feletseng (100 %) joalokaha ho boletsoe.

Tlhahlobo ea UT e sa senyeheng

Tlhahlobo ea RT e sa senyeheng

Chate ea Kemiso ea Pipe ea API 5L

Bakeng sa ho shebella le ho sebelisoa habonolo, re hlophisitse kemiso e nepahetseng ea lifaele tsa PDF. U ka khoasolla le ho sheba litokomane tsena ha ho hlokahala.

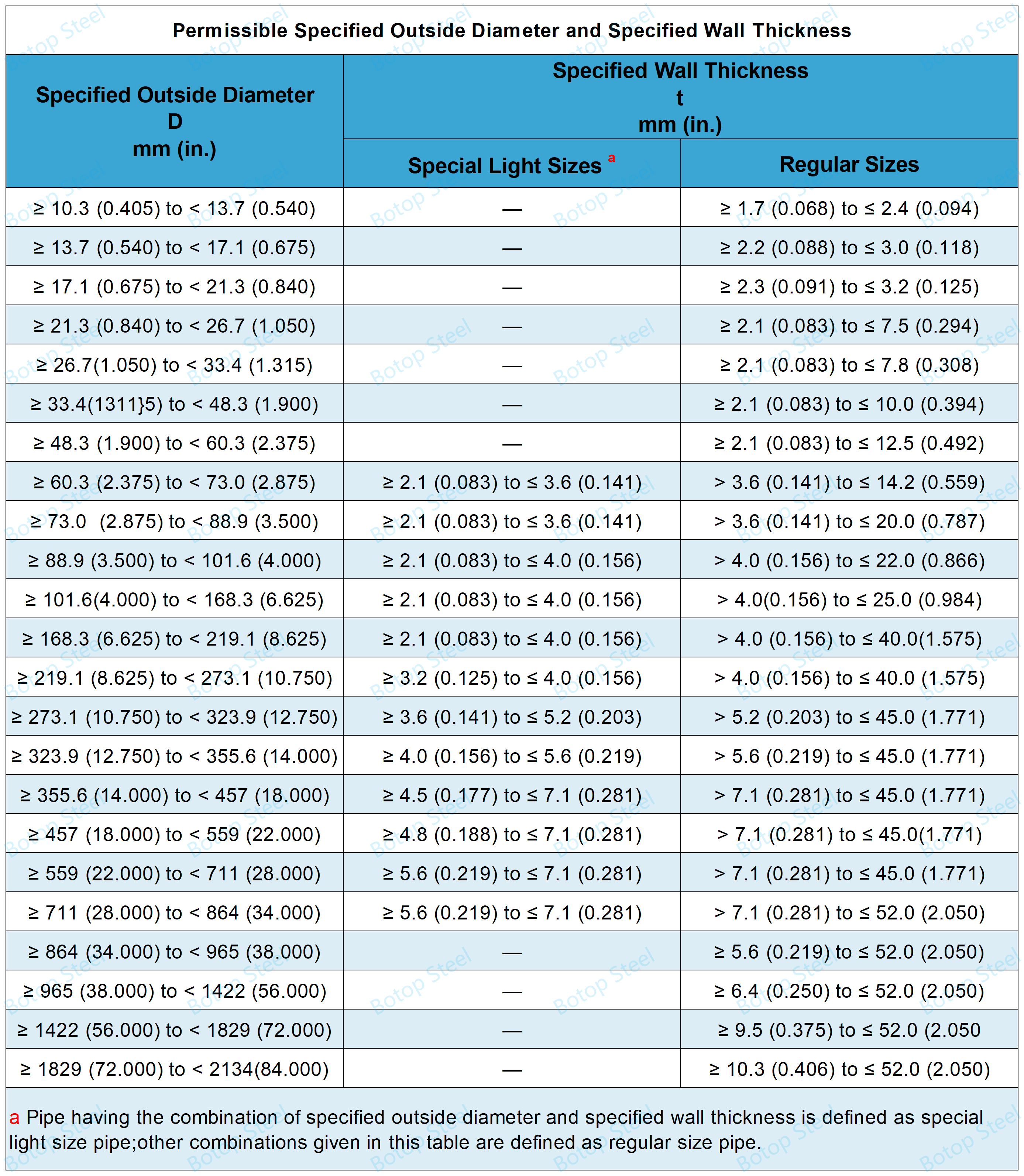

Hlalosa Kantle ho Diameter le Botenya ba Lebota

Litekanyetso tse emeng bakeng sa li-diameter tse boletsoeng ka ntle le botenya ba lebota bo boletsoeng ba phala ea tšepe li fanoaISO 4200leASME B36.10M.

Dimensional Tolerances

Litlhoko tsa API 5L bakeng sa mamello ea boholo li hlalositsoe ka botlalo hoAPI 5L Sehlopha sa B. Ho qoba ho pheta-pheta, o ka tobetsa fonte e putsoa ho bona lintlha tse amehang.

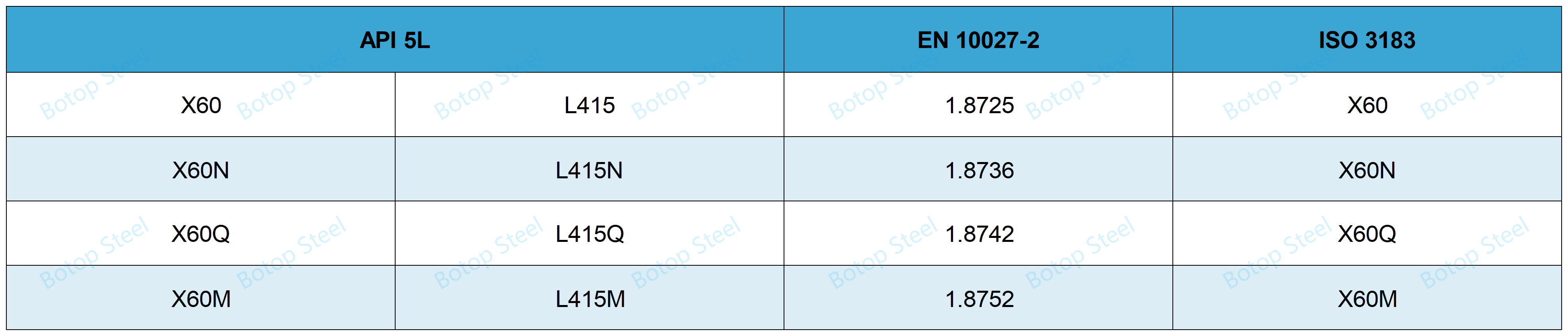

X60 Steel Equivalent le eng?

Phapano ke Efe Pakeng tsa API 5L X60 le X65?