ASTM A178lipeipi tsa tšepe ke lipeipi tse kopantsoeng ka ho hanyetsa motlakase (ERW) tsatšepe ea k'habone le k'habone-manganesee sebelisoa e le liphaephe tsa boiler, liphaephe tsa boiler, liphaephe tsa superheater, le lipheletso tsa polokeho.

E loketse lipeipi tsa tšepe tse bophara ba kantle ba 12.7-127mm le botenya ba lebota bo pakeng tsa 0.9-9.1mm.

Li-tube tsa ASTM A178 li loketse li-tube tse kopantsoeng ka ho hanyetsa tse nang lebophara ba kantle bo pakeng tsa 1/2 - 5 in [12.7 - 127 mm] le botenya ba lebota bo pakeng tsa 0.035 - 0.360 in [0.9 - 9.1 mm], leha boholo bo bong bo fumaneha ha ho hlokahala, ha feela lipeipi tsena li fihlela litlhoko tse ling tsohle tsa tlhaloso ena.

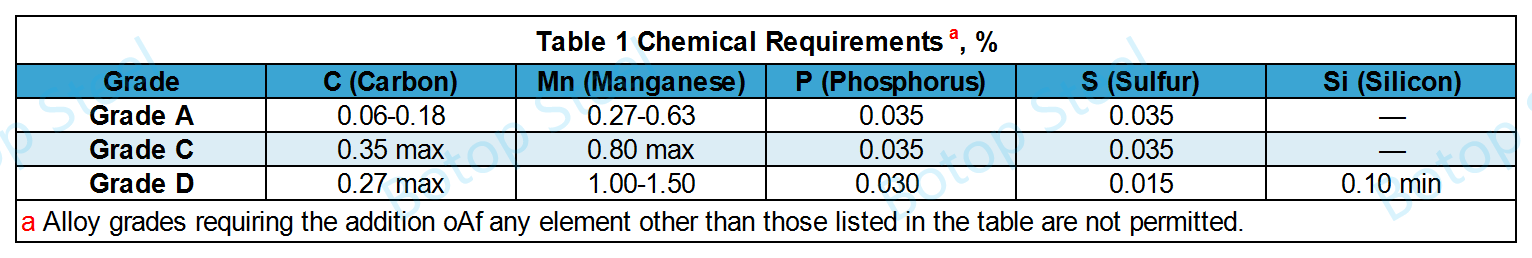

Ho na le mekhahlelo e meraro ea ho sebetsana le maemo a fapaneng a ts'ebeliso.

Sehlopha sa A, Sehlopha sa C, le Sehlopha sa D.

| Sehlopha | Mofuta oa Tšepe ea Khabone |

| Sehlopha sa A | Tšepe e nang le Khabone e Tlase |

| Sehlopha sa C | Tšepe ea Khabone e Mahareng |

| Sehlopha sa D | Tšepe ea Carbon-Manganese |

Thepa e fanoeng tlas'a tlhaloso ena e tla latela litlhoko tse sebetsang tsa khatiso ea hona joale ea Tlhaloso A450/A450M. ntle le haeba ho fanoe ka tsela e 'ngoe mona.

Sehlopha sa AleSehlopha sa Cu se ke ua totobatsa tšepe e itseng; khetha thepa e tala e loketseng ha ho hlokahala.

Tšepe bakeng saSehlopha sa Do tla bolaoa.

Tšepe e bolailoeng e hlahisoa ka ho eketsa li-deoxidizer (mohlala, silicon, aluminium, manganese, jj.) ho tšepe e qhibilihisitsoeng nakong ea ts'ebetso ea tlhahiso ea tšepe, ka hona ho fokotsa kapa ho felisa oksijene ea tšepe.

Kalafo ena e ntlafatsa ho tšoana le botsitso ba tšepe, e ntlafatsa litšobotsi tsa eona tsa mechini, 'me e ntlafatsa ho hanyetsa mafome.

Ka hona, litšepe tse bolailoeng li sebelisoa haholo lits'ebetsong moo ho hlokahalang tekanyo e phahameng ea ho tšoana le thepa e ntle ea mechini, joalo ka tlhahiso ea lijana tsa khatello, liboiler le likarolo tse kholo tsa sebopeho.

Liphaephe tsa tšepe li etsoa ka ho sebelisaERWmokhoa oa tlhahiso.

ERW (E kopantsoeng le Khanyetso ea Motlakase)ke ts'ebetso e loketseng hantle bakeng sa ho etsa phaephe ea tšepe ea khabone.

Ka melemo ea matla a ho tjheseletsa a phahameng, bokaholimo bo boreleli ba ka hare le ba kantle, lebelo le potlakileng la tlhahiso, le theko e tlase, e sebelisoa haholo masimong a mangata a indasteri le a kaho.

ASTM A178phaephe ea tšepee lokela ho phekoloa ka mochesonakong ea ts'ebetso ea tlhahiso. E sebelisetsoa ho ntlafatsa litšobotsi tsa mechini le botsitso ba sebopeho sa phaephe, hammoho le ho felisa likhatello tse ka beng li hlahisitsoe nakong ea ts'ebetso ea ho tjheseletsa.

Kamora ho tjheseletsa, diphaephe tsohle di tla futhumatswa mochesong wa 1650°F [900°C] kapa ho feta mme di latelwe ke ho phodisa moyeng kapa ka phapusing ya ho phodisa ya onto ya sepakapaka e laolwang.

Liphaephe tse huloang ka seramee tla phekoloa ka mocheso kamora hore ho fete ho batang ha ho qetela mochesong oa 650°C kapa ho feta.

Ha tlhahlobo ea sehlahisoa e etsoa, khafetsa ea tlhahlobo e fumanoa ka tsela e latelang.

| Tlhophiso | Maqhubu a Tlhahlobo |

| Bophara ba kantle ≤ 3in [76.2mm] | 250 likhomphutha/nako |

| Bophara ba kantle > 3in [76.2mm] | Likhomphutha tse 100/nako |

| Khetholla ka palo ea mocheso oa tube | Palo ka mocheso |

Litlhoko tsa thepa ea mechini ha li sebetse ho liphaephe tse nyane ho feta 1/8 in. [3.2 mm] bophara ba kahare kapa 0.015 in. [0.4 mm] ka botenya.

1. Thepa e Tenyetsehang

Bakeng sa Sehlopha sa C le sa D, teko ea ho thaepa e lokela ho etsoa liphaepheng tse peli karolong ka 'ngoe.

Bakeng sa phaephe ea Kereiti ea A, liteko tsa ho thaepa hangata ha li hlokehe. Sena se bakoa ke taba ea hore phaephe ea Kereiti ea A e sebelisoa haholo-holo bakeng sa lits'ebetso tsa khatello e tlase le mocheso o tlase.

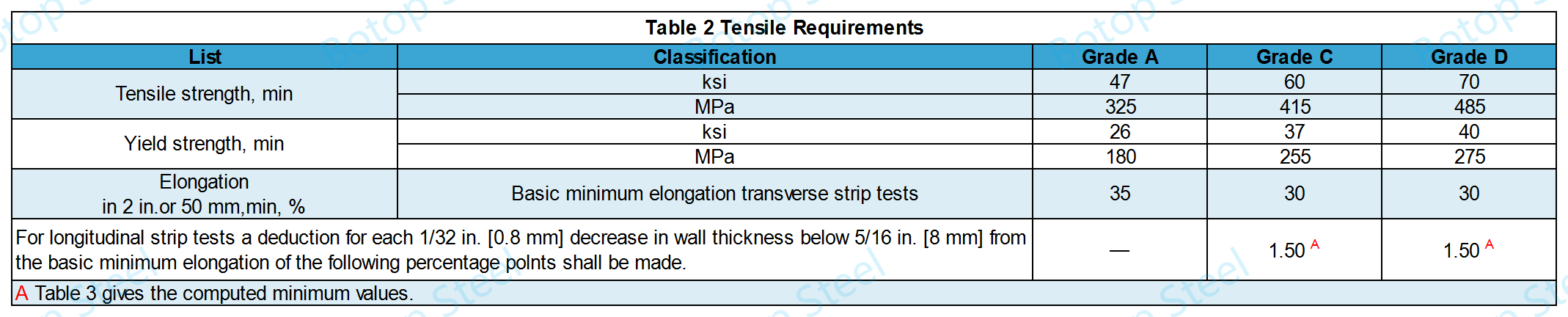

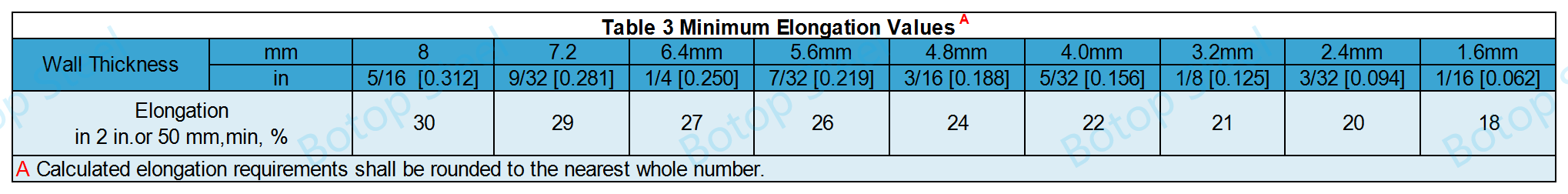

Tafole ea 3 e fana ka boleng bo tlase ba ho lelefatsa bo baliloeng bakeng sa phokotso e 'ngoe le e 'ngoe ea botenya ba lebota ea 1/32 in. [0.8 mm].

Haeba botenya ba lebota la phaephe ea tšepe e se e 'ngoe ea botenya bona ba lebota, bo ka boela ba baloa ka mokhoa ona.

Diyuniti tsa lisenthimithara: E = 48t + 15.00kapaDiyuniti tsa ISI: E = 1.87t + 15.00

E = ho lelefala ka lisenthimithara tse 2 kapa 50 mm, %,

t= botenya ba sebele ba sampole, ka hare ho. [mm].

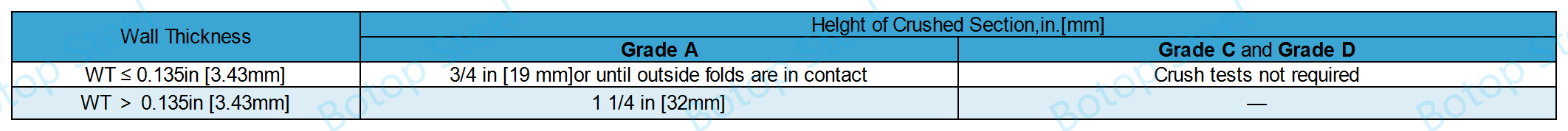

2. Teko ea ho Silakanya

Liteko tsa ho ntša metsi li etsoa likarolong tsa liphaephe tse bolelele ba lisenthimithara tse 63 tse lokelang ho mamella ho ntša metsi ka nako e telele ntle le ho petsoha, ho petsoha, kapa ho petsoha ha li-weld.

Bakeng sa ho kenya tube ka bophara bo ka tlase ho 1 in. [25.4 mm] ka ntle, bolelele ba sampole e tla ba makhetlo a 2 1/2 ho feta bophara ba kantle ba tube. Liteko tse nyane tsa bokaholimo e ke ke ea e-ba sesosa sa ho haneloa.

3. Teko ea ho Batalatsa

Mokhoa oa teko o lumellana le litlhoko tse amehang tsa ASTM A450 Karolo ea 19.

4. Teko ea Flange

Mokhoa oa teko o lumellana le litlhoko tse amehang tsa ASTM A450 Karolo ea 22.

5. Teko ea ho Fokotsa Boea

Mokhoa oa teko o lumellana le litlhoko tse amehang tsa ASTM A450, Karolo ea 20.

Teko ea motlakase e etsoang ka metsi kapa e sa senyeheng e etsoa phaepheng e 'ngoe le e 'ngoe ea tšepe.

Litlhoko li latela ASTM A450, Karolo ea 24 kapa ea 26.

Lintlha tse latelang li nkiloe ho ASTM A450 'me li fihlela litlhoko tse amehang bakeng sa phaephe ea tšepe e bōpehileng joaloka welded feela.

Ho kheloha ha boima ba 'mele

0 - +10%.

Ho kheloha ha botenya ba lebota

0 - +18%.

Ho kheloha ha bophara ba kantle

| Bophara ba Kantle | Mefuta e Lumelloang | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ± 0.004 | ± 0.1 |

| 1 OD ≤1½ | 25.4 ± OD ≤38.4 | ± 0.006 | ± 0.15 |

| 1½ OD 2 | 38.1< OD<50.8 | ± 0.008 | ± 0.2 |

| 2≤ OD <2½ | 50.8≤ OD <63.5 | ± 0.010 | ± 0.25 |

| 2½≤ OD 1.3 | 63.5≤ OD <76.2 | ± 0.012 | ± 0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ± 0.015 | ± 0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Kamora ho kenngoa ka har'a boiler, tube e lokela ho khona ho mamella katoloso le ho kobeha ntle le liphoso tsa ho petsoha kapa ho petsoha ha li-weld.

Phaephe ea superheater e tla khona ho mamella ts'ebetso eohle e hlokahalang ea ho betla, ho tjheseletsa le ho kobeha ntle le liphoso.

E sebelisoa haholo-holo liphaepheng tsa boiler, liphaepheng tsa boiler, liphaepheng tsa superheater, le lipheletsong tse sireletsehileng.

ASTM A178 Kereiti ATekanyo e tlase ea khabone ea tube e e fa bokhoni bo botle ba ho tjheseletsa le ho ba thata haholo bakeng sa lits'ebetso tse sa keneng tlas'a khatello e phahameng.

E sebelisoa haholo-holo bakeng sa lits'ebetso tsa khatello e tlase le mocheso o mahareng joalo ka liboiler tsa khatello e tlase (mohlala, liboiler tsa malapeng, meaho e menyenyane ea liofisi kapa liboiler tsa fektheri) le li-exchange tse ling tsa mocheso libakeng tse nang le mocheso o tlase.

ASTM A178 Kereiti Ce na le khabone e ngata le manganese e fang tube ena matla a betere le ho hanyetsa mocheso bakeng sa maemo a ts'ebetso a thata haholoanyane.

E loketse lits'ebetso tsa khatello e mahareng le mocheso o mahareng joalo ka liboiler tsa indasteri le tsa metsi a chesang, tseo hangata li hlokang khatello le mocheso o phahameng ho feta liboiler tsa lapeng.

ASTM A178 Kereiti DLi-tube li na le manganese e ngata le silicon e loketseng ho fana ka matla a matle le ho hanyetsa mocheso, e leng se etsang hore li tsitse libakeng tse nang le mocheso o phahameng le khatello e phahameng 'me li loketse ho mamella maemo a feteletseng a ts'ebetso.

Hangata e sebelisoa libakeng tse nang le khatello e phahameng le mocheso o phahameng, joalo ka liboiler tsa seteishene sa motlakase le li-superheater tsa indasteri.

1. ASTM A179 / ASME SA179: Sehokelo sa mocheso sa tšepe e bonolo se se nang sekoli le liphaephe tsa condenser bakeng sa tšebeletso ea cryogenic. Haholo-holo e sebelisoa libakeng tse nang le khatello e tlase, e tšoana le ASTM A178 ka thepa ea lik'hemik'hale le ea mechini.

2. ASTM A192 / ASME SA192: Liphaephe tsa boiler tsa tšepe ea khabone tse se nang sekoli tse sebetsang ka khatello e phahameng. Haholo-holo li sebelisoa ho etseng mabota a metsi, li-economizer le likarolo tse ling tsa khatello bakeng sa liboiler tsa khatello e phahameng haholo.

3. ASTM A210 / ASME SA210: E koahela boiler ea tšepe ea khabone e mahareng le e kopantsoeng e se nang sekoli le liphaephe tsa superheater bakeng sa litsamaiso tsa boiler tsa mocheso o phahameng le khatello e mahareng.

4. DIN 17175: Liphaephe tsa tšepe tse se nang mohele le liphaephe bakeng sa ho sebelisoa maemong a khatello e phahameng le a mocheso o phahameng. Haholo-holo li sebelisoa ho etseng liphaephe tsa mouoane bakeng sa liboiler le lijana tsa khatello.

5. EN 10216-2: E beha maemo a tekheniki bakeng sa lipeipi tse se nang mohele le lipeipi tsa tšepe tse se nang moloi le tsa motsoako tse nang le thepa e boletsoeng ea mocheso o phahameng bakeng sa lits'ebetso tse tlas'a khatello.

6. JIS G3461: E koahela liphaephe tsa tšepe ea khabone bakeng sa liboiler le li-heat exchanger. E loketse maemo a akaretsang a phapanyetsano ea mocheso o tlase le o mahareng.

Re moetsi le mofani oa liphaephe tsa tšepe ea carbon tse lahletsoeng ka welded tsa boleng bo holimo ho tsoa Chaena, hape re morekisi oa liphaephe tsa tšepe tse se nang sekoli, re u fa mefuta e mengata ea litharollo tsa liphaephe tsa tšepe!

Bakeng sa lipotso leha e le life kapa ho ithuta ho eketsehileng ka linyehelo tsa rona, u se ke ua tsilatsila ho ikopanya le rona. Litharollo tsa hau tse ntle tsa liphaephe tsa tšepe li fumaneha feela!