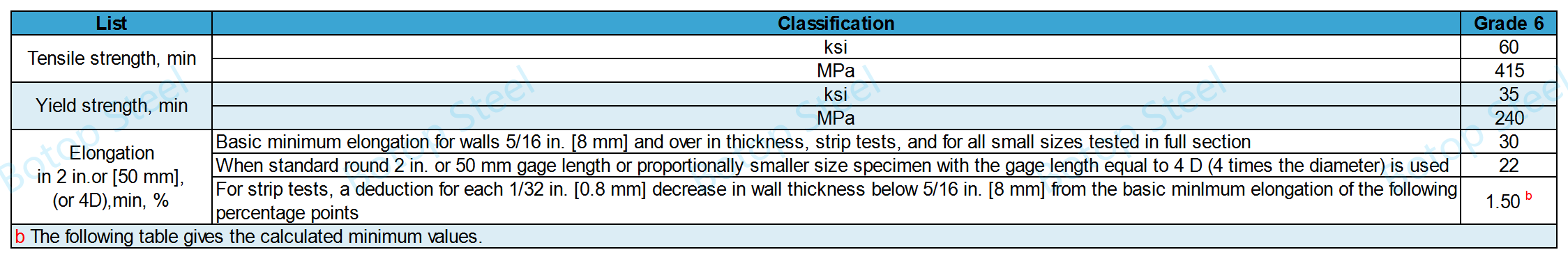

ASTM A334Sehlopha sa 6ke phaephe ya tshepe ya khabone e matla haholo, e nang le mocheso o tlase e nang le khabone e phahameng ka ho fetisisa ya 0.30%, dikahare tsa manganese tsa 0.29-1.06%, matla a ho kganna a bonyane 415Mpa (60ksi), le matla a tlhahiso a 240Mp (35ksi).

E sebelisoa haholo-holo lefapheng la khase ea tlhaho e metsi, boenjiniere ba polar, le theknoloji ea sehatsetsing, e ikamahanyang le maemo a mocheso o tlase haholo.

ASTM A334ke tlhaloso e tloaelehileng bakeng sa liphaephe tsa tšepe ea carbon le alloy tse se nang seamless le tse welded bakeng sa lits'ebetso tsa cryogenic.

Ho na le mephato e mengata ho fihlela litlhoko tse fapaneng.

Sehlopha sa 1, Sehlopha sa 3, Sehlopha sa 6, Sehlopha sa 7, Sehlopha sa 8, Sehlopha sa 9, le Sehlopha sa 11.

Sehlopha sa 1le Sehlopha sa 6 ka bobeli ke liphaephe tsa tšepe ea khabone.

Phaephe ea tšepe ea ASTM A334 ea Sehlopha sa 6 e ka hlahisoa ka mekhoa e se nang sekoli kapa e phuthetsoeng ka welded.

Mekhoa ea ho tjheseletsa e kenyelletsa mekhoa e fapaneng e kangho tjheseletsa ho hanyetsa motlakase (ERW)leho tjheseletsa arc e qoelitsoeng ka metsing (SAW).

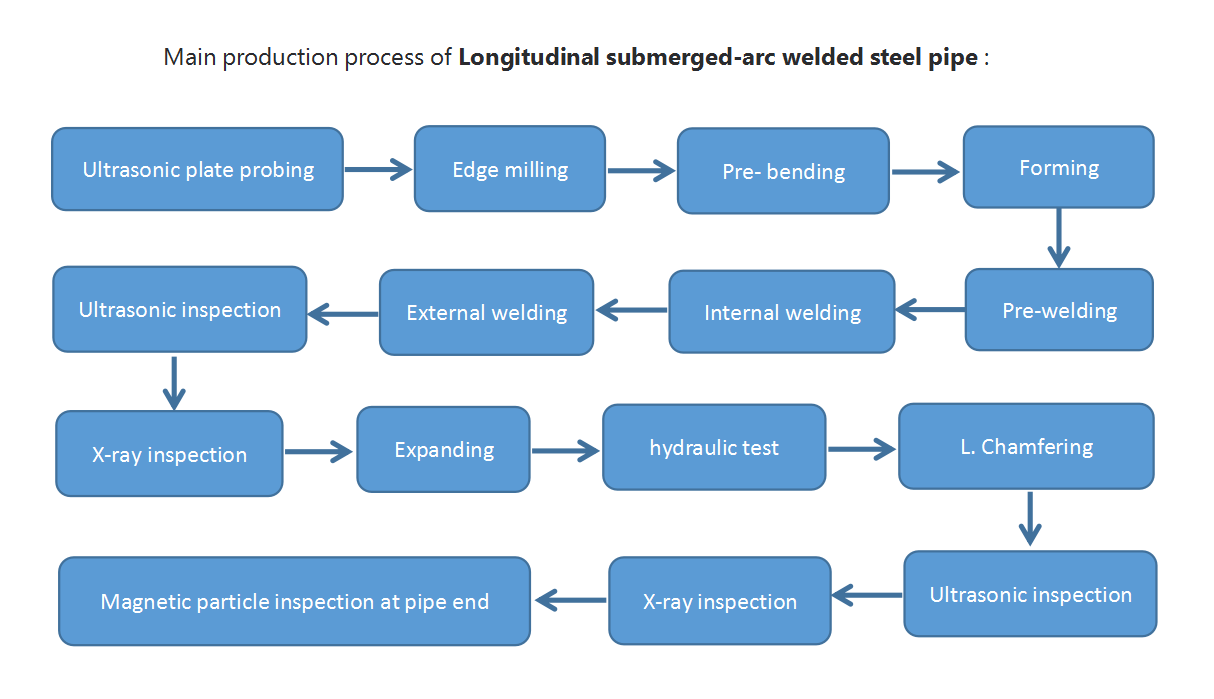

Ka tlase, ke ts'ebetso ea tlhahiso bakeng saHo Welding ea Arc e Kenelletseng ka Longitudinal (LSAW).

Jwalo ka moetsi wa diphaephe tsa tshepe tse welditsweng, re kgona ho fihlela ditlhoko tse ikgethang tsa bareki ba rona ba fapaneng, re fana ka mefuta e fapaneng ya dikgetho tsa dihlahiswa ho netefatsa tshebetso e ntle ka ho fetisisa le boleng bakeng sa tshebediso e nngwe le e nngwe.

Ho tjheseletsa ha tube ya LSAW ka karolo e le nngwe ho ntlafatsa matla a kakaretso a tube haholo, ho e dumella ho mamella kgatello e phahameng.

Ho phaella moo, e loketse hantle tlhahiso ea phaephe ea tšepe e bophara bo boholo le e nang le mabota a teteaneng e fihlelang litlhoko tsa ASTM A334 Kereiti ea 6 lits'ebetsong tse kholo tsa indasteri le tsa phepelo ea matla, joalo ka kaho ea libaka tse kholo tsa khase ea tlhaho e metsi (LNG).

Ka nako e ts'oanang, taolo e nepahetseng ea litekanyo e netefatsa bophara bo tsitsitseng ba liphaephe le botenya ba mabota bakeng sa ts'epo e ntlafetseng ea khokahano le thibelo ea ho lutla lits'ebetsong tsa liphaephe.

Tloaetsa ka ho futhumatsa mocheso o lekanang o seng ka tlase ho 1550 °F [845 °C] 'me u o pholise moeeng kapa ka phapusing ea ho pholisa ea onto e laoloang ke sepakapaka.

Haeba ho hlokahala ho lokisa maemo, ho tla hlokahala hore ho buisanoe ka hona.

Sebopeho sa lik'hemik'hale sa phaephe ea tšepe ea ASTM A334 Kereiti ea 6 se etselitsoe ho netefatsa thepa e ntle ea mechini mochesong o tlase le ho tiea ho lekaneng bakeng sa ts'ebeletso e tšepahalang tlas'a maemo a feteletseng.

| Sehlopha | C (Khabone) | Mn (Manganese) | P (Fosforase) | S (Sebabole) | Si (Silicone) |

| Sehlopha sa 6 | palo e kahodimodimo 0.30 | 0.29-1.06 | palo e kahodimodimo 0.025 | palo e kahodimodimo 0.025 | bonyane 0.10 |

| Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ea khabone ka tlase ho 0.30%, keketseho ea 0.05% ea manganese ka holimo ho 1.06% e tla lumelloa ho fihlela ho 1.35% ea manganese. | |||||

Bakeng sa ditshipi tsa Kereiti ya 1 kapa ya Kereiti ya 6, ha ho dumellwe ho fana ka dikereiti tsa ho kopanya bakeng sa dielemente tse ding ntle le tse hlokahalang ka ho hlaka. Leha ho le jwalo, ho dumellwa ho eketsa dielemente tse hlokahalang bakeng sa ho tlosa oksideishene tshepeng.

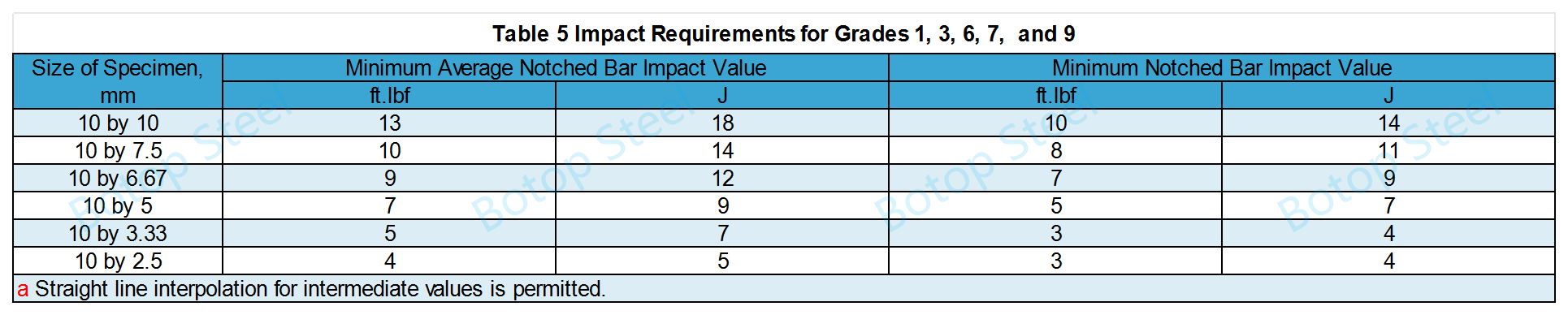

Liteko tsa tshusumetso phaepheng ya tshepe ya Kereiti ya 6 di etswa ho -45°C [-50°F] e le mokhoa wa ho netefatsa ho tiya le ho hanyetsa tshusumetso ya thepa dibakeng tse nang le mocheso o tlase haholo.

Teko e entsoe ka ho khetha matla a tshusumetso a nepahetseng ho latela botenya ba lebota la phaephe ya tshepe.

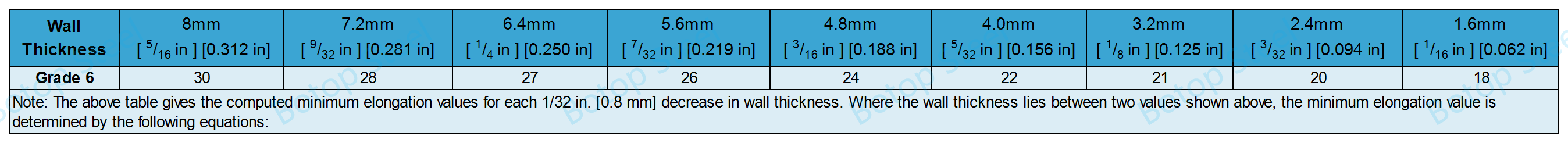

Boleng bo tlase ba ho lelefatsa bo baliloeng bakeng sa phokotso e 'ngoe le e 'ngoe ea botenya ba lebota ea 1/32 in.[0.80 mm].

| Sehlopha | Rockwell | Brinell |

| ASTM A334 Kereiti ea 6 | B 90 | 190 |

Phaephe e 'ngoe le e 'ngoe e lokela ho lekoa ka motlakase kapa ka metsi ntle le ho senya ho latela Tlhaloso A1016/A1016M.

Ntle le haeba ho boletsoe ka tsela e 'ngoe odareng ea theko, mofuta oa teko o tla sebelisoa o tla ba khethong ea moetsi.

Teko ea ho Batalatsa

Teko ea Flare (Li-Tube tse se nang Seam)

Teko ea Flange (Li-Tube tse Welded)

Teko ea ho Fokotsa Boea

1. Meaho ea Khase ea Tlhaho e Metsi (LNG): Ka lebaka la thepa ea eona e ntle ea mocheso o tlase, phaephe ea tšepe ea Sehlopha sa 6 e sebelisoa haholo litsing tsa tlhahiso ea LNG, polokelo le lipalangoang. Lits'ebeletso tsena li hloka thepa e bolokang matla a holimo le ho tiea hantle mochesong o tlase haholo.

2. Litsamaiso tsa lipalangoang tsa oli le khase: e sebelisetsoang ho tsamaisa li-hydrocarbon tse metsi kapa tsa khase, tse kang khase ea petroleum e metsi (LPG) le maro a mang a mocheso o tlase tikolohong e mocheso o tlase.

3. Theknoloji ea sehatsetsing le libaka tsa polokelo ea serame: Sena se sebetsa le libakeng tse ling tsa theknoloji ea sehatsetsing, joalo ka litsamaiso tsa ho hoamisa le tsa polokelo e batang ts'ebetsong ea lijo le lits'ebetso tse ling tsa lik'hemik'hale tse hlokang ts'ebetso ea mocheso o tlase.

4. Boenjiniere ba polar: Mererong ea boenjiniere libakeng tsa polar, joalo ka liteishene tsa lipatlisiso tsa saense Arctic kapa Antarctica, li sebelisetsoa ho haha mekhoa le meaho e tsitsitseng le e tšepahalang ea ho tsamaisa thepa e lokelang ho khona ho mamella mocheso o batang haholo le maemo a thata a tikoloho.

5. Mekhoa ea ho pholisa moea le li-exchange tsa mocheso: E boetse e sebelisoa hangata lits'ebetsong tse kholo tsa moea o pholileng le li-exchange tsa mocheso, tse hlokang ho sebetsa hantle mochesong o tlase ho netefatsa katleho le polokeho ea sistimi.

6. Boenjiniere ba motlakase le liteishene tsa motlakase: Mererong e khethehileng ea boenjiniere ba motlakase, joalo ka mefuta e itseng ea liteishene tsa motlakase, lipeipi tsa tšepe tsa Kereiti ea 6 li ka sebelisoa ho sebetsana le maro kapa likhase mochesong o tlase ho netefatsa ts'ebetso e sireletsehileng le e sebetsang hantle ea sistimi.

EN 10216-4:P265NL: E sebelisoa haholo-holo bakeng sa methapo ea khatello ea cryogenic le litsamaiso tsa liphaephe tsa cryogenic, e na le matla le ho tiea hantle 'me e loketse ho sebelisoa libakeng tsa cryogenic.

DIN 17173:TTSt41N: E etselitsoe lits'ebetso tsa mocheso o tlase, e fana ka ts'ebetso e ntle haholo ea mocheso o tlase 'me e sebelisoa hangata lisebelisoa le liphaepheng tse hlokang tikoloho ea ts'ebetso ea mocheso o tlase haholo.

JIS G3460:STPL46: E sebelisoa bakeng sa litsamaiso tsa lipalangoang tsa lipeipi libakeng tse nang le mocheso o tlase, tse khonang ho mamella litlamorao le likhatello tse itseng tsa mocheso o tlase.

GB/T 18984:09Mn2V: Thepa ena e ikhethile ka ho etsa lipeipi tsa tšepe tse se nang mohele bakeng sa tšebeliso libakeng tse nang le mocheso o tlase, tse nang le ho tiea ho hotle ha mocheso o tlase le ho hanyetsa mapetso.

Ha o kgetha thepa ena e lekanang, ho bohlokwa ho netefatsa hore sebopeho sa tsona sa dikhemikhale le thepa ya mechini di fihlella ditekanyetso tse hlokahalang tsa tshebediso le ditlhoko tsa tshebetso.

Mekhahlelo ena e lokela ho bapiswa ka botlalo mme ditshebetso tse ding tsa teko le setifikeiti di ka hlokahala ho netefatsa ho tshwaneleha le tshebetso ya thepa.

Ho tloha ha e theoa ka 2014, Botop Steel e se e le mofani ea ka sehloohong oaphala ea tšepe ea k'haboneChaena Leboea, e tsebahala ka tšebeletso e ntle haholo, lihlahisoa tsa boleng bo holimo, le litharollo tse felletseng. Khamphani e fana ka mefuta e fapaneng ea liphaephe tsa tšepe ea khabone le lihlahisoa tse amanang le tsona, ho kenyeletsoa le phaephe ea tšepe e se nang seamless, ERW, LSAW, le SSAW, hammoho le lethathamo le felletseng la li-fitting tsa liphaephe le li-flange.

Lihlahisoa tsa eona tse ikhethang li boetse li kenyelletsa litšepe tse kopantsoeng tsa boleng bo holimo le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho fihlela litlhoko tsa merero e fapaneng ea liphaephe.