ASTM A335 P11pipe ea tšepe ke phala ea tšepe e sa tsitsang ea ferritic e tlase bakeng sa ts'ebeletso e phahameng ea mocheso, lebitso la UNS K11597.

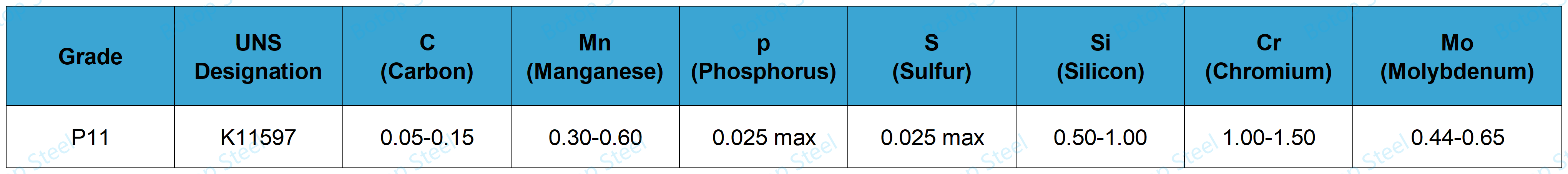

P11 ke motsoako oa chromium-molybdenum o nang le chromium ea 1.00-1.50% le molybdenum ea 0.44-0.65%.

E sebelisoa hangata ho li-boilers, li-superheaters, le li-heaters tsa mocheso liteisheneng tsa motlakase le limela tsa lik'hemik'hale.

Litlhoko tsa tekheniki tsaASME SA335leASTM A335li ts'oana, kahoo ho nolofatsa tlhahiso, re tla sebelisa "ASTM A335" ho bua ka litekanyetso tsena tse peli.

Lintho tse bonahalangl: phala ea tšepe ea ASTM A335 P11;

OD: 1/8"- 24";

WT: ho latelaASME B36.10litlhoko;

Kemiso: SCH10, SCH20, SCH30,SCH40, SCH60,SCH80, SCH100, SCH120, SCH140 le SCH160;

Boitsebiso: STD, XS, XXS;

Boikemisetso: Liphaephe tse sa tloaelehang li fumaneha hape, boholo bo hlophisitsoeng bo fumaneha ka kopo;

Bolelele: Bolelele bo khethehileng le bo sa reroang;

Setifikeiti sa IBR: Re ka ikopanya le mokhatlo oa boraro oa tlhahlobo ho fumana setifikeiti sa IBR ho latela litlhoko tsa hau, mekhatlo ea rona ea tlhahlobo ea tšebelisano-mmoho ke BV, SGS, TUV, joalo-joalo;

QETA: Qetello e bataletseng, e beveled, kapa pheletso ea lipeipi tse kopaneng;

Bokaholimo: Peipi e khanyang, pente, le tšireletso e meng ea nakoana, ho tlosa mafome le ho belisoa, masenke le polasetiki e koahetsoeng, le tšireletso e meng ea nako e telele;

Ho paka: Nyeoe ea lehong, lebanta la tšepe kapa terata ea tšepe ea tšepe, mosireletsi oa ho qetela oa phala ea polasetiki kapa ea tšepe, jj.

Ntle le ha ho boletsoe ka tsela e 'ngoe ho A335, thepa e fanoeng tlas'a tlhaloso ena e tla lumellana le litlhoko tse sebetsang tsa khatiso ea hajoale ea Specification.A999/A999M.

phala ea tšepe ea ASTM A335 e tlameha ho baseamless. Li-tubes tsa tšepe tse se nang seamless li fana ka ts'epo e kholo le ho ts'oana ha li le tlas'a khatello e phahameng le maemo a mocheso.

Seamless e ka aroloa ka ho khetheha e le e batang e huloang le ho chesa ho felile, ho latela ts'ebeliso le boholo bo ikhethileng.

Hangata setšoantšo se batang se sebelisoa bakeng sa li-diameter tse nyane kapa bakeng sa li-tubes tse hlokang ho nepahala ho phahameng le boleng bo botle ba bokaholimo. Hangata ho qeta ho chesa ho sebelisoa ho hlahisa liphaephe tse kholo tsa tšepe tse otlolohileng le tse teteaneng.

Ka tlaase mona ho na le chate e phallang ea mokhoa oa ho etsa tlhahiso ea pipe ea tšepe e se nang seamless e chesang.

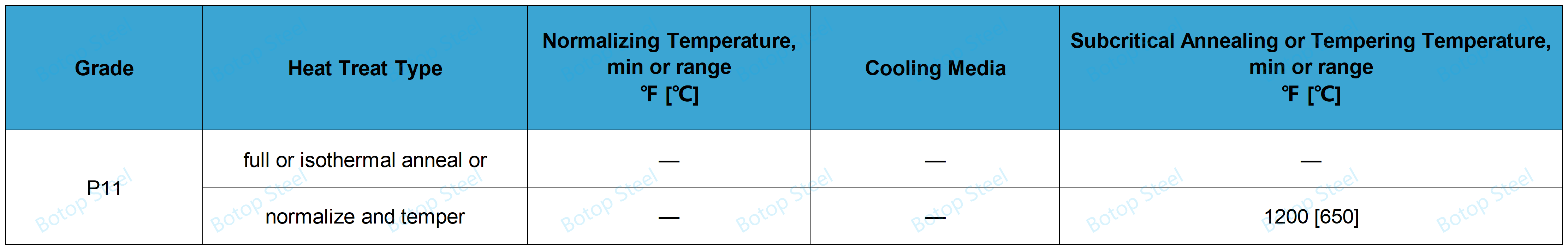

Kalafo ea mocheso ea thepa ea P11 e ka ba e tletseng kapa ea ho futhumatsa kapa ea mocheso ka mor'a ho tloaeleha, 'me ha e tloaeleha le ho futhumala, mocheso oa mocheso o lokela ho ba bonyane 1200 ° F (650 ° C).

Ho latela sebopeho sa lik'hemik'hale, re ka bona seo habonoloP11 ke motsoako oa chromium-molybdenum.

Li-alloys tsa Chromium-molybdenum ke sehlopha sa litšepe tse nang le chromium (Cr) le molybdenum (Mo) e le likarolo tse ka sehloohong tsa motsoako. Ho eketsoa ha lintho tsena ho eketsa matla, ho thatafala, ho hanyetsa le ho hanyetsa ha tšepe ea tšepe. Ka mocheso o phahameng, li-alloys tsa Cr-Mo li khona ho boloka thepa e ntle ea mochine le mohaho o tsitsitseng.

Cr: e ntlafatsa ho hanyetsa ha oxidation le khanyetso ea kutu ea motsoako, e thusa ho theha filimi e matla ea oxide, le ho sireletsa thepa ho tloha mecheng e senyang.

Mo: E matlafatsa matla a alloy, haholo-holo mocheso o phahameng, e ntlafatsa khanyetso ea creep, 'me e matlafatsa matla a mocheso o phahameng oa thepa.

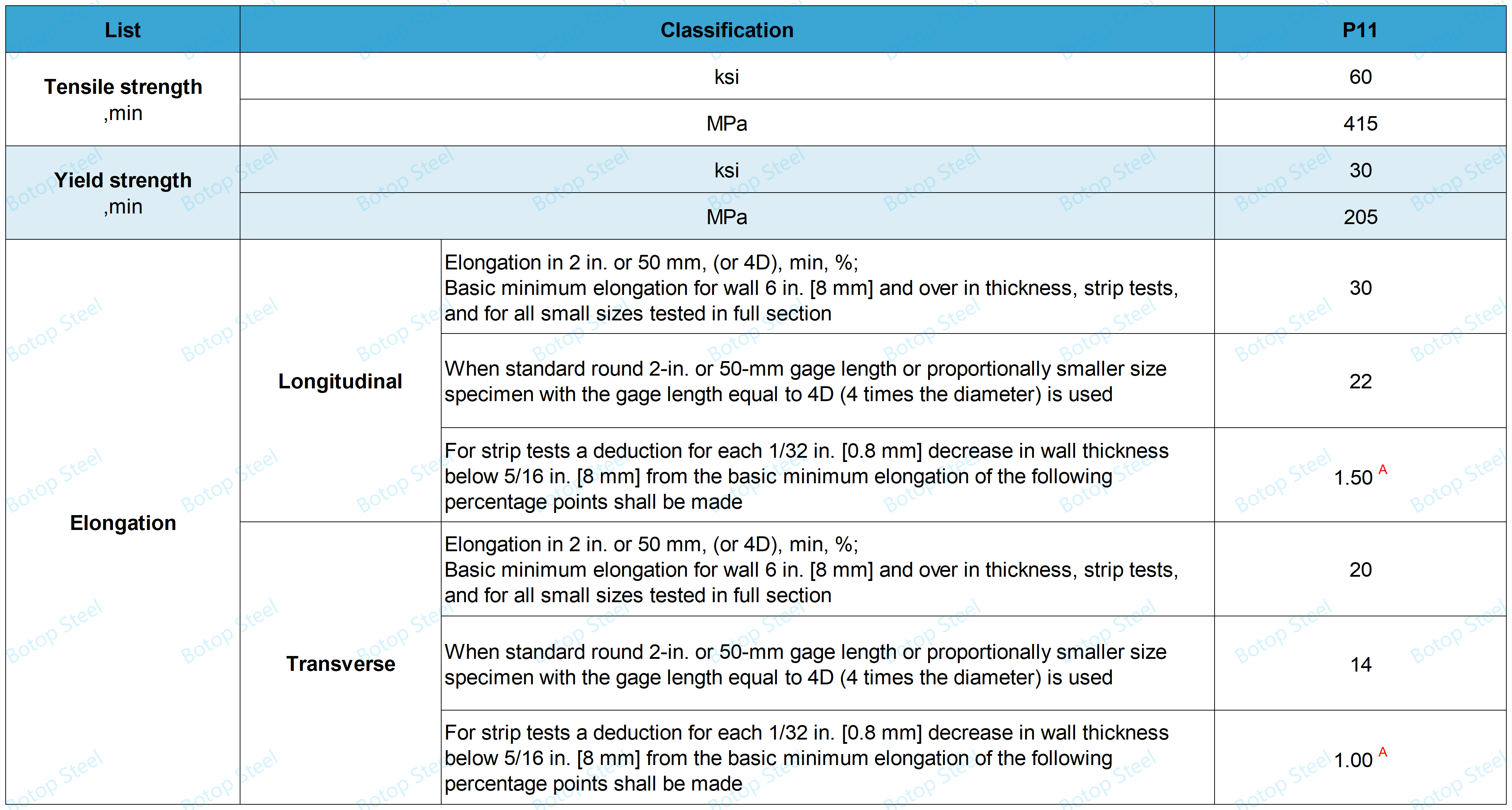

1. Thepa ea Tensile

Teko ea tensile hangata e sebelisoa ho methafana ka matla, matla a tšepe, leelongation ea lenaneo la liteko tsa phala ea tšepe, 'me e sebelisoa haholo ho thepa ea tlhahlobo.

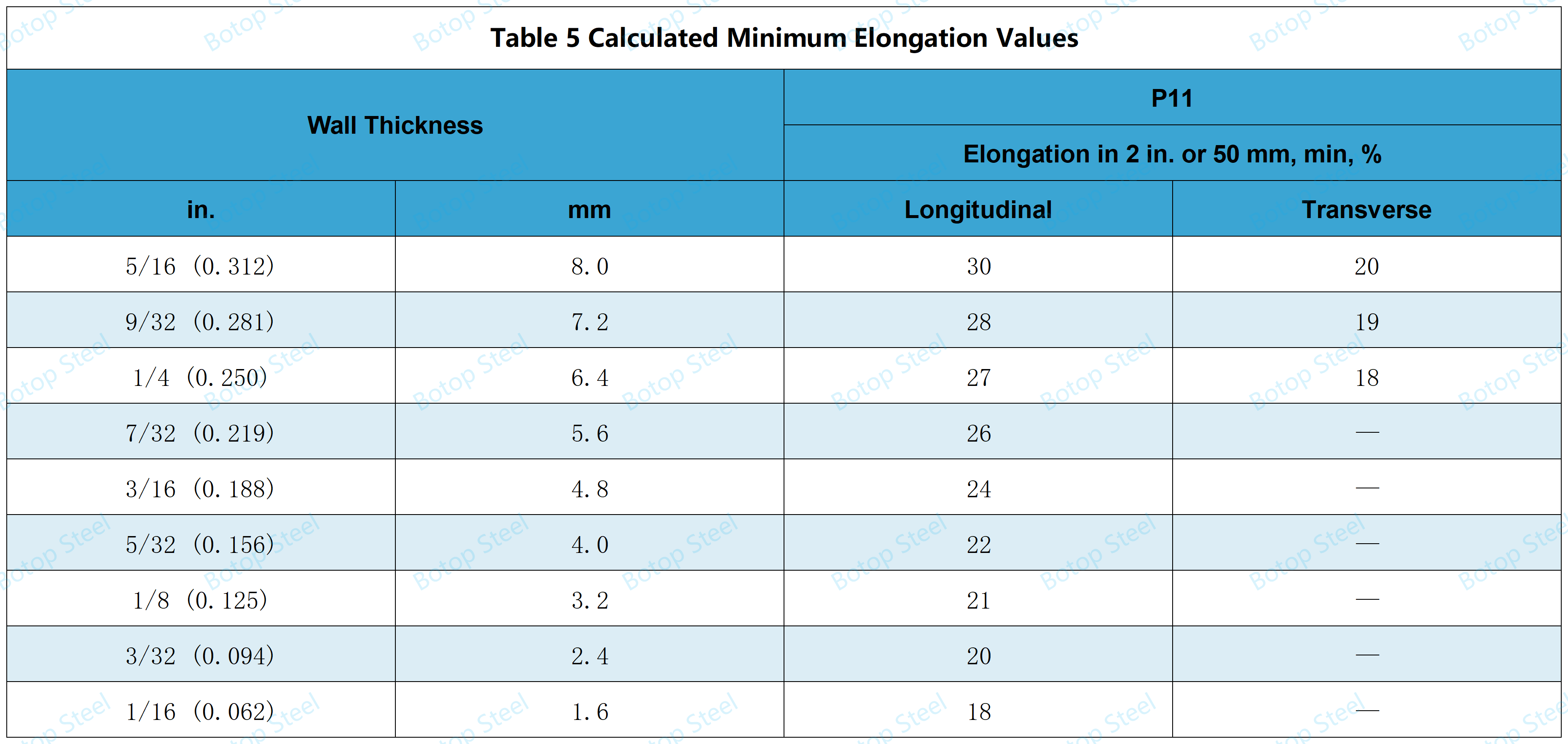

ALetlapa la 5 le fana ka litekanyetso tse baloang.

Moo botenya ba lebota bo leng teng pakeng tsa boleng ba bobeli bo kaholimo, boleng bo tlase ba bolelele bo khethoa ke foromo e latelang:

Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

moo:

E = bolelele ho 2 in. kapa 50 mm, %,

t = botenya ba sebele ba mehlala, ka. [mm].

2. Ho thatafala

Pipe ea Grade P11 ha e hloke tlhahlobo ea boima.

Ka tlase ho fanoe ka boleng ba boima ba referense.

Anealed boemo:

Hangata boima bo pakeng tsa 150 le 200 HB.

Boemo bo tloaelehileng le bo itekanetseng:

Ho thatafala ho tloha ho hoo e ka bang 170 ho isa ho 220 HB.

Boemo bo thata le bo itekanetseng:

Ho thatafala ho ka fihla ho 250 ho isa ho 300 HB kapa ho feta, ho itšetlehile ka mocheso oa mocheso le nako.

3. Mananeo a Boikhethelo a Teko

Lintho tse latelang tsa liteko ha li hlokehe lintho tsa tlhahlobo, haeba ho hlokahala li ka khethoa ka lipuisano.

Tlhahlobo ea Lihlahisoa

Teko e bataletseng

Bend Test

Sebopeho sa Metal le Liteko tsa ho Etching

Photomicrographs

Photomicrographs bakeng sa likotoana ka bomong

P11 hydrotest e tla ikamahanya le litlhoko tse latelang.

Ka ntle bophara ~10in. [250mm] le botenya ba lebota ≤ 0.75in. [19mm]: sena e lokela ho ba teko ea hydrostatic.

Mefuta e meng ea liteko tsa motlakase tse sa senyeheng.

Litlhoko tse latelang tsa tlhahlobo ea hydrostatic li hlophisitsoe ho latela litlhoko tsa ASTM A999:

Bakeng sa tšepe ea alloy ea ferritic le li-tubes tsa tšepe tse sa hloekang, lerako le tlas'a khatello e seng ka tlase ho60% ea matla a tlase a tlhahiso a boletsoeng.

Khatello ea hydro test e tla bolokoa bonyane 5sntle le ho dutla kapa bofokodi bo bong.

Khatello ea metsie ka baloa ho sebelisoa formula:

P = 2St/D

P= khatello ea teko ea hydrostatic ho psi [MPa];

S = khatello ea lerako la pipe ka psi kapa [MPa];

t = botenya ba lebota bo boletsoeng, botenya ba lebota le botenya ho latela nomoro ea kemiso ea ANSI e boletsoeng kapa makhetlo a 1.143 ho feta botenya ba lebota bo boletsoeng, ho. [mm];

D = e boletsoeng ka ntle ho bophara ba bophara, bophara bo ka ntle bo lumellanang le boholo bo boletsoeng ba phala ea ANSI, kapa bophara bo ka ntle bo baloang ka ho eketsa 2t (joalokaha ho hlalositsoe ka holimo) ho bophara bo boletsoeng ka hare, ho. [mm].

Pipe e 'ngoe le e' ngoe e tla hlahlojoa ka mokhoa o sa senyeheng oa tlhahlobo ho latela Ts'ebetsoE213, ItloaetseE309, kapa ItloaetseE570.

Phapang e lumelletsoeng ka Diameter

Bakeng sa phala e laetsoeng hobophara ba ka hare, bophara ba ka hare ha bo na ho fapana ho feta ± 1% ho tloha bophara bo boletsoeng ka hare.

Phapang e Dumelletseng Botenya ba Lerako

Litekanyo tsa botenya ba lebota li tla etsoa ho sebelisoa li-caliper tsa mochini kapa lisebelisoa tsa tlhahlobo tse sa senyeheng tse nepahetseng tse nepahetseng. Haeba ho na le phehisano, tekanyo e lekantsoeng ka li-caliper tsa mochini e tla ba teng.

Botenya ba lebota bo tlase le bophara ba kantle bakeng sa tlhahlobo bakeng sa ho latela tlhoko ena ea phala e laetsoeng ke NPS [DN] le nomoro ea kemiso e bonts'itsoeng hoASME B36.10M.

Ka tloaelo e sebelisoa ka liboilers, li-superheaters, le li-heaters tsa mocheso liteisheneng tsa motlakase le limela tsa lik'hemik'hale.

Li-boilers: P11 e sebelisoa haholo ha ho hahoa li-boilers ka lebaka la ho hanyetsa mocheso o phahameng le likhatello, haholo-holo likarolong tse tlas'a mocheso o feteletseng le likhatello.

Superheater: E sebelisoa ho eketsa mocheso oa mouoane ho ntlafatsa ts'ebetso ea mocheso. p11 e tiisa hore matla le ho tšoarella ha thepa li bolokiloe esita le ka mocheso o phahameng.

Lisebelisoa tsa mocheso: P11 e ntlafatsa ho senya le ho hanyetsa mocheso o phahameng oa mocheso oa mocheso, kahoo ho ntlafatsa botšepehi le polokeho ea thepa.

Sistimi ea liphaephe: Lisebelisoa tsa lipeipi tsa limela tsa lik'hemik'hale hangata li hloka ho tsamaisa maro a mocheso o phahameng kapa mouoane. matla a mocheso o phahameng le thepa e ntle ea mochini ea P11 e etsa hore e be e loketseng bakeng sa lits'ebetso tsena.

a) ASTM A335 P11 e lekana le eng?

GB/T 5310: 12CrMo;

DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

BS 3604: 10CrMo9-10;

JIS G3462: STPA23;

GOST 550-75: 12Kh1MF.

b)Na P11 ke tšepe ea alloy e tlase?

Ee, P11 ke tšepe e tlase ea alloy.

Tšepe ea alloy e tlase ke motsoako oa tšepe oa carbon moo motsoako o le mong kapa ho feta (mohlala, chromium, molybdenum, nickel, joalo-joalo) o kentsoeng, ka kakaretso ea motsoako oa motsoako ho tloha ho 1 ho isa ho 5%.

c)Matla a tensile a ASTM A335 P11 ke afe?

Matla a fokolang a 415 MPa [60 ksi].

d)Matla a tlhahiso ea ASTM A335 P11 ke afe?

Matla a fokolang a 205 MPa [30 ksi].

e) Tekanyo ea mocheso ea ASTM A335 P11 ke efe?

Libakeng tse nang le oxidizing: Lithempereichara tse phahameng tsa tšebeletso hangata li ka ba 593°C (1100°F).

Libakeng tse se nang oxidizing: mocheso o phahameng oa litšebeletso o ka bang 650°C (1200°F) o ka finyelloa.

f)Na A335 P11 ke ea matla?

Ke makenete mochesong oa kamore. Thepa ena e ka ba molemo lits'ebetsong tse ling, joalo ka ha thepa e hlokahala hore e tsamaisane le lisebelisoa tsa ho lemoha makenete.

g)Theko ea ASTM A335 P11 ke eng?

Litheko li fapana ho ea ka 'maraka, ikopanye le rona bakeng sa quote e nepahetseng.