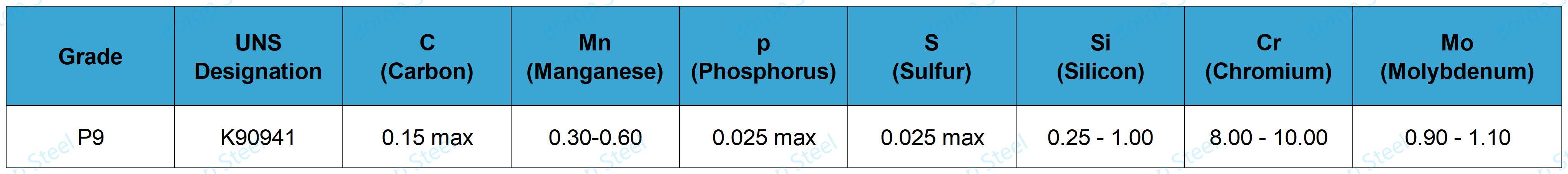

ASTM A335 P9, e tsejoang hape e le ASME SA335 P9, ke phaephe ea tšepe ea ferritic alloy e se nang sekoli bakeng sa tšebeletso ea mocheso o phahameng e nang leNomoro ea UNS K90941.

Dielemente tse kopanyang ke haholo-holo chromium le molybdenum. Dikahare tsa chromium di tloha ho 8.00 - 10.00%, ha dikahare tsa molybdenum di le pakeng tsa 0.90% - 1.10%.

P9e na le matla a matle haholo le ho hanyetsa mafome hantle libakeng tse nang le mocheso o phahameng 'me e sebelisoa haholo liboiler, lisebelisoa tsa petrochemical, le liteisheneng tsa motlakase moo ho hlokahalang libaka tse nang le mocheso o phahameng le khatello e phahameng.

⇒ Boitsebiso: ASTM A335 P9 / ASME SA335 P9 phaephe ea tšepe e kopantsoeng e se nang mohele.

⇒Bophara ba kantle: 1/8"- 24".

⇒Botenya ba lebota: Litlhoko tsa ASME B36.10.

⇒Kemiso: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 le SCH160.

⇒Boitsebiso: STD (e tloaelehileng), XS (e matla haholo), kapa XXS (e matla haholo habeli).

⇒Bolelele: Bolelele bo itseng kapa bo sa reroang.

⇒Ho iketsetsa: Bophara ba kantle bo sa tlwaelehang, botenya ba lebota, bolelele, jj. ho latela ditlhoko.

⇒Lisebelisoa: Re ka fana ka dikobeho tse tshwanang tsa thepa, di-flange tse hatakelang, le dihlahiswa tse ding tse tshehetsang diphaephe tsa tshepe.

⇒Setifikeiti sa IBR: Setifikeiti sa IBR se ka fanoa haeba ho hlokahala.

⇒QETA: Qetello e se nang letho, pheletso e betlotsoeng, kapa pheletso ea phaephe e kopaneng.

⇒Ho paka: khetla ea lepolanka, lebanta la tšepe kapa terata ea tšepe, tšireletso ea pheletso ea phaephe ea polasetiki kapa ea tšepe.

⇒Lipalangoang: ka likepe kapa lifofane.

Phaephe ea tšepe ea ASTM A335 e lokela ho ba e se nang sekoli.

Phaephe ea tšepe e se nang seamless ke phaephe ea tšepe e se nang li-welds hohle.

Kaha phaephe ea tšepe e se nang mohele ha e na li-seam tse phuthetsoeng ka har'a sebopeho sa eona, e qoba likotsi tse ka bang teng tsa polokeho tse ka amanang le mathata a boleng ba ho phuthela. Tšobotsi ena e lumella phaephe e se nang mohele ho mamella khatello e phahameng, 'me sebopeho sa eona sa kahare se ts'oanang se tiisa botšepehi le polokeho ea phaephe libakeng tse nang le khatello e phahameng.

Ho phaella moo, ho tshepahala ha tube ya ASTM A335 ho matlafatswa ke ho eketswa ha dikarolo tse ikgethang tsa ho kopanya bakeng sa maemo a mocheso o phahameng le a kgatello e phahameng.

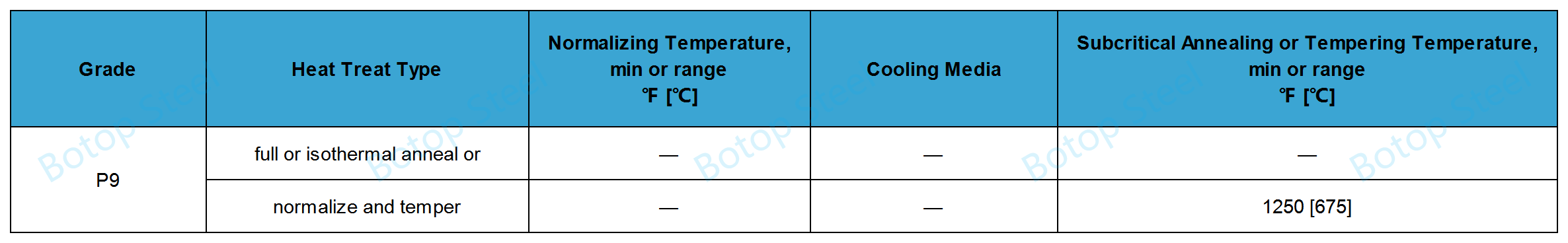

Mefuta ea kalafo ea mocheso e fumanehang bakeng sa thepa ea P9 e kenyelletsa ho kenya metsi ka botlalo kapa ka isothermal, hammoho le ho normalizing le ho temperature. Ts'ebetso ea normalizing le ho temperature e na le mocheso oa ho temperature oa 1250°F [675°C].

Lintho tse ka sehloohong tsa ho kopanya tsa P9 keCrleMo, e leng metsoako e kopantsoeng ea chromium-molybdenum.

Cr (Chromium): Jwalo ka karolo ya mantlha ya motswako, Cr e fana ka matla a matle a mocheso o phahameng le ho hanyetsa oxidation. E bopa filimi e teteaneng ya chromium oxide hodima tshepe, e eketsa botsitso le ho hanyetsa ho bola ha phaephe maemong a lehodimo a phahameng.

Mo (Molybdenum): Ho eketsoa ha Mo ho ntlafatsa matla le ho tiea ha di-alloy haholo, haholo-holo dibakeng tse nang le mocheso o phahameng. Mo e boetse e thusa ho ntlafatsa matla a ho thekesela ha thepa, ke hore, bokgoni ba ho hanela ho fetoha ha e pepesehela mocheso nako e telele.

Matlo a ho Tenyetseha

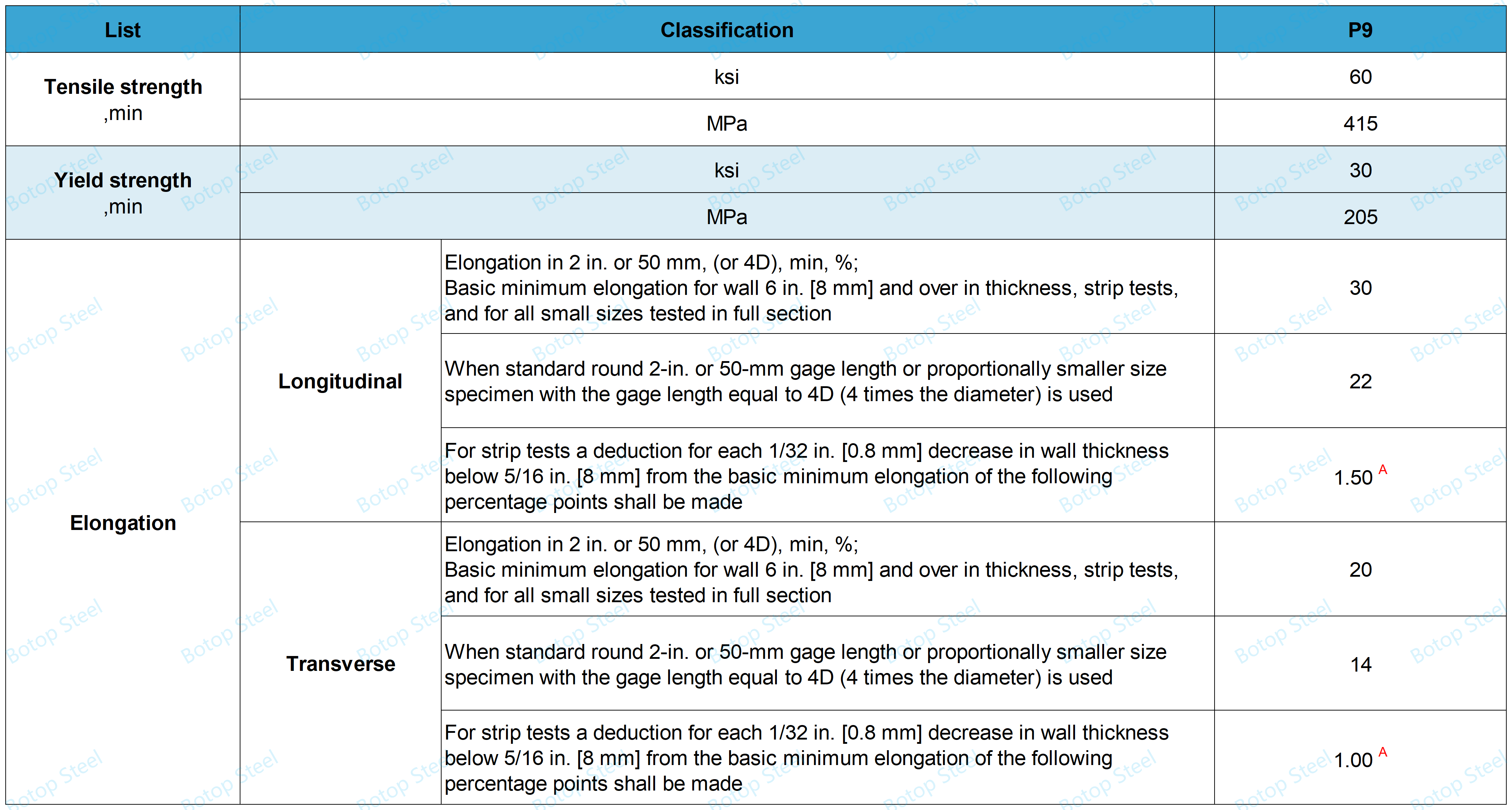

P5, P5b, P5c, P9,P11, P15, P21, le P22: Matla a ho tsikinyeha le a ho ntsha a tshwana.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, le P22: Ho lelefala ho tšoanang.

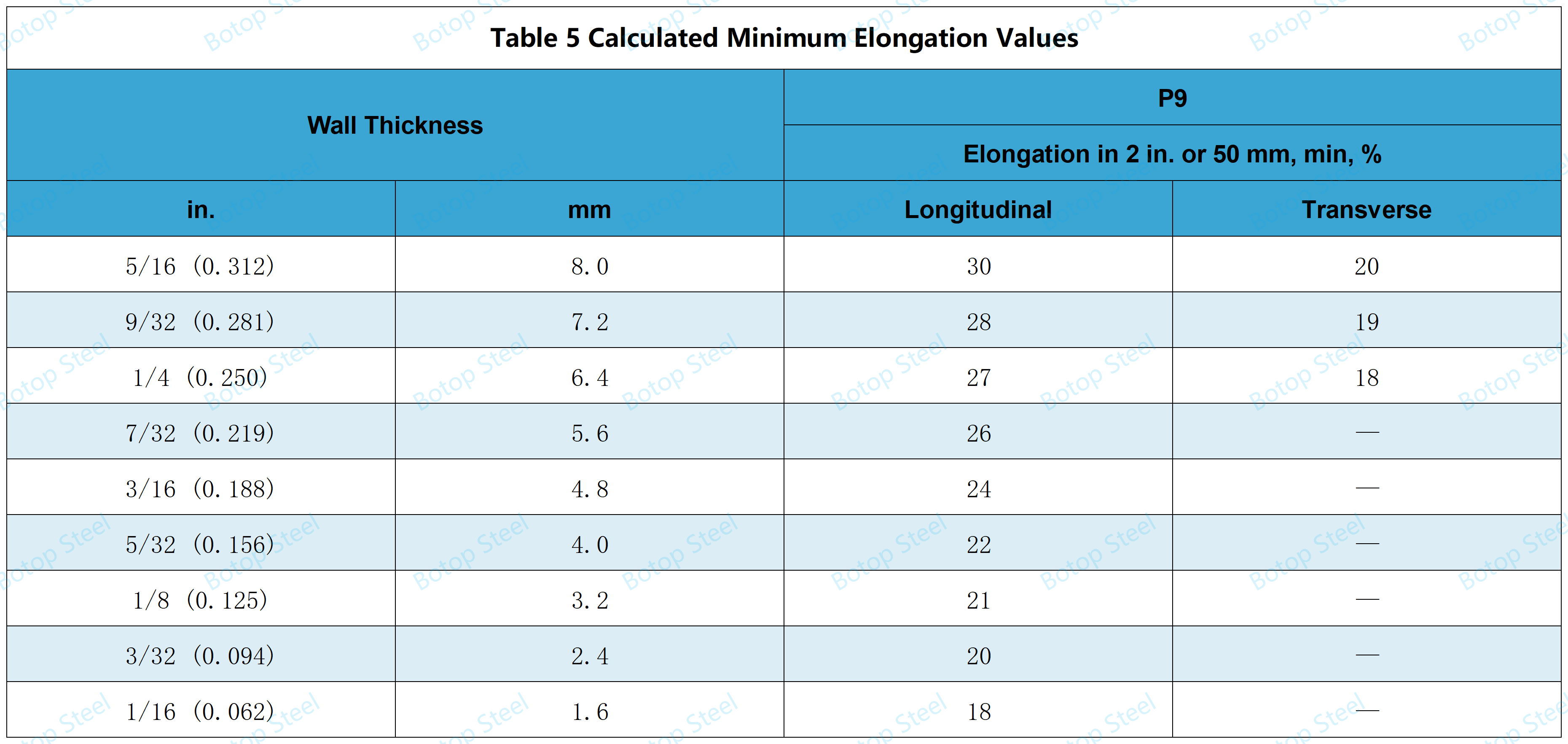

ATafole ea 5 e fana ka boleng bo tlase bo baliloeng.

Moo botenya ba lebota bo leng pakeng tsa boleng bo peli bo kaholimo, boleng bo tlase ba ho lelefatsa bo khethoa ke foromo e latelang:

Longitudinal, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

moo:

E = ho lelefala ka lisenthimithara tse 2 kapa 50 mm, %,

t = botenya ba sebele ba mehlala, ka hare ho. [mm].

Bothata

P9 ha e hloke teko ea ho thatafala.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, le P921: Ha ho hlokahale teko ea ho thatafala.

Ha bophara ba kantle bo le > 10 in. [250 mm] le botenya ba lebota bo le ≤ 0.75 in. [19 mm], tsohle di lokela ho lekoa ka hydrostatic.

Kgatelelo ya teko e ka balwa ho sebediswa equation e latelang.

P = 2St/D

P= kgatello ya teko ya hydrostatic ho psi [MPa];

S= kgatello ya lebota la phaephe ho psi kapa [MPa];

t= botenya ba lebota bo boletsoeng, botenya ba lebota bo boletsoeng ho latela nomoro ea kemiso ea ANSI e boletsoeng kapa makhetlo a 1.143 a botenya ba lebota bo boletsoeng, ka hare ho. [mm];

D= bophara bo boletsoeng kantle, bophara ba kantle bo tsamaellanang le boholo ba phaephe e boletsoeng ea ANSI, kapa bophara ba kantle bo baloang ka ho eketsa 2t (joalokaha ho hlalositsoe kaholimo) ho bophara bo boletsoeng kahare, ka hare. [mm].

Nako ea teko: boloka bonyane metsotso e 5, ha ho na ho dutla.

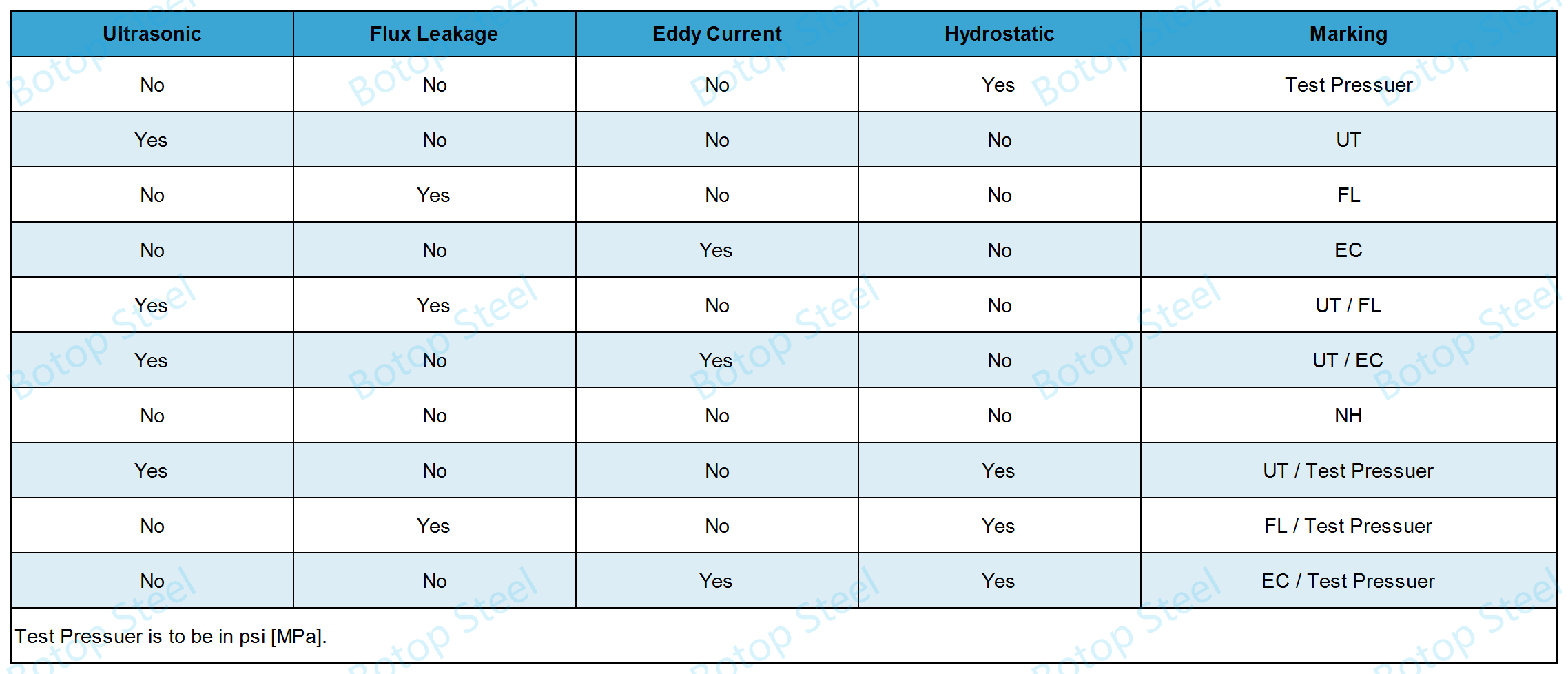

Ha phaephe e sa lokela ho hlahlojwa ka metsi, ho tla etswa teko e sa senyeheng phaepheng ka nngwe ho fumana diphoso.

Teko e sa senyeheng ea thepa ea P9 e lokela ho etsoa ka e 'ngoe ea mekhoaE213, E309 or E570.

E213: Tloaelo ea ho etsa Teko ea Ultrasonic ea Pipe ea Tšepe le Tube;

E309: Boitlhakiso bakeng sa Tlhahlobo ea Eddy Current ea Lihlahisoa tsa Tšepe tsa Tubular tse Sebelisang Khoeli ea Magnetic;

E570: Tshebetso bakeng sa Tlhahlobo ea ho Dutla ha Flux ea Lihlahisoa tsa Ferromagnetic Steel Tubular;

Liphetoho tse Lumellehang ka Bophara

Ho kheloha ha bophara ho ka aroloa ho latela 1. ho latela bophara ba kahare kapa 2. ho latela bophara ba lebitso kapa ba kantle.

1. Bophara ba ka hare: ± 1%.

2. NPS [DN] kapa bophara ba kantle: Sena se dumellana le diphapang tse dumelletsweng tafoleng e ka tlase.

Liphetoho tse Lumellehang tsa Botenya ba Lebota

Botenya ba lebota la phaephe ntlheng efe kapa efe ha boa lokela ho feta mamello e boletsoeng.

Botenya bo fokolang ba lebota le bophara ba kantle bakeng sa tlhahlobo bakeng sa ho latela tlhoko ena bakeng sa phaephe e laetsoeng ke NPS [DN] le nomoro ea kemiso li bontšitsoe hoASME B36.10M.

Dikahare tsa ho tshwaya: Lebitso kapa letshwao la kgwebo la moetsi; nomoro e tlwaelehileng; kereiti; bolelele le letshwao le eketsehileng "S".

Matšoao a khatello ea hydrostatic le liteko tse sa senyeheng tafoleng e ka tlase le ona a lokela ho kenyelletsoa.

Sebaka sa ho tšoaea: Ho tshwaya ho lokela ho qala ho tloha bohōleng ba lisenthimithara tse ka bang 300 ho tloha pheletsong ea phaephe.

Bakeng sa liphaephe tse fihlang ho NPS tse bolelele ba 2 kapa ka tlase ho 3 ft (1 m), letšoao la tlhahisoleseling le ka hokelloa ho tag.

Phaephe ea tšepe ea ASTM A335 P9 e sebelisoa haholo liboiler, liteisheneng tsa motlakase tsa lisebelisoa tsa petrochemical, jj., tse hlokang ho mamella mocheso o phahameng le khatello e phahameng ka lebaka la mocheso oa eona o phahameng le khanyetso e phahameng ea khatello.

Liboiler: Haholo-holo liphaepheng tse kholo tsa mouoane le liphaepheng tsa ho futhumatsa hape tsa liboiler tse bohlokoa haholo le tse bohlokoa haholo bakeng sa mocheso le khatello e phahameng haholo.

Lisebelisoa tsa peterolo: Jwalo ka diphaephe tsa cracker le diphaephe tsa mocheso o phahameng, tse sebetsanang le mouwane le dikhemikhale tsa mocheso o phahameng, di hloka thepa e nang le mocheso o motle le ho hanyetsa mafome.

Liteishene tsa motlakase: Bakeng sa liphaephe tse kholo tsa mouoane le li-heater tse nang le khatello e phahameng, hammoho le liphaephe tsa turbine tse ka hare ho sebetsana le linako tse telele tsa mocheso o phahameng le khatello.

Lisebelisoa tsa P9 li na le limaraka tsa tsona tse tloaelehileng litsamaisong tse fapaneng tsa maemo a naha.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

GOST 550: 12ChM;

Pele o kgetha thepa efe kapa efe e lekanang, ho kgothaletswa hore ho etswe dipapiso tse qaqileng tsa tshebetso le diteko ho netefatsa hore thepa e nngwe e tla fihlela ditlhoko tsa moralo wa pele.

Ho tloha ha e theoa ka 2014,Tšepe ea Botope se e le mofani ea ka sehloohong oa liphaephe tsa tšepe ea khabone Leboea la Chaena, ea tsebahalang ka tšebeletso e ntle haholo, lihlahisoa tsa boleng bo holimo le litharollo tse felletseng.

Khamphani e fana ka mefuta e fapaneng ya diphaephe tsa tshepe ya khabone le dihlahiswa tse amanang le yona, ho kenyeletswa le phaephe ya tshepe e se nang moedi, ERW, LSAW, le SSAW, hammoho le lethathamo le felletseng la diphaephe le di-flange. Dihlahiswa tsa yona tse ikgethang di boetse di kenyelletsa di-alloy tsa maemo a hodimo le ditshipi tse sa hlwekang tsa austenitic, tse etseditsweng ho fihlela ditlhoko tsa diporojeke tse fapaneng tsa diphaephe.

Ka kopo ikutloe u lokolohile ho ikopanya le rona haeba u na le litlhoko kapa lipotso mabapi le liphaephe tsa tšepe. Re labalabela ho fumana tlhahisoleseling ea hau 'me re labalabela ho u thusa.