Tšepe ea ASTM A513ke phaephe le tube ya tshepe ya khabone le alloy e entsweng ka tshepe e phutholotsweng ka ho tjhesa kapa e batang e le thepa e tala ka ho tjheseletsa kganyetso (ERW), e sebediswang haholo mefuteng yohle ya meaho ya mechini.

Mofuta oa 5ka hare ho maemo a ASTM A513 ho buuoa kaE Setšoantšo se Hlahisitsoeng holim'a Mandrel (DOM)phaephe.

Ho kenya tube ea DOM ho hlahisoa ka ho qala ka ho etsa tube e phuthetsoeng ebe e huloa ka serame ka har'a li-dies le holim'a mandrel ho qeta ho fihlela mamello e batlang e le haufi le qetello e boreleli ea bokaholimo ha e bapisoa le mefuta e meng ea ho kenya tube e phuthetsoeng.

Tekanyetso ea ts'ebetso: ASTM A513

Thepa: Tšepe e phutholohileng ka ho chesa kapa e batang

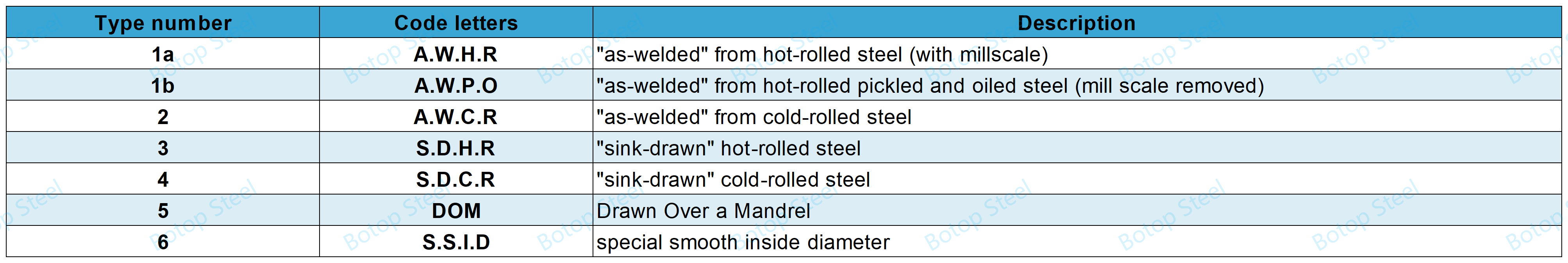

Mofuta:Mofuta oa 1 (1a kapa 1b), Mofuta wa 2, Mofuta wa 3, Mofuta wa 4, Mofuta wa 5, Mofuta wa 6.

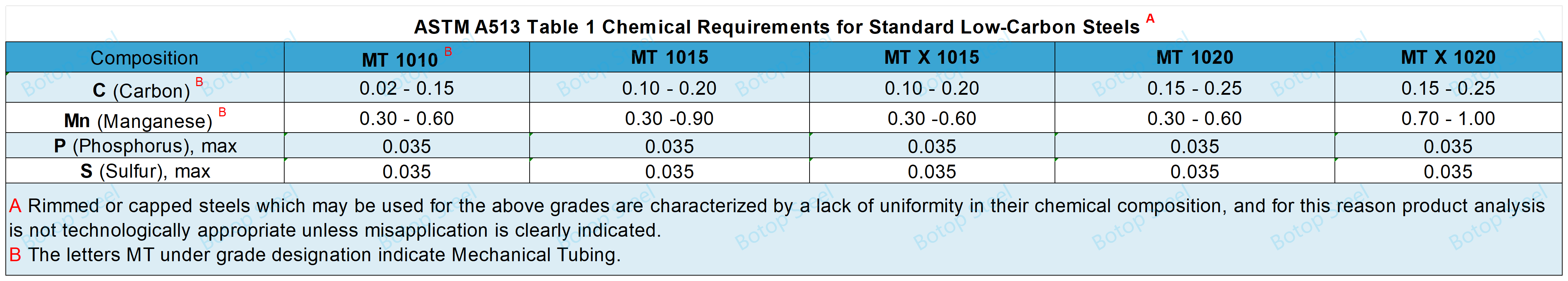

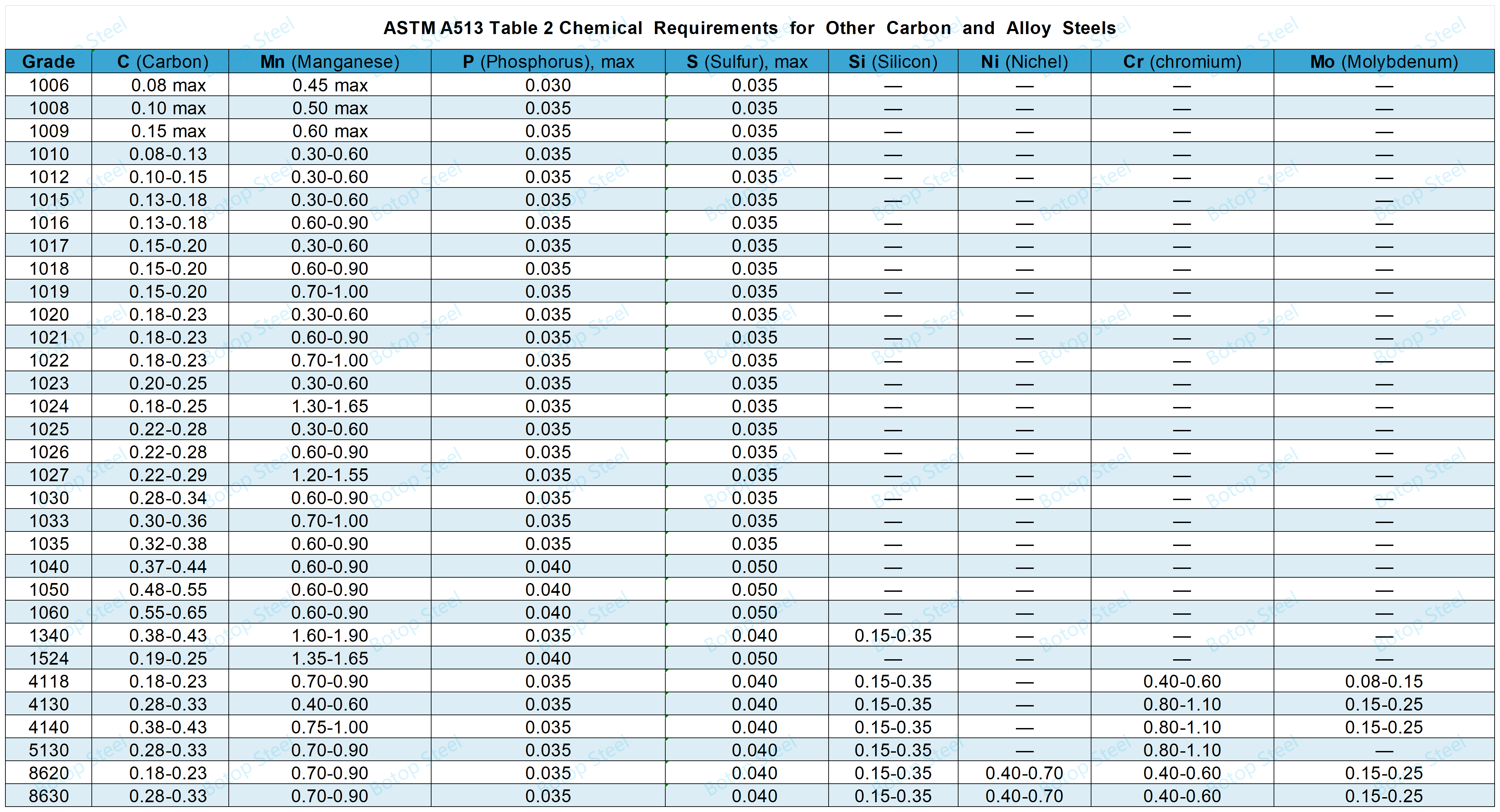

Sehlopha: MT 1010, MT 1015,1006, 1008, 1009 jj.

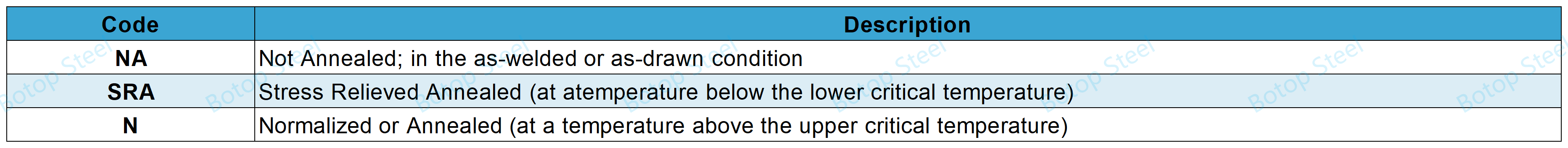

Kalafo ea mocheso: NA, SRA, N.

Boholo le botenya ba lebota

Sebopeho sa karolo e se nang letho: Selikalikoe, sekwere, kapa dibopeho tse ding

Bolelele

Kakaretso ea Bongata

Mefuta ea ASTM A513 e khetholloa ho latela maemo kapa lits'ebetso tse fapaneng tsa phaephe ea tšepe.

Mefuta e tloaelehileng ea ASTM A513 ea liphaephe tse chitja ke ena:

1008, 1009, 1010, 1015, 1020, 1021, 1025, 1026, 1030, 1035, 1040, 1340, 1524, 4130, 4140.

Selika-likoe

Sekwere kapa khutlonnetsepa

Dibopeho tse ding

tse kang tse otlolohileng, tse mahlakore a tsheletseng, tse mahlakore a tsheletseng, tse chitja kahare le tse mahlakore a tsheletseng kapa tse mahlakore a tsheletseng kantle, tse nang le metsu kahare kapa kantle, tse kgutlotharo, tse chitja tse kgutlonnetsepa, le dibopeho tsa D.

Tšepe e phutholotsoeng ka mocheso kapa e batang

Lisebelisoa tse tala bakeng sa tlhahiso ea Tšepe e phutholohileng e Chesang kapa e Cold-rolled li ka etsoa ka mokhoa ofe kapa ofe.

Tšepe e Metsuoang ka Mocheso: Ts'ebetsong ea tlhahiso, tšepe e phuthoang ka mocheso e qala ka ho futhumatsoa mochesong o phahameng, e leng se lumellang tšepe ho phuthoa boemong ba polasetiki, e leng se etsang hore ho be bonolo ho fetola sebopeho le boholo ba tšepe. Qetellong ea ts'ebetso ea ho phuthoa ka mocheso, thepa hangata e a seketsoa le ho fetoloa.

Tšepe e Menoang ka Batang: Tšepe e phutholotsoeng ka serame e phutholoha ho ea pele ka mor'a hore thepa e phole ho fihlela boholo le sebopeho se lakatsehang. Ts'ebetso ena hangata e etsoa mochesong oa kamore 'me e fella ka tšepe e nang le boleng bo betere ba bokaholimo le litekanyo tse nepahetseng haholoanyane.

Liphaephe li tla etsoa kee kopantsoeng ka ho tjheseletsa motlakase (ERW)tshebetso.

Phaephe ea ERW ke mokhoa oa ho theha weld ka ho kopanya thepa ea tšepe ka har'a silindara le ho sebelisa khanyetso le khatello boleleleng ba eona.

Tšepe e lokela ho latela litlhoko tsa sebopeho sa lik'hemik'hale tse boletsoeng ho Tafole ea 1 kapa Tafole ea 2.

| Sehlopha | Matla a Yied ksi[MPa], mets | Matla a ho Qetela ksi[MPa], mets | Ho lelefatsa ka lisenthimithara tse 2 (50 mm), metsotso, | RB motsotso | RB boholo |

| Liphaephe tsa DOM | |||||

| 1008 | 50 [345] | 60 [415] | 5 | 73 | — |

| 1009 | 50 [345] | 60 [415] | 5 | 73 | — |

| 1010 | 50 [345] | 60 [415] | 5 | 73 | — |

| 1015 | 55 [380] | 65 [450] | 5 | 77 | — |

| 1020 | 60 [415] | 70 [480] | 5 | 80 | — |

| 1021 | 62 [425] | 72 [495] | 5 | 80 | — |

| 1025 | 65 [450] | 75 [515] | 5 | 82 | — |

| 1026 | 70 [480] | 80 [550] | 5 | 85 | — |

| 1030 | 75 [515] | 85 [585] | 5 | 87 | — |

| 1035 | 80 [550] | 90 [620] | 5 | 90 | — |

| 1040 | 80 [550] | 90 [620] | 5 | 90 | — |

| 1340 | 85 [585] | 95 [655] | 5 | 90 | — |

| 1524 | 80 [550] | 90 [620] | 5 | 90 | — |

| 4130 | 85 [585] | 95 [655] | 5 | 90 | — |

| 4140 | 100 [690] | 110[760] | 5 | 90 | — |

| Liphaephe tse Fokotsang Khatello ea Kelello ea DOM | |||||

| 1008 | 45 [310] | 55 [380] | 12 | 68 | — |

| 1009 | 45 [310] | 55 [380] | 12 | 68 | — |

| 1010 | 45 [310] | 55 [380] | 12 | 68 | — |

| 1015 | 50 [345] | 60 [415] | 12 | 72 | — |

Tlhokomeliso 1: Litekanyetso tsena li ipapisitse le mocheso o tloaelehileng oa ho imolla khatello ea tšilo. Bakeng sa lits'ebetso tse itseng, thepa e ka fetoloa ka lipuisano pakeng tsa moreki le mohlahisi.

Tlhokomeliso 2: Bakeng sa liteko tsa longitudinal strip, bophara ba karolo ea gauge bo tla ba ho latela A370 Annex A2, Steel Tubular Products, le ho tlosoa ha lintlha tsa peresente ea 0.5 ho tloha ho bolelele ba bonyane ba motheo bakeng sa e 'ngoe le e 'ngoe.1/32ka phokotso ea [0.8 mm] botenya ba lebota tlas'a5/16ka botenya ba lebota ba [7.9 mm] bo tla dumellwa.

1% ea lipeipi tsohle karolong ka 'ngoe le bonyane lipeipi tse 5.

Liphaephe tse chitja le liphaephe tse etsang libopeho tse ling ha li le chitja lia sebetsa.

Liphaephe tsohle li tla fuoa teko ea hydrostatic.

Boloka khatello e tlase ea teko ea metsi bonyane metsotso e 5.

Khatello e baloa ka tsela ena:

P=2St/D

P= khatello e tlase ea teko ea hydrostatic, psi kapa MPa,

S= khatello ea fiber e lumelletsoeng ea 14,000 psi kapa 96.5 MPa,

t= botenya ba lebota bo boletsoeng, ka hare kapa ka mm,

D= bophara bo boletsoeng ka ntle, ka hare kapa mm.

Sepheo sa teko ena ke ho hana lipeipi tse nang le likoli tse kotsi.

Phaephe ka 'ngoe e tla lekoa ka teko ea motlakase e sa senyeheng ho latela Mokhoa oa E213, Mokhoa oa E273, Mokhoa oa E309, kapa Mokhoa oa E570.

Bophara ba Kantle

Tafole ea 5Mamello ea Bophara bakeng sa Mefuta ea 3, 4, 5, le 6 (SDHR, SDCR, DOM, le SSID) Round

Botenya ba lebota

Tafole ea 8Mamello ea Botenya ba Lebota ea Mefuta ea 5 le ea 6 (DOM le SSID) Liphaephe tse chitja (Liyuniti tsa lisenthimithara)

TAFOLE EA 9Mamello ea Botenya ba Lebota ea Mefuta ea 5 le ea 6 (DOM le SSID) Liphaephe tse Potolohileng (Liyuniti tsa SI)

Bolelele

Tafole ea 13Mamello ea Bolelele ba ho Khaola bakeng sa Liphaephe tse Potolohileng tsa Lathe-Cut

Tafole ea 14Mamello ea Bolelele bakeng sa Tube e Potolohileng ea Punch-, Saw-, kapa Disc-Cut

Sekwere

Tafole ea 16Mamello, Litekanyo tsa Kantle Tube e Sekwere le e Khutšoane

Tšoaea tlhahisoleseling e latelang ka tsela e loketseng bakeng sa thupa kapa sephutheloana se seng le se seng.

lebitso la moetsi kapa letshwao, boholo bo boletsweng, mofuta, nomoro ya odara ya moreki, le nomoro ena ya tlhaloso.

Barcoding e amoheleha e le mokhoa o tlatsetsang oa ho khetholla.

Phaephe e lokela ho tlotsoa ka filimi ea oli pele e romelloa ho thibela mafome.

Haeba odara e ka bolela hore liphaephe li romelloe ntle leoli e thibelang mafome, filimi ea oli e hlahisoang ka tšohanyetso e tla sala holim'a metsi.

E ka thibela ka katleho bokaholimo ba phaephe ho arabela mongobo le oksijene moeeng, ka hona e qoba mafome le ho bola.

Ka 'nete, leha setlolo sa motheo kapa filimi e bonolo ea oli e ka fana ka tšireletso ea nakoana e itseng, bakeng sa lits'ebetso tse hlokang tšireletso e phahameng, kalafo e nepahetseng ea tšireletso ea mafome e lokela ho khethoa ho latela nyeoe ka 'ngoe.

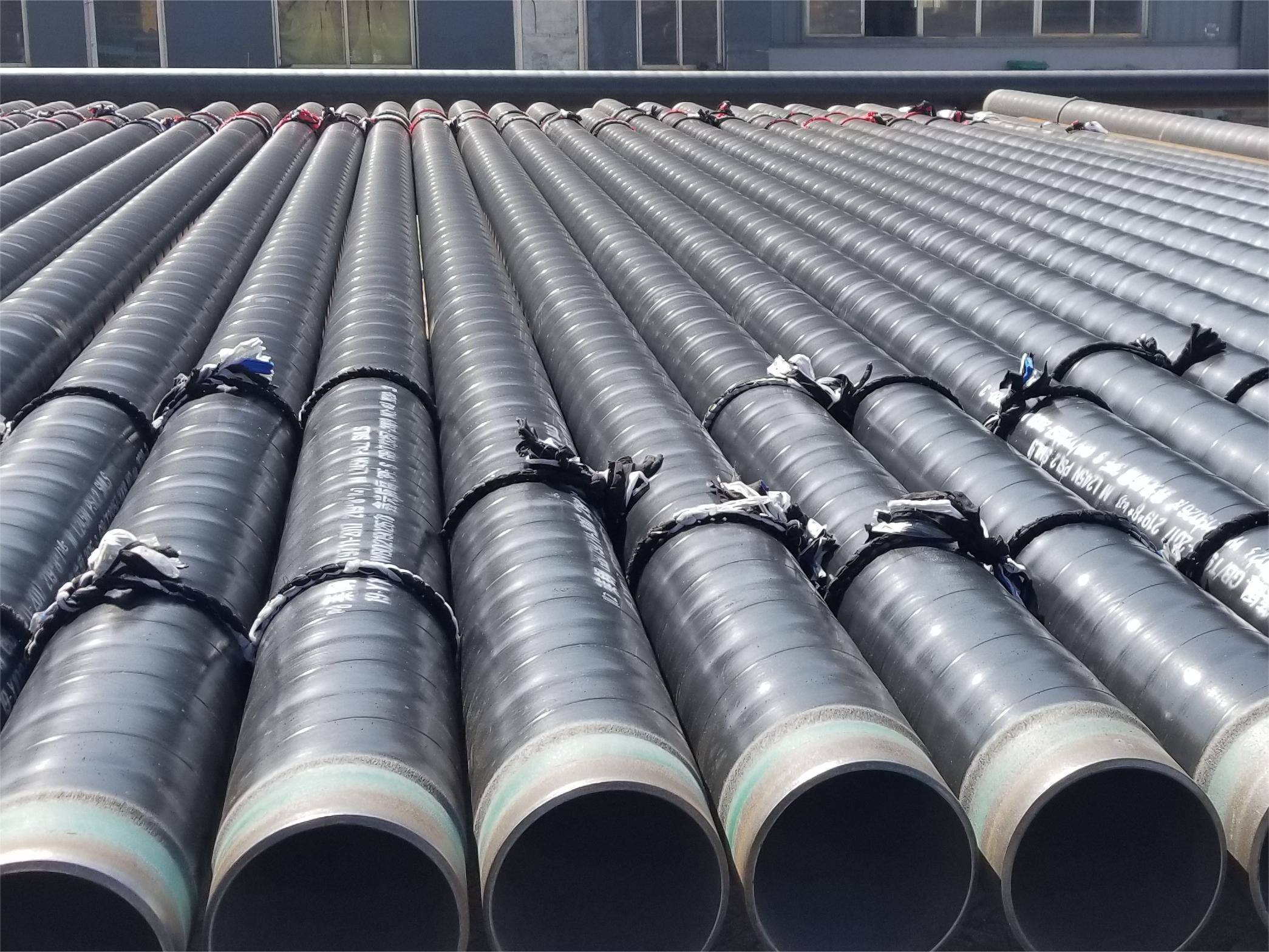

Mohlala, bakeng sa liphaephe tse patiloeng,3PEsekoahelo (polyethylene ea mekhahlelo e meraro) se ka sebelisoa ho fana ka tšireletso ea nako e telele khahlanong le mafome; bakeng sa liphaephe tsa metsi,FBE(phofo ea epoxy e kopantsoeng le fusion) e ka sebelisoa, hagalvanizedMekhoa ea phekolo e ka ba khetho e sebetsang libakeng tseo ho tsona ho hlokahalang tšireletso khahlanong le ho bola ha zinki.

Ka mahlale ana a khethehileng a tšireletso ea mafome, bophelo ba tšebeletso ea phaephe bo ka atolosoa haholo 'me ts'ebetso ea eona ea bolokoa.

Ho nepahala ho hoholo: Mamello e nyane ho feta lipeipi tse ling tse welletsoeng.

Boleng ba bokaholimo: Libaka tse boreleli li loketse lits'ebetso tse hlokang ponahalo e ntle le liphoso tse fokolang tsa bokaholimo.

Matla le ho tšoarella: Ts'ebetso ea ho hula ka serame e ntlafatsa litšobotsi tsa mechini, e leng se etsang hore e lokele lits'ebetso tse nang le khatello e phahameng.

Ho sebetsa ha mechine: Ho bonolo ho e sebelisa ka lebaka la sebopeho sa eona se senyenyane le thepa e tsitsitseng ho pholletsa le thepa.

Indasteri ea likoloi: bakeng sa tlhahiso ea likarolo tsa bohlokoa tse kang li-drive shafts, li-bearing tubes, li-steering columns le litsamaiso tsa ho emisoa.

Likarolo tsa lifofane: bakeng sa tlhahiso ea li-bushing le likarolo tsa sebopeho tse seng tsa bohlokoa bakeng sa lifofane.

Mechine ea indasteri: E sebelisoa haholo tlhahisong ea li-shaft, li-gear, jj., ka lebaka la bonolo ba tsona ba ho sebetsa le ho tšoarella.

Thepa ea lipapali: dikarolo tsa sebopeho tse kang diforeimi tsa baesekele tse sebetsang hantle le disebediswa tsa boikoetliso.

Lekala la eneji: e sebediswang ka hara masakaneng kapa dikarolong tsa dirolara bakeng sa diphanele tsa letsatsi.

Re e mong oa bahlahisi le bafepedi ba liphaephe tsa tšepe tsa carbon tse qhibilihisitsoeng ka ho tjheseletsa le tse se nang sekoli ba tsoang Chaena, re na le mefuta e mengata ea liphaephe tsa tšepe tsa boleng bo holimo tse fumanehang, re ikemiselitse ho u fa mefuta e felletseng ea litharollo tsa liphaephe tsa tšepe.

Bakeng sa lintlha tse ling tsa sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona, re labalabela ho u thusa ho fumana likhetho tse ntle ka ho fetisisa tsa phala ea tšepe bakeng sa litlhoko tsa hau!