ASTM A519li-tubing li tla etsoa ka mokhoa o sa tsitsang 'me li tla phethoa ka ho chesa kapa ho bata joalokaha ho boletsoe.

Bakeng sa li-tubes tse chitja tse nang le bophara ba kantle bo sa feteng 12 3/4 in (325 mm).

Li-tubing tsa tšepe le tsona li ka etsoa ka lisekoere, tse khutlonnetsepa, kapa libopeho tse ling kamoo ho hlokahalang.

ASTM A519 e ka aroloa ho latela thepa ea tšepe:Tšepe ea Carbonle Alloy Steel.

Tšepe ea carbone arotsoe kaLow Carbon MT(Mechanik Tubing),Tšepe e phahameng ea CarbonleDesulfurized or Rephosphorized, kapa ka bobeliTšepe ea Carbon, ho lumellana le litlhoko tse fapaneng tsa indasteri le maemo a ts'ebeliso.

Ha ho sa boleloe kereiti, bahlahisi ba na le boikhethelo ba ho fanaMT1015 kapa MTX1020limaraka.

Ka ntle bophara: 13.7 - 325 limilimithara;

Botenya ba lebota: 2-100mm.

Tšepe e ka etsoa ka mokhoa ofe kapa ofe.

Tšepe e ka 'na ea kenngoa ka li-ingots kapa e ka ba strand cast.

Lithapo li tla etsoa ke amokhoa o se nang moeli'me e tla be e felile ka ho chesa kapa e batang, joalo ka ha ho boletsoe.

Li-tubes tsa tšepe tse se nang seam ke li-tubes tse se nang li-welded seams hohle.

Li-tubes tse phethiloeng ka serameli khothaletsoa bakeng sa litlhoko tse phahameng mabapi le ho nepahala ha dimensional le boleng ba bokaholimo.

Ntho e amehang haholo ke ho boloka litšenyehelo le ho tiea ha lintho tse bonahalang,phala ea tšepe e felileng ho chesae ka ba khetho e nepahetseng haholoanyane.

E latelang ke ts'ebetso ea tlhahiso ea phala ea tšepe e se nang seamless e chesang.

Moetsi oa tšepe o tla sekaseka mocheso oa tšepe e 'ngoe le e' ngoe ho fumana hore na peresente ea likarolo tse boletsoeng.

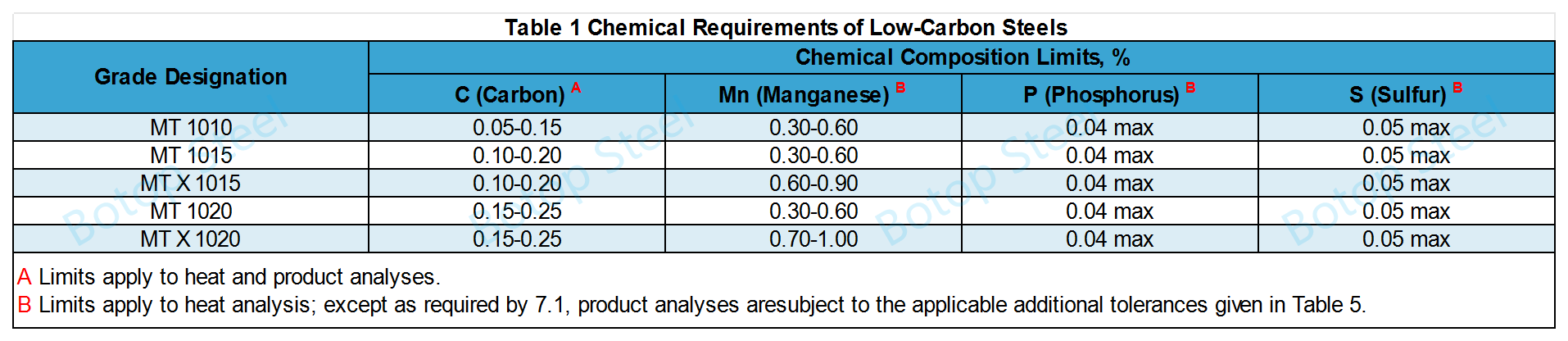

Lethathamo la 1 Litlhoko tsa Lik'hemik'hale tsa Litšepe tse Tlase tsa Carbon

Tšepe e bonolo ke tšepe e nang le khabone hangata e sa feteng 0.25%. Ka lebaka la khabone ea eona e tlase, tšepe ena e na le ductility e betere ebile e bonolo ebile ha e thata ebile ha e matla ha e bapisoa le tšepe e phahameng ea khabone.

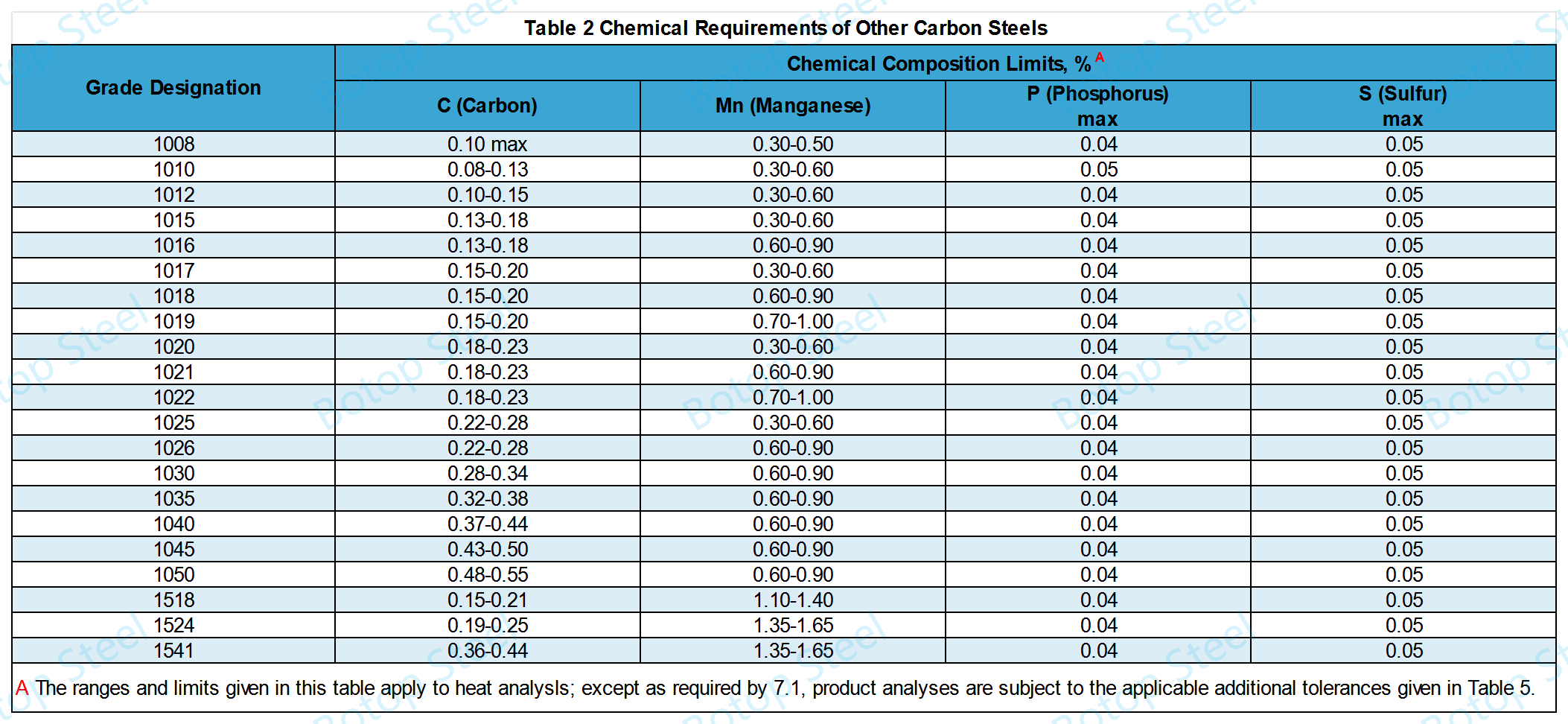

Lethathamo la 2 Litlhoko tsa Lik'hemik'hale tsa Litšepe Tse Ling tsa Carbon

Litšepe tsa khabone tse mahareng: E na le pakeng tsa 0.25% le 0.60% carbon, li fana ka boima bo phahameng le matla 'me li hloka phekolo ea mocheso ho ntlafatsa thepa.

Tšepe e phahameng ea carbon: E na le pakeng tsa 0.60% le 1.0% kapa ho feta k'habone, 'me e fana ka boima bo phahameng haholo le matla, empa boima bo tlase.

Lethathamo la 3 Litlhoko tsa Lik'hemik'hale tsa Alloy Steels

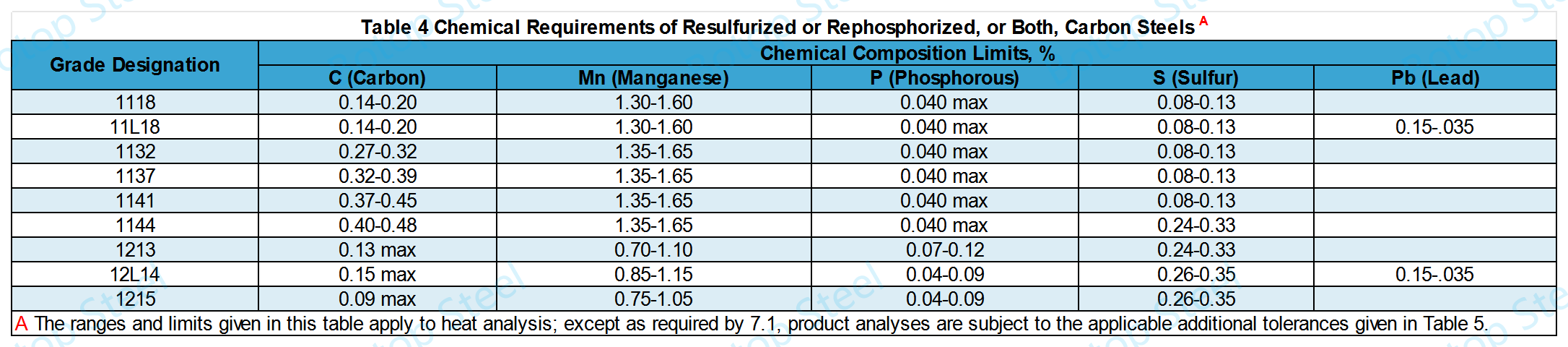

Lethathamo la 4 Litlhokahalo tsa Lik'hemik'hale tsa Resulfurized kapa Rephosphorized, kapa ka bobeli, Litšepe tsa Carbon

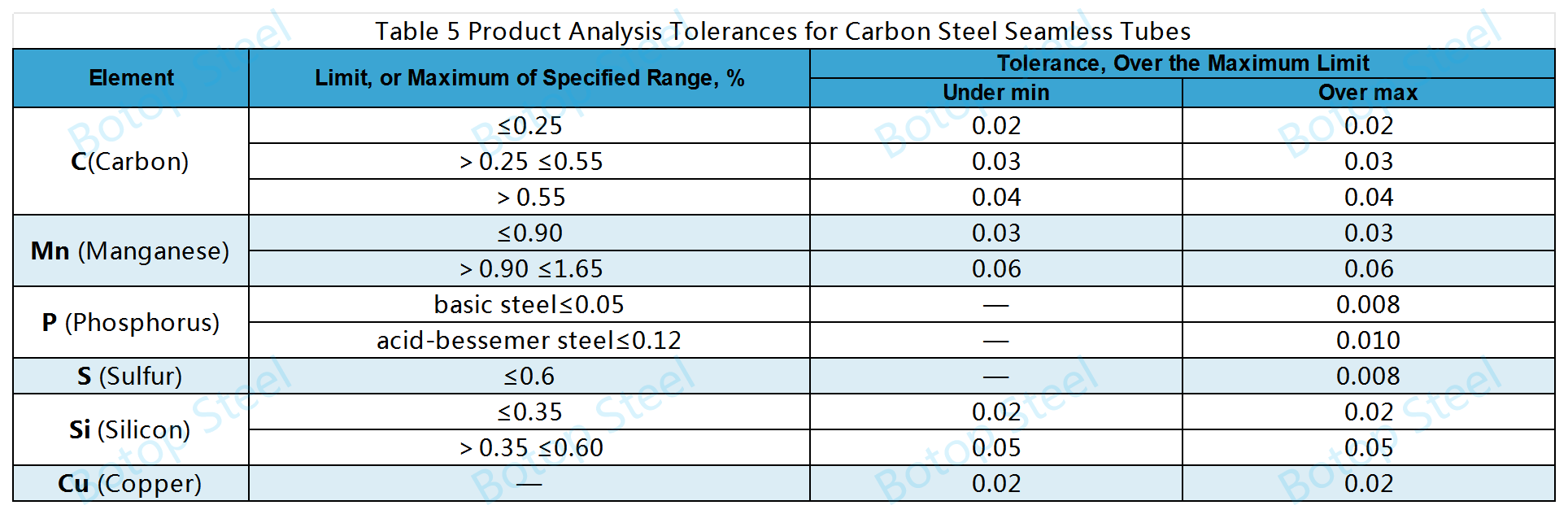

TABLE 5 Product Analysis Tolerances Over or UnderSpecified Range or Limit

Moetsi o lokela ho botsoa feela hore a hlahlobe sehlahisoa haeba se hlokoa ke taelo.

ASTM A519 e akaretsa lintlha tse latelang tsa liteko:

Teko ea boima; Liteko tsa tsitsipano; Teko e sa senyeheng; Flaring Test; Bohloeki ba tšepe le ho thatafala.

| Khetho ea Mophato | Mofuta oa Pipe | Boemo | Uitimate Matla | Kotulo Matla | Elongation ka 2in.[50mm],% | Rockwell, Thata B Sekala | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Tšepe ea Carbon | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Tšepe ea Carbon | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Tšepe ea Carbon | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Tšepe ea Carbon | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Tšepe ea Carbon | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized kapa Rephosphorized, kapa ka bobeli, Litšepe tsa Carbon | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized kapa Rephosphorized, kapa ka bobeli, Litšepe tsa Carbon | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Litšepe tsa Alloy | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Litšepe tsa Alloy | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-Hot Rolled, CW-Cold Worked, SR-Stress Fokotswa, A-Annealed le N-Normalized.

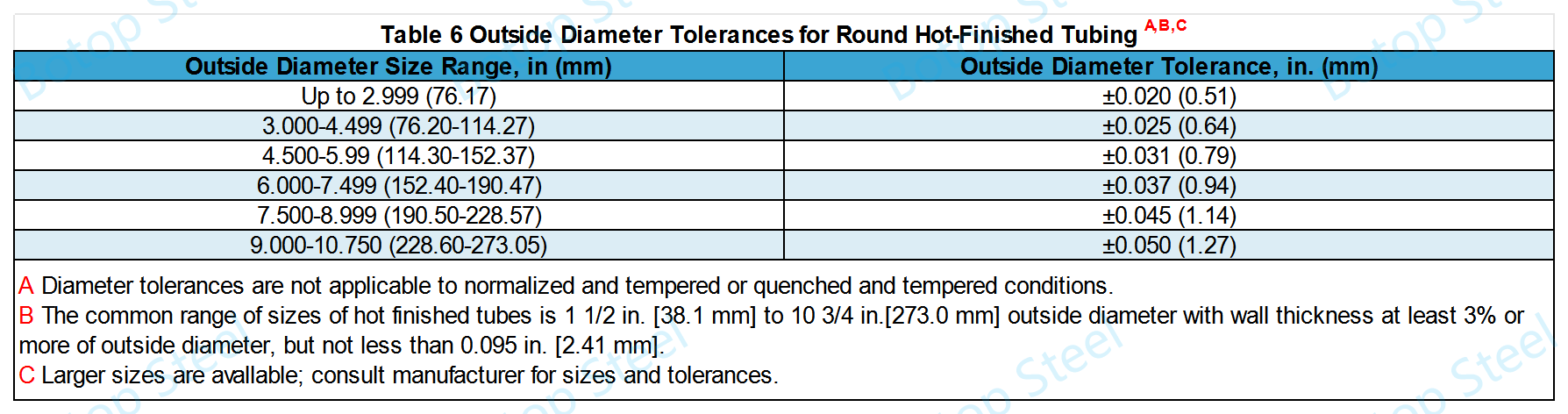

Mamello ea Kantle ea Diameter

Lethathamo la 6 Mamello ea Kantle ea Diameterbakeng sa Round Hot-Finished Tubing

Lethathamo la 12 Mamello ea Kantle ea Diameter bakeng saPhatlalatso ea Seamless Tubing

| Boholo bo kantle ho Diameter, ka.[mm] | Mamello ea Kantle ea Diameter bakeng sa Boholo le Bolelele bo Fanoeng, ka. [mm] | |||

| Fetile | Tlas'a | Fetile | Tlas'a | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] ha L≤16ft[4.9m] | 0.000 | 0.004 [0.10] ha L>16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] ha L≤16ft[4.9m] | 0.000 | 0.006 [0.15] ha L>16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] ha L≤12ft[3.7m] | 0.000 | 0.006 [0.15] ha L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] ha L≤12ft[3.7m] | 0.000 | 0.006 [0.15] ha L≤16ft[4.9m] | 0.000 |

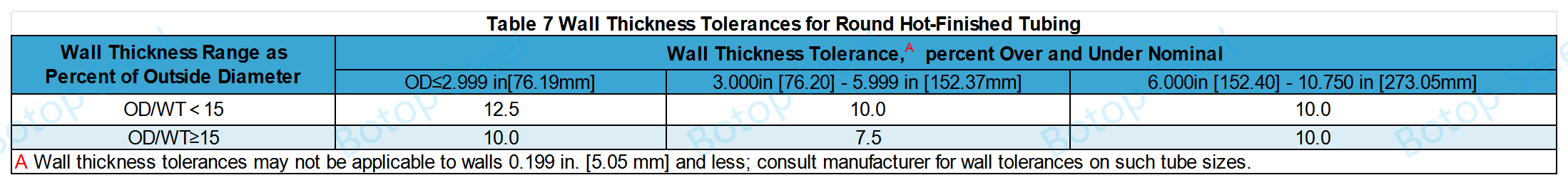

Mamello ea Botenya ba Lerako

Lethathamo la 7 Mamello ea Botenya ba Marakobakeng sa Round Hot-Finished Tubing

Lethathamo la 10 Mamello ea Botenya ba Marakobakeng sa Round Cold-Worked Tubing

| Botenya ba Lerako bo Range e le Peresente ea Kantle Diameter | Mamello ea Botenya ba Lerako ho Feta le Tlas'a Lebitso,% | |

| OD≤1.499in[38.07mm] | OD≥1.500 ho [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

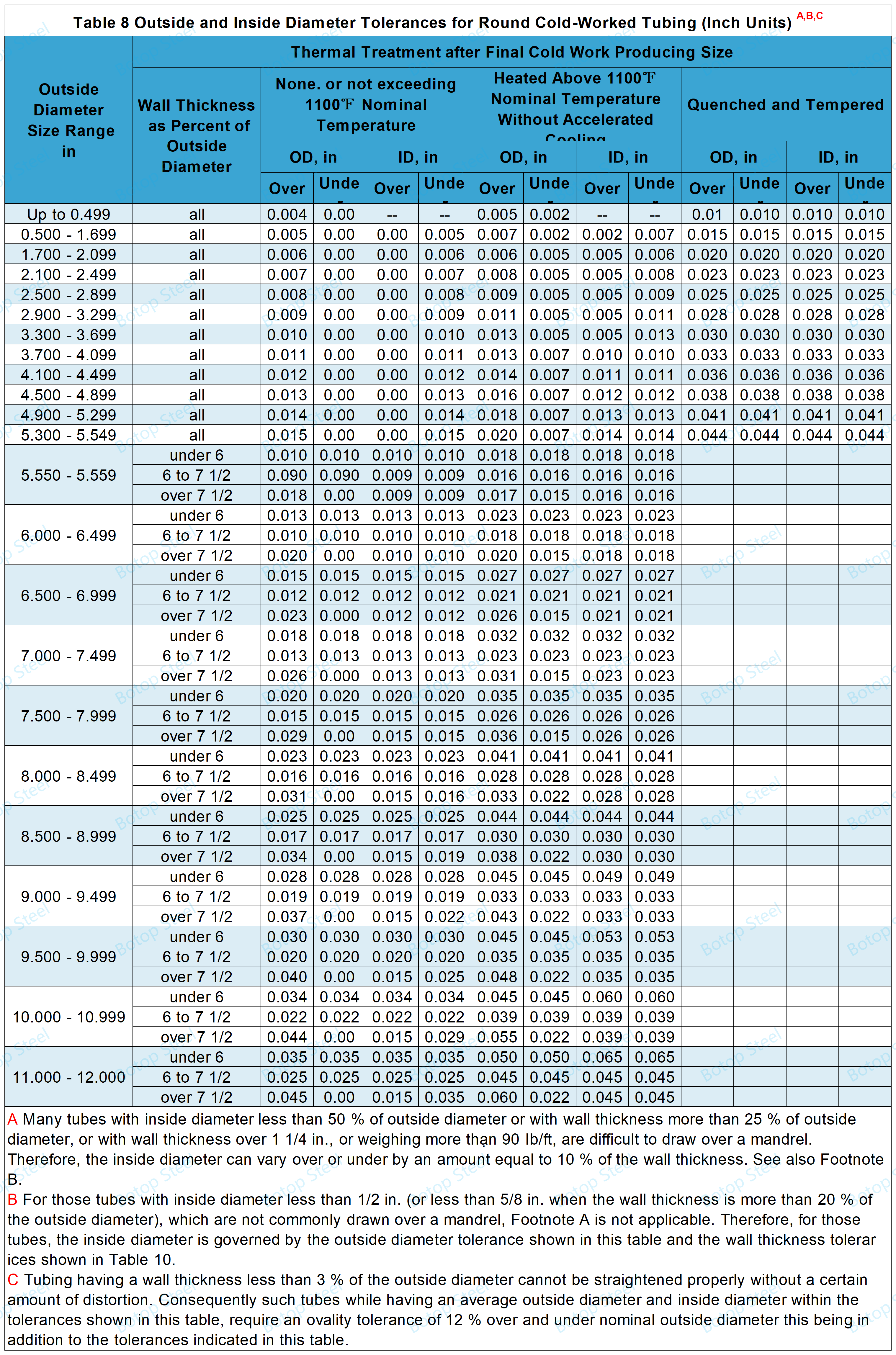

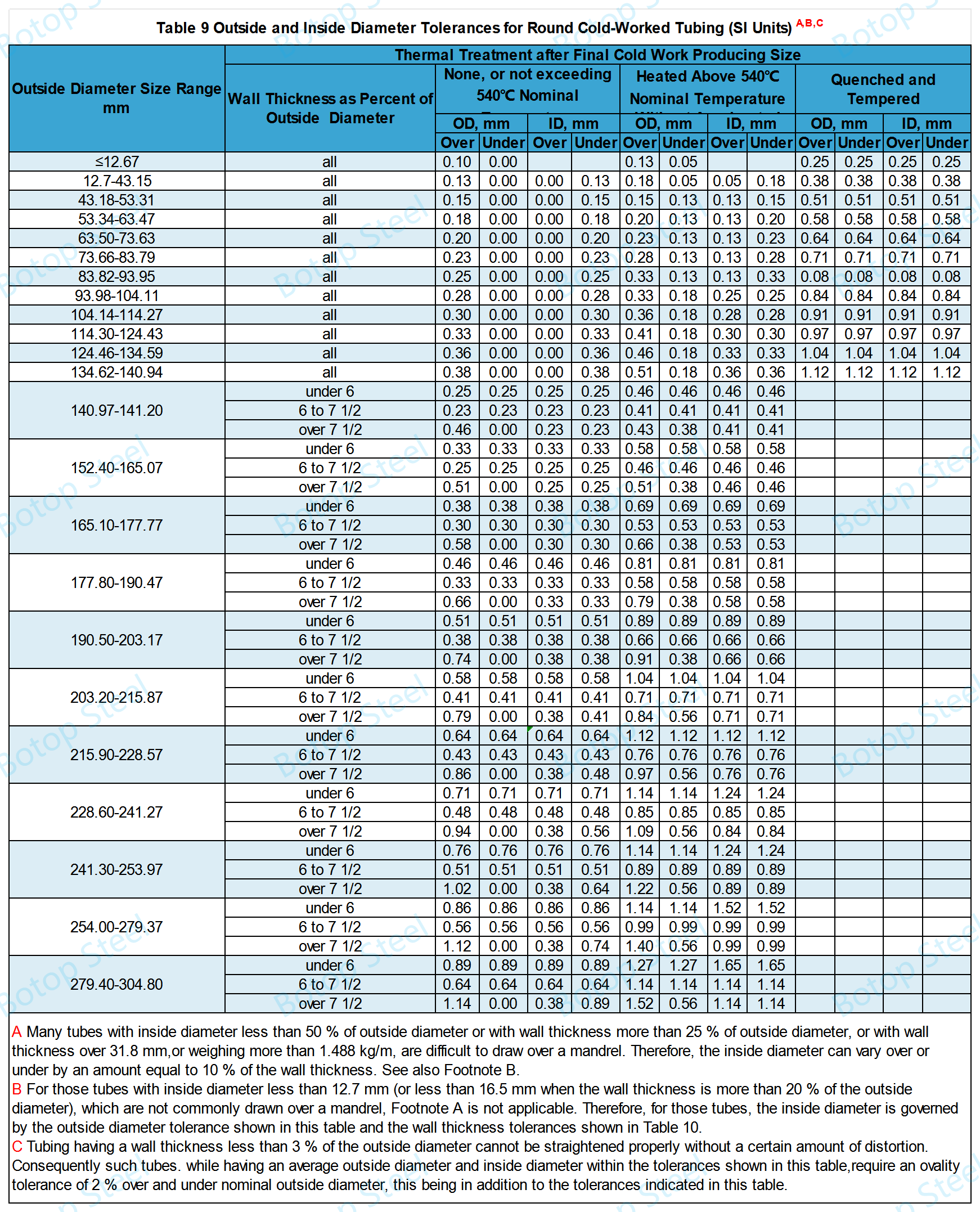

Mamello ea Kantle le ka Hare Diameter

Lethathamo la 8 Mamello ka Ntle le ka Hare Diameter bakeng saLi-Round-Worked Tubing (Li-Inch Units)

Lethathamo la 9 Mamello ea Kantle le ka Hare Diameterbakeng sa Round Cold-Worked Tubing (SI Units)

Kantle ho Diameter le Mamello ea Botenya ba Lebota

Tafole 11 Kantle Diameter le Mamello ea Lebotabakeng sa Rough-Turned Seamless Steel Tubing

| Boholo bo boletsoeng ka ntle ho Diameter, ho. [mm] | Kantle Diameter, ho. [mm] | Botenya ba Lerako, % |

| 6 3/4 [171.4] | ±0.005 [0.13] | ± 12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ± 12.5 |

Bolelele Mamello

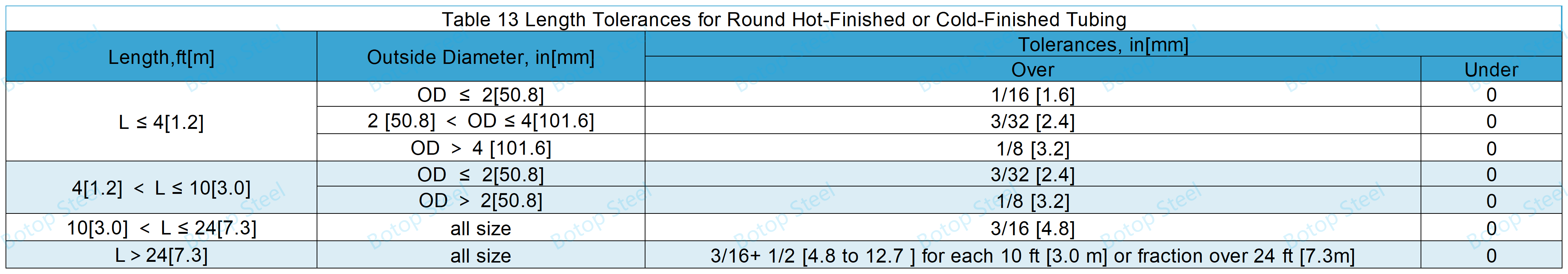

Tafole 13 Bolelele Mamellobakeng sa Round Hot-Finished kapa Cold-Finished Tubing

Mamello e otlolohileng

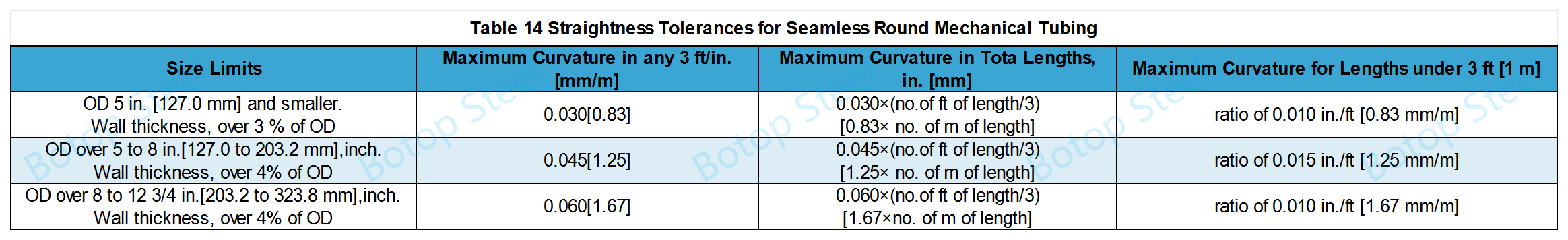

Lethathamo la 14 Mamello ea ho Otlolohabakeng sa Seamless Round Mechanical Tubing

Peipi e lokela ho tlotsoa ka filimi ea oli pele e bōptjoa ho thibela mafome.

Oli e thibelang mafome e ka boela ea sebelisoa libakeng tse ka hare le tse ka ntle tsa phala.

Sefofane le sefofane: ho etsoa ha likarolo tsa bohlokoa tse kang lienjineri tsa lifofane le litsamaiso tsa tšehetso tsa sepaka-paka.

Indasteri ea matla: lisebelisoa tsa ho cheka le tlhahiso ea liphaephe tsa boiler tse nang le khatello e phahameng.

Ho etsa mechine le lisebelisoa: Likarolo tsa mantlha tse etsang mefuta e mengata ea mechini le lisebelisoa tsa indasteri.

Lisebelisoa tsa lipapali: Ho etsoa ha liforeimi tsa libaesekele tse sebetsang hantle haholo le lisebelisoa tse ling tsa lipapali.

Kaho le kaho: likarolo tsa ts'ehetso ea meralo bakeng sa meaho le lits'ebetso tse maemong a khatello e phahameng.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, joalo-joalo. Lisebelisoa tsena li ka nkoa e le tse lekanang le litšepe tse ling tsa carbon le alloy ho ASTM A519.

2. DIN 1629: St52, St37.4, joalo-joalo Hangata e sebelisetsoa merero ea mechine le ea meralo, tsena li tšoana le limaraka tse bonolo tsa tšepe ho ASTM A519.

3. JIS G3445: STKM13A, STKM13B, joalo-joalo Tsena ke li-tubes tsa carbon steel tse sebelisetsoang merero ea mechine le ea moralo.

4. BS 6323:CFS 3, CFS 4, CFS 8, joalo-joalo Tsena ke li-tubes tsa tšepe tse se nang moroallo le tse cheselitsoeng bakeng sa merero ea likoloi, ea mechini le ea boenjiniere ka kakaretso.

5. GB / T 8162: 20 #, 45 #, 40Cr, 20CrMo, joalo-joalo Li-tubes tsa tšepe tse se nang seamless le liphaephe bakeng sa sebopeho se akaretsang le sebopeho sa mechine.

6. ISO 683-17: 100Cr6, joalo-joalo, e atisang ho sebelisoa ha ho etsoa lihlahisoa, e ka boela ea fumana kopo ho boenjiniere ba mechine 'me e na le lisebelisoa tse tšoanang ho litšepe tse itseng tsa alloy tsa ASTM A519.

Ha u khetha thepa e lekanang, ke habohlokoa ho bua ka lintlha tse qaqileng tsa lik'hemik'hale le lisebelisoa tsa thepa ea mochine ho netefatsa hore thepa e khethiloeng e tla finyella litlhoko tsa ts'ebetso ea kopo e itseng.

Ho tloha ha e thehoa ka 2014, Botop Steel e fetohile mofani ea ka sehloohong oa phala ea carbon steel Northern China, e tsejoang ka tšebeletso e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse feletseng. Khampani e fana ka mefuta e sa tšoaneng ea liphaephe tsa tšepe ea carbon le lihlahisoa tse amanang le tsona, tse kenyelletsang seamless, ERW, LSAW, le phala ea tšepe ea SSAW, hammoho le lethathamo le feletseng la liphaephe le li-flanges.

Lihlahisoa tsa eona tse khethehileng li boetse li kenyelletsa li-alloys tsa boemo bo phahameng le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho finyella litlhoko tsa merero e fapaneng ea liphaephe.