BS EN 10210 S275J0Hke sekoti se chesang se phethiloeng ka tšepe e entsoeng ka tšepeBS EN 10210ka mefuta e fapaneng ya dibopeho tse chitja, sekwere, kgutloane kapa oval.

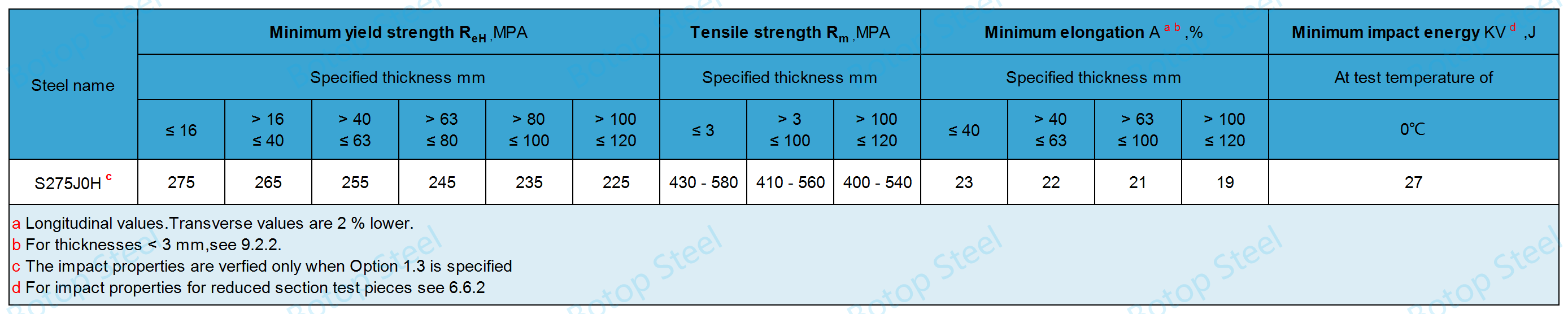

Lisebelisoa tsa S275J0H li khetholloa ke matla a fokolang a 275 MPa ka botenya bo sa feteng 16 mm; matla a eona a tšusumetso e tlase ke bonyane ba 27 J ho 0℃.

S275J0H ke ea mofuta oa tšepe ea carbon, nomoro ea tšepe1.0149, e nang le thepa e ntle ea sebopeho le ea ho sebetsa, haholo-holo e sebelisoang mehahong ea mohaho, empa hape e sebelisetsoa likarolo tse sa jereng mojaro, e ka fana ka ho boloka botsitso ba moralo le ho tšoarella ho itšetlehile ka ho phethahala ha melemo e theko e tlaase.

Tlhokomeliso: Litlhokahalo tsohle ho BS EN 10210 le tsona li sebetsa ho EN 10210 mme ka hona ha li phetoa mona.

Likhetho tsa sehlopha ho BS EN 10210 li abeloa ho latela EN 10027-1 mme linomoro tsa tšepe li abeloa ho latela EN 10027-2.

| Lebitso la tšepe | Nomoro ea tšepe | Mofuta oa tšepe | Lebitso la tšepe | Nomoro ea tšepe | Mofuta oa tšepe |

| S235JRH | 1.0039 | tšepe ea carbon | S275NH | 1.0493 | tšepe ea carbon |

| S275J0H | 1.0149 | tšepe ea carbon | S275NLH | 1.0497 | tšepe ea carbon |

| S275J2H | 1.0138 | tšepe ea carbon | S355NH | 1.0539 | tšepe ea carbon |

| S355J0H | 1.0547 | tšepe ea carbon | S355NLH | 1.0549 | tšepe ea carbon |

| S355J2H | 1.0576 | tšepe ea carbon | S420NH | 1.8750 | tšepe ea motsoako |

| S355K2H | 1.0512 | tšepe ea carbon | S420NLH | 1.8751 | tšepe ea motsoako |

| S460NH | 1.8953 | tšepe ea motsoako | |||

| S460NLH | 1.8956 | tšepe ea motsoako |

Bakeng sa tlhaiso-leseling e batsi mabapi le meelelo e ikhethileng ea litlhaku le linomoro tsa limaraka,o ka tobetsa mona.

Botenya ba lebota ≤120mm.

selikalikoe: Ka ntle bophara ho fihlela ho 2500 limilimithara;

Square: Ka ntle litekanyo ho fihlela ho 800 mm x 800 mm;

Rectangular: Ka ntle litekanyo ho fihlela ho 750 mm x 500 mm;

Elliptical: Litekanyo tsa ka ntle ho fihla ho 500 mm x 250 mm.

Re ipabola ka ho fana ka litlhaloso tse fapaneng tsa Round Hollow Structural Steel Pipe, haeba u na le litlhoko, ka kopo ikutloe u lokolohile ho ikopanya le rona, re labalabela ho sebelisana le uena!

LSAW liphaephe tsa tšepe tse cheselitsoeng li etsoa haholo-holo ka ho etsa lipoleiti tsa tšepe ka har'a li-tubes ho sebelisa mokhoa oa ho bopa oa JCOE, o lateloa ke ho tjheseletsa ho sebelisa arc e nang le mahlakoreng a mabeli.DSAW) theknoloji ea ho tjheseletsa, 'me e phethetsoe ka litlhahlobo le liphekolo tse ngata.

U khetha mokhoa o nepahetseng oa tlhahiso joang? Liphapang le melemo ea phala ea tšepe e se nang seamless, LSAW, welding ea arc e ka tlas'a metsi ke efe, le welding ea arc e ka tlas'a metsi? Hona boholo ba tšebetso e 'ngoe le e 'ngoe ke bofe? U ka tobetsa sehokelo se latelang ho e sheba.

Litšobotsi JR,J0, J2 le K2 -ho chesa ho felile;

Litšobotsi tsa N le NL - tse tloaelehileng. Normalized e kenyeletsa ho tloaeleha ho phuthoa.

| Steel grade | Mofuta oa deoxidationa | % ka boima, boholo | |||||||

| C (Khabone) | Si (Silikone) | Mn (Manganese) | P (Phosphorous) | S (Sebabole) | Nb,c (Naetrojene) | ||||

| Lebitso la tšepe | Nomoro ea tšepe | Botenya bo boletsoeng (mm) | |||||||

| ≤40 | >40≤120 | ||||||||

| S275J0H | 1.0149 | FN | 0.20 | 0.22 | - | 1.5 | 0.035 | 0.035 | 0.009 |

aFN = Litšepe tse rimming ha lia lumelloa;

bHo lumelloa ho feta litekanyetso tse boletsoeng tse fanoeng hore bakeng sa keketseho ka 'ngoe ea 0.001 % N the P, max. litaba li boetse li fokotsehile ka 0.005%. Likahare tsa N tsa tlhahlobo ea cast, leha ho le joalo, ha li na ho feta 0.012%;

cBoleng bo ka holimo ba naetrojene ha bo sebetse haeba motsoako oa lik'hemik'hale o bontša bonyane kakaretso ea Al content ea 0.020 % ka karolelano ea bonyane ea Al/N ea 2:1, kapa haeba likarolo tse ling tse tlamang tsa N li le teng. Lintlha tse tlamang N li tla tlalehoa Tokomaneng ea Tlhahlobo.

Mehaho ea mochini ea BS EN 10210 e kenyelletsa matla a tlhahiso, matla a ho tsitsa, ho lelefatsa, le thepa ea tšusumetso.

Likarolo tse sekoti li tla ba le bokaholimo bo boreleli bo lumellanang le mokhoa oa tlhahiso o sebelisoang; li-bumps, li-cavities, kapa li-grooves tse sa tebang tsa longitudinal tse bakoang ke ts'ebetso ea tlhahiso li lumelloa, ha feela botenya bo le ka har'a mamello.

TS EN 10210 Bokaholimo ba lipeipi tsa tšepe li loketse bakeng sa ho kolobisoa ka metsi a chesang.

EN 10210 ha e hloke tlhahlobo ea khatello ea hydrostatic ea lipeipi tsa tšepe.

Lebaka ke hobane lihlahisoa tse emeng tsa EN 10210 li sebelisoa haholo molemong oa meralo eseng bakeng sa lits'ebetso tsa liphaephe tse hlokang ho hatelloa.

Haeba ho hlokahala tlhahlobo ea khatello ea hydrostatic, ho ka buuoa ka litekanyetso tsa EN 10216 (seamless steel tubes) kapa EN 10217 (welded steel tubes).

Ha ho na tlhoko e tlamang ho latela maemo a ho etsa NDT liphaepheng tsa tšepe tse se nang letho.

Haeba NDT e etsoa liphaepheng tsa tšepe tse cheselitsoeng, litlhoko tse latelang li ka boleloa.

Motlakase Welded likarolo

Bakeng sa karolo e chitja e sekoti li-tubes tsa tšepe ke ERW.

U ka khetha e 'ngoe ea mekhoa e latelang ea liteko bakeng sa tlhahlobo.

a) EN 10246-3 ho isa boemong ba kamohelo ea E4, ntle le hore mokhoa o potolohang oa li-tube/pancake coil o ke ke oa lumelloa;

b) EN 10246-5 ho isa boemong ba kamohelo F5;

c) EN 10246-8 ho isa boemong ba kamohelo ea U5.

Likarolo tse ka tlas'a metsi tsa Arc Welded

Bakeng sa li-tubes tsa tšepe tse chitja tse sekoti ke LSAW le SSAW.

Sekhahla sa weld sa likarolo tse se nang metsi se tla lekoa ho latela EN 10246-9 ho ea boemong ba kamohelo ea U4 kapa ka radiography ho latela EN 10246-10 e nang le boleng ba setšoantšo sa R2.

Bakeng sa tlhaiso-leseling e batsi mabapi le litlhoko tse amanang le mamello ea dimensional,ka kopo, tobetsa mona ho fumana lintlha tse ling.

EN 10025 - S275J0;

JIS G3106 - SM400B;

CSA G40.21 - 300W;

Ha ho khethoa EN 10210 S275J0H e lekanang, papiso e qaqileng ea sebopeho sa lik'hemik'hale le thepa ea mochini e lokela ho etsoa ho netefatsa hore thepa e khethiloeng e fihlela litlhoko tse ikhethang tsa projeke.

Ho tloha ha e thehoa ka 2014,Botop Steele fetohile morekisi ea ka sehloohong oa pipe ea tšepe ea carbon e ka Leboea ea Chaena, e tsejoang ka tšebeletso e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse pharaletseng.

Khampani e fana ka mefuta e sa tšoaneng ea liphaephe tsa tšepe ea carbon le lihlahisoa tse amanang le tsona, tse kenyelletsang seamless, ERW, LSAW, le phala ea tšepe ea SSAW, hammoho le lethathamo le feletseng la liphaephe le li-flanges. Lihlahisoa tsa eona tse khethehileng li boetse li kenyelletsa li-alloys tsa boemo bo phahameng le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho finyella litlhoko tsa merero e fapaneng ea liphaephe.