Sebopeho sa K'hemik'hale le sa Sehlopha (%)

| Sehlopha | C≤ | Mn | P≤ | S≤ | Si≥ | Cr≤ | Cu≤ | Mo≤ | Ni≤ | V≤ |

| A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15

| 0.40 | 0.08 |

| C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Thepa ea Mechanical:

|

|

|

| A% |

|

| A | ≥330 | ≥205 | 20 | Annealed |

| B | ≥415 | ≥240 | 20 | Annealed |

| C | ≥485 | ≥275 | 20 | Annealed |

| Lebitso la Sehlahisoa | Phaephe ea tšepe e se nang seamless |

| Thepa | Tšepe ea carbon le tšepe ea alloy |

| E tloaelehileng | ASTMA53,ASTMA106,ASTMA179,ASTMA192,ASTMA210,ASTM A213,ASTM A335,DIN2391-2,DIN1629.DIN2448, DIN17175.DIN17176,EN10219,EN10210 |

| Sehlopha | Likereiti tsa tšepe ea k'habone tse kang A53 Gr.B, A106 GrA, B, C, A210 GrA1.Gr.C. API 5L Gr.B.X42,X52.X56, jj. limaraka tsa tšepe tse kopantsoeng tse kang T5, T9, T11, T12, T22, T23, T91, P1, P2, P5, P9.P11, P12 P22.P91,P92,25CrMo4.34CrMo4,42CrMo4SAE4130,SAE4140,SAE4145,SAE4340,jj. |

| Mefuta ea boholo | 10*1-810*25, Boima ba 'mele ho fihlela ho 120mm max |

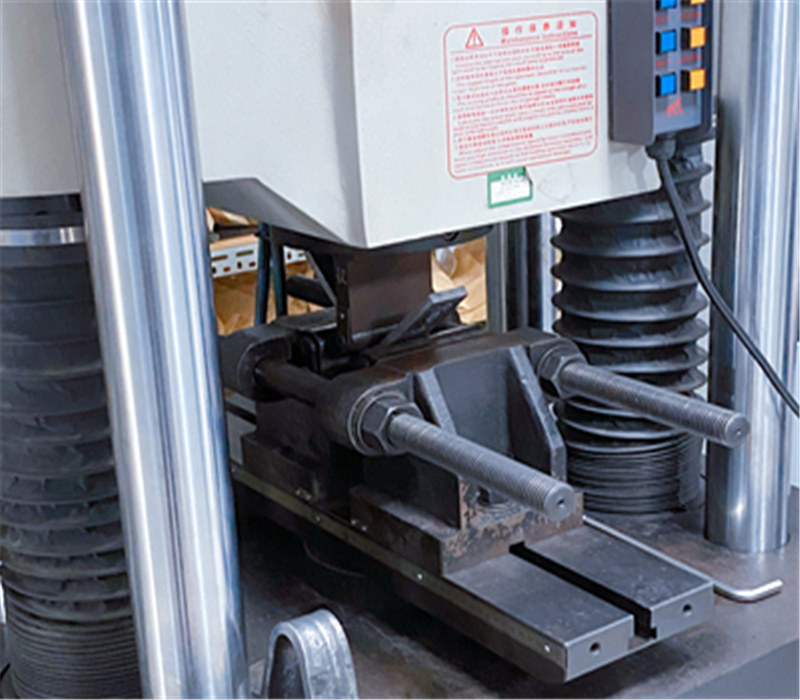

| Mokhoa oa tlhahiso | Ho huloa ka serame, ho phuthoa ka serame, ho huloa ka serame sa haeteroliki, Ho phuthoa ka mocheso, ho atolosoa ka mocheso |

| Boemo ba ho tlisa | Ha e ntse e phutholohile, e imolloa khatellong ea maikutlo, e atolositsoe, e tloaelehile, e timisitsoe + e halefile |

| Qetella qetellong | Lipheletso tse se nang letho tse nang le maqeba a suqare, lipheletso tse bentsoeng, lipheletso tse nang le khoele |

| Tšebeliso/Ts'ebeliso | Methapo ea khatello, Tsamaiso ea mokelikeli, Tšebeliso ea sebopeho. Mechini. Oli le khase lipalangoang, Ho hlahloba le ho cheka, jj. |

| Mefuta ea tube | Phaephe ea boilertube e nepahetseng, tube ea mechine. tube ea silindara.liphaephe tsa mohala.jj. |

-

-

Tekanyo ea mamello:

Mofuta oa Phaephe

Boholo ba Liphaephe Mamello Ho Huloa ka Batang

OD ≤48.3mm ± 0.40mm ≥60.3mm ± 1% mm WT ±12.5%

-