EN 10219 S275J0H le S275J2Hke likarolo tse se nang letho tsa sebopeho tse entsoeng ka thapo tse batang tse entsoeng ka tšepe e sa tsoakoang ho latela EN 10219.

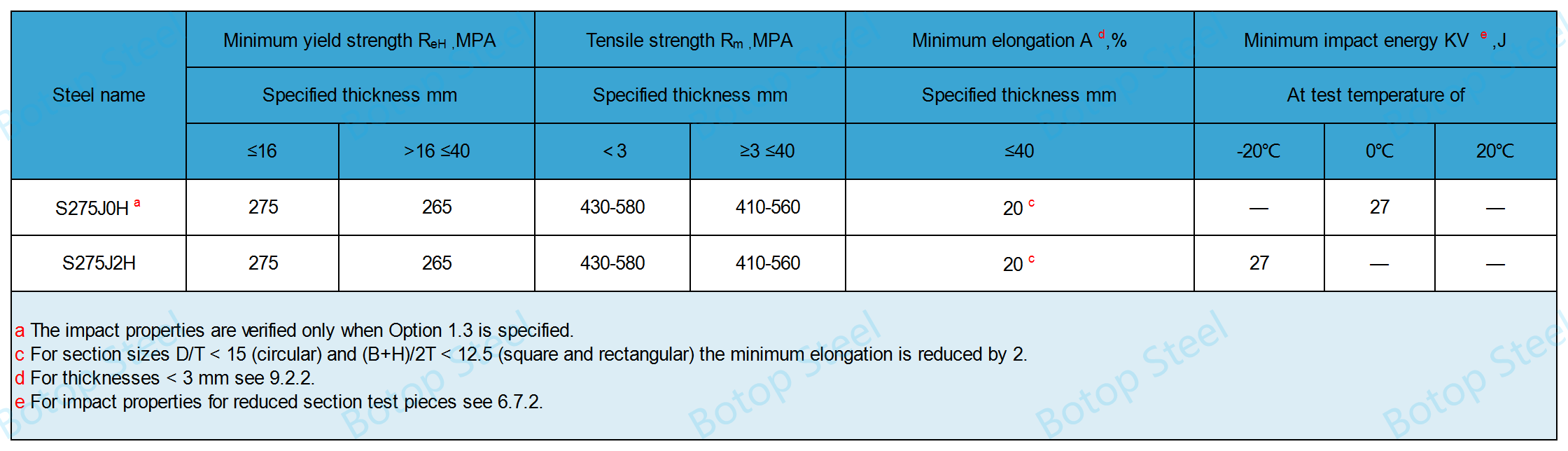

Ka bobeli li na le matla a bonyane a tlhahiso ea 275MPa (botenya ba lebota ≤16mm). Phapang e kholo e litšobotsing tsa tšusumetso: S275J0H e na le matla a bonyane a tšusumetso ea 27 J ho 0°C, ha S275J2H e na le matla a bonyane a tšusumetso ea 27 J ho -20°C.

E loketse lits'ebetso mehahong le meahong ea boenjiniere e nang le meroalo e bobebe.

BS EN 10219 ke Tekanyetso ea Europe EN 10219 e amohetsoeng ke UK.

Botenya ba lebota ≤40mm, Bophara ba kantle ≤2500mm.

CFCHS ke khutsufatso ea Karolo e Selikalikoe e Entsoeng ka Moqomo e Batang.

Tekanyetso ea EN 10219 e akaretsa mefuta e mengata ea libopeho tsa tšepe tse nang le sekoti, ho kenyeletsoa chitja, sekwere, khutlonnetsepa le oval, ho latela litlhoko tse fapaneng tsa ts'ebeliso.

Tšepe ea Botope ikgethile ka ho fana ka diphaephe tsa tshepe tse chitja tse nang le sekoti ka boholo le ditshebetso tse fapaneng ho lekana mefuta e mengata ya ditshebediso tsa indasteri, ho netefatsa hore ditlhoko tse ikgethang tsa bareki ba rona di ka fihlellwa.

Ho tloha ha e theoa ka 2014,Tšepe ea Botope se e le mofani ea ka sehloohong oa liphaephe tsa tšepe ea khabone Leboea la Chaena, ea tsebahalang ka tšebeletso e ntle haholo, lihlahisoa tsa boleng bo holimo le litharollo tse felletseng.

Khamphani e fana ka mefuta e fapaneng ea liphaephe tsa tšepe ea khabone le lihlahisoa tse amanang le tsona, ho kenyeletsoaSMLS, ERW, LSAWleSSAWphaephe ea tšepe, hammoho le lethathamo le felletseng la lisebelisoa tsa liphaephe le li-flange. Lihlahisoa tsa eona tse ikhethang li boetse li kenyelletsa li-alloy tsa boleng bo holimo le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho fihlela litlhoko tsa merero e fapaneng ea liphaephe.

Re labalabela ho theha kamano ea tšebelisano-'moho le uena le ho theha bokamoso bo tla ba le katleho ho bohle hammoho.

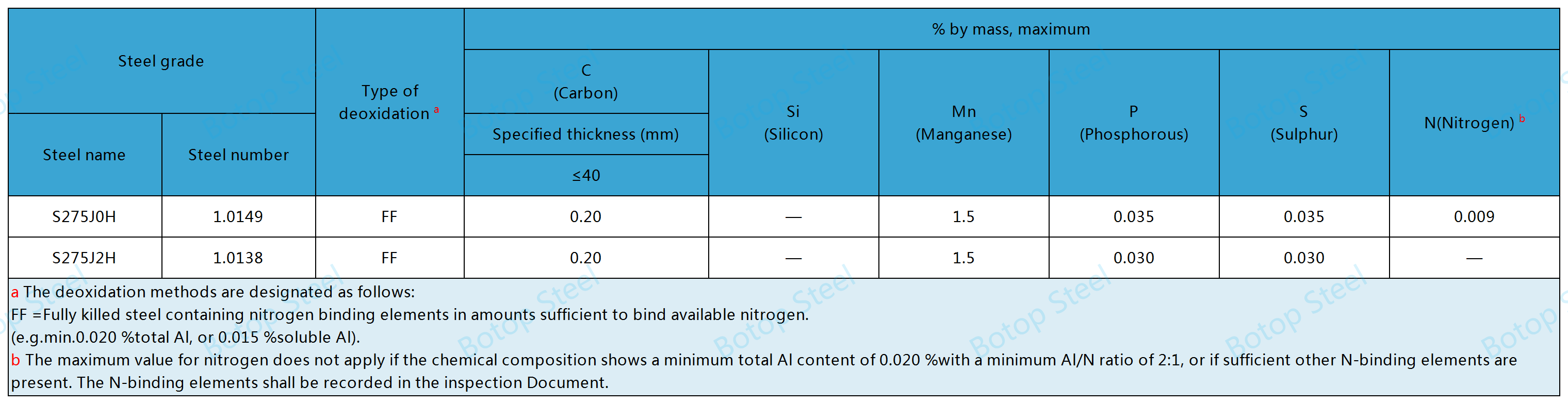

Tšepe e tala bakeng sa ho etsa likarolo tse se nang letho tse batang e tlosoa oksijene 'me e tlameha ho fihlela maemo a itseng a ho tlisoa.

Litlhoko tse amehang bakeng sa S275J0H le S275J2H ke tsenaFF(Tšepe e bolailoeng ka botlalo e nang le likarolo tse tlamang naetrojene ka bongata bo lekaneng ho tlama naetrojene e fumanehang (mohlala, bonyane 0,020 % kakaretso ea Al kapa 0,015 % Al e qhibilihang)).

Boemo ba ho tlisa: E phutholohile kapa e ntlafalitsoe/e phutholohile (N) bakeng sa litšepe tsa JR, J0, J2, le K2.

Liphaephe tsa tšepe ho ea ho EN 10219 li ka hlahisoa ke bobeliERW(ho tjheseletsa ka ho hanyetsa motlakase) leSAWMekhoa ea tlhahiso (ho tjheseletsa arc e ka tlas'a metsi).

Tlhahiso eaLiphaephe tsa ERWe na le molemo oa ho ba kapele le ho theko e tlase haholo 'me hangata e khethoa bakeng sa merero e hlokang tlhahiso e kholo le katleho e phahameng ea litšenyehelo.

ERWHangata lipeipi li sebelisoa ho hlahisa bophara bo bonyenyane le botenya bo bonyenyane ba lebota, haSAWLipeipi li loketse haholoanyane bakeng sa bophara bo boholo le mabota a teteaneng. Ka kopo khetha mofuta o loketseng oa phala ea tšepe bakeng sa projeke ea hau.

Liphaephe tsa ERW tse entsoeng ho latela EN 10219 hangata ha li hloke ho kuta ka hare ho weld.

Lebaka ke hobane lipeipi tsa EN 10219 li sebelisoa haholo-holo lits'ebetsong tsa meaho, joalo ka kaho le boenjiniere ba mechini, moo litlhoko tsa ponahalo ea weld hangata li sa thatafallang ho feta tsa likepe tsa khatello kapa liphaephe tse nang le khatello e phahameng. Ka hona, ha feela matla le botšepehi ba weld li fihlela litlhoko tsa maemo a tloaelehileng, weld tsa kahare li ka sebelisoa ntle le ho kuta ho eketsehileng.

Ha ho phekolo ea mocheso e latelang e etsoang, ntle le hore weld e ka ba boemong ba welded kapa ba phekoloa ka mocheso.

Tlhahlobo ea Cast (Tlhahiso ea Lik'hemik'hale tsa Lisebelisoa tse Tala)

Ka bobeli S275J0H le S275J2H li na le boleng bo phahameng ba khabone bo lekanang (CEV) ba 0.40%.

S725J0H le S275J2H tse nang le CEV e phahameng ka ho fetisisa ea 0.4% li bontša ho tjheseletsa ho betere ka kotsi e nyane ea ho thatafala le ho petsoha nakong ea ho tjheseletsa.

E ka boela ea baloa ho sebelisoa foromo e latelang:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

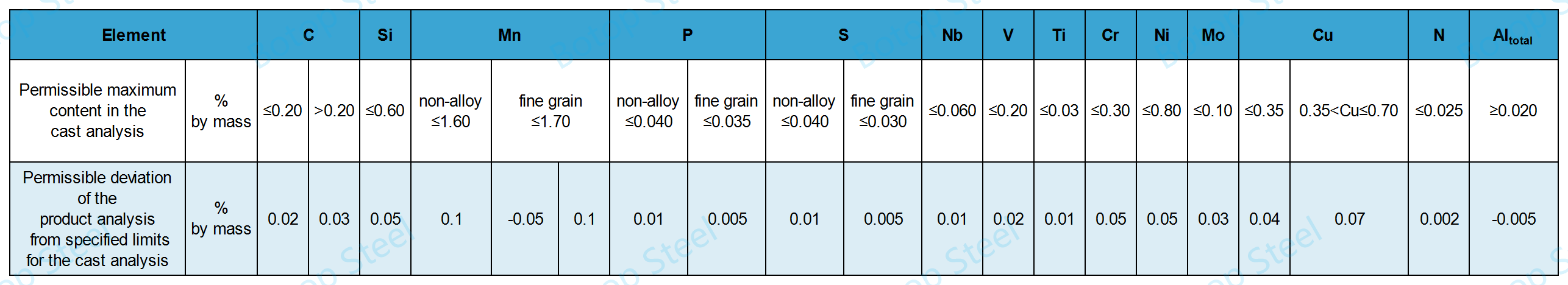

Tlhahlobo ea Sehlahisoa (Tlhahiso ea Lik'hemik'hale ea Lihlahisoa tse Feliloeng)

Nakong ea tlhahiso ea tšepe, metsoako ea lik'hemik'hale e ka fetoha ka mabaka a 'maloa,' me liphetoho tsena li ka ama litšobotsi le boleng ba tšepe.

Sebopeho sa lik'hemik'hale sa phala ea tšepe se felileng se tlameha ho latela sebopeho sa lik'hemik'hale sa ho betla le ho kheloha ha sona ho lumelletsoeng.

Dipharamithara tsa thepa ya mechini di kenyeletsa matla a tlhahiso, matla a ho thapolla, ho lelefala, le matla a tshusumetso.

Ho fokotsa khatello ea maikutlo mochesong o fetang 580 ℃ kapa ho feta hora e le 'ngoe ho ka lebisa ho senyeha ha thepa ea mechini.

Lintlha:

Teko ea tšusumetso ha e hlokehe ha botenya bo boletsoeng bo le <6mm.

Litšobotsi tsa tšusumetso ea lipeipi tsa boleng ba JR le J0 ha li netefatsoe ntle le haeba ho boletsoe.

EN 10219 Li-weld tse liphaepheng tsa tšepe tsa ERW li ka lekoa ka ho khetha e 'ngoe ea tse latelang.

EN 10246-3 ho fihlela boemong ba kamohelo E4, ntle le hore mokhoa oa ho potoloha tube/pancake coil o ke ke oa lumelloa;

EN 10246-5 ho fihlela boemong ba kamohelo F5;

EN 10246-8 ho fihlela boemong ba kamohelo U5.

Ho baloa ha boima ba khopolo-taba ba lipeipi tsa EN 10219 ho ka ipapisa le boima ba lipeipi tsa 7.85 kg/dm³.

M=(DT)×T×0.02466

M ke boima ka bolelele ba yuniti;

D ke bophara bo boletsoeng ka ntle, diyuniti ka mm;

T ke botenya ba lebota bo boletsoeng, diyuniti ka mm.

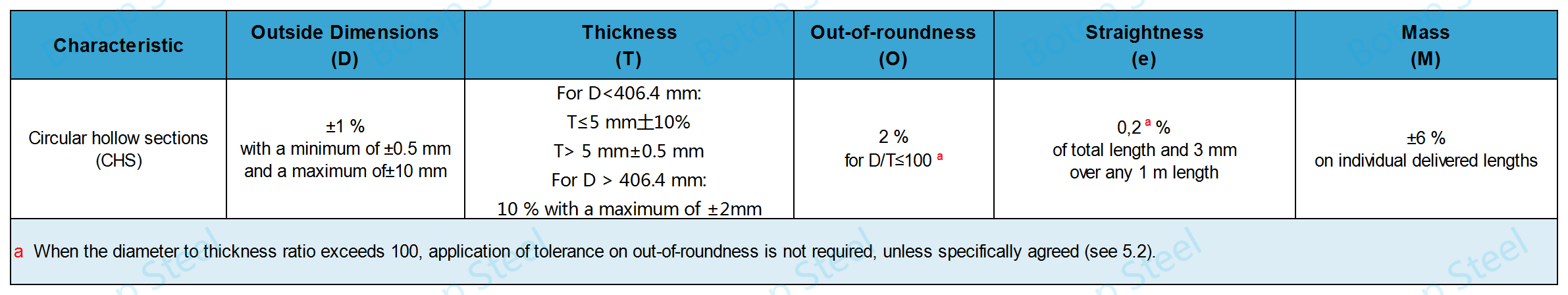

Mamello mabapi le Sebopeho, Ho Otloloha le Boima

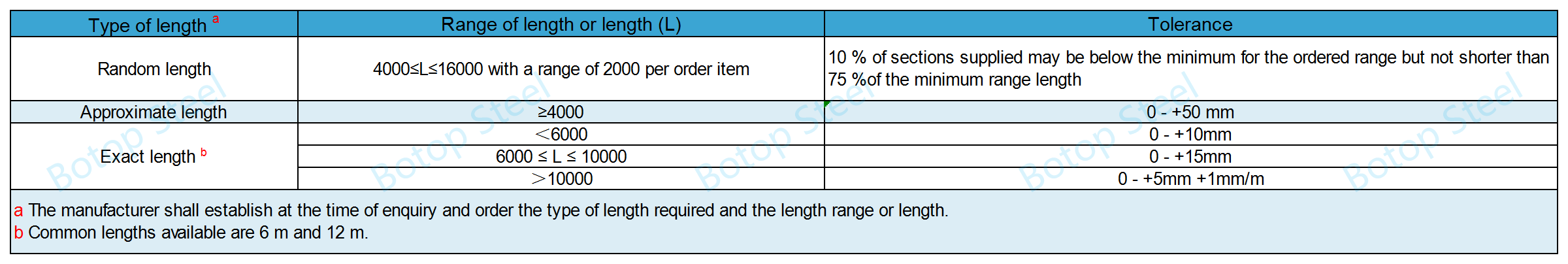

Bolelele ba Mamello

Liphaephe tsa karolo e se nang letho tse entsoeng ho latela EN 10219 lia tjheseletsa.

Ha ho tjhesetswa, ho petsoha ha serame sebakeng sa ho tjheseletsa ke kotsi e kgolo ha botenya, boemo ba matla le CEV ya sehlahiswa di ntse di eketseha. Ho petsoha ha serame ho bakwa ke motswako wa mabaka a mmalwa:

maemo a phahameng a haedrojene e hasanang ka hara tshepe e weld;

sebopeho se robehang habonolo sebakeng se amehileng ke mocheso;

khatello e matla ea ho hatelloa lenonyellong le welletsoeng.

Bokaholimo ba phaephe ea tšepe bo lokela ho ba boreledi 'me bo se na liphoso tse ka amang ts'ebetso ea sehlahisoa, joalo ka mapetso, masoba, mengoapo kapa mafome.

Maqhubu, li-groove, kapa li-groove tse sa tebang tse entsoeng ke ts'ebetso ea tlhahiso lia amoheleha ha feela botenya ba lebota bo setseng bo le ka har'a mamello, sekoli se ka tlosoa ka ho sila, 'me botenya ba lebota bo lokisitsoeng bo fihlela litlhoko tse tlase tsa botenya.

Tšepe ea BotopHa e fane feela ka lipeipi tsa tšepe tsa boleng bo holimo ho latela EN 10219, empa e boetse e fana ka mefuta e mengata ea likhetho bakeng sa ho koahela holim'a lipeipi tsa tšepe ho latela litlhoko tse ikhethileng tsa bareki ba eona mererong e fapaneng ea boenjiniere. Lipeipi tsena li etselitsoe ho ntlafatsa ho hanyetsa ho bola ha lipeipi le ho eketsa tšireletso e eketsehileng, ka hona ho atolosa bophelo ba tsona ba ts'ebeletso.

Ho kenya Galvanizing ka ho Chesa

Sekoahelo sa 3LPE (HDPE)

Sekoahelo sa FBE

Seaparo sa Varnish

Ho penta

Sekoahelo sa Boima ba Samente

Likarolo tsa borokho: meaho e seng ya mantlha e jarang mojaro e sebediswang marokhong, jwalo ka diterei le diparapet.

Litšiea tsa meralo: litšiea tsa tšehetso le libalaka tse sebelisoang mehahong le boenjiniere ba sechaba.

Mekhoa ea liphaephe: liphaephe bakeng sa ho tsamaisa metsi le likhase, haholo-holo lits'ebetsong tse hlokang tekanyo e itseng ea ho tenyetseha le ho hanyetsa mafome.

Meaho ea nakoana: litšehetso tsa nakoana le liforeimi tse loketseng libaka tsa kaho le tsa boenjiniere.

Lisebelisoa tsena li sebelisa monyetla oa thepa e ntle ea mechini le bokhoni ba ho kopanya ba S275J0H le S275J2H ho fihlela litlhoko tsa meaho e bobebe empa e tsitsitse.

ASTM A500:Tlhaloso e Tloaelehileng bakeng sa Liphaephe tsa Sebopeho sa Tšepe ea Khabone e Entsoeng ka Moqomo le e se Nang Seamless ka Li-Curling le Libopeho.

ASTM A501: Tlhaloso e Tloaelehileng bakeng sa Tubing ea Sebopeho sa Tšepe ea Khabone e Entsoeng ka Mocheso le e se Nang Seamless.

EN 10210: Likarolo tse nang le masoba tse qetiloeng ka mokhoa o chesang tsa litšepe tse se nang motsoako le tsa lijo-thollo tse ntle.

EN 10219: Likarolo tse se nang letho tse entsoeng ka sebopeho se batang tsa litšepe tse se nang motsoako le tsa lijo-thollo tse ntle.

JIS G 3466: Liphaephe tsa tšepe ea khabone tse sekwere le tse khutlonnetsepa bakeng sa sebopeho se akaretsang.

AS/NZS 1163: Likarolo tse se nang letho tsa tšepe tse entsoeng ka sebopeho se batang.

Litekanyetso tsena li sebelisoa haholo lefatšeng ka bophara, 'me li thusa ho netefatsa hore lipeipi tsa tšepe tsa sebopeho li fihlela litekanyetso tse lebelletsoeng tsa ts'ebetso lits'ebetsong tse fapaneng tsa boenjiniere. Ha u khetha tekanyetso ea phala ea tšepe, ho bohlokoa ho nahana ka litlhoko tsa eona tse ikhethileng tsa ts'ebeliso, melaoana ea libaka le litlhoko tsa ts'ebetso.

ASTM A252 GR.3 Sebopeho sa LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) Pipe ea Tšepe

Pipe ea Tšepe ea ASTM A671/A671M LSAW

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe

Pipe ea Tšepe ea Khabone ea API 5L X65 PSL1/PSL 2 LSAW / Pipe ea Tšepe ea API 5L ea Sehlopha sa X70 LSAW

EN10219 S355J0H Sebopeho sa LSAW (JCOE) Steel Pipe