EN 10210 S355J2Hke hot-qetellong tlhophiso sekoti karolo tšepe ho ea kaEN 10210e nang le matla a fokolang a tlhahiso ea 355 MPa (bakeng sa marako a marako ≤ 16 mm) le thepa e ntle ea tšusumetso mocheso o tlaase ho fihlela ho -20 ° C, e leng se etsang hore e be se loketseng bakeng sa ho sebelisoa meahong e mengata ea mohaho le ea boenjiniere.

E, EN 10210 =BS EN 10210.

BS EN 10210 le EN 10210 li ts'oana litabeng tsa tekheniki 'me ka bobeli li emela litekanyetso tsa Europe bakeng sa moralo, tlhahiso le litlhoko tsa likarolo tsa sekoti sa thermoformed.

BS EN 10210 ke mofuta o amohetsoeng UK, athe EN 10210 ke maemo a Europe ka bophara. Mekhatlo e fapaneng ea maemo a naha e ka theha maemo ka likhutsufatso tse khethehileng tsa naha, empa litaba tsa mantlha tsa maemo li lula li tsitsitse.

Likarolo tse se nang letho li ka aroloa e le selikalikoe, lisekoere kapa khutlonnetsepa, kapa elliptical.

Hape hobane ke ts'ebetso e felileng e chesang ho latela EN 10210, ho ka sebelisoa khutsufatso e latelang.

HFCHS= likarolo tse se nang letho tse chitja;

HFRHS= lisekoere tse chesang tse felileng kapa likarolo tse sekoti tse khutlonnetsepa;

HFEHS= likarolo tse se nang letho tsa elliptical.

Potoloho: Bophara ba ka ntle ho fihlela ho 2500 mm;

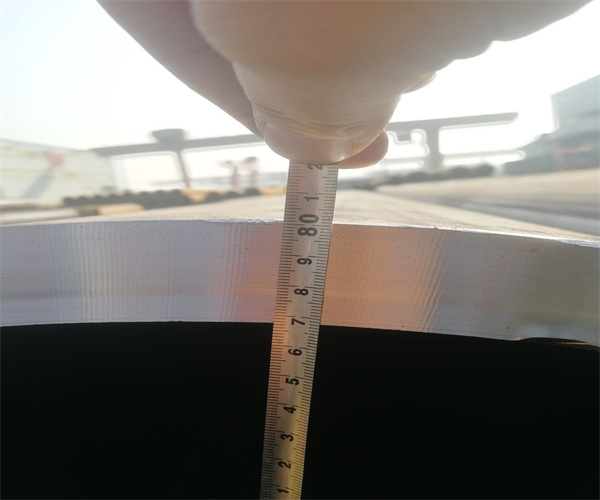

Botenya ba marako bo fihla ho 120 mm.

Ha e le hantle, ha ho na mokhoa oa ho hlahisa li-tubes tsa boholo bona le botenya ba lebota haeba ho sebelisoa mokhoa oa ERW.

ERW e ka hlahisa li-tubes tse fihlang ho 660mm ka botenya ba lebota ba 20mm.

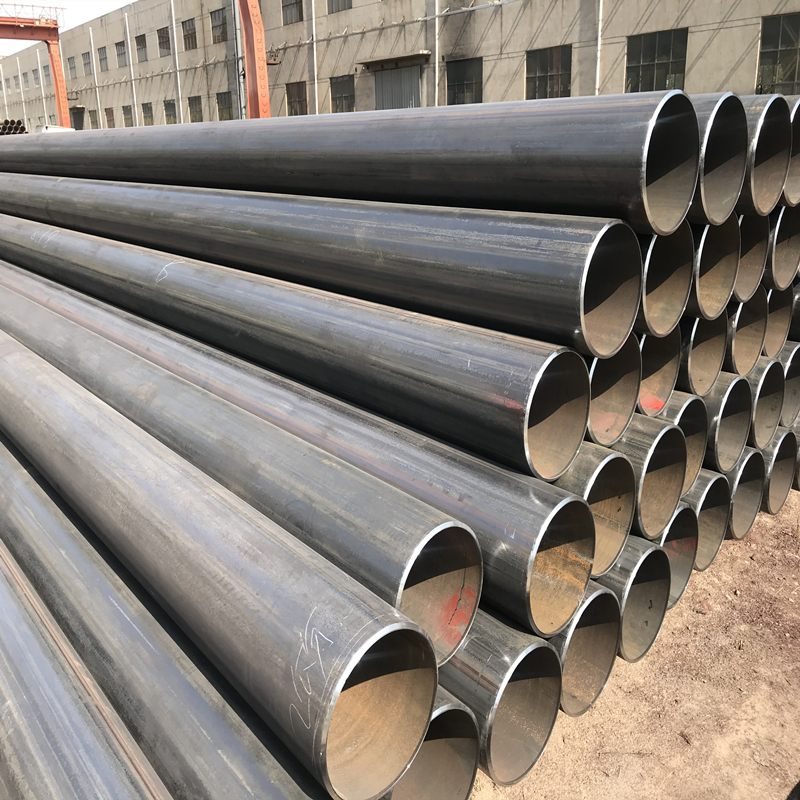

Tšepe e ka etsoa ebang ke ka ae se nang moroko kapa weldingtshebetso.

Har'a tsemekhoa ea ho cheselletsa, mekhoa e tloaelehileng ea tjheseletsa e kenyelletsaERW(motlakase resistance welding) leBONA(ho tjheseletsa arc ka metsing).

Har'a tse ling,ERWke mokhoa oa ho cheselletsa o kopanyang likarolo tsa tšepe hammoho ka mocheso o thibelang le khatello. Mokhoa ona o sebetsa mefuteng e mengata ea lisebelisoa le botenya mme o nolofalletsa ts'ebetso e sebetsang ea welding.

BONA, ka lehlakoreng le leng, ke mokhoa oa ho cheselletsa o sebelisang phallo ea granular ho koahela arc, e fanang ka ho kenella ho tebileng le boleng bo botle ba weld mme e loketse ka ho khetheha bakeng sa ho cheselletsa lipoleiti tse teteaneng.

Ka mor'a moo, ke ts'ebetso ea ERW, e leng mokhoa o sebetsang hantle haholo oa tlhahiso o sebelisoang haholo ho hlahisa mefuta e mengata ea li-tubes tsa tšepe le litlaleho.

Hoa lokela ho hlokomeloa hore bakeng sa likarolo tse se nang letho le tse ntle tsa lijo-thollo tse entsoeng ka mokhoa oa ho tjheseletsa, li-welds tsa ho lokisa ha lia lumelloe ntle le ho kenngoa ka tlas'a metsi arc welding.

Qualities JR, JO, J2 le K2 - ho chesa ho felile,

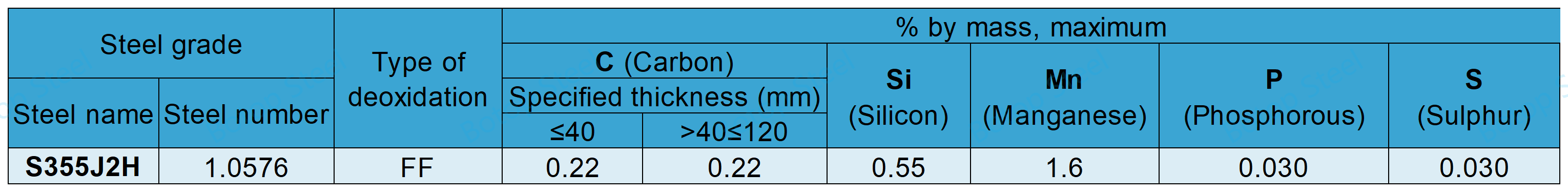

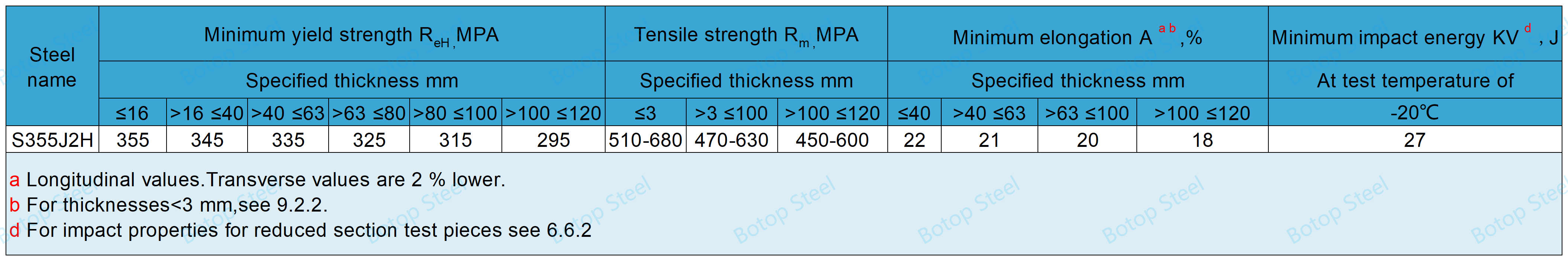

Matla a fokolang a tlhahiso ea phala ea tšepe ea S355J2H ha e tsitsitsoe, e tla fetoha ka botenya bo fapaneng ba lerako.

Ka ho khetheha, matla a tlhahiso ea S355J2H a behiloe ho ea ka mokhoa o tloaelehileng ha lerako la lerako le le tlase kapa le lekana le 16mm, empa ha lerako le ntse le eketseha, matla a lihlahisoa a tla fokotseha, kahoo hase pipe eohle ea tšepe ea S355J2H e ka finyellang matla a fokolang a 355MPa.

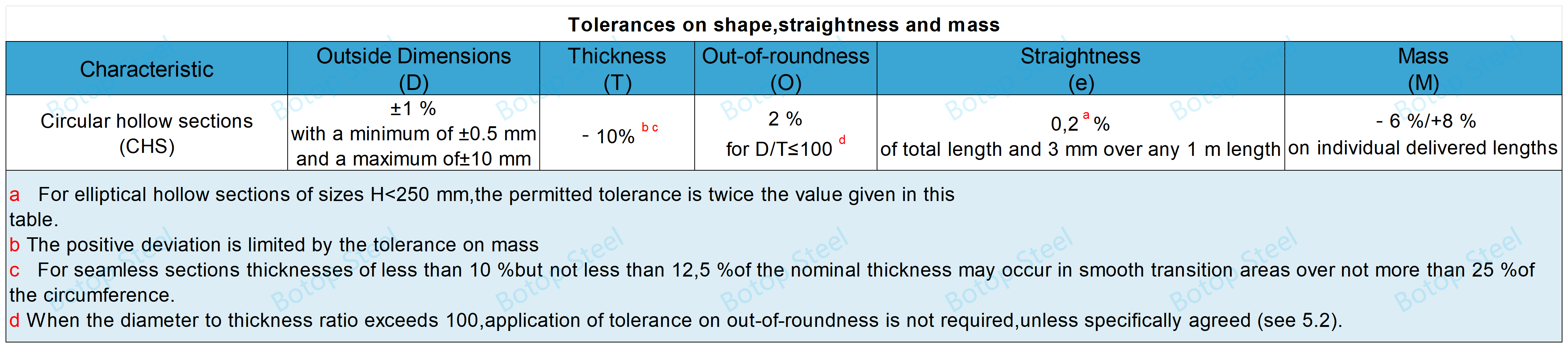

Ho mamella sebopeho, ho otloloha le boima

Bolelele ba mamello

| Mofuta oa bolelelea | Lethathamo la bolelele kapa bolelele L | Mamello |

| Bolelele bo sa reroang | 4000≤L≤16000 e nang le mefuta e mengata ea 2000 ka ntho e le 'ngoe ea odara | 10 % ea likarolo tse fanoeng e ka ba ka tlase ho palo e fokolang bakeng sa mofuta o laetsoeng empa e se khutsoanyane ho feta 75 % ea bolelele bo fokolang |

| Bolelele bo lekantsoeng | 4000≤L≤16000 | ± 500 limilimitharab |

| Bolelele bo nepahetseng | 2000≤L≤6000 | 0 - + 10mm |

| 6000c | 0 - + 15 limilimithara | |

| aMoetsi o tla theha ka nako ea lipatlisiso le ho hlophisa mofuta oa bolelele bo hlokahalang le bolelele ba bolelele kapa bolelele. bOntion 21 mamello ka annrevimata bolelele ke 0 - +150mm cBolelele bo tloaelehileng bo fumanehang ke 6 m le 12 m. | ||

Pipe ea tšepe ea S355J2H ke phala ea tšepe e nang le matla a phahameng e nang le ts'ebetso e ntle ea ho tjheseletsa le ho ba le tšusumetso e matla ea mocheso o tlase, kahoo e na le mefuta e mengata ea tšebeliso masimong a 'maloa a indasteri.

1. Kaho: e sebelisoa ka marokho, litora, mehaho ea liforeimi, lipalangoang tsa terene, litsela tse tsamaeang ka tlas'a lefatše, liforeimi tse marulelong, liphanele tsa mabota, le meaho e meng ea meaho.

2. Sistimi ea liphaephe: E sebelisoa e le liphaephe bakeng sa ho tsamaisa maro, haholo-holo maemong ao ho hlokahalang matla a phahameng le khatello ea khatello.

3. Boenjiniere ba metsing le lebōpong la leoatle: e sebelisoa meahong ea likepe, lipolaneteng tsa kantle ho naha, le meahong e meng ea boenjiniere ba metsing.

4. Indasteri ea matla: e sebelisoang litsing tsa matla a motlakase joalo ka litora tsa matla a moea, sethala sa ho cheka oli, le liphaephe.

5. Lijana tsa khatello: e sebelisoang ha ho etsoa lijana tsa khatello ho latela litlhoko tse khethehileng tsa ho cheselletsa le mocheso.

6. Indasteri ea merafo: e sebelisoa bakeng sa likarolo tsa sebopeho sa meaho ea ts'ehetso ea morafo, lits'ebetso tsa conveyor, le lisebelisoa tsa ho lokisa ore.

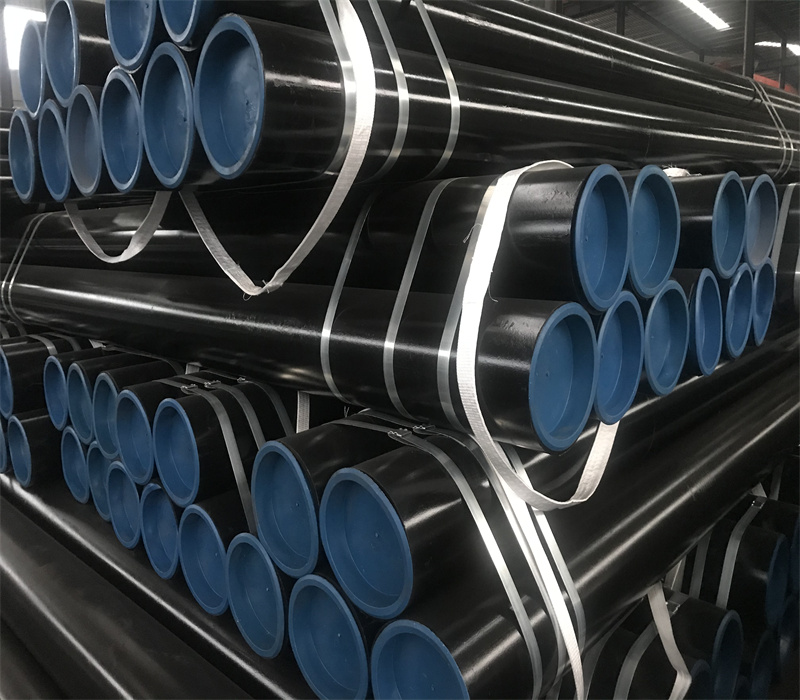

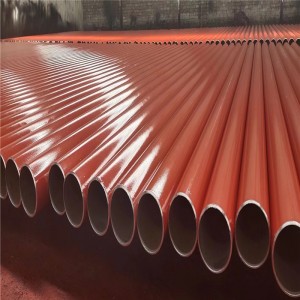

Pipe e se nang letho kapa seaparo se setšo / varnish (e hlophisitsoeng);

ka dingata kapa e hlephile;

Ka bobeli li qetella ka basireletsi ba ho qetela;

Qetello e hlakileng, pheletso ea bevel(2"le ka holimo e nang le lipheletso tsa bevel, degree: 30 ~ 35°), e khoele le ho kopanya;

Ho tshwaya.