EN 10219 S355J0Hkee entsoeng ka mokhoa o batangphaephe ea tšepe e se nang letho e hahiloeng ho eaEN 10219, ka matla a fokolang a tlhahiso ea355 MPa(botenya ba lebota la phaephe ≤ 16 mm) le matla a tshusumetso a bonyane27 J ho 0°C.

Li entsoe ka ho sebelisa mekhoa ea ho tjheseletsa ka motlakase kapa ea ho tjheseletsa ka har'a arc e ka tlas'a metsi ntle le tlhoko ea kalafo e latelang ea mocheso, li loketse mefuta e mengata ea lits'ebetso tsa meaho le tsa boenjiniere, ho kenyeletsoa likarolo tsa bohlokoa tsa meaho tse kang liqubu tsa tšehetso ea motheo.

BS EN 10219 ke Tekanyetso ea Europe EN 10219 e amohetsoeng ke UK.

E kenyelletsa ho tjheseletsa ho batangchitja, sekwere, khutlonnetsepa, le ellipticallikarolo tse se nang letho tse nang le sebopeho.

CFCHS = karolo e chitja e bōpehileng joaloka serame;

CFRHS = karolo e batang e nang le sekwere kapa e nang le sekoti se khutlonnetsepa;

Re ikhethile ka ho fana ka karolo e chitja e nang le sekoti sa boleng bo holimo (CHS) phaephe ea tšepe ho fihlela litlhoko tsa hau tse fapaneng tsa boenjiniere.

Botenya ba lebota ≤40mm;

Selikalikoe: Bophara ba kantle ho fihlela ho 2500 mm;

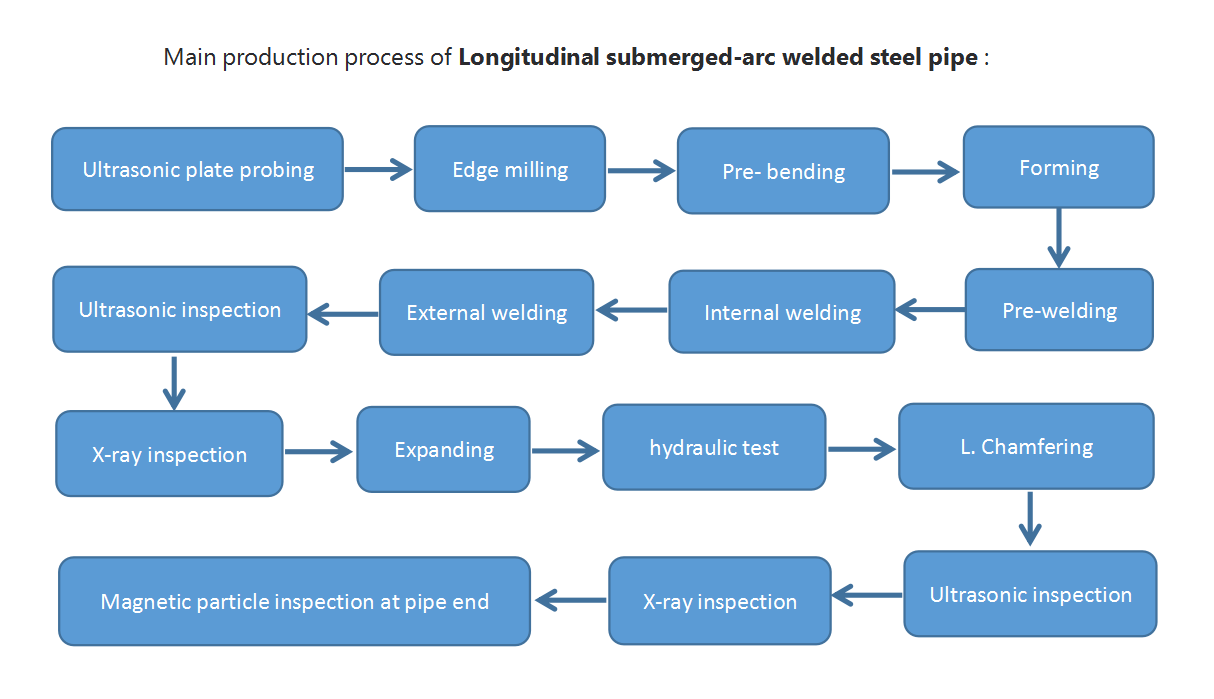

Likarolo tse se nang letho tsa sebopeho li lokela ho etsoa keho tjheseletsa ka motlakase kapa ho tjheseletsa ka arc e ka tlasa metsi (SAW).

Likarolo tse se nang letho tsa EN 10219 li tla tlisoa li bōpehile joaloka serame ntle le kalafo e latelang ea mocheso, empa li-weld li ka ba boemong ba ho tjheseletsa kapa ba phekoloa ka mocheso.

Haeba ho sebelisoa theknoloji ea ho tjheseletsa arc e qoelitsoeng ka metsing, e ka aroloa ka lihlopha tse peli.LSAW(SAWL) (Ho Welding Arc e Keneng ka Morao e Telele) leSSAW(HSAW(Ho Welding ka Arc e Keneng ka Spiral) ho itshetlehile ka tataiso ya seam ya weld.

LSAWe na le melemo e meholo tlhahisong eabophara bo bohololeliphaephe tsa tšepe tse nang le mabota a teteaneng'me e loketse haholo bakeng sa maemo a ts'ebeliso moo matla a phahameng, boleng le litekanyo tse nepahetseng li hlokahalang ka tieo.

JCOEke ts'ebetso ea bohlokoa haholo le e emelang tlhahiso ea phaephe ea tšepe ea LSAW. Lebitso la ts'ebetso le tsoa mehatong e mene e meholo ts'ebetsong ea ho etsa phaephe: ho etsa J, ho etsa C, ho etsa O, le ho Atolosa.

Re moetsi le mofani oa liphaephe tsa tšepe ea carbon tse lahletsoeng ka welded tsa boleng bo holimo ho tsoa Chaena, hape re morekisi oa liphaephe tsa tšepe tse se nang sekoli, re u fa mefuta e mengata ea litharollo tsa liphaephe tsa tšepe!

Tlhahlobo ea Sehlopha

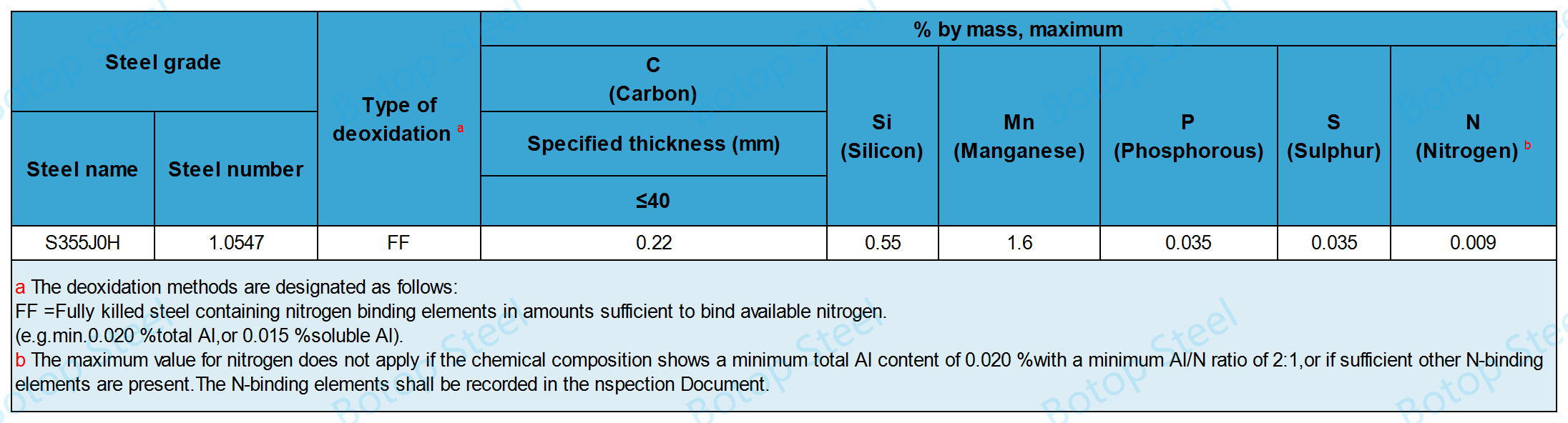

Tlhahlobo ea lik'hemik'hale ea lisebelisoa tse tala tsa phala ea tšepe

S355J0H Boleng bo phahameng ba khabone bo lekanang (CEV): 0.45%.

CEV = C + Mn/6 +(Cr + Mo + V)/5 + (Ni + Cu)/15.

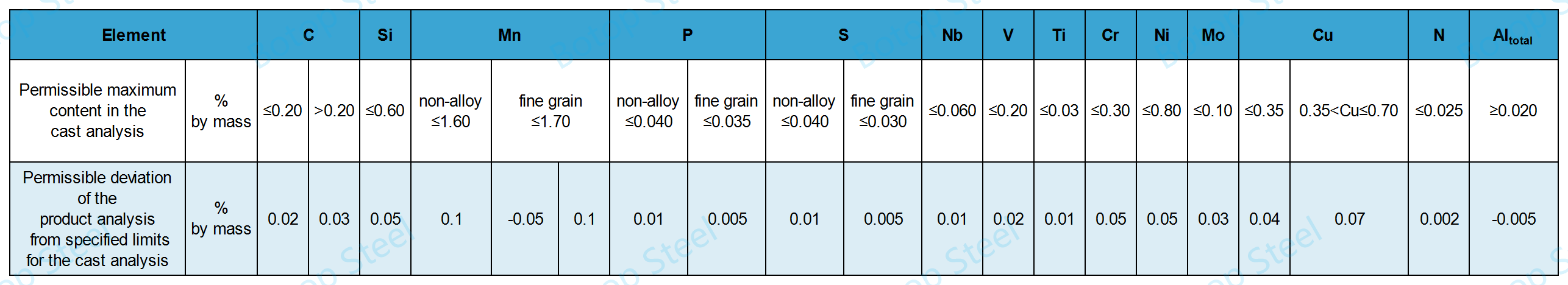

Tlhahlobo ea Sehlahisoa

Tlhahlobo ea lik'hemik'hale tsa likarolo tse se nang letho tse felileng

Ho kheloha ha tlhahlobo ea sehlahisoa ho tloha meeling e boletsoeng bakeng sa tlhahlobo ea ho lahla ho tla latela litlhoko tse ka tlase.

Ho fokotsa khatello ea maikutlo mochesong o fetang 580 °C kapa ho feta hora e le 'ngoe ho ka lebisa ho senyeha ha thepa ea mechini.

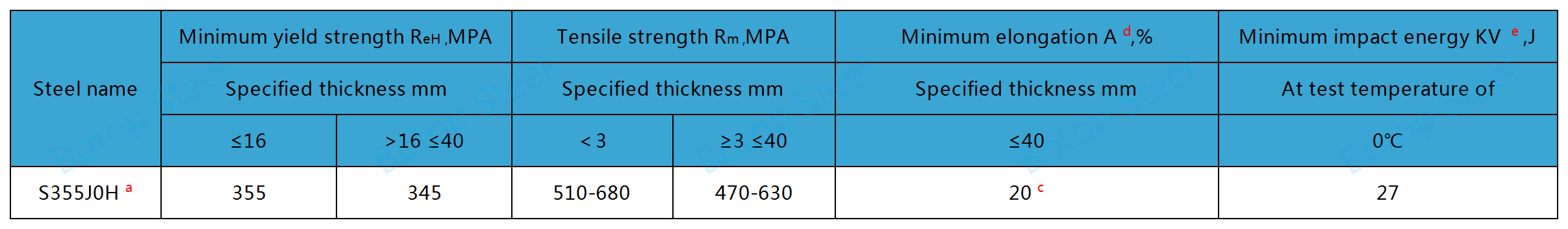

Teko ea ho tsitlella e lokela ho etsoa ho latela EN 10002-1.

Teko ea tšusumetso e lokela ho etsoa ho latela EN 10045-1.

a Thepa ea tšusumetso e netefatsoa feela ha Khetho ea 1.3 e hlalositsoe.

c Bakeng sa boholo ba likarolo D/T < 15 (e chitja) le (B+H)/2T < 12,5 (e sekwere le e khutlonnetsepa) bolelele bo bonyane bo fokotsoa ka 2.

d Bakeng sa botenya < 3 mm sheba 9.2.2.

e Bakeng sa thepa ea ho thula likarolo tsa teko tse fokolitsoeng sheba 6.7.2.

Lintlha: Teko ea tšusumetso ha e hlokehe ha botenya bo boletsoeng bo le <6mm.

Li-weld tse ka har'a likarolo tse se nang letho tse koahetsoeng ka arc tse koahetsoeng ka tlas'a metsi li tla lekoa ho latela EN 10246-9 bakeng sa sehlopha sa kamohelo sa U4 kapa ka radiographic ho latela EN 10246-10 bakeng sa sehlopha sa boleng ba setšoantšo sa R2.

Teko ea NDT(RT)

Teko ea NDT(UT)

Teko ea Hydrostatic

Re sebelisa mekhoa e fapaneng ea liteko tse sa senyeheng le liteko tsa khatello ea hydrostatic ho netefatsa matla le ho tšoarella ha phaephe ka 'ngoe. Re fa bareki ba rona lihlahisoa tsa phaephe ea tšepe tse fihlelang maemo a holimo a polokeho le netefatso ea boleng.

Liphaephe tsa karolo e se nang letho tse entsoeng ho latela EN 10219 lia tjheseletsa.

Ha ho tjhesetswa, ho petsoha ha serame sebakeng sa ho tjheseletsa ke kotsi e kgolo ha botenya, boemo ba matla le CEV ya sehlahiswa di ntse di eketseha. Ho petsoha ha serame ho bakwa ke motswako wa mabaka a mmalwa:

maemo a phahameng a haedrojene e hasanang ka hara tshepe e weld;

sebopeho se robehang habonolo sebakeng se amehileng ke mocheso;

khatello e matla ea ho hatelloa lenonyellong le welletsoeng.

Liphaephe tsa tšepe tsa EN 10219 li loketse ho kenya galvanizing ka ho chesa. Khetho e ka etsoa ho latela litlhoko tsa 'nete.

E lokela ho ba le bokaholimo bo boreleli bo tsamaellanang le mokhoa oa tlhahiso o sebelisitsoeng; li-bumps, li-voids, kapa li-groove tse sa tebang tse tsoang ts'ebetsong ea tlhahiso lia lumelloa ha feela botenya ba tsona bo setseng bo le ka har'a mamello.

Liphoso tsa bokaholimo li ka tlosoa ka ho sila, ha feela botenya ba karolo e se nang letho e lokisitsoeng bo se ka tlase ho botenya bo lumelletsoeng bo boletsoeng ho EN 10219-2.

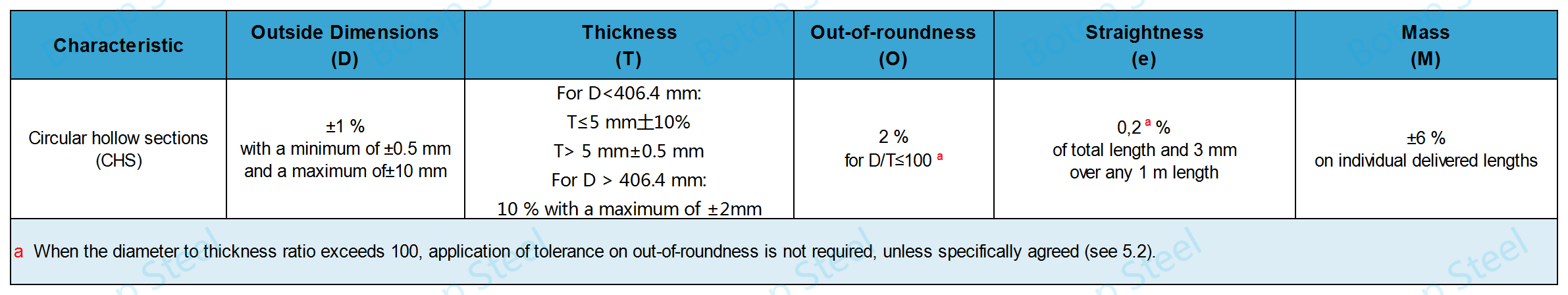

Mamello mabapi le Sebopeho, Ho Otloloha le Boima

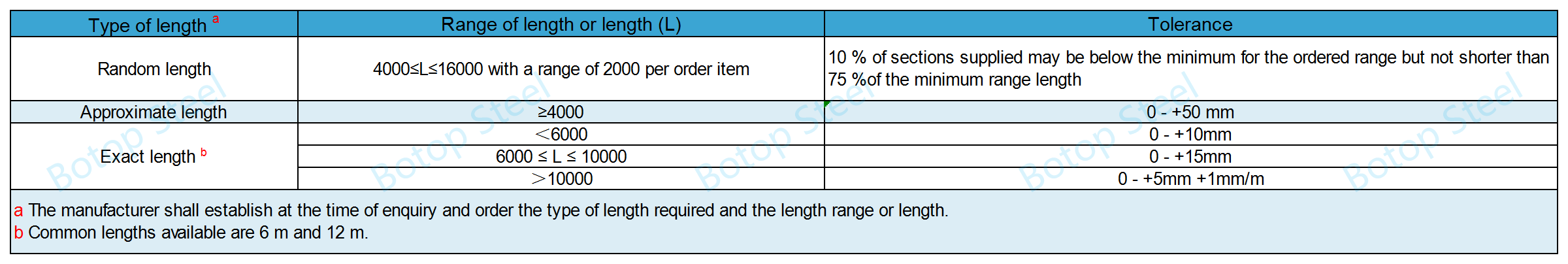

Bolelele ba Mamello

Bophahamo ba ho tjheseletsa

Tlhokahalo ea bophahamo ba ho tjheseletsa e sebetsa feela ho liphaephe tsa SAW.

| Botenya, mm | Bophahamo bo boholo ba sefaha sa weld, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Phaephe ea tšepe ea EN 10219 S355J0H ke thepa e matla le e sa senyeheng e loketseng mefuta e mengata ea meaho le boenjiniere, ho kenyeletsoa le lits'ebetso tsa liqubu tsa liphaephe.

1. Qubu ea Liphaephe: Phaephe ea tšepe ea S355J0H e loketse haholo ho sebelisoa e le liqubu tsa motheo ka lebaka la matla a eona le ho hanyetsa mafome 'me e sebelisoa haholo kahong ea likepe tsa likepe, marokho, metheo ea meaho le merero e meng e hlokang metheo e tebileng.

2. Meaho ea meaho: E sebediswa hangata bakeng sa dikarolo tse kang meaho ya masapo, dipilara tse tshehetsang, le maballo a meaho.

3. Sepalangoang sa liphaephe: E boetse e loketse hantle ho sebelisoa e le phaephe ea ho tsamaisa oli le khase libakeng tse telele. Leha ho le joalo, hangata e koahetsoe ho lelefatsa bophelo ba ts'ebeletso, mohlala, 3LPE, FBE, galvanized, jj.

4. Mechini ea kaho: E ka sebelisoa ho etsa li-bracket le likarolo tsa mechini e fapaneng ea kaho.

5. Meaho ea sechaba: tse kang li-bleacher mabaleng a lipapali le mehahong e meng ea tšehetso bakeng sa libaka tse kholo tsa sechaba.

EN 10210 S355J0H: Karolo e se nang letho bakeng sa meaho e welletsoeng ka thermoforming. Le hoja e sebelisoa haholo bakeng sa thermoforming, sebopeho sa eona sa lik'hemik'hale le thepa ea mechini li tšoana le tsa S355J0H 'me e ka sebelisoa e le thepa e ntle e lekanang.

ASTM A500 Kereiti C: E sebelisoa tlhahisong ea lipeipi tse chitja, tse sekoere le tse khutlonnetsepa tse kopantsoeng ka thapo kapa tse se nang sekoli tse batang tse entsoeng ka mokhoa o batang bakeng sa lits'ebetso tsa meaho. ASTM A500 Kereiti ea C e fana ka matla a tšoanang a tlhahiso le a ho thapolla bakeng sa meaho ea meralo le ea mechini.

CSA G40.21 350W: Ena ke tlhaloso ea Mokhatlo oa Maemo a Canada e akaretsang mefuta e mengata ea limaraka tsa tšepe tsa sebopeho. Tšepe ea sehlopha sa 350W e na le matla a tšoanang a tlhahiso le ho thaepa le S355J0H.

JIS G3466 STKR490: Ena ke thepa ea tube e sekoere le e khutlonnetsepa bakeng sa tšebeliso ea sebopeho joalo ka ha ho boletsoe ho Japanese Industrial Standard (JIS). E loketse meaho ea kaho le merero ea mechini.

Ho tloha ha e theoa ka 2014,Tšepe ea Botope se e le mofani ea ka sehloohong oa liphaephe tsa tšepe ea khabone Leboea la Chaena, ea tsebahalang ka tšebeletso e ntle haholo, lihlahisoa tsa boleng bo holimo le litharollo tse felletseng.

Khamphani e fana ka mefuta e fapaneng ya diphaephe tsa tshepe ya khabone le dihlahiswa tse amanang le yona, ho kenyeletswa le phaephe ya tshepe e se nang moedi, ERW, LSAW, le SSAW, hammoho le lethathamo le felletseng la diphaephe le di-flange. Dihlahiswa tsa yona tse ikgethang di boetse di kenyelletsa di-alloy tsa maemo a hodimo le ditshipi tse sa hlwekang tsa austenitic, tse etseditsweng ho fihlela ditlhoko tsa diporojeke tse fapaneng tsa diphaephe.

ASTM A252 GR.3 Sebopeho sa LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) Pipe ea Tšepe

Pipe ea Tšepe ea ASTM A671/A671M LSAW

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe

Pipe ea Tšepe ea Khabone ea API 5L X65 PSL1/PSL 2 LSAW / Pipe ea Tšepe ea API 5L ea Sehlopha sa X70 LSAW

EN10219 S355J0H Sebopeho sa LSAW (JCOE) Steel Pipe