JIS G 3454ke tekanyetso ea indasteri ea Majapane bakeng sa liphaephe tsa tšepe ea carbon bakeng sa litsamaiso tsa khatello tse nang le mocheso o phahameng oa ts'ebetso oa 350°C. Tekanyetso e kenyelletsa lihlopha tse peli:STPG 370leSTPG 410E sebetsa ho liphaephe tse kopantsoeng ka ho hanyetsa motlakase (ERW) kapa tse se nang mohele tse nang le bophara bo tloaelehileng ba 10.5 mm ho isa ho 660.4 mm (ke hore, 6A ho isa ho 650A, kapa 1/8B ho isa ho 26B).

JIS G 3454 Liphaephe tsa tšepe li lokela ho etsoa ho sebelisoa motsoako o loketseng oa mekhoa ea tlhahiso ea liphaephe tsa tšepe le mekhoa ea ho qeta tafoleng e ka tlase.

| Letšoao la kereiti | Letšoao la ts'ebetso ea tlhahiso | ||

| Mokhoa oa tlhahiso ea liphaephe | Mokhoa oa ho qeta | Tlhophiso ea sekoahelo sa zinki | |

| STPG370 STPG410 | Ha e na seamless: S Khanyetso ea motlakase e tjheselitsoe: E | E phethiloe ka ho chesa: H E felile ka serame: C Jwalo ka ha ho kentswe motlakase ho tjheseletsa: G | Liphaephe tse ntšo: liphaephe tse sa fuoang sekoahelo sa zinki Liphaephe tse tšoeu: liphaephe tse koahetsoeng ka zinki |

Ka ho khetheha, ho na le mekhoa e mehlano ea tlhahiso:

SH: Phaephe ea tšepe e se nang sekoli e felileng ka mocheso;

SC: Phaephe ea tšepe e se nang sekoli e qetiloeng ka serame;

EH: Phaephe ea tšepe e tjheselitsoeng e nang le khanyetso ea motlakase e phethiloeng ka mocheso;

EC: Phaephe ea tšepe e tjheselitsoeng e hanetsoeng ka motlakase e felileng ka serame;

EG: Phaephe ea tšepe e tjheselitsoeng e hanyetsang motlakase ntle le e qetiloeng ka mocheso le e batang.

Tšepe ea Botopke moetsi le mofani oa liphaephe tsa tšepe ea carbon tse lahletsoeng ka thapo ea boleng bo holimo tse tsoang Chaena, hammoho le morekisi oa liphaephe tsa tšepe tse se nang sekoli. Haeba u na le litlhoko life kapa life, ka kopo ikutloe u lokolohile ho ikopanya le rona 'me re tla u fa tšehetso ea tekheniki ea litsebi ea mahala.

| Letšoao la kereiti | C | Si | Mn | P | S |

| boholo | boholo | — | boholo | boholo | |

| STPG 370 | 0.25% | 0.35% | 0.30-0.90% | 0.040% | 0.040% |

| STPG 410 | 0.30% | 0.35% | 0.30-1.00% | 0.040% | 0.040% |

E lumella ho eketsoa ha likarolo tse ling tsa ho kopanya.

Matla a ho Thahasellisa, Khatello ea Tekanyo kapa Bopaki, le ho Lelefatsa

| Letšoao ea sehlopha | Matla a tšepe | Ntlha ea tlhahiso kapa bopaki ba khatello ea maikutlo | Ho lelefatsa bonyane, % | |||

| Sekhechana sa teko ea tensile | ||||||

| Nomoro ea 11 kapa ea 12 | Nomoro ea 5 | Nomoro ea 4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Tsela ea teko ea ho tenyetseha | ||||

| motsotso | motsotso | E bapile le mothapo oa phaephe | E otlolohileng ho axis ea phaephe | E bapile le mothapo oa phaephe | E otlolohileng ho axis ea phaephe | |

| STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Teko ea ho Batalatsa

Ha sebaka se pakeng tsa lipoleiti tse peli se fihla ho sebaka se boletsoeng H, ho ke ke ha e-ba le likoli kapa mapetso holim'a phaephe ea tšepe.

Bakeng sa lipeipi tsa tšepe tse se nang mohele: H = (1+e)t/(e + t/D);

Bakeng sa liphaephe tsa tšepe tsa ERW: H = 1/3 D (bakeng sa ho tjheseletsa) kapa H = 2/3 D (bakeng sa karolo e se nang ho tjheseletsa);

H: sebaka se pakeng tsa lipoleiti tse bataletseng (mm);

е: e sa fetoheng e hlalositsoeng ka bonngoe bakeng sa sehlopha se seng le se seng sa phaephe, 0.08 bakeng sa STPG 370, 0.07 bakeng sa STPG 410;

t: botenya ba lebota la phaephe (mm);

D: bophara ba kantle ba phaephe (mm);

Teko ea ho Foforetsa e sebetsa liphaepheng tsa tšepe tse nang le bophara bo fetang 40A (48.6mm).

Ho kobeha

Ho kobeha ho sebetsa ho liphaephe tse nang le bophara bo tloaelehileng ba 40 A (48.6) kapa bo bonyenyane.

Phaephe e lokela ho kobeha ka 90° ka radius ya bophara ba yona ba ka ntle ka makgetlo a 6. Lebota la phaephe le lokela ho se be le diphoso kapa mapetso.

Phaephe e 'ngoe le e 'ngoe ea tšepe e tlameha ho feta tekong ea khatello ea hydrostatic kapa teko e sa senyeheng.

Teko ea Hydrostatic

Boloka khatello e itseng bonyane metsotsoana e 5 ntle le ho dutla.

Boleng ba khatello bo amana le kemiso ea Palo ea phaephe ea tšepe.

| Botenya ba lebota bo ikgethang | Nomoro ea kemiso: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Khatello e tlase ea teko ea hydraulic, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Teko e sa senyeheng

Haeba tlhahlobo ea ultrasound e sebelisoa, e lokela ho ipapisa le maemo a thata ho feta lets'oao la sehlopha sa UD ho JIS G 0582.

Haeba ho sebelisoa teko ea eddy current, e lokela ho ipapisa le maemo a thata ho feta lets'oao la sehlopha sa EY ho JIS G 0583.

| Bophara ba lebitso | Bophara ba kantle | Botenya ba lebota | Boima ba yuniti | Nomoro ea kemiso (Nomoro ea Sekolo) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0.629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0.675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

JIS G 3454 e kenyelletsakemiso ea 10, kemiso ea 20, kemiso ea 30, kemiso ea 40, kemiso ea 60lekemiso ea 80.

O ka tobetsa nomoro ea kemiso eo o batlang ho e sheba; re hlophisitse mefuta e tsamaellanang ea PDF bakeng sa boiketlo ba hau.

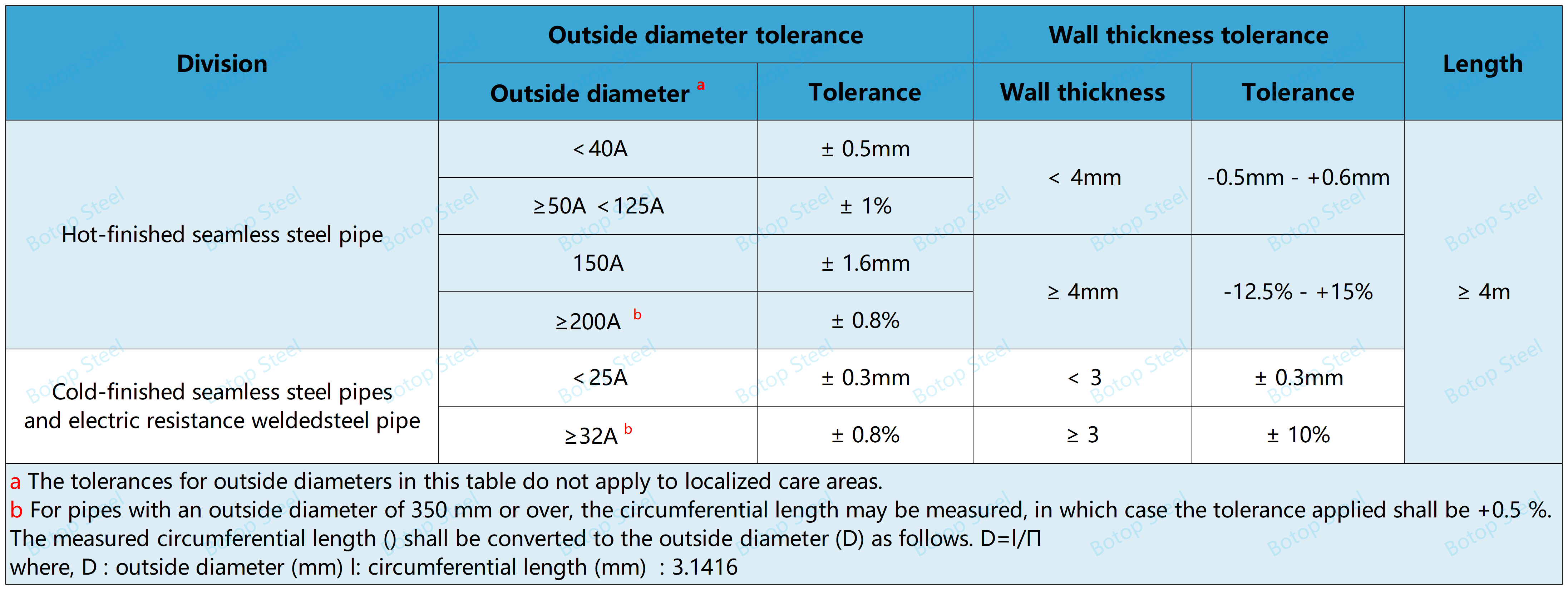

JIS G 3454 Mamello ea bophara ba kantle, botenya ba lebota, ho se fetohe ha sebopeho le bolelele e tla fihlela litlhoko tse latelang.

Ho tloha ha e theoa ka 2014, Botop Steel e se e le mofani ea ka sehloohong oa liphaephe tsa tšepe ea khabone Leboea la Chaena, e tsebahalang ka tšebeletso e ntle haholo, lihlahisoa tsa boleng bo holimo le litharollo tse felletseng.

Khamphani e fana ka mefuta e fapaneng ea liphaephe tsa tšepe ea khabone le lihlahisoa tse amanang le tsona, ho kenyeletsoa le phaephe ea tšepe e se nang seamless, ERW, LSAW, le SSAW, hammoho le lethathamo le felletseng la liphaephe le li-flange.

Lihlahisoa tsa eona tse ikhethang li boetse li kenyelletsa litšepe tse kopantsoeng tsa boleng bo holimo le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho fihlela litlhoko tsa merero e fapaneng ea liphaephe.

Ka kopo ikopanye le rona, re tla o fa liphaephe tsa tšepe tsa boleng bo holimo, tse tloaelehileng tse nang le tšebeletso ea profeshenale le e sebetsang hantle. Botop e labalabela ho u sebeletsa.