API (American Petroleum Institute Standard) 5L ke tekanyetso ea machaba ea phala ea tšepe e sebelisoang lits'ebetsong tsa lipeipi tsa liphaephe.

API 5L e koahela phala ea tšepe bakeng sa lits'ebetso tse fapaneng tsa ho tsamaisa khase ea tlhaho, oli le lino tse ling.Letsatsi la ho sebetsa la khatiso ea bo-46: e qala ka la 1 Pulungoana 2018.

Haeba u batla feela ho fumana mohopolo o akaretsang oa API 5L, ka kopo, tobetsaKakaretso ea Tlhaloso ea Pipe ea API 5L.

Likonopo tsa ho Tsamaisa

Ke Eng e Nchafalitsoeng ho API 5L 46th

Tšimoloho ea API 5L PSL

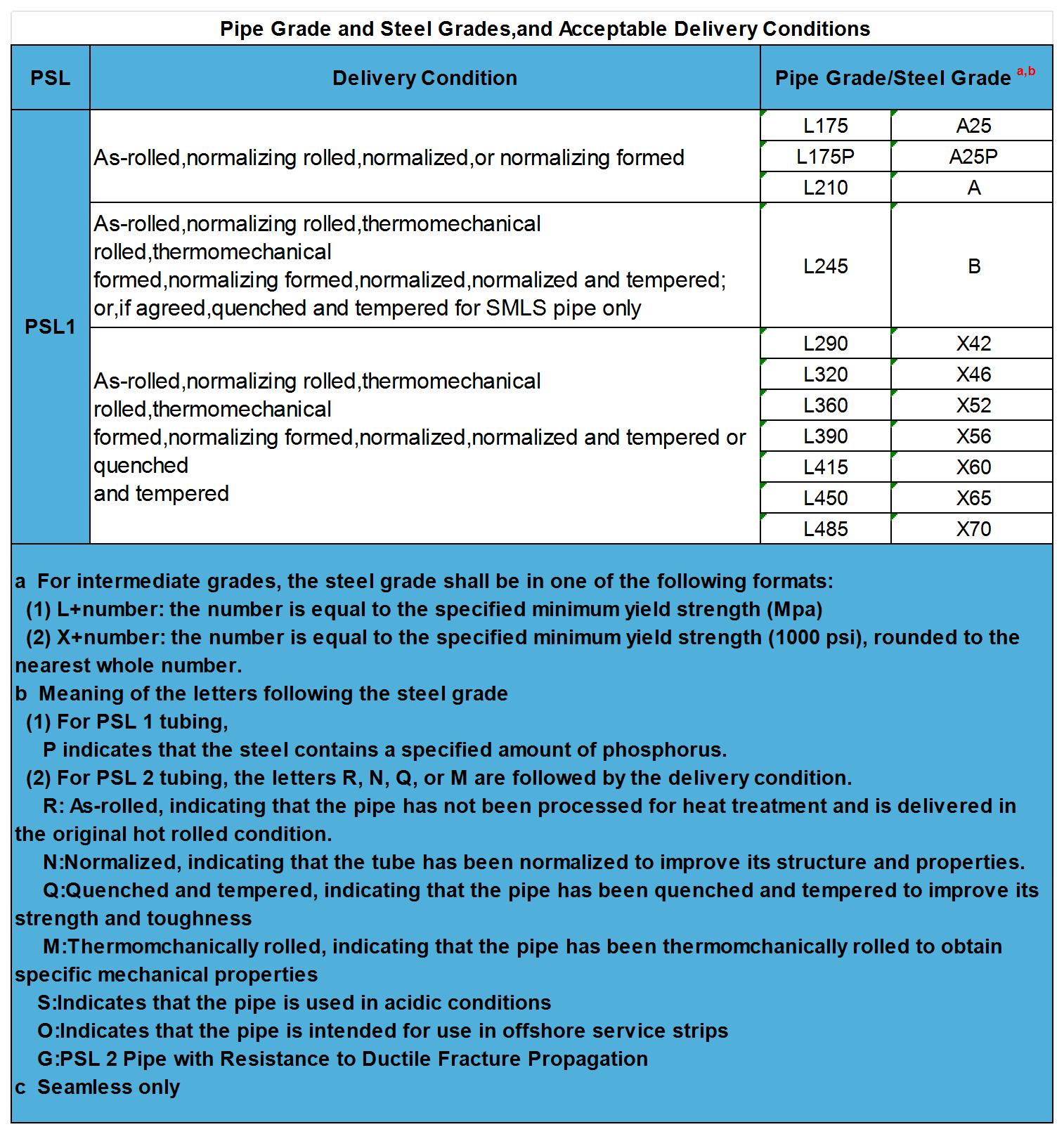

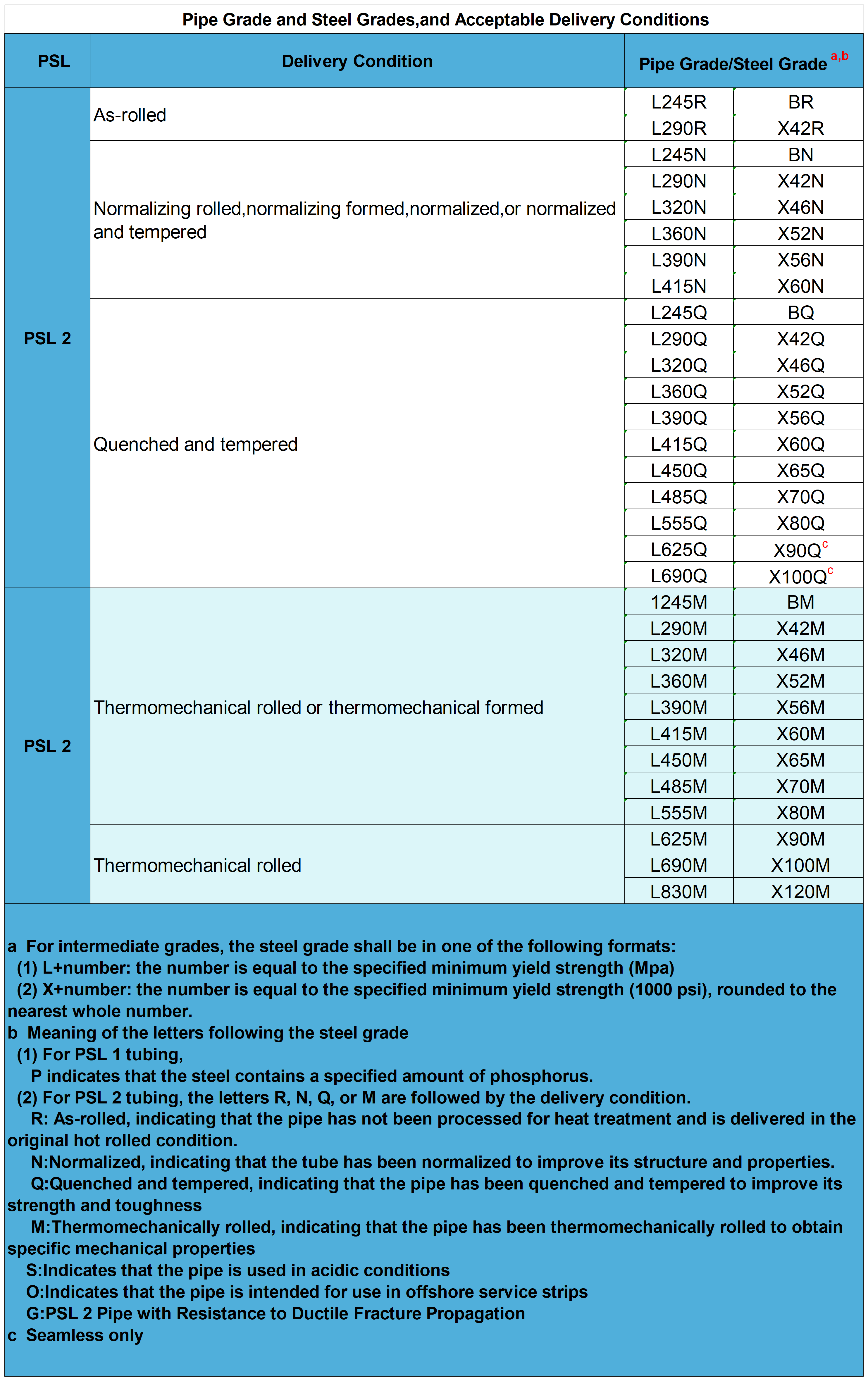

Classification of Steel Grades le Pipe Grades

Linaha tse Amohelehang tsa Phano

Lisebelisoa tse tala bakeng sa liphaephe tsa tšepe

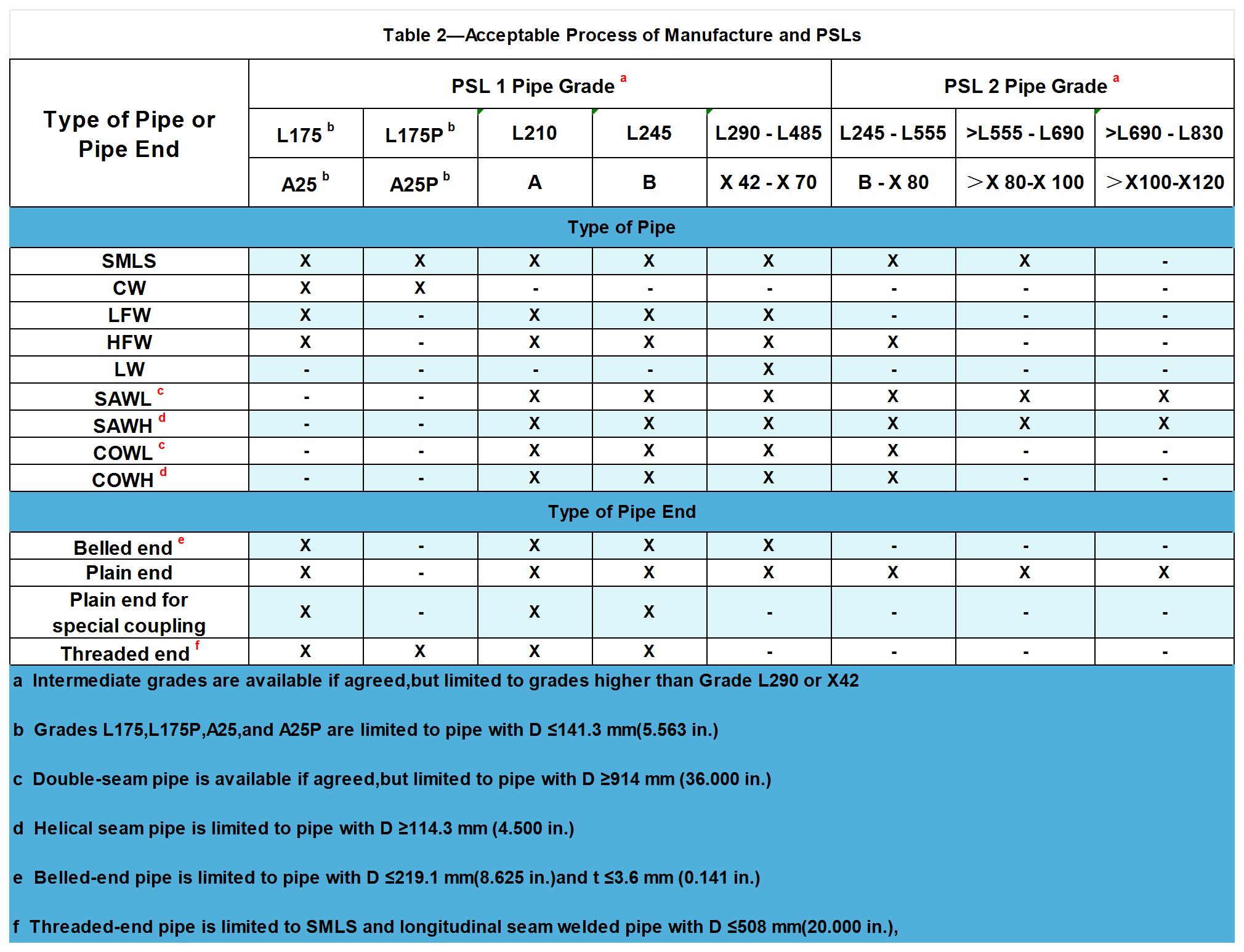

Mefuta ea Pipe ea Tšepe le Tube Ends E Koaheletsoeng ke API 5L

Mekhoa e Amohelehang ea Tlhahiso bakeng sa PSL2 Steel Tubing

Tlhahlobo ea ponahalo le liphoso tse tloaelehileng tsa API 5L

Tlhahlobo ea Dimensional (Dimensional Deviations)

Lintho tsa Teko tsa API 5L

Letšoao la Pipe le Sebaka

Tekano Tekanyetso

Lihlahisoa tsa rona tse Amanang

Ke Eng e Nchafalitsoeng ho API 5L 46th

Lintlafatso

Litlhoko tse nchafalitsoeng le tse atolositsoeng bakeng sa manonyeletso a milled;

Litlhoko tse ntlafalitsoeng bakeng sa perpendicularity ea liphaephe;

Litlhoko tse ntlafalitsoeng tsa tlhahlobo ea boima ba lipeipi tsa API 5LPSL 2 bakeng sa tikoloho e bolila le lipeipi tsa API 5L PSL 2 bakeng sa tikoloho e kantle ho naha;

E ncha

API 5L PSL 2 pipe bakeng sa lits'ebetso tse hlokang matla a polasetiki a longitudinal.

Tšimoloho ea API 5L PSL

PSL: Kgutsufatso ya Boemo ba Pipeline Specification;

E arotsoe ka: API 5L PSL 1 le API 5L PSL 2.

Classification of Steel Grades le Pipe Grades

L + nomoro(tlhaku L e lateloa ke matla a tlase a tlhahiso a MPa):

L175, L175P, L210, L245, L290, L320, L360, L390, L415, L450, L485, L555, L625, L690, L830

X + nomoro(nomoro e latelang tlhaku X e bolela bonyane matla a tlhahiso ho 1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

Le sehlopha sa A le sa b.Kereiti A=L210 Kereiti B=L 2459

Linaha tse amohelehang tsa thomello

Ela hloko: L415/X60 kapa limaraka tse holimo ha lia lokela ho sebelisoa sebakeng sa L360/X52 kapa limaraka tse tlase ntle le tumellano ea moreki.

Lisebelisoa tse tala bakeng sa liphaephe tsa tšepe

Ingot, billet, billet, strip (coil) kapa poleiti.

Hlokomela:

1. Thepa e tala bakeng saAPI 5L PSL2phala ea tšepe e tla ba tšepe e entsoeng ka lijo-thollo tse ntle.

2. Letlapa la tšepe (coil) kapa poleiti e sebelisetsoang ho etsa pipe ea tšepe ea API 5L PSL2 e ke ke ea jara li-welds tsa tack.

Mefuta ea Pipe ea Tšepe le Tube Ends E Koaheletsoeng ke API 5L

Pipe ea tšepe e cheselitsoeng

Pipe ea CW:Mokhoa oa ho etsa seam ka ho futhumatsa lesela ka seboping le ho hatella ntlha e kopaneng, moo likhoele tse latellanang tsa lesela li kopantsoeng hammoho ho fana ka phallo e tsoelang pele ea leloala la tjheseletsa.

KOKOPipe:Sehlahisoa sa Tubular se nang le seam se le seng sa helical se hlahisoang ke motsoako oa tšepe ea tšepe ea khase le welding e ka tlas'a metsi, moo sefaha sa tšepe sa arc weld ha se tlosoe ka ho feletseng ke ho feta ha metsi a koahetsoeng ke arc.

KHOMO Pipe:Sehlahisoa sa Tubular se nang le seams se le seng kapa tse peli tsa longitudinal tse hlahisoang ke motsoako oa tšepe ea tšepe ea khase le welding e ka tlas'a metsi, eo ho eona khase ea tšepe ea arc weld bead e sa tlosoe ka ho feletseng ke ho feta ka tlas'a metsi.

EW Pipe:Sehlahisoa sa tubula se nang le seam se le seng sa longitudinal se hlahisoang ke welding ea motlakase e tlase kapa e phahameng.

HFW Pipe:EWpipe e hlahisoang ka maqhubu a hona joale a welding a lekanang kapa a fetang 70 kHz.

LFW Pipe:Pipe ea EW e hlahisoa ka maqhubu a hona joale a welding a ka tlase ho 70 kHz.

LW Pipe:Sehlahisoa sa tubula se nang le seam se le seng sa longitudinal se hlahisoang ke welding ea laser.

Pipe ea SAWH:Sehlahisoa sa Tubular se nang le seam se le seng sa helical se hlahisoang ke ts'ebetso ea welding ea arc e ka tlas'a metsi.

SAWLPipe:Sehlahisoa sa Tubula se nang le seams se le seng kapa tse peli tsa longitudinal tse hlahisoang ke welding e kentsoeng ka metsing.

Pipe ea tšepe e se nang Seam

Pipe ea SMLS:Pipe ea tšepe e chesang e kentsoeng e se nang seamless le phala e batang ea tšepe e sa koaeloang, ho na le mekhoa e meng ea ts'ebetso, joalo ka ho taka ho batang, ho taka ho batang, ho forging, joalo-joalo.

API 5L PSL2 Mefuta ea liphaephe bakeng sa lisebelisoa tse khethehileng

Ho hanana le Phatlalatso ea ho Fracture ea Ductile (G)

Sour Service Condition Pipe (S)

Offshore Service Condition Pipe (O)

E Hlokang Longitudinal Plastic Strain Capacity Pipe

Mefuta ea Bofelo ba Pipe

Socket End, Flat End, Special Clamp Flat End, Threaded End.

Hlokomela:

1. Socket ends, pipe ends for special clamps, le threaded pipe ends ke tsa API 5L PSL1 feela.

2. L175 P / A25 P ea tšepe ea tšepe ea API 5L PSL1 pipe ea tšepe e tla kenngoa ka likhoele tse nang le likhoele, 'me pipe ea tšepe ea API 5L PSL1 ea lihlopha tse ling tsa tšepe e tla etsoa ka mechine e nang le lintlha tse bataletseng.

3. Li-tubes tsa API 5L PSL 2 li tla tsamaisoa ka mahlakore a bataletseng.

Mekhoa e Amohelehang ea Tlhahiso bakeng sa PSL2 Steel Tubing

| Letlapa la 3-Litsela tse Amohelehang tsa Tlhahiso bakeng sa PSL 2 Pipe | ||||

| Mofuta oa Pipe | Ho qala Materia | Ho Etsa Lipeipi | Mocheso oa Pipe Kalafo | Phano Boemo |

| SMLS | Ingot, palesa, kapa billet | Joalo ka ha e phuthiloe | - | R |

| Normalizing ho theha | - | N | ||

| Ho theha ho chesang | Ho tloaeleha | N | ||

| Ho khutsisa le ho khutsisa | Q | |||

| Ho theha le ho bata finishing | Ho tloaeleha | N | ||

| Ho khutsisa le ho khutsisa | Q | |||

| HFW | Normalizing-rolled coil | Ho etsa serame | Ho phekola mochesoa sebakeng sa weld feela | N |

| Thermomechanical-rolled khoele | Ho etsa serame | Ho phekola mochesoa sebakeng sa weld feela | M | |

| Ho phekola mochesoa ea sebaka sa weld le khatello ea maikutlo ea phala eohle | M | |||

| Jwaloka-ho phuthilwe kapa khoele e kentsoeng ka thermomechanical | Ho etsa serame | Ho tloaeleha | N | |

| Ho tima le ho halefisa | Q | |||

| Ho ba le serame ho lateloa ke ho chesa ho fokotsa tlasa taolo mocheso o fellang ka boemo bo tloaelehileng | - | N | ||

| Ho ba le serame ho lateloa ke ho etsa thermomechanical ea phala | - | M | ||

| BONA kapa KHOMO | E tloaelehileng kapa e tloaelehileng- khoele kapa poleiti | Ho etsa serame | - | N |

| Joalo ka ha e phuthiloe thermomechanical-rolled normalizing-rolled, kapa tloaelehile | Ho etsa serame | Ho tloaeleha | N | |

| Thermomechanical-rolled khoele kapa poleiti | Ho etsa serame | - | M | |

| E khutsitsoe ebile e halefile poleiti | Ho etsa serame | - | Q | |

| Joalo ka ha e phuthiloe thermomechanical-rolled normalizing-rolled, kapa sekoele kapa poleiti e tloaelehileng | Ho etsa serame | Ho tima le ho halefisa | Q | |

| Joalo ka ha e phuthiloe thermomechanical-rolled normalizing-role, kapa sekoele kapa poleiti e tloaelehileng | Normalizing ho theha | - | N | |

| aSheba ISO 5L 8.8 bakeng sa liphekolo tse sebetsang tsa mocheso | ||||

Tlhahlobo ea ponahalo le liphoso tse tloaelehileng tsa API 5L

Ponahalo

Karolo e ka ntle ea phala e tla ba e boreleli ebile e se na mefokolo e ka amang matla le thepa ea ho tiisa phala.

Mefokolo e Meholo

Maqhubu a Nibbled:Libaka tse nang le li-nibbled li ka fumanoa hantle ka ho hlahloba pono.

Arc e chesa:Ho chesoa ha li-arc ho tla ahloloa e le sekoli.

Arc burns ke palo ea libaka tsa libaka tse nang le bokooa tse entsoeng ke ho qhibiliha ha bokaholimo ba tšepe ho bakoang ke arc pakeng tsa electrode kapa electrode ea fatše le bokaholimo ba phala ea tšepe.

Matheba a ho kopana ke matheba a nakoana a haufi le mohala oa weld oa pipe ea EW, e bakoang ke ho kopana pakeng tsa electrode e fanang ka hona joale ea welding le bokaholimo ba phala.

Delamination:delamination efe kapa efe kapa kenyelletso efe kapa efe e fetelang holim'a phaephe kapa sefahleho se kobehileng 'me e> 6.4 mm (0.250 in) ka bolelele bo pota-potileng tlhahlobo ea pono e tla nkuoa e le sekoli.

Liphapang tsa Jiometri:Phapang ea geometri (mohlala, boloko bo bataletseng kapa pout, joalo-joalo), ntle le sekoti sa marotholi, se bakoang ke ts'ebetso ea ho etsa li-tube kapa ts'ebetso ea tlhahiso.Sebaka se pakeng tsa ntlha e feteletseng le katoloso ea contour e tloaelehileng ea tube, ke hore, botebo bo fetang 3.2 mm (0.125 in), bo tla nkoa e le sekoli.

Likoti tsa marotholi li tla ba ≤ 0.5 D ka tsela efe kapa efe.

Ho thatafala: Ha tlhahlobo ea pono e senola ho belaelloang hore ke thatafala, ho tla sebelisoa mochine o nkehang habobebe oa ho lekola boima ba 'mele, 'me indentation ea ntlha e le 'ngoe e nang le boleng ba boima bo fetang 35 HRC, 345 HV10, kapa 327 HBW e tla nkoa e le sekoli ha boholo bo le teng. ea indentation e kholo ho feta 50 limilimithara (2.0 in) ka tsela efe kapa efe.

Ho sebetsana le Sekoli

Ka kopo, sheba litlhoko tse amehang ho API 5L Sehlomathiso C bakeng sa ho sebetsana.

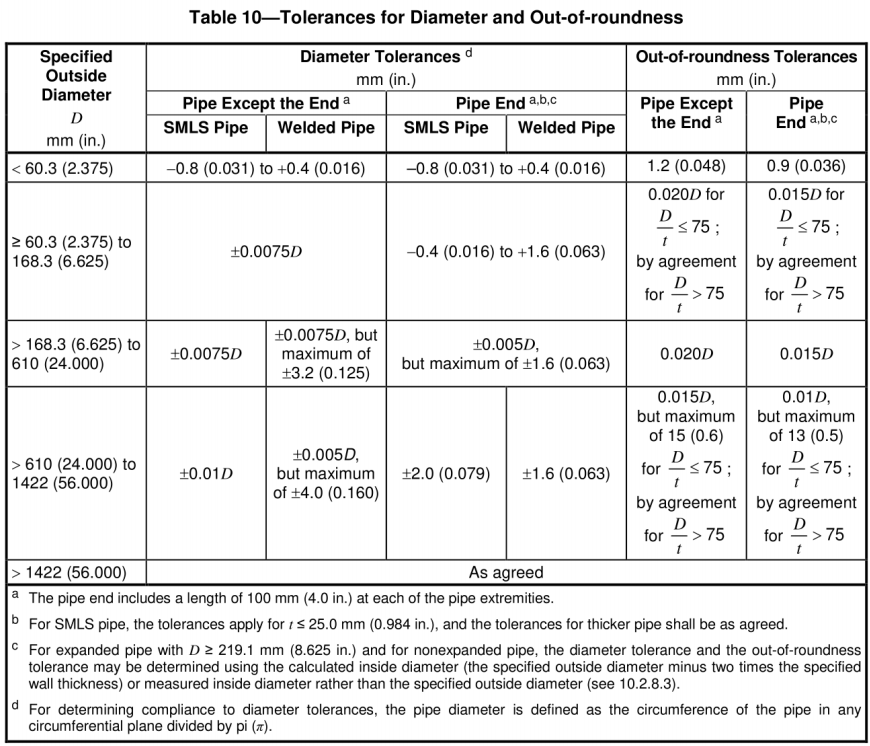

Tlhahlobo ea Dimensional (Dimensional Deviations)

Chate ea Boima ba Pipe le Boima ba Boima

Foromo ea Boima

M=(DT)×T×C

M ke boima ka bolelele ba yuniti;

D ke bophara bo ka ntle bo boletsoeng, bo hlahisoang ka limilimithara (li-inch);

T ke botenya ba lebota bo boletsoeng, bo hlahisoang ka limilimithara (lisenthimithara);

C ke 0.02466 bakeng sa lipalo tsa liyuniti tsa SI le 10.69 bakeng sa lipalo tsa liyuniti tsa USC.

PIPE DICHATE KA BOIMA LE MANUMETSO

litafole tsa boima ba liphaephe ho API 5L li boleloaISO 4200leASME B36.10M, e fanang ka litekanyetso tse tloaelehileng bakeng sa phaephe e nang le bophara bo ka ntle bo boletsoeng le botenya ba lebota bo boletsoeng.

Kemiso ea 40 le Kemiso ea 80li khomaretsoe ka tlase, haeba u ka rata ho bona lenane le felletseng la liphaephe,ka kopo tlanya mona!

Boima ba Boima

Boleng ba phala e 'ngoe le e' ngoe e amanang le khopolo-taba: boima: 95% ≤ boima ba khopolo ≤ 110;

Ho kheloha le li-tubes tse khethehileng tse tšesaane: 5% ≤ 110% ea boima ba khopolo;

L175, L175P, A25, le A25P limaraka tsa tšepe: 95% ≤ 110% ea boima ba khopolo-taba.

Kantle Diameter le Botenya ba Lebota Range

| Letlapa la 9 - Diamethara ea Kantle e lumelletsoeng le Botenya ba Lerako bo Khethiloeng | ||

| Bophara bo Kantle bo Boletsoe D mm (ka.) | Botenya ba Lebota bo boletsoeng t mm (ka.) | |

| Boholo ba Leseli bo Khethehilenga | Boholo ba kamehla | |

| ≥10.3 (0.405)ho <13.7 (0.540) | - | ≥1.7 (0.068)ho≤2.4 (0.094) |

| ≥13.7 (0.540)ho <17.1 (0.675) | - | ≥2.2 (0.088)ho≤3.0 (0.118) |

| ≥17.1 (0.675)ho <21.3 (0.840) | - | ≥2.3 (0.091)ho≤3.2 (0.125 |

| ≥21.3 (0.840) ho <26.7 (1.050) | - | ≥2.1 (0.083)ho≤7.5(0.294) |

| ≥26.7(1.050)ho <33.4(1.315) | - | ≥2.1 (0.083)ho≤7.8 (0.308) |

| ≥33.4(1311}5)ho<48.3 (1.900) | - | ≥2.1 (0.083)ho≤10.0 (0.394) |

| ≥48.3 (1.900)ho <60.3 (2.375) | - | ≥2.1 (0.083)ho≤12.5 (0.492) |

| ≥60.3 (2.375)ho<73.0 (2.875) | ≥2.1 (0.083)ho≤3.6 (0.141) | >3.6 (0.141)ho≤14.2 (0.559) |

| ≥73.0 (2.875) ho <88.9(3.500) | ≥2.1 (0.083)ho≤3.6 (0.141) | >3.6 (0.141)ho≤20.0 (0.787) |

| ≥88.9 (3.500) ho <101.6(4.000) | ≥2.1 (0.083)ho≤4.0 (0.156) | >4.0 (0.156)ho≤22.0 (0.866) |

| ≥101.6(4.000)ho <168.3 (6.625) | ≥2.1 (0.083)ho≤4.0 (0.156) | >4.0(0.156)ho≤25.0 (0.984) |

| ≥168.3 (6.625)ho <219.1 (8.625) | ≥2.1 (0.083)ho≤4.0 (0.156 | >4.0 (0.156)ho≤40.0(1.575) |

| ≥219.1 (8.625)ho <273.1 (10.750) | ≥3.2 (0.125)ho≤4.0 (0.156 | >4.0 (0.156)ho≤40.0 (1.575 |

| ≥273.1 (10.750)ho<323.9 (12.750) | ≥3.6 (0.141)ho≤5.2 (0.203) | >5.2 (0.203)ho≤45.0 (1.771) |

| ≥323.9(12.750)ho<355.6(14.000) | ≥4.0 (0.156)ho≤5.6 (0.219) | >5.6 (0.219)ho≤45.0(1.771 |

| ≥355.6(14.000)ho<457(18.000) | ≥4.5 (0.177)ho≤7.1 (0.281) | >7.1 (0.281)ho≤45.0(1.771 |

| ≥457 (18.000) ho <559 (22.000) | ≥4.8 (0.188)ho≤7.1 (0.281) | >7.1 (0.281)ho≤45.0(1.771) |

| ≥559 (22.000) ho <711(28.000) | ≥5.6 (0.219)ho≤7.1 (0.281) | >7.1 (0.281)ho≤45.0(1.771) |

| ≥711 (28.000) ho <864(34.000) | ≥5.6(0.219)ho≤7.1 (0.281) | >7.1 (0.281)ho≤52.0 (2.050) |

| ≥864 (34.000) ho <965(38.000) | - | ≥5.6 (0.219)ho≤52.0 (2.050) |

| ≥965(38.000)ho<1422 (56.000) | - | ≥6.4 (0.250)ho≤52.0 (2.050) |

| ≥1422(56.000)ho <1829 (72.000) | - | ≥9.5 (0.375)ho≤52.0 (2.050 |

| ≥1829(72.000)ho<2134(84.000) | - | ≥10.3 (0.406)ho≤52.0 (2.050) |

| aPipe e nang le motsoako oa bophara bo ka ntle le botenya bo boletsoeng bo hlalosoa e le phala e khethehileng ea boholo ba leseli;metsoako e meng e fanoeng tafoleng ena e hlalosoa e le phala ea boholo bo tloaelehileng. | ||

Phapang ea bophara le Roundness

Phapang ea Botenya ba Lerako

| Letlapa la 11-Mamello bakeng sa Botenya ba Lerako | |

| Botenya ba Lerako t mm (ka.) | Mamelloa mm (ka.) |

| Pipe ea SMLSb | |

| ≤4.0 (0.157) | +0.6(0.024) -0.5 (0.020) |

| >4.0 (0.157) ho <25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146) kapa+0.1t, ho sa tsotellehe hore na ke efe e kholo -3.0 (0.120) kapa-0.1t, ho sa tsotellehe hore na e kholo ke efe |

| Pipe e cheselitsoengcd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| > 5.0 (0.197) ho <15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aHaeba taelo ea theko e totobatsa ho mamella ha lerako ka botenya bo nyane ho feta boleng bo sebetsang bo fanoeng tafoleng ena, mamello e eketsehileng bakeng sa botenya ba lebota e tla eketsoa ka chelete e lekaneng ho boloka tekanyo e sebetsang ea mamello. bBakeng sa phaephe e nang le D2 355.6 mm (14.000 in.) le 1 2 25.0 mm (0.984 in.), mamello ea botenya ba lerako sebakeng sa heno e ka feta ho mamellana le botenya ba lerako ka 0.05t e eketsehileng, ha feela mamello e eketsehileng bakeng sa boima (bona 9.14) ha e fete. cMamello e eketsehileng bakeng sa botenya ba lerako ha e sebetse sebakeng sa weld. dSheba 9.13.2 bakeng sa lithibelo tse ling. | |

Phapang ea Bolelele

Mamello ea li-tubing tsa bolelele bo tsitsitseng: Ho kheloha ha bolelele e lokela ho ba 500 mm (20 inches).

Mamello ea lipeipi tsa bolelele bo sa reroang:

| Letlapa la 12-Mamello bakeng sa Pipe e Bolelele e sa Raroeng | |||

| Random Length Khethollo m(ft) | Bonyane Bolelele m (maft) | Bonyane Bolelele ba Kakaretso Bakeng sa Ntho ka 'ngoe ea Odara m (maft) | Boholo Bolelele m (ft) |

| Pipe e khoele-le-mahantsoeng | |||

| 6(20) | 4.88(16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9(30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67(35.0) | 13.72(45.0 |

| Pipe e sa feleng | |||

| 6(20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00(26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72(45.0) |

| 15(50) | 5.33 (17.5) | 13.35(43.8) | 16.76(55.0) |

| 18(60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24(80) | 8.53 (28.0) | 21.34(70.0) | 25.91(85.0) |

Ho kheloha ho otloloha

Ho kheloha ho feletseng ho tloha molaong o otlolohileng ho feta bolelele bohle ba phala e tla ba <0.2% ea bolelele ba pipe;

Ho kheloha sebakeng ho tloha moleng o otlolohileng ho tla ba <3.2 mm (0.125 in) ho feta bolelele ba 1.5 m (5.0 ft) pheletsong ka 'ngoe ea phaephe.

Bevel Angle Deviation

Tube e nang le t > 3.2 mm (0.125 in) lipheletsong tse bataletseng li tla etsoa ka mochine ka bevel ea weld e nang le angle ea bevel ea 30 ° -35 °.

Bophara ba Sebaka sa Motso o Atolositsoeng

1.6 mm (0.063 ho) ka ho kheloha ha ±0.8 mm (0.031 ho).

Range of Inner Cone Angle (feela bakeng sa peipi ea tšepe e se nang seam)

| Letlapa la 13-Boholo ba Angle ea Internal Taper bakeng sa Pipe ea SMLS | |

| Botenya ba Lebota bo boletsoeng t mm (ka.) | Maximum Angle of Taper likhato |

| <10.5(0.413) | 7.0 |

| 10.5 (0.413) ho <14.0 (0.551) | 9.5 |

| 14.0 (0.551) ho <17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

Pipe End Squareness (out-of-squareness)

Sebaka se ka ntle ho lisekoere se lekantsoe e le lekhalo pakeng tsa pheletso ea phala le leoto la ho qetela la pipe, e tla ba 1.6 mm (0.063 in.).

Ho kheloha Seam Welding

Ho se nepahale ha Leqephe/Lakane:

Bakeng sa phaephe ea electro-welded (EW) le laser-welded (LW), ho se lumellane ha hoa lokela ho fella ka botenya bo setseng ba lebota ho weld bo ka tlase ho bonyane bo lekaneng ba lebota bo amohelehang.

Bakeng sa pipe ea Submerged Arc Welded (SAW) le Combination Welded (COW), ho se lumellane ha hoa lokela ho feta litekanyetso tse lumellanang tse fanoeng ho Lethathamo la 14 la API 5L.

Burrs ( electro-welded (EW) le laser-welded (LW) tubes):

Li-burrs tsa ka ntle li tla tlosoa hore li be boemong bo matla haholo (ka thepa ea motheo).

Li-burrs tsa ka hare ha li na ho atolosa 1.5 mm (0.060 in) ka nģ'ane ho mokoloko oa tube, 'me botenya ba lebota sebakeng sa ho tlosoa ha li-burr ha boa lokela ho ba tlase ho bonyane bo lekaneng ba lebota bo amohelehang.

Weld Height(Summerged Arc Welding (SAW) le Combination Welding (COW) Pipe):

Tlosa bophahamo bo setseng ba weld ea ka hare ka hare ho bonyane ba 100 mm (4.0 ka) ea pheletsong ea phala karolong e 'ngoe le e' ngoe ea phala, 'me u sila weld e le hore e se ke ea phahama ho feta 0.5 mm (0.020 in) ka holim'a metsi. ea phala e haufi.

Lintho tsa Teko tsa API 5L

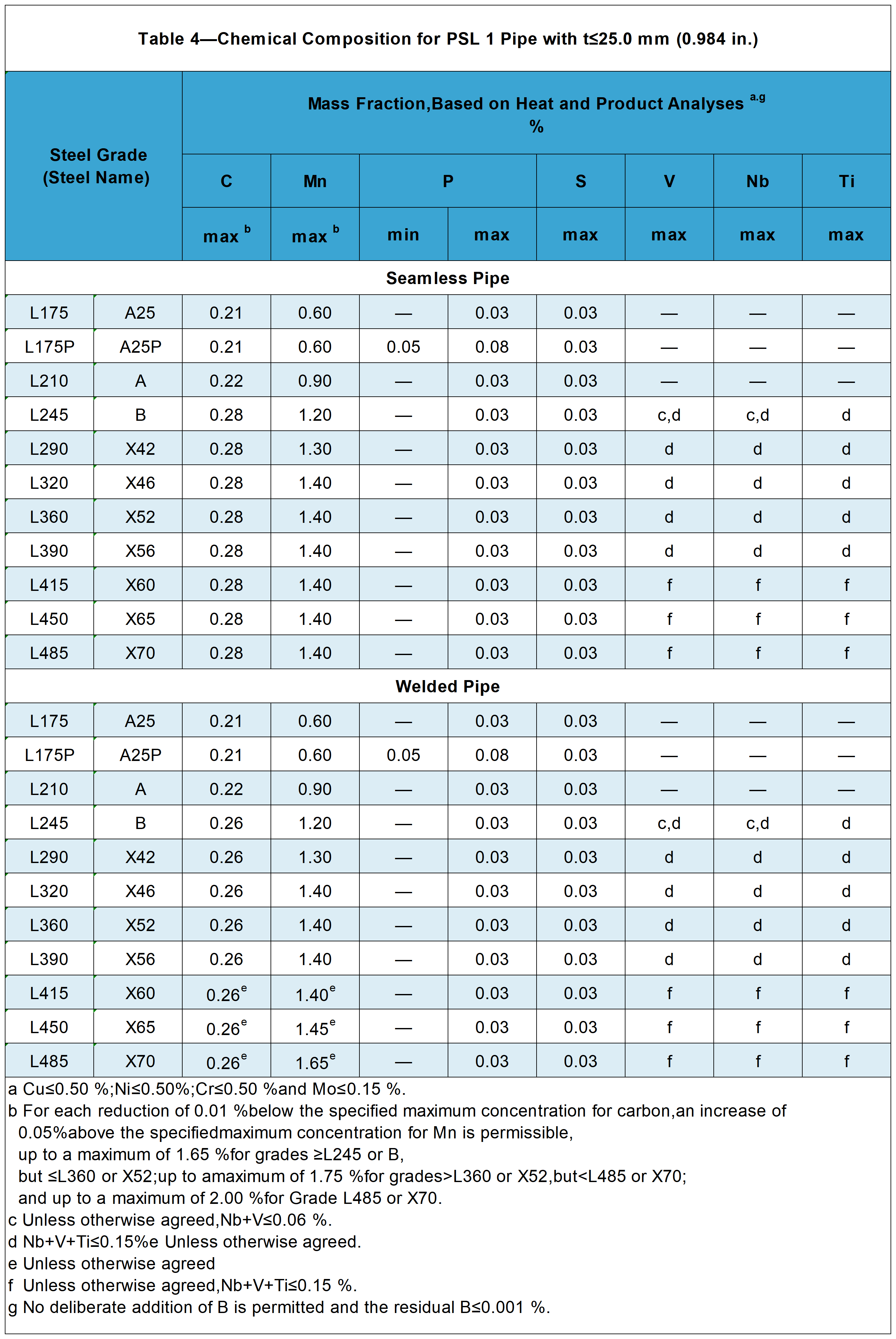

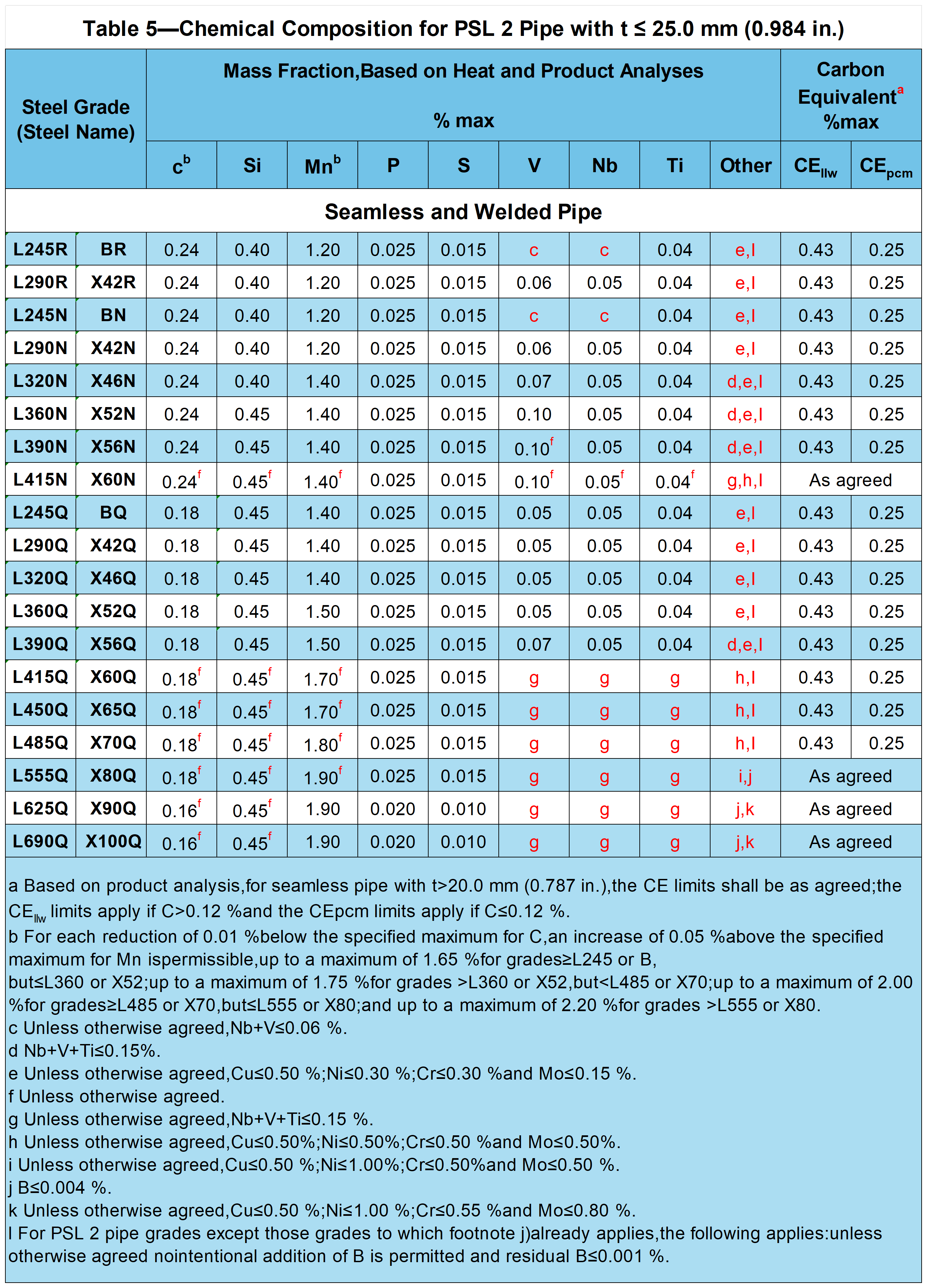

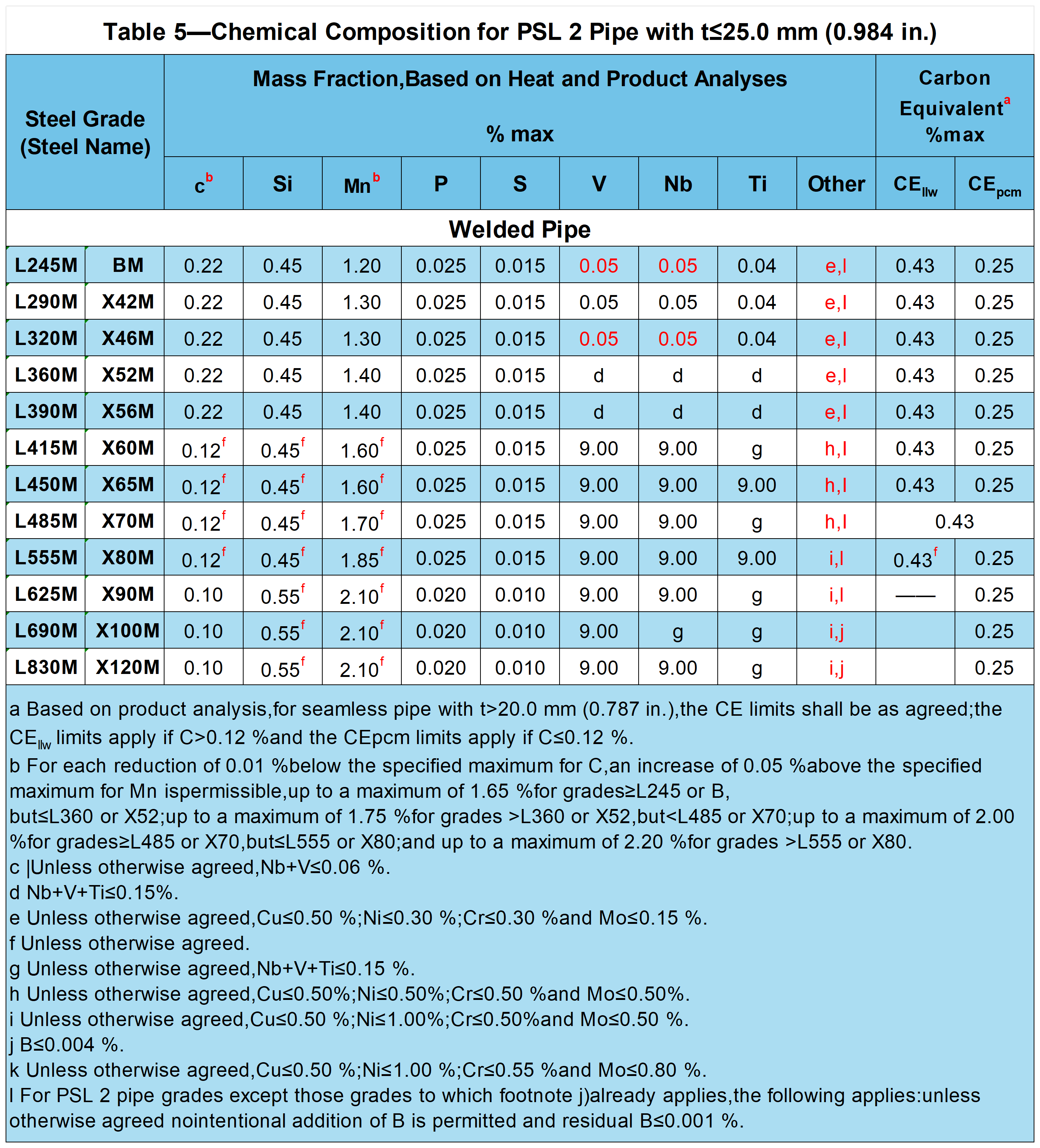

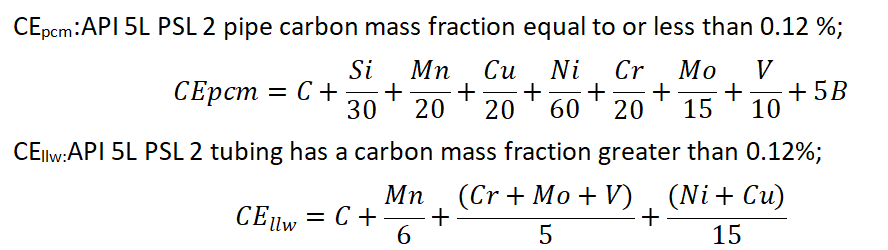

Sebopeho sa Lik'hemik'hale

Mokhoa oa Teko: Sheba ISO 9769 kapa ASTM A751.

Sebopeho sa lik'hemik'hale tsa API 5L PSL1 le API 5L PSL2 pipe ea tšepe t> 25.0 mm (0.984 in) e tla khethoa ka lipuisano tse thehiloeng ho metsoako ea lik'hemik'hale litafoleng tse lumellanang.

Sebopeho sa Lik'hemik'hale bakeng sa PSL 1 Pipe e nang le t≤25.0 mm (0.984 in.)

Sebopeho sa Lik'hemik'hale bakeng sa PSL 2 Pipe e nang le t≤25.0 mm (0.984 in.)

Tensile Properties

Mekhoa ea Teko: E tla etsoa ho latela ISO 6892-1 kapa ASTM A370.

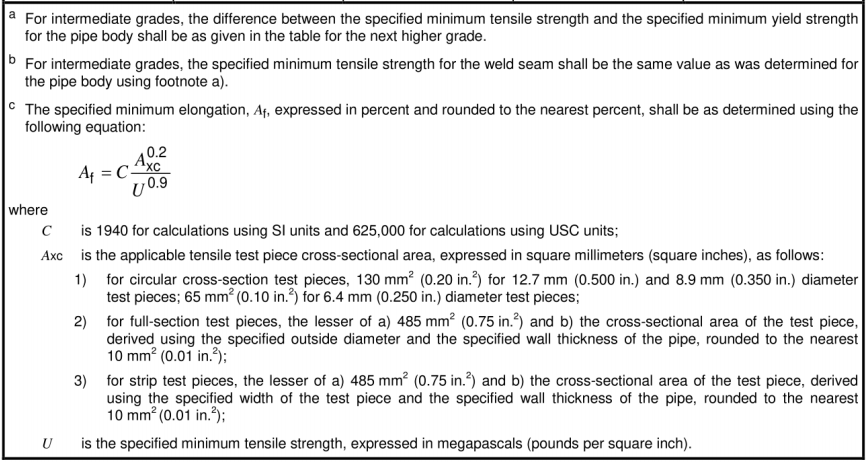

Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 1 Pipe

| Letlapa la 6-Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 1 Pipe | ||||

| Phaephe Kereiti | Pipe 'Mele oa Pipe e Seamless le e Welded | Weld Seam ea EW, LW, SAW, le Pipe ea KHOMO | ||

| Hlahisa Matlaa Rho.5 MPa(psi) | Matla a tšepea Rm MPa(psi) | Elongation (ho 50 mm kapa 2 in.) Af % | Matla a tšepeb Rm MPa(psi) | |

| min | min | min | min | |

| L175 kapa A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| L175P kapa A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 kapa A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 kapa B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 kapa X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| L320 kapa X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 kapa X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| L390 kapa X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 kapa X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| L450 kapa X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| L485 kapa X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

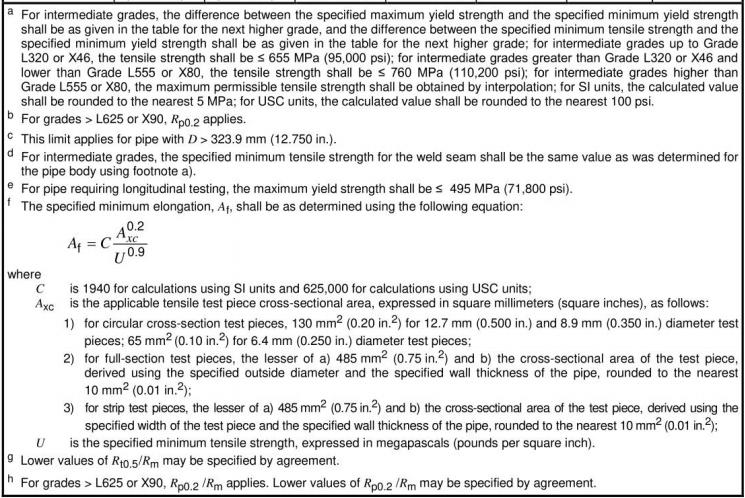

Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 2 Pipe

| Letlapa la 7-Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 2 Pipe | |||||||

| Phaephe Kereiti | Pipe 'Mele oa Pipe e Seamless le e Welded | Weld Seam ea HFW BONA le Pipe ea CoW | |||||

| Hlahisa Matlaa Rto.5 MPa(psi) | Matla a tšepea Rm MPa (psi) | Karolelanoac Rt0.5/Rm | Elongation (ka 50 mm kapa 2 in.) Af % | Tensile Matlad Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R kapa BR L245N kapa BN L245Q kapa BQ L245M kapa BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R kapa X42R L290N kapa X42N L290Q kapa X42Q L290M kapa X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N kapa X46N L320Q kapa X46Q L320M kapa X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N kapa X52N L360Q kapa X52Q L360M kapa X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N kapa X56N L390Q kapa X56Q L390M kapa X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N kapa X56N L390Q kapa X56Q L390M kapa X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N kapa X60N L415Q kapa X60Q L415M kapa X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q kapa X65Q L450M kapa X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q kapa X70Q L485M kapa X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q kapa X80Q L555M kapa X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M kapa X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q kapa X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M kapa X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q kapa X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M kapa X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Bolelele ba peresente nakong ea khefu bo tla tlalehoa bakeng sa mehlala e nang le bolelele ba 50 mm (2 in).

Bakeng sa mehlala e nang le bolelele bo ka tlase ho 50 mm (2 in), bolelele nakong ea khefu bo tla fetoloa ho bolelele ba 50 mm (2 in) ho latela ISO 2566-1 kapa ASTM A370.

Teko ea Khatello ea Hydrostatic

Mokhoa oa teko: API 5L 10.2.6.

Mefuta eohle ea phala e se nang seamless (SMLS) le phala e cheselitsoeng e nang le D ≤ 457 mm (18.000 in) e tla ba le nako ea botsitso e seng ka tlase ho metsotsoana e 5.phala e cheselitsoeng e nang le D> 457 mm (18.000 in) e tla ba le nako ea botsitso e seng ka tlase ho metsotsoana e 10.

Bend Test

Mekhoa ea Teko: Teko ea ho kobeha e tla lumellana le litlhoko tsa ISO 8491 kapa ASTM A370.

Ha ho karolo ea mohlala e tla petsoha 'me cheselle e ke ke ea peperana.

Sehlopha sa L175P/A25P ke tšepe e ntlafalitsoeng ea phosphorus e fanang ka ts'ebetso e ntle ea likhoele ho feta tšepe ea L175/A25 empa ho thata ho e koba.

Teko e bataletseng

Mekhoa ea Teko: Teko ea compression e tla lumellana le litlhoko tsa ISO 8492 kapa ASTM A370.

Sebaka se pakeng tsa lipoleiti tse peli e tla ba hoo ho se nang ho phunyeha ha weld ho tla etsahala ho fihlela sebaka se boletsoeng se fihlile.

Tataiso ea ho Koba Teko

Mekhoa ea Teko: Teko e tataisoang ea ho koba e tla lumellana le litlhoko tsa ISO 5173 kapa ASTM A370.

Tlhahlobo ea boima

Mokhoa oa teko: Teko ea boima ho latela ISO 6506, ISO 6507, ISO 6508, kapa ASTM A370.

Ha makukuno a thata a belaetsang a fumanoa tlhahlobong ea ponahalo, ho lokela ho sebelisoa mochine o nkehang oa boima ba 'mele bakeng sa tlhahlobo ea boima ba 'mele.

CVN Impact Test for API 5L PSL2 Steel Pipe

Mekhoa ea Teko: Teko ea phello ea charpy e tla fihlela litlhoko tsa ASTM A370.

Teko ea DWT bakeng sa API 5L PSL2 Welded Pipe

Mokhoa oa teko: Teko ea DWT e tla ipapisa le API5L3.

Tlhahlobo ea Macro le Tlhahlobo ea Metallographic

Ho kheloha ka hare le ka ntle ho tjheseletsa ka hare ho metsi a arc welded (SAW) le combi-welded (COW) pipe e tla hlahlojoa ka tlhahlobo ea macroscopic.

Bakeng sa li-tubes tse hlokang phekolo ea mocheso oa weld, tlhahlobo ea metallurgical e tla etsoa ho netefatsa hore HAZ eohle e tšoeroe ka mocheso o nepahetseng ka lehlakoreng le feletseng la lerako.

Bakeng sa li-tubes tse sa hlokeng phekolo ea mocheso oa weld, tlhahlobo ea metallographic e tla etsoa ho netefatsa hore ha ho na martensite e setseng ea untempered.

Teko e sa Senyeheng (feela bakeng sa liphaephe tse tharo tsa morero o khethehileng tsa API 5L PSL2)

Mokhoa oa teko: API 5L Annex E.

Letšoao la Pipe le Sebaka

Lintlha tse tloaelehileng tsa ho tšoaea li-tubes tsa tšepe:

Lebitso kapa letšoao la moetsi oa liphaephe;

Ho tšoaea "API Spec 5L".(Ka kakaretso e khutsufalitsoe ho API 5L.) Lihlahisoa tse lumellanang le maemo a fetang bonngoe li ka tšoauoa ka lebitso la boemo bo bong le bo bong.

Bophara bo Kantle bo Boletsoe

Botenya ba lebota bo boletsoeng

Pipe grade (lebitso la tšepe)

Mofuta oa lipeipi

Bolelele (bolelele ba pompo ho m ho isa ho 0.01 m e haufi (ho ft ho isa ho karolo e haufi ea leshome ea leoto))

Sebaka sa matšoao a lipeipi tsa tšepe

D ≤ 48.3 mm (1.900 in) pipe ea tšepe: Li-tab tse entsoeng ka mokhoa o tsoelang pele ho latela bolelele ba phala ea tšepe kapa tse ka tiisoang ho bongata ba lipeipi tsa tšepe.

Pipe e nang le D > 48.3 mm (1.900 in):

Sebaka se ka ntle: Ho qala sebakeng se ka ntle ho phaephe e pakeng tsa 450 mm le 760 mm (1.5 ft le 2.5 ft) ho tloha pheletsong e 'ngoe ea phala.

Bokaholimo ba kahare: Qala ho tšoaea bokaholimo ba phala bonyane 150 mm (6.0 in) ho tloha pheletsong e 'ngoe ea phala.

Tekano Tekanyetso

Litekanyetso tsa lipeipi tsa machaba le tsa tikoloho tseo API 5L e lekanang le tsona kapa, maemong a itseng, khetho e 'ngoe, hammoho le palo ea litekanyetso tse ikhethileng tsa ts'ebeliso:

Litekanyetso tsa machaba le tsa libaka

1. ISO 3183 - Tekanyetso ea lipeipi tsa lefats'e bakeng sa indasteri ea oli le khase e phatlalalitsoeng ke Mokhatlo oa Machaba oa Boemo 'me e amana haufi-ufi le API 5L.

2. EN 10208 - Tekanyetso ea Europe bakeng sa lipeipi tsa tšepe bakeng sa ho tsamaisa likhase tsa mafura le metsi.

3. GB/T 9711 - Tekanyetso ea naha ea Chaena bakeng sa tsamaiso ea lipeipi tsa lipeipi indastering ea oli le khase.

4. CSA Z245.1 - Canadian Standard e koahelang pipe ea ho tsamaisa oli le khase.

5. GOST 20295 - Tekanyetso ea Serussia bakeng sa pipe ea mohala oa tšepe bakeng sa ho tsamaisa lihlahisoa tsa oli le oli.

6. IPS (Maemo a Iranian Petroleum) - Litekanyetso tsa Iranian Petroleum bakeng sa pipe ea mohala bakeng sa indasteri ea oli le khase.

7. JIS G3454, G3455, G3456 - Litekanyetso tsa Liindasteri tsa Japane bakeng sa liphaephe tsa phetisetso ea lihlopha tse fapaneng tsa khatello.

8. DIN EN ISO 3183 - Tekanyetso ea Liindasteri ea Jeremane e thehiloeng ho ISO 3183 bakeng sa pipe ea mohala.

9. AS 2885 - Tekanyetso ea Australia bakeng sa tsamaiso ea lipeipi tsa line bakeng sa ho tsamaisa oli le khase.

Maemo a Khethehileng a Kopo

1. API 5CT - Tekanyetso ea Setsi sa Amerika sa Petroleum bakeng sa casing ea seliba sa oli le li-tubing, tseo, leha li sebelisoa haholo lilibeng tsa oli, le tsona li bohlokoa indastering ea oli le khase.

2. ASTM A106 - Mokhatlo oa Amerika oa Teko le Lisebelisoa bakeng sa pipe ea tšepe e se nang seamless le e cheselitsoeng bakeng sa tšebeletso e phahameng ea mocheso.

3. ASTM A53 - Tekanyetso ea Setsi sa Naha sa Teko le Lisebelisoa bakeng sa peipi ea tšepe ea khabone e seamless le e cheselitsoeng, eo hangata e sebelisetsoang ho tsamaisa mokelikeli mochesong oa kamore kapa mocheso o tlase.

4. ISO 3834 - Tekanyetso ea Mokhatlo oa Machaba oa Boemo bakeng sa litlhoko tsa boleng, e shebaneng le litsamaiso tsa netefatso ea boleng ba litšepe tse cheselitsoeng.

5. dnv-os-f101 - Tekanyetso ea sechaba ea Norway bakeng sa lipeipi tsa liphaephe tse tsamaeang ka tlas'a metsi bakeng sa lipeipi tsa phetisetso ea oli le khase kantle ho leoatle.

6. MSS SP-75 - Tekanyetso ea Mokhatlo oa Baetsi ba Maemo e shebaneng le matla a phahameng, lipeipi tsa tšepe tse nang le bophara bo boholo ba selika-likoe.

Taolo ea Boleng le Maemo a Tšoanelehang a Tikoloho

1. NACE MR0175/ISO 15156 - Litlhoko tsa lisebelisoa tse sebelisoang ho ntšoa ha oli le khase libakeng tse nang le sebabole tse nang le hydrocarbon, tseo, leha li amehile haholo ka khetho ea thepa, li bohlokoa bakeng sa ho netefatsa ho hanyetsa ho bola ha thepa e sebelisoang indastering ea oli le khase.

Lihlahisoa tsa rona tse Amanang

API 5L PSL1&PSL2 GR.B Longitudinal Submerged-arc Peipi e Welded

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Pipe ya Tshipi ya Carbon

API 5L GR.B Botenya Bo boima ba Lebota Peipi e Seamless bakeng sa Tshebetso ea Mechini

API 5L Gr.X52N PSL 2 Seamless Steel Pipe ACC.To IPS-M-PI-190(3) & NACE MR-01-75 bakeng sa tshebeletso e bolila

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Oli le Gas Carbon Seamless Steel Pipe

API 5L GR.B Seamless Line Pipe bakeng sa Khatello le Sebopeho

API 5L/ASTM A106/ASTM A53 Gr.B Seamless Carbon Steel Pipe

BotopSteel ke Setsebi sa ChaenaMoetsi le Bafani ba Lipeipi tsa tšepe tse cheselitsoeng tsa CarbonHo feta Lilemo tse 16 ka Lithane tse 8000+ tsa Seamless Linepipe tse fumanehang ka har'a Stoko Khoeli e 'ngoe le e 'ngoe.Re se re ikemiselitse ho u araba nakong ea lihora tse 24 hang ka mor'a ho fumana kopo e le 'ngoe le ho hlahisa melemo le mekhatlo e sa lekanyetsoang ho pota-pota bokhoni.

Tags: API 56 46th, Dimensional Deviations, PSL1, PSL2,barekisi, bahlahisi, lifeme, barekisi ba thepa, lik'hamphani, thekiso, theko, qotsulo, bongata, thekiso, theko.

Nako ea poso: Mar-22-2024