AS/NZS 1163e totobatsa likarolo tse batang tse entsoeng ka mokhoa o batang, tse hanyetsanang, tse entsoeng ka tšepe tse se nang letho bakeng sa lisebelisoa tse akaretsang tsa sebopeho le boenjiniere ntle le kalafo e latelang ea mocheso.

Mekhoa e tloaelehileng e sebetsang ho Australia le New Zealand.

Likonopo tsa ho Tsamaisa

Classification by Cross-section Shape

Sehlopha sa AS/NZS 1163 sa Mahareng

Lisebelisoa tse so ntlafatsoe

Mokhoa oa Tlhahiso

AS/NZS 1163 Sebopeho sa Lik'hemik'hale

Tlhahlobo ea AS/NZS 1163 Tensile

AS/NZS 1163 Impact Test

Cold Flattening Test

Tlhahlobo e sa senyeheng

Mamello bakeng sa Sebopeho le 'Misa

Mamello ea Bolelele

AS/NZS 1163 SSHS Lethathamo la Boholo ba Pipe le Litafole tsa Boima bo Kenyellelitsoeng

Tokiso ea Mefokolo ea Kantle le ea Litlolo

Sesetiloe

AS/NZS 1163 Ho tšoaea

Likopo tsa AS/NZS 1163

Lihlahisoa tsa rona tse Amanang

Classification by Cross-section Shape

Mefuta e meraro ho AS/NZS 1163 e ka aroloa ho latela sebopeho sa karolo ea sefapano, e leng:

circular hollow sections (CHS)

Likarolo tse sekoti tse khutlonnetsepa (RHS)

Square Hollow Sections (SHS)

Sepheo sa sehlooho sena ke ho akaretsa litlhoko tsa li-tubes tsa tšepe tse nang le likarolo tse chitja tse sekoti.

Sehlopha sa AS/NZS 1163 sa Mahareng

Limaraka tse tharo ho AS/NZS 1163 ho ipapisitsoe le bonyane ba matla a chai (MPA) a sehlahisoa se felileng:

C250, C350 le C450.

E tsamaellanang le 0 ℃ boemo ba teko ea mocheso o tlase oo phala ea tšepe e ka kopanang le eona:

C250L0, C350L0 le C450L0.

Tekanyetso e boetse e bolela hore tsela e nepahetseng ea ho hlalosa boemo ba pipe ea tšepe ke:

AS/NZS 1163-C250 or AS/NZS 1163-C250L0

Lisebelisoa tse so ntlafatsoe

khoele e biditsoeng ka ho tjhesa kapa khoele e kentsoeng ka serame

Khoeli e bilikang ka serame ke khoele e bilikang e chesang e phokotsehileng ho feta 15%.Coil e tla ba le potoloho ea subcritical annealing e khutlisetsang sebopeho mme e thehe lithollo tse ncha tsa ferrite.Lintho tse hlahisoang li tšoana le coil e chesang e chesang.

Litšepe tse khabane li hlalosoa e le thepa e tala bakeng sa likhoele tsa tšepe.Litšepe tse nang le boholo ba lijo-thollo tsa austenitic tsa nomoro ea 6 kapa ho feta ha li lekoa ho latela AS 1733.

Ts'epe ena e hlahisoa ka mokhoa oa Basic Oxygen Method (BOS) kapa Electric Arc Furnace (EAF) mme e ka hloekisoa ka Vacuum Arc Remelting (VAR), Electroslag Remelting (ESR), kapa ka mekhoa ea bobeli ea ho etsa tšepe e kang Vacuum Degassing kapa Calcium Injection. .

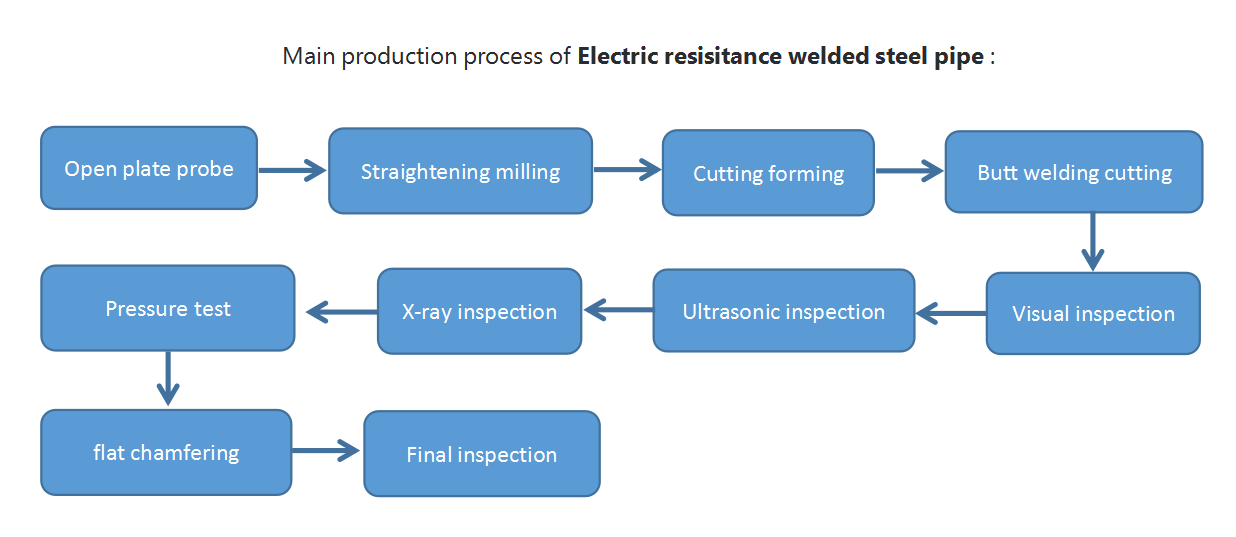

Mokhoa oa Tlhahiso

Sehlahisoa se feliloeng sa sekoti se tla etsoa ka mokhoa o batang oa ho etsa le ho sebelisoaelectric resistance-welding-welding (ERW)mekhoa ea ho kopanya mahlakore a hlobolisa.

The weld seam e lokela ho ba longitudinal 'me e tla tlosa pherekano e ka ntle.

Ha ho na ho ba le phekolo e latelang ea mocheso ka kakaretso sehlahisoa se felileng.

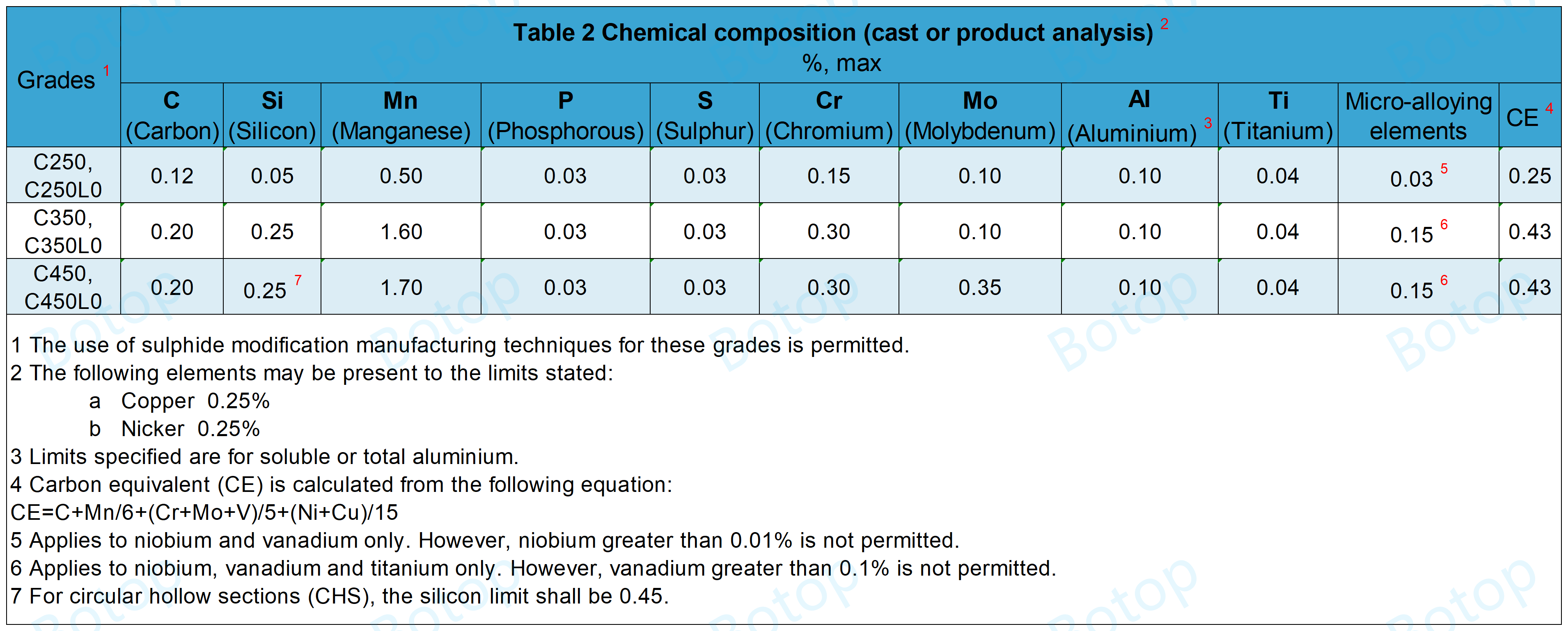

AS/NZS 1163 Sebopeho sa Lik'hemik'hale

AS/NZS 1163 tekong ea sebopeho sa lik'hemik'hale e arotsoe ka maemo a mabeli:

nyeoe e 'ngoe ke lisebelisoa tse tala bakeng sa tlhahlobo ea sebopeho sa lik'hemik'hale,

e 'ngoe ke tlhahlobo e phethiloeng ea lipeipi tsa tšepe.

Tlhahlobo ea ho Lahlela Litšepe

Tlhahlobo ea tšepe ea tšepe e tla etsoa ho tloha mocheso o mong le o mong ho fumana likarolo tsa likarolo tse boletsoeng.

Maemong ao ho sa khoneheng ho fumana lisampole ho tsoa tšepeng e metsi, tlhahlobo ea lisampole tsa liteko tse nkuoeng ho latela AS/NZS 1050.1 kapa ISO 14284 e ka tlalehoa e le tlhahlobo ea cast.

Tlhahlobo ea tšepe ea tšepe e tla lumellana le meeli ea kereiti e nepahetseng e fanoengLethathamo la 2.

Tlhahlobo ea Lik'hemik'hale ea Sehlahisoa se Feletseng

AS/NZS 1163ha e fane ka taelo ea tlhahlobo ea metsoako ea lik'hemik'hale ea sehlahisoa sa ho qetela.

Haeba tlhahlobo e etsoa, e lokela ho lumellana le meeli e fanoengLethathamo la 2le mamello e fanoengLethathamo la 3.

| TABLE 3 Mamello ea ho mamella tlhahlobo ea lihlahisoa bakeng sa limaraka tse fanoeng Lethathamong la 2 | |

| Element | Mamello ho feta tekanyo e phahameng |

| C(Khabone) | 0.02 |

| Si(Silikone) | 0.05 |

| Mn(Manganese) | 0.1 |

| P(Phosphorous) | 0.005 |

| S(Sebabole) | 0.005 |

| Cr(Chromium) | 0.05 |

| Ni(Nickel) | 0.05 |

| Mo(Molybdenum) | 0.03 |

| Cu(Koporo) | 0.04 |

| AI(Aluminium) (kakaretso) | -0.005 |

| Micro-alloying elements (niobium le vanadium feela) bakeng saMephato C250, C250L0 | 0.06 e nang le niobium e seng kholo ho feta 0.020 |

| Micro-alloying elements (niobium, vanadium, le titanium feela) bakeng sa MephatoC350, C350L0, C450, C450L0 | 0.19 e nang le vanadium e seng kholo ho feta 0.12 |

Tlhahlobo ea AS/NZS 1163 Tensile

Mokhoa oa liteko: AS 1391.

Pele ho tlhahlobo e tsitsitseng, mohlala o lokela ho futhumatsoa ho mocheso o seng ka tlase ho metsotso e 15 ka ho futhumatsa mocheso o pakeng tsa 150 ° C le 200 ° C.

| Kereiti | Bonyane Khefutsa matla | Bonyane tsitsinyeha matla | Bonyane elongation joalo ka karolo ea bolelele ba 5.65√S0 | ||

| etsa/t | |||||

| ≤ 15 | >15 ≤30 | >30 | |||

| MPA | MPA | % | |||

| C250, C250L0 | 250 | 320 | 18 | 20 | 22 |

| C350, C350L0 | 350 | 430 | 16 | 18 | 20 |

| C450, C450L0 | 450 | 500 | 12 | 14 | 16 |

AS/NZS 1163 Impact Test

Mokhoa oa teko: ho 0°C ho latela AS 1544.2.

Pele ho tlhahlobo ea phello, mohlala o tla futhumatsoa ka mocheso ho pakeng tsa 150 ° C le 200 ° C nako e seng ka tlase ho metsotso e 15.

| Kereiti | Mocheso oa teko | Matla a fokolang, J | |||||

| Boholo ba sengoathoana sa teko | |||||||

| 10 limilimithara × 10 limilimithara | 10 limilimithara × 7.5 limilimithara | 10 limilimithara × 5 limilimithara | |||||

| Karolelano ea liteko tse 3 | Motho ka mong teko | Karolelano ea liteko tse 3 | Motho ka mong teko | Karolelano ea liteko tse 3 | Motho ka mong teko | ||

| C250L0 C350L0 C450L0 | 0℃ | 27 | 20 | 22 | 16 | 18 | 13 |

Cold Flattening Test

Sekhechana sa teko se tla batalatsoa ho fihlela sebaka se pakeng tsa libaka ke 0.75 etsa kapa ka tlase.

E se ke ea bontša matšoao a mapetsong kapa sekoli.

Tlhahlobo e sa senyeheng

Joalo ka ntho e sa tlameheng, li-welds tse likarolong tse sekoti tsa meaho e cheselitsoeng li ka etsoa tlhahlobo e sa senyeheng (NDE).

Mamello bakeng sa Sebopeho le 'Misa

| Mofuta | Range | Mamello |

| Sebopeho | - | Likarolo tse chitja tse sekoti |

| Litekanyo tsa kantle(etsa) | - | ± 1%, ka bonyane ba ± 0.5 mm le boholo ba ± 10 mm |

| Botenya (t) | ho fihlela≤406,4 limilimithara | 土10% |

| ho fihlela ho 406.4 limilimithara | ± 10% ka boholo ba ±2 mm | |

| Hantle-ntle (o) | Botenya ba bokantle(bo)/botenya ba lebota(t)≤100 | ±2% |

| Ho otloloha | bolelele bohle | 0.20% |

| Boima (m) | boima bo boletsoeng | ≥96% |

Botenya:

Botenya (t) bo tla lekanyetsoa sebakeng se seng ka tlase ho 2t (Moelelo oa botenya ba 2x) kapa 25 mm, ho sa tsotellehe hore na ke bofe bo fokolang, ho tloha ho seam ea weld.

ntle ho pota:

Ho tsoa ho pota-pota (o) ho fanoa ke:o=(etsamax-etsamin)/etsa×100

Mamello ea Bolelele

| Mofuta oa bolelele | Range m | Mamello |

| Bolelele bo sa reroang | 4m ho isa ho 16m ka sebaka sa 2m ka ngoe ntho ea taelo | 10% ea likarolo tse fanoeng e ka ba ka tlase ho palo e tlase bakeng sa mofuta o laetsoeng empa e se ka tlase ho 75% ea bonyane |

| bolelele bo sa hlalosoang | TSOHLE | 0-+100mm |

| Bolelele bo nepahetseng | ≤ 6m | 0-+5 limilimithara |

| >6m ≤10m | 0-+15 limilimithara | |

| >10m | 0-+(5+1mm/m)mm |

AS/NZS 1163 SSHS Lethathamo la Boholo ba Pipe le Litafole tsa Boima bo Kenyellelitsoeng

Ho AS/NZS 1163, ho fanoe ka manane a likarolo tse tloaelehileng tse entsoeng ka serame (SSHS) Australia le New Zealand.

Manane ana a fana ka mabitso a likarolo, boholo ba mabitso, litšoaneleho tsa likarolo, le litšoaneleho.

| Kantle Diameter | Botenya | Massperunitlength | Kantle sebaka sa bokahodimo | Karolelano | |

| do | t | ka bolelele ba yuniti | ka boima ba yuniti | ||

| mm | mm | kg/m | m²/m | m²/t | etsa/t |

| 610.0 | 12.7CHS | 187 | 1.92 | 10.2 | 48.0 |

| 610.0 | 9.5CHS | 141 | 1.92 | 13.6 | 64.2 |

| 610.0 | 6.4CHS | 95.3 | 1.92 | 20.1 | 95.3 |

| 508.0 | 12.7CHS | 155 | 1.60 | 10.3 | 40.0 |

| 508.0 | 9.5CHS | 117 | 1.60 | 13.7 | 53.5 |

| 508.0 | 6.4CHS | 79.2 | 1.60 | 20.2 | 79.4 |

| 457.0 | 12.7CHS | 139 | 1.44 | 10.3 | 36.0 |

| 457.0 | 9.5CHS | 105 | 1.44 | 13.7 | 48.1 |

| 457.0 | 6.4CHS | 71.1 | 1.44 | 20.2 | 71.4 |

| 406.4 | 12.7CHS | 123 | 1.28 | 10.4 | 32.0 |

| 406.4 | 9.5CHS | 93.0 | 1.28 | 13.7 | 42.8 |

| 406.4 | 6.4CHS | 63.1 | 1.28 | 20.2 | 63.5 |

| 355.6 | 12.7CHS | 107 | 1.12 | 10.4 | 28.0 |

| 355.6 | 9.5CHS | 81.1 | 1.12 | 13.8 | 37.4 |

| 355.6 | 6.4CHS | 55.1 | 1.12 | 20.3 | 55.6 |

| 323.9 | 2.7CHS | 97.5 | 1.02 | 10.4 | 25.5 |

| 323.9 | 9.5CHS | 73.7 | 1.02 | 13.8 | 34.1 |

| 323.9 | 6.4CHS | 50.1 | 1.02 | 20.3 | 50.6 |

| 273.1 | 9.3CHS | 60.5 | 0.858 | 14.2 | 29.4 |

| 273.1 | 6.4CHS | 42.1 | 0.858 | 20.4 | 42.7 |

| 273.1 | 4.8CHS | 31.8 | 0.858 | 27.0 | 56.9 |

| 219.1 | 8.2CHS | 42.6 | 0.688 | 16.1 | 26.7 |

| 219.1 | 6.4CHS | 33.6 | 0.688 | 20.5 | 34.2 |

| 219.1 | 4.8CHS | 25.4 | 0.688 | 27.1 | 45.6 |

| 168.3 | 71CHS | 28.2 | 0.529 | 18.7 | 23.7 |

| 168.3 | 6.4CHS | 25.6 | 0.529 | 20.7 | 26.3 |

| 168.3 | 4.8CHS | 19.4 | 0.529 | 27.3 | 35.1 |

| 165.1 | 5.4CHS | 21.3 | 0.519 | 24.4 | 30.6 |

| 165.1 | 5.0CHS | 19.7 | 0.519 | 26.3 | 33.0 |

| 165.1 | 3.5CHS | 13.9 | 0.519 | 37.2 | 47.2 |

| 165.1 | 3.0CHS | 12.0 | 0.519 | 43.2 | 55.0 |

| 139.7 | 5.4CHS | 17.9 | 0.439 | 24.5 | 25.9 |

| 139.7 | 5.0CHS | 16.6 | 0.439 | 26.4 | 27.9 |

| 139.7 | 3.5CHS | 11.8 | 0.439 | 37.3 | 39.9 |

| 139.7 | 3.0CHS | 10.1 | 0.439 | 43.4 | 46.6 |

| 114.3 | 6.0CHS | 16.0 | 0.359 | 22.4 | 19.1 |

| 114.3 | 5.4CHS | 14.5 | 0.359 | 24.8 | 21.2 |

| 114.3 | 4.8CHS | 13.0 | 0.359 | 27.7 | 23.8 |

| 114.3 | 4.5CHS | 12.2 | 0.359 | 29.5 | 25.4 |

| 114.3 | 3.6CHS | 9.83 | 0.359 | 36.5 | 31.8 |

| 114.3 | 3.2CHS | 8.77 | 0.359 | 41.0 | 35.7 |

| 101.6 | 5.0CHS | 11.9 | 0.319 | 26.8 | 20.3 |

| 101.6 | 4.0CHS | 9.63 | 0.319 | 33.2 | 25.4 |

| 101.6 | 3.2CHS | 7.77 | 0.319 | 41.1 | 31.8 |

| 101.6 | 2.6CHS | 6.35 | 0.319 | 50.3 | 39.1 |

| 88.9 | 5.9CHS | 12.1 | 0.279 | 23.1 | 15.1 |

| 88.9 | 5.0CHS | 10.3 | 0.279 | 27.0 | 17.8 |

| 88.9 | 5.5CHS | 11.3 | 0.279 | 24.7 | 16.2 |

| 88.9 | 4.8CHS | 9.96 | 0.279 | 28.1 | 18.5 |

| 88.9 | 4.0CHS | 8.38 | 0.279 | 33.3 | 22.2 |

| 88.9 | 3.2CHS | 6.76 | 0.279 | 41.3 | 27.8 |

| 88.9 | 2.6CHS | 5.53 | 0.279 | 50.5 | 34.2 |

| 76.1 | 5.9CHS | 10.2 | 0.239 | 23.4 | 12.9 |

| 76.1 | 4.5CHS | 7.95 | 0.239 | 30.1 | 16.9 |

| 76.1 | 3.6CHS | 6.44 | 0.239 | 37.1 | 21.1 |

| 76.1 | 3.2CHS | 5.75 | 0.239 | 41.6 | 23.8 |

| 76.1 | 2.3CHS | 4.19 | 0.239 | 57.1 | 33.1 |

| 60.3 | 5.4CHS | 7.31 | 0.189 | 25.9 | 11.2 |

| 60.3 | 4.5CHS | 6.19 | 0.189 | 30.6 | 13.4 |

| 60.3 | 3.6CHS | 5.03 | 0.189 | 37.6 | 16.8 |

| 48.3 | 5.4CHS | 5.71 | 0.152 | 26.6 | 8.9 |

| 48.3 | 4.0CHS | 4.37 | 0.152 | 34.7 | 12.1 |

| 48.3 | 3.2CHS | 3.56 | 0.152 | 42.6 | 15.1 |

| 42.4 | 4.9CHS | 4.53 | 0.133 | 29.4 | 8.7 |

| 42.4 | 4.0CHS | 3.79 | 0.133 | 35.2 | 10.6 |

| 42.4 | 3.2CHS | 3.09 | 0.133 | 43.1 | 13.3 |

Tokiso ea Mefokolo ea Kantle le ea Litlolo

Ponahalo

Sehlahisoa se phethiloeng ha se na likoli tse senyang botšepehi ba sebopeho sa thepa.

Ho Tlosa Mefokolo ea Bokahohle

Ha liphoso tse ka holim'a metsi li tlosoa ka lehlabathe, sebaka sa lehlabathe se tla ba le phetoho e ntle.

Botenya bo setseng ba lerako sebakeng sa lehlabathe ha boa lokela ho ba ka tlase ho 90% ea botenya ba lebitso.

Tokiso ea Weld ea Mefokolo ea Bokaholimo

Li-welds li tla utloahala, li tjheseletsa li kopanngoe ka botlalo ntle le ho cheka kapa ho fetana.

Tšepe ea weld e tla hlahisa bonyane 1.5 mm ka holim'a bokaholimo, 'me tšepe e shebileng e tlosoe ka ho sila ka holim'a bokaholimo.

Sesetiloe

Likarolo tse chitja tse pota-potiloeng ka masenke tse bophara bo ka ntle ba ≤ 60.3 limilimithara le likarolo tse ling tse nang le sekoti tse nang le litekanyo tse lekanang li tla khona ho mamella kobeho ea 90 ° ho potoloha mandrel e grooved.

Ho roala ka masenke ho ke ke ha bontša matšoao a mapetsong kapa likoli ka mor'a ts'ebetso ea ho kobeha.

AS/NZS 1163 Ho tšoaea

Se latelang se hlaha bonyane hanngoe ho tšoaea phala ea tšepe.

(a) Lebitso la moetsi kapa letšoao, kapa bobeli.

(b) Boitsebahatso ba sebaka sa moetsi kapa leloala, kapa ka bobeli.

(c) Boitsebahatso bo ikgethang, bo ka latelwang morao, bo tla ba ka mokgwa o le mong kapa ka bobedi ho tse latelang:

(i) Nako le letsatsi la tlhahiso ea sehlahisoa.

(ii) Nomoro e ikhethileng ea boitsebahatso bakeng sa taolo ea boleng/tiisetso le sepheo sa ho latedisa.

Mohlala:

BOTOP CHINA AS/NZS 1163-C350L0 457×12.7CHS×12000MM PIPE NO.001 HEAT NO.000001

Likopo tsa AS/NZS 1163

Mehaho ea Mehaho le Boenjiniere: E sebelisoa meahong ea tšehetso ea meaho, joalo ka meaho e mekato e phahameng le mabala a lipapali.

Mehaho ea Lipalangoang: E sebelisoa ha ho hahoa marokho, lithanele le meaho ea liporo.

Oli, khase le merafo: tse sebelisoang ho aheng lirafshoa tsa oli, lisebelisoa tsa merafo, le litsamaiso tse tsamaisanang le tsona.

Liindasteri tse ling tse boima: ho kenyelletsa le meaho ea foreimi bakeng sa limela tsa tlhahiso le mechini e boima.

Lihlahisoa tsa rona tse Amanang

Re moetsi oa liphaephe tsa tšepe tsa tšepe tsa boleng bo holimo tse cheselitsoeng le mofani oa thepa ea tsoang Chaena, hape re na le setoko sa liphaephe tsa tšepe tse se nang seam, tse u fang mefuta e mengata ea tharollo ea lipeipi tsa tšepe!

Tags: as/nzs 1163,chs, structural, erw, barekisi, bahlahisi, lifeme, li-stock, lik'hamphani, thekiso, theko, qotso, bongata, thekiso, litšenyehelo.

Nako ea poso: Apr-21-2024