ASTM A513 tšepeke phala ea tšepe ea carbon le alloy le tube e entsoeng ka tšepe e chesang e chesang kapa e batang e le lisebelisoa tse tala ka mokhoa oa ho tjheseletsa ka motlakase (ERW), o sebelisoang haholo mefuteng eohle ea mekhoa ea mechine.

Likonopo tsa ho Tsamaisa

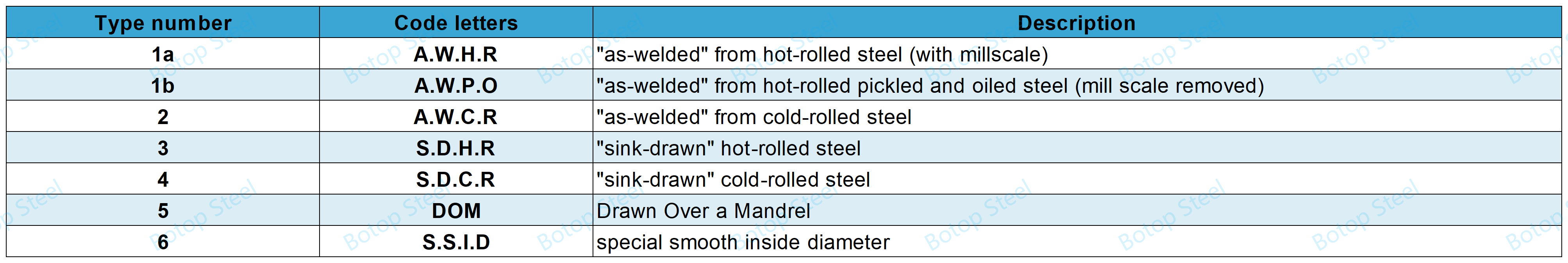

Mefuta le Maemo a Thermal a ASTM A513

Karolelano ea Kereiti

ASTM A513 boholo Range

Sebopeho sa Karolo e Sekoti

Lisebelisoa tse so fetoloe

Mekhoa ea Tlhahiso ea ASTM A513

Kalafo e Chesang

Welding Seam Ho sebetsana le

Sebopeho sa lik'hemik'hale sa ASTM A513

Thepa ea Mechini ea ASTM A513

Tlhahlobo ea boima

Teko e bataletseng

Flaring Test

Hydrostatic Test Round Tubing

Teko ea Motlakase e sa Senyeheng

Mamello bakeng sa Round Pipe Dimensions

Mamello ea Sekwere le Rectangular Tube Dimensions

Ponahalo

Ho roala

Ho tshwaya

Lisebelisoa tsa ASTM A513

Melemo ea Rōna

Mefuta le Maemo a Thermal a ASTM A513

Karohano e itšetlehile ka maemo a fapaneng kapa mekhoa ea phala ea tšepe.

Karolelano ea Kereiti

ASTM A513 e ka ba tšepe ea carbon kapa alloy, ho latela ts'ebeliso ea 'nete.

Tšepe ea Carbon

MT 1010, MT 1015, MT X 1015, MT 1020, MT X 1020.

1006, 1008, 1009, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1023, 1024, 1026, 1025, 1 1033, 1035, 1040, 1050, 1060, 1524.

Lisebelisoa tsa tšepe

1340, 4118, 4130, 4140, 5130, 8620, 8630.

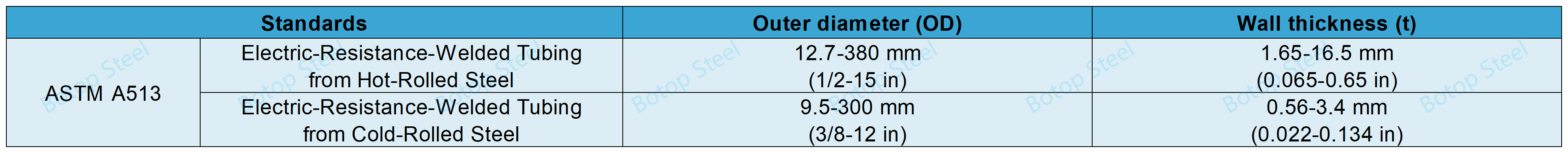

ASTM A513 boholo Range

Sebopeho sa Karolo e Sekoti

Ratoa

Sekwere kapa khutlonnetsepa

Libopeho tse ling

joalo ka e streamlined, hexagonal, octagonal, chitja ka hare le hexagonal kapa octagonal kantle, e nang le likhopo ka hare kapa kantle, tse tharo, tse chitja tsa khutlonnetsepa le D.

Lisebelisoa tse so fetoloe

Tšepe e ka etsoa ka mokhoa ofe kapa ofe.

Ho qhibiliha ho ka sehloohong ho ka kenyelletsa ho senya kapa ho hloekisa ka thōko 'me ho ka lateloa ke ho qhibiliha ha bobeli, joalo ka electro slag kapa vacuum-arc remelting.

Tšepe e ka 'na ea kenngoa ka li-ingots kapa e ka ba strand cast.

Mekhoa ea Tlhahiso ea ASTM A513

Li-tubes li tla etsoa keelectric-resistance-welded (ERW)ts'ebetso 'me e tla etsoa ka tšepe e kolobisitsoeng e chesang kapa e batang joalo ka ha ho boletsoe.

ERW pipe ke mokhoa oa ho etsa weld ka ho kopanya thepa ea tšepe ka har'a silinda le ho sebelisa khanyetso le khatello ka bolelele ba eona.

Tšepe e Chesang: Ts'ebetsong ea tlhahiso, tšepe e chesang e chesang e qala ho futhumala ka mocheso o phahameng, ho lumella tšepe hore e kenngoe ka mokhoa oa polasetiki, e leng se etsang hore ho be bonolo ho fetola sebōpeho le boholo ba tšepe. Qetellong ea ts'ebetso e chesang ea ho roala, hangata thepa e fokotsehile ebile e holofetse.

Tšepe e Batang: Litšepe tse batang li phuthoa ho ea pele ka mor'a hore thepa e pholile ho finyella boholo le sebōpeho se lakatsehang. Hangata mokhoa ona o etsoa mocheso oa kamore 'me o fella ka tšepe e nang le boleng bo holimo le litekanyo tse nepahetseng haholoanyane.

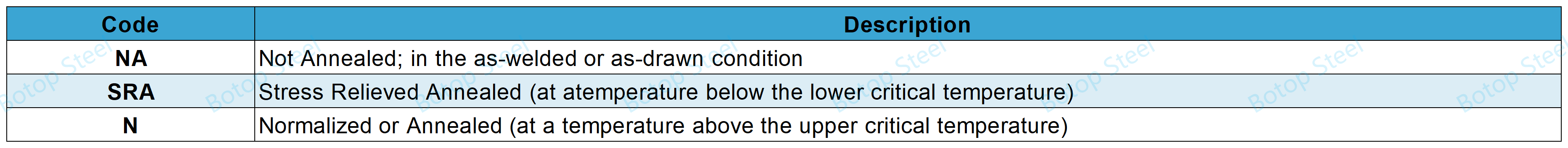

Kalafo e Chesang

Ha boemo ba mocheso bo sa hlalosoa, tube e ka fanoa ka boemo ba NA.

Ha phekolo ea ho qetela ea mocheso e hlalosoa, oxide e thata e tloaelehile.

Ha ho boletsoe sebaka se se nang oxide e se nang oxide, tube e ka 'na ea e-ba e khanyang kapa ea khabisoa ka khetho ea moetsi.

Welding Seam Ho sebetsana le

Li-welds tsa kantle li tlameha ho hloekisoa

Li-welds tsa ka hare li tla ba le litlhoko tse fapaneng tsa bophahamo ho latela Mofuta.

Litlhoko tse khethehileng li ka fumanoa ho ASTM A513, karolo ea 12.3.

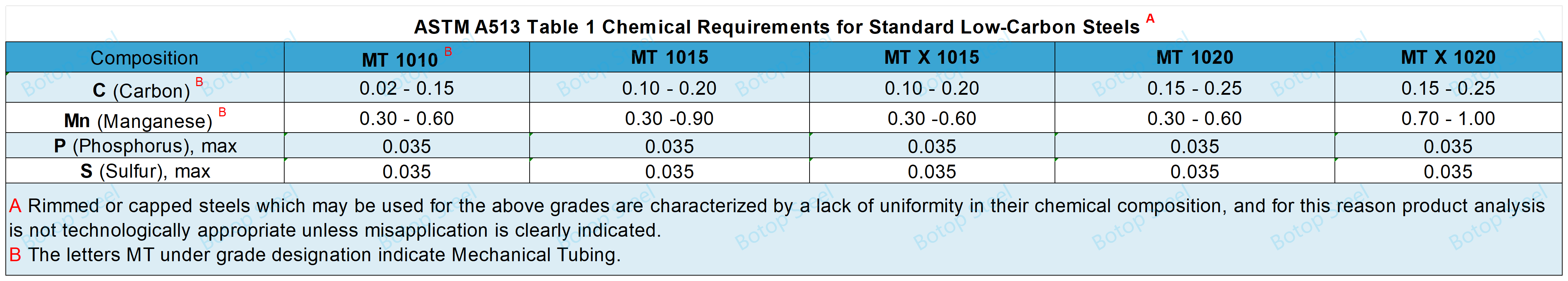

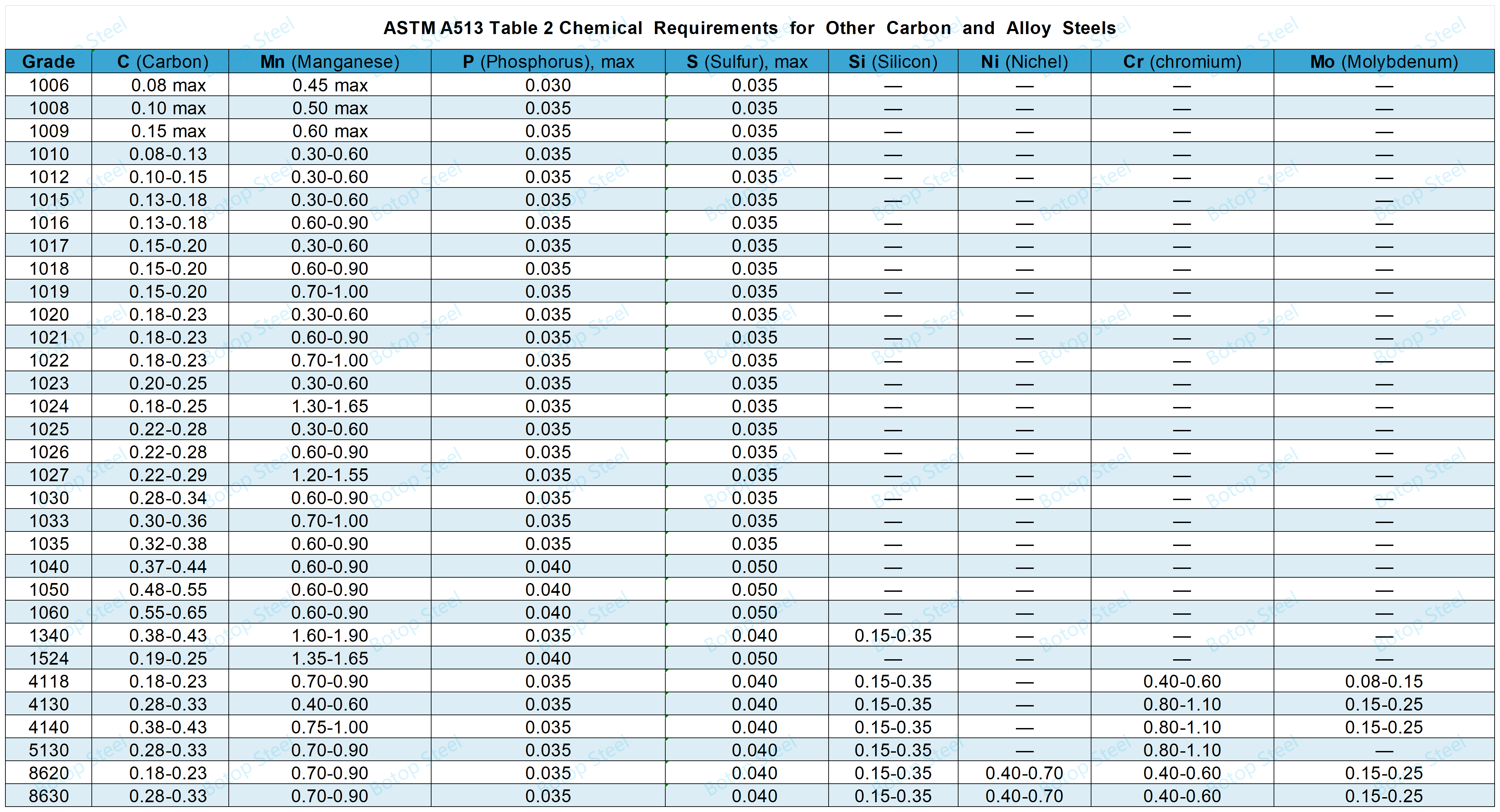

Sebopeho sa lik'hemik'hale sa ASTM A513

Tšepe e tla lumellana le litlhoko tsa sebopeho sa lik'hemik'hale tse boletsoeng ho Lethathamo la 1 kapa Lethathamo la 2.

Ha limaraka tsa carbon steel li laeloa ho tsoa ho maemo a tloaelehileng, ha ho lumelloe ho fana ka limaraka tsa alloy tse hlokang ka ho khetheha ho eketsoa ha ntho efe kapa efe ntle le e thathamisitsoeng ho Tafole ea I le ea 2.

Haeba ho se kereiti e boletsoeng, limaraka tsa MT 1010 ho isa ho MT 1020 lia fumaneha.

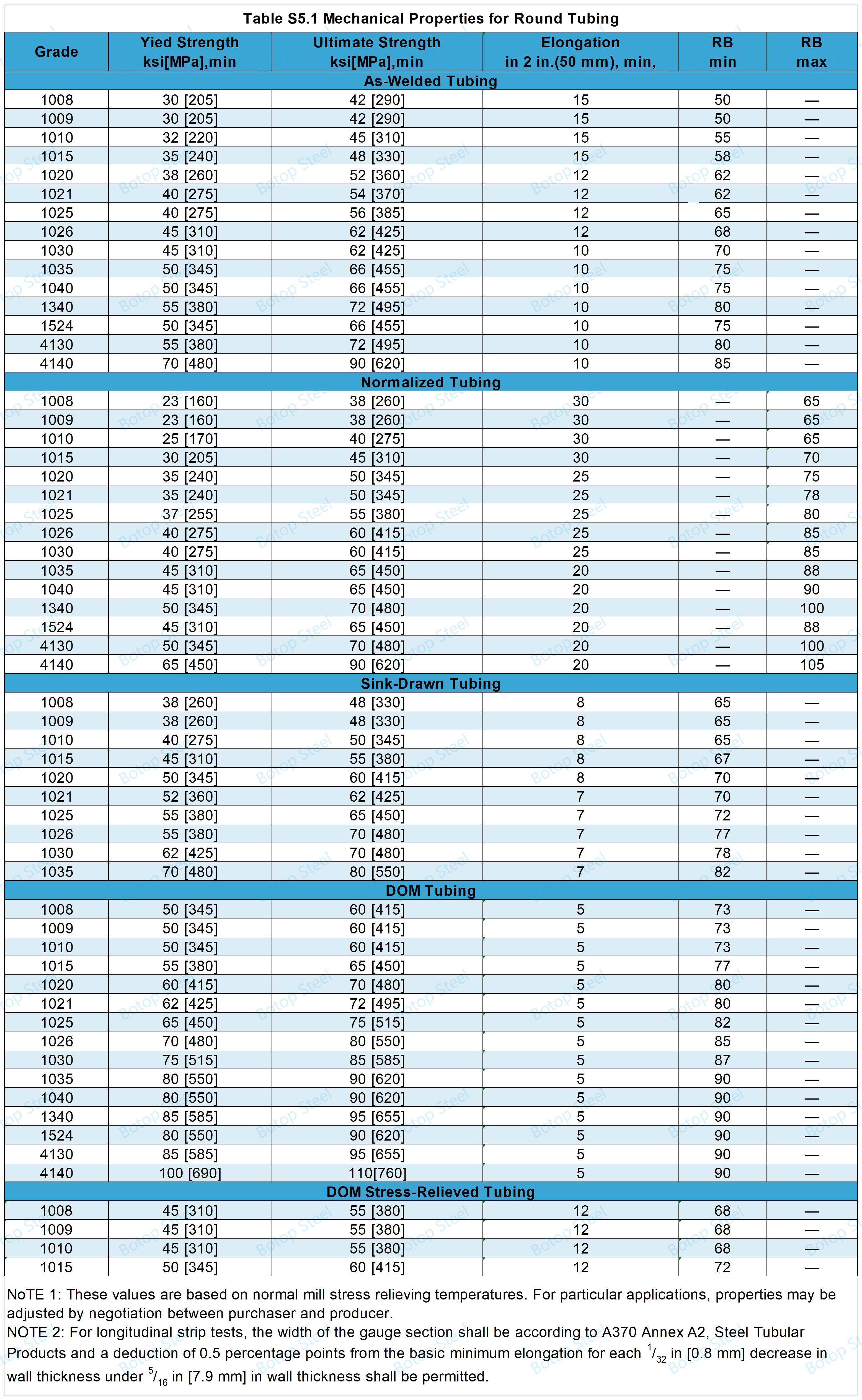

Thepa ea Mechini ea ASTM A513

Teko ea tensile e tla etsoa hang ka lotho.

Ha "Lithepa tse Hlokehang tsa Tensile" li hlalositsoe ho Theko ea Theko, li-tubing tse pota-potileng li tla lumellana le litlhokahalo tse tsitsitseng eseng hakaalo meeli ea boima bo bontšitsoeng ho Lethathamo la 5.

Tlhahlobo ea boima

1% ea li-tubes tsohle sebakeng se seng le se seng mme eseng ka tlase ho li-tubes tse 5.

Teko e bataletseng

Li-tubes tse chitja le li-tubes tse etsang libopeho tse ling ha li le chitja lia sebetsa.

Ha ho buloa ka cheselleng ho tla etsahala ho fihlela sebaka se pakeng tsa lipoleiti se le ka tlase ho karolo ea bobeli ho tse tharo ea bophara ba pele ba kantle ba tubing.

Ha ho mapetsong a tšepe ea motheo ho tla etsahala ho fihlela sebaka se pakeng tsa lipoleiti se ka tlase ho karolo ea boraro ea bophara bo ka ntle ba tubing empa ha ho joalo ka tlase ho makhetlo a mahlano ho feta lebota la tubing.

Bopaki ba ho lamination kapa thepa e chesitsoeng e ke ke ea ntshetsa pele nakong ea ho batalla, 'me weld e ke ke ea bontša mefokolo e kotsi.

Tlhokomeliso: Ha ho lekoa karo-karolelano e tlase ea D-to-t, hobane khatello e behiloeng ka lebaka la geometry e phahame ka mokhoa o sa utloahaleng ka holim'a bokahare ba libaka tsa hora ea botšelela le ea leshome le metso e 'meli, mapetsong a libaka tsena e ke ke ea e-ba lebaka la ho hana haeba karolelano ea D-to-t e ka tlase ho 10.

Flaring Test

Li-tubes tse chitja le li-tubes tse etsang libopeho tse ling ha li le chitja lia sebetsa.

Karolo ea tšupu e ka bang bolelele ba limilimithara tse 4 e tla ema e besitsoe ka sesebelisoa se nang le angle ea 60 ° ho fihlela tšupu e molomong oa mollo e atolosoa ka 15% ea bophara ba ka hare, ntle le ho phatloha kapa ho bontša mefokolo.

Hydrostatic Test Round Tubing

Li-tubing tsohle li tla fuoa tlhahlobo ea hydrostatic.

Boloka khatello e tlase ea tlhahlobo ea metsi sebakeng se seng ka tlase ho 5s.

Khatello e baloa joalo ka:

P=2St/D

P= khatello e tlase ea tlhahlobo ea hydrostatic, psi kapa MPa,

S= khatello e lumelletsoeng ea fiber ea 14,000 psi kapa 96.5 MPa,

t= botenya ba lebota bo boletsoeng, ka hare kapa mm,

D= e hlalositsoe bophara ba kantle, ka hare kapa mm.

Teko ea Motlakase e sa Senyeheng

Ke sepheo sa tlhahlobo ena ho hana liphaephe tse nang le likoli tse kotsi.

Tube e 'ngoe le e' ngoe e tla lekoa ka teko ea motlakase e sa senyeheng ho latela Practice E213, Practice E273, Practice E309, kapa Practice E570.

Mamello bakeng sa Round Pipe Dimensions

Bakeng sa tlhaiso-leseling e batsi, ka kopo sheba tafole e tsamaisanang le maemo.

Kantle Diameter

Lethathamo la 4Mamello ea Diameter bakeng sa Mofuta oa I (AWHR) Round Tubing

Lethathamo la 5Mamello ea Diameter bakeng sa Mefuta ea 3, 4, 5, le 6 (SDHR, SDCR, DOM, le SSID) Round Tubing

Lethathamo la 10Mamello ea Diameter bakeng sa Mofuta oa 2 (AWCR) Round Tubing

Botenya ba Lerako

Lethathamo la 6Mamello ea Botenya ba Lebota bakeng sa Mofuta oa I (AWHR) Round Tubing (Inch Units)

Lethathamo la 7Mamello ea Botenya ba Lebota bakeng sa Mofuta oa I (AWHR) Round Tubing (SI Units)

Lethathamo la 8Mamello ea Botenya ba Lebota ea Mefuta ea 5 le 6 (DOM le SSID) Round Tubing (Li-Inch Units)

TAEBELE 9Mamello ea Botenya ba Lerako ea Mefuta ea 5 le 6 (DOM le SSID) Round Tubing (Li-SI Units)

Lethathamo la 11Mamello ea Botenya ba Lebota bakeng sa Mofuta oa 2 (AWCR) Round Tubing (Inch Units)

Lethathamo la 12Mamello ea Botenya ba Lebota bakeng sa Mofuta oa 2 (AWCR) Round Tubing (SI Units)

Bolelele

Lethathamo la 13Mamello ea Bolelele ba Khaola bakeng sa Lathe-Cut Round Tubing

Lethathamo la 14Mamello ea Bolelele bakeng sa Punch-, Saw-, kapa Disc-Cut Round Tubing

Squareness

Lethathamo la 15Mamello (Inch) bakeng sa Squareness of Cut (Ebang Qetello) Ha e Hlalositsoe bakeng sa Round Tubing

Mamello ea Sekwere le Rectangular Tube Dimensions

Bakeng sa tlhaiso-leseling e batsi, ka kopo sheba tafole e tsamaisanang le maemo.

Kantle Diameter

Lethathamo la 16Mamello, Kantle Dimensions Square le Rectangular Tubing

Radii ea Likhutlong

Lethathamo la 17Radii ea Likhutlo tsa Motlakase-Resistance-Welded Square le Rectangular Tubing

Bolelele

Lethathamo la 18Bolelele Mamello-Square le Rectangular Tubing

Sotha Tolerances

Lethathamo la 19Twist Tolerances Motlakase-Resistance-Welded for Square and Rectangular-Mechanical Tubing

Ponahalo

Tubing e ke ke ea e-ba le mefokolo e kotsi 'me e tla ba le qetello e kang ea mosebetsi.

Ho roala

Tubing e tla tlotsoa ka filimi ea oli pele e romelloa ho thibela mafome.

E thibela mafome ho hlaha ka nako e khuts'oane.

Haeba taelo e bolela hore li-tubing li romeloe ntle le mafome a thibelang mafome, filimi ea oli e tla etsoa e tla lula holim'a metsi.

Ho tshwaya

Bokaholimo ba tšepe bo tšoauoa ho sebelisoa mokhoa o loketseng mme bo na le lintlha tse latelang:

Lebitso la moetsi kapaletšoao

Boholo bo boletsoeng

Mofuta

nomoro ea odara ea moreki,

Nomoro e tloaelehileng, ASTM A513.

Li-barcode li ka boela tsa sebelisoa e le mokhoa o tlatsetsang oa boitsebiso.

Lisebelisoa tsa ASTM A513

Indasteri ea likoloi: E sebelisoa ho liforeimi tsa litulo tsa likoloi, likarolo tse emisitsoeng, litšiea tse tsamaisang, masakaneng le likarolo tse ling tsa sebopeho sa koloi.

Indasteri ea kaho: joalo ka lisebelisoa tsa ts'ehetso bakeng sa meaho ea kaho, joalo ka li-tubes tsa scaffolding, guardrails, railings, joalo-joalo.

Mechinimtlhahiso: E sebelisoa ha ho etsoa lisebelisoa tse sa tšoaneng tsa mechine, tse kang li-cylinders tsa tsamaiso ea hydraulic, likarolo tse potolohang, li-bearings, joalo-joalo.

Lisebelisoa tsa temo: Ka tlhahiso ea mechini ea temo, e sebelisetsoang ho etsa likarolo tsa sebopeho sa lisebelisoa tsa temo, litsamaiso tsa phetisetso, jj.

Tlhahiso ea thepa ea ka tlung: E sebelisoa ha ho etsoa thepa ea thepa ea tšepe e fapaneng, joalo ka lishelefo tsa libuka, liforeimi tsa litulo, liforeimi tsa libethe, joalo-joalo.

Lisebelisoa tsa lipapali: litsing tsa lipapali le tlhahiso ea lisebelisoa, tse sebelisoang e le likarolo tsa tšepe, joalo ka lisebelisoa tsa boikoetliso, lipheo tsa basketball, lipheo tsa bolo ea maoto, jj.

Lisebelisoa tsa indasteri: e sebelisoa ha ho etsoa mabanta a conveyor, lirolara, litanka le lisebelisoa tse ling tsa indasteri.

Melemo ea Rōna

Ho tloha ha e thehoa ka 2014, Botop Steel e fetohile mofani oa pele oa lipeipi tsa tšepe tsa carbon steel Northern China, e tsejoang ka tšebeletso ea eona e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse feletseng. Lihlahisoa tse ngata tsa k'hamphani li kenyelletsa liphaephe tsa tšepe tse se nang seamless, ERW, LSAW, le SSAW, hammoho le lisebelisoa tsa liphaephe, li-flange le litšepe tse khethehileng.

Ka boitlamo bo matla ba boleng, Botop Steel e sebelisa taolo le liteko tse thata ho netefatsa ho ts'epahala ha lihlahisoa tsa eona. Sehlopha sa eona se nang le boiphihlelo se fana ka litharollo tsa motho ka mong le tšehetso ea litsebi, se tsepamisitse maikutlo khotsofalong ea bareki.

Tags: ASTM A513, carbon steel, mofuta 5, mofuta 1, dom.

Nako ea poso: May-07-2024