ASTM A671 ke phala ea tšepe e entsoeng ka poleiti ea boleng ba sekepe sa khatello,Motlakase-Fusion-Welded (EFW)bakeng sa ditikoloho tse nang le kgatello e phahameng dithempereitjhang tse ka hare le tse tlase.

E loketse ka ho khetheha bakeng sa likopo tse hlokang botsitso bo phahameng ba khatello le thepa e khethehileng ea mocheso o tlaase.

Likonopo tsa ho Tsamaisa

ASTM A671 boholo Range

Ho tšoaea ASTM A671

Karolelano ea Kereiti

Sehlopha sa Sehlopha

Lisebelisoa tse so fetoloe

Lintlha tsa Bohlokoa tsa Welding

Kalafo ea Mocheso Bakeng sa Lihlopha Tse Fapaneng

Merero ea Liteko ea ASTM A671

ASTM A671 Ponahalo

Ho kheloha ho lumelletsoeng ka boholo

Likopo tsa ASTM A671 Steel Tubing

Lihlahisoa tsa rona tse Amanang

ASTM A671 boholo Range

Mefuta e khothalletsoang: liphaephe tsa tšepe tse nang le DN ≥ 400 mm [16 in] le WT ≥ 6 mm [1/4].

E ka boela ea sebelisoa bakeng sa boholo bo bong ba pipe, ha feela e finyella litlhoko tse ling tsa tlhaloso ena.

Ho tšoaea ASTM A671

Bakeng sa ho utloisisa ASTM A671 hamolemo, ha re qaleng ho utloisisa litaba tsa eona tsa matšoao. Sena se thusa ho hlakisa boholo ba ts'ebeliso le litšobotsi tsa tekanyetso ena.

Mohlala oa ho tšoaea ha Spray:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 HEAT NO.4589716

BOTHATA: Lebitso la moetsi.

EFW: Ts'ebetso ea ho etsa li-tube tsa tšepe.

ASTM A671: Tekanyetso ea Phethahatso bakeng sa Tubing ea tšepe.

CC60-22: Likgutsufatso tsa kereiti:cc60 le sehlopha sa 22.

16" x SCH80: Diameter le Botenya ba Lebota.

MOCHESO NO. 4589716: Chelete ea mocheso. bakeng sa tlhahiso ea li-tubes tsa tšepe.

Ena ke mokhoa o tloaelehileng oa ho ngola li-spray tsa ASTM A671.

Ha ho thata ho fumana ASTM A671 sehlopheng le sehlopha sa bobeli, joale likarolo tsena tse peli li emela hore na moelelo ke ofe.

Karolelano ea Kereiti

E khethiloe ho latela mofuta oa poleiti e sebelisetsoang ho etsa li-tubes tsa tšepe.

Limaraka tse fapaneng li emela likarolo tse fapaneng tsa lik'hemik'hale le thepa ea mochini bakeng sa maemo a fapaneng a khatello le mocheso.

Ka mohlala, limaraka tse ling ke litšepe tse hlakileng tsa carbon, ha tse ling ke litšepe tse nang le likarolo tse ling tsa alloying, tse kang nickel steels.

| Phaephe Kereiti | Mofuta oa tšepe | Tlhaloso ea ASTM | |

| Che. | Kereiti/mophato/mofuta | ||

| CA 55 | khabone e hlakileng | A285/A285M | Gr C |

| CB60 | khabone e hlakileng, e bolailoeng | A515/A515M | Gr 60 |

| CB65 | khabone e hlakileng, e bolailoeng | A515/A515M | Gr 65 |

| CB70 | khabone e hlakileng, e bolailoeng | A515/A515M | Gr 70 |

| CC 60 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516/A516M | Gr 60 |

| CC 65 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516/A516M | Gr 65 |

| CC 70 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516/A516M | Gr 70 |

| CD70 | manganese-silicon, e tloaelehileng | A537/A537M | Cl 1 |

| CD80 | manganese-silicon, e tima ebile e halefile | A537/A537M | Cl 2 |

| CFA 65 | tšepe ea nickel | A203/A203M | Gr A |

| CFB 70 | tšepe ea nickel | A203/A203M | Gr B |

| CFD 65 | tšepe ea nickel | A203/A203M | Gr D |

| Tlhaloso: CFE70 | tšepe ea nickel | A203/A203M | Gr E |

| CG100 | 9% nickel | A353/A353M | |

| CH 115 | 9% nickel | A553/A553M | Mofuta oa 1 |

| CJA 115 | tšepe ea motsoako, e tingoe ebile e halefile | A517/A517M | Gr A |

| CJB 115 | tšepe ea motsoako, e tingoe ebile e halefile | A517/A517M | Gr B |

| Tlhaloso: CJE115 | tšepe ea motsoako, e tingoe ebile e halefile | A517/A517M | Gr E |

| CJF 115 | tšepe ea motsoako, e tingoe ebile e halefile | A517/A517M | Gr F |

| CJH 115 | tšepe ea motsoako, e tingoe ebile e halefile | A517/A517M | Gr H |

| CJP 115 | tšepe ea motsoako, e tingoe ebile e halefile | A517/A517M | Gr P |

| CK 75 | carbon-manganese-silicon | A299/A299M | Gr A |

| CP85 | tšepe ea motsoako, ho thatafatsa lilemo, ho tima le mocheso oa pula o tšoaroa | A736/A736M | Gr A, Sehlopha sa 3 |

Sehlopha sa Sehlopha

Li-tubes li arotsoe ho ea ka mofuta oa phekolo ea mocheso eo ba e fumanang nakong ea ts'ebetso ea tlhahiso le hore na li hlahlojoa ka radiographical le khatello ea khatello kapa che.

Likarolo tse fapaneng li bonts'a litlhaloso tse fapaneng tsa kalafo ea mocheso bakeng sa li-tubes.

Mehlala e kenyelletsa ho tloaeleha, ho imolla khatello ea maikutlo, ho tima, le ho halefa.

| Sehlopha | Phekolo ea mocheso ka phala | Radioography, bona molaetsa: | Teko ea khatello, bona molaetsa: |

| 10 | ha ho letho | ha ho letho | ha ho letho |

| 11 | ha ho letho | 9 | ha ho letho |

| 12 | ha ho letho | 9 | 8.3 |

| 13 | ha ho letho | ha ho letho | 8.3 |

| 20 | khatello ea maikutlo e imolohile, sheba 5.3.1 | ha ho letho | ha ho letho |

| 21 | khatello ea maikutlo e imolohile, sheba 5.3.1 | 9 | ha ho letho |

| 22 | khatello ea maikutlo e imolohile, sheba 5.3.1 | 9 | 8.3 |

| 23 | khatello ea maikutlo e imolohile, sheba 5.3.1 | ha ho letho | 8.3 |

| 30 | e tloaelehileng, sheba 5.3.2 | ha ho letho | ha ho letho |

| 31 | e tloaelehileng, sheba 5.3.2 | 9 | ha ho letho |

| 32 | e tloaelehileng, sheba 5.3.2 | 9 | 8.3 |

| 33 | e tloaelehileng, sheba 5.3.2 | ha ho letho | 8.3 |

| 40 | e tloaelehileng le e halefileng, bona 5.3.3 | ha ho letho | ha ho letho |

| 41 | e tloaelehileng le e halefileng, bona 5.3.3 | 9 | ha ho letho |

| 42 | e tloaelehileng le e halefileng, bona 5.3.3 | 9 | 8.3 |

| 43 | e tloaelehileng le e halefileng, bona 5.3.3 | ha ho letho | 8.3 |

| 50 | ho tingoa le ho halefa, sheba 5.3.4 | ha ho letho | ha ho letho |

| 51 | ho tingoa le ho halefa, sheba 5.3.4 | 9 | ha ho letho |

| 52 | ho tingoa le ho halefa, sheba 5.3.4 | 9 | 8.3 |

| 53 | ho tingoa le ho halefa, sheba 5.3.4 | ha ho letho | 8.3 |

| 70 | timo le ho tsitsa mocheso | ha ho letho | ha ho letho |

| 71 | timo le ho tsitsa mocheso | 9 | ha ho letho |

| 72 | timo le ho tsitsa mocheso | 9 | 8.3 |

| 73 | timo le ho tsitsa mocheso | ha ho letho | 8.3 |

Mocheso oa tšebeliso o lokela ho hlokomeloa ha u khetha thepa. Ho ka buuoa ka lintlha tsa ASTM A20/A20M.

Lisebelisoa tse so fetoloe

Lipoleiti tsa boleng bo phahameng bakeng sa likepe tsa khatello, lintlha tsa mefuta, le litekanyetso tsa ho bolaoa li ka fumanoa tafoleng eaKarolelano ea Kereitihodimo.

Lintlha tsa Bohlokoa tsa Welding

Welding: Li-seam li tla ba tse cheselitsoeng habeli, li kene ka ho feletseng.

Welding e tla etsoa ho latela mekhoa e boletsoeng Karolong ea IX ea ASME Boiler and Pressure Vessel Code.

Li-welds li tla etsoa ka letsoho kapa ka boiketsetso ka ts'ebetso ea motlakase e kenyelletsang ho beoa ha tšepe ea ho tlatsa.

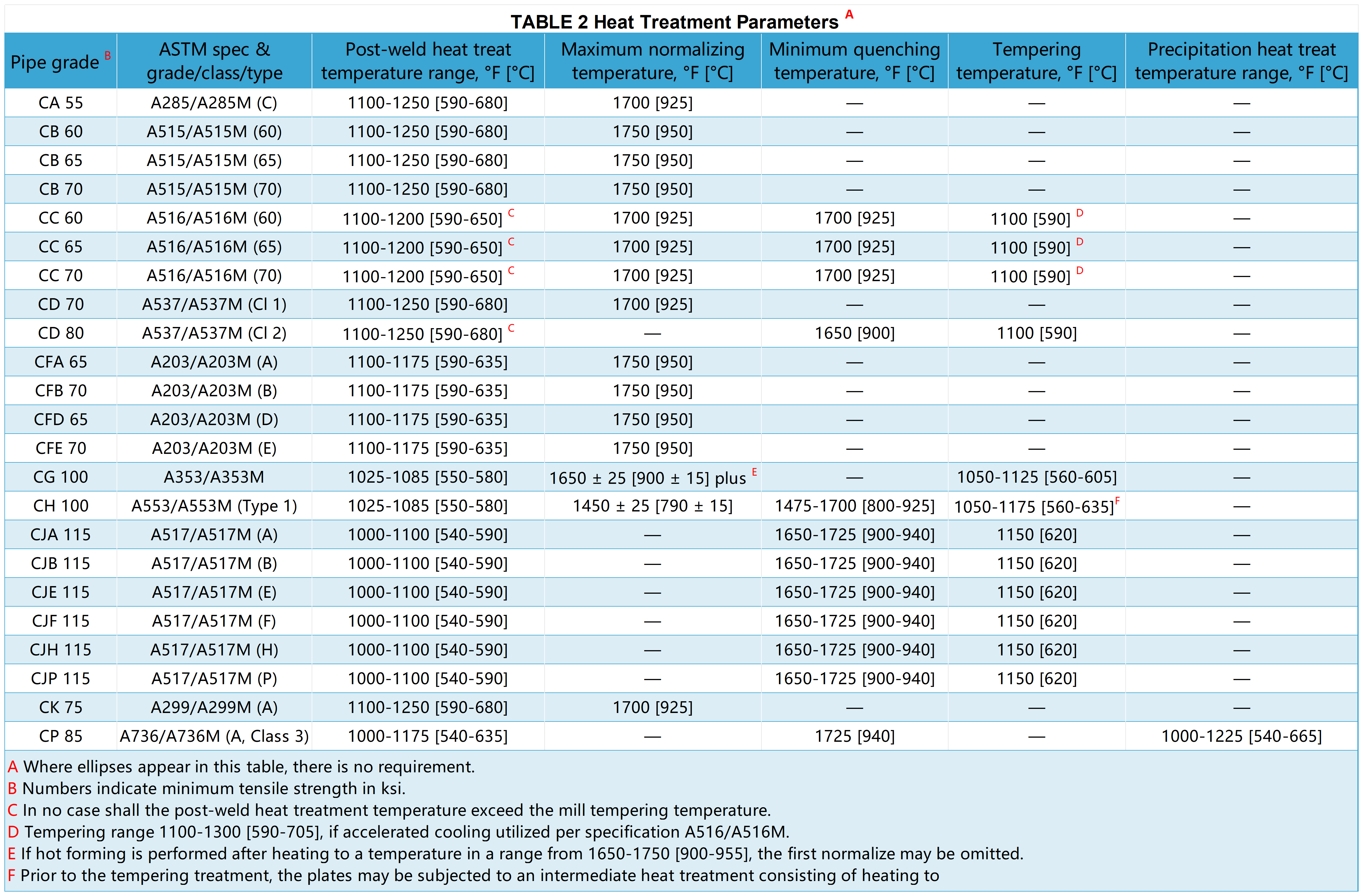

Kalafo ea Mocheso Bakeng sa Lihlopha Tse Fapaneng

Lihlopha tsohle ntle le 10, 11, 12, le 13 li tla phekoloa mocheso ka sebōping se laoloang ho ±25 °F[± 15°C].

Litlelase 20, 21, 22, le 23

E lokela ho futhumatsoa ka mokhoa o ts'oanang ka har'a mefuta e fapaneng ea mocheso oa pheko ea mocheso o bontšitsoeng ho Lethathamo la 2 bakeng sa bonyane 1 h/in. [0.4 h/cm] ea botenya kapa bakeng sa 1 h, ho sa tsotellehe hore na ke efe e kholoanyane.

Litlelase 30, 31, 32, le 33

E lokela ho futhumatsoa ka mokhoa o ts'oanang ho mocheso sebakeng sa austenitizing mme e sa fete mocheso o tloaelehileng oa ho tloaeleha o bontšitsoeng ho Lethathamo la 2 'me ka mor'a moo e pholile moeeng mocheso oa kamore.

Litlelase 40, 41, 42, le 43

Pipe e tla ba e tloaelehileng.

Pipe e tla futhumatsoa hape ho mocheso oa mocheso o bontšitsoeng ho Lethathamo la 2 e le bonyane 'me o ts'oaroe mocheso oa bonyane ba 0.5 h / in.[0.2 h / cm] ea botenya kapa 0.5 h, ho sa tsotellehe hore na ke efe e kholoanyane, le moea o pholileng.

Lihlopha tsa 50, 51, 52, le 53

Pipe e lokela ho futhumatsoa ka mokhoa o ts'oanang ho ea ho mocheso ka har'a mefuta e mengata ea li-austenitizing le e sa feteng mocheso o phahameng oa ho tima o bontšitsoeng ho Lethathamo la 2.

Ka mor'a moo, tima ka metsi kapa oli. Ka mor'a ho tima, phala e tla tsosolosoa ho mocheso o fokolang oa mocheso o bontšitsoeng ho Lethathamo la 2 ebe o tšoaroa ka nako eo.

mocheso oa bonyane ba 0,5 h/inch ea botenya kapa 0,5 h, ho sa tsotellehe hore na o moholoanyane, le o pholileng moeeng.

Litlelase 70, 71, 72, le 73

Liphaephe li tlae futhumatsoe ka mokhoa o ts'oanang ho mocheso sebakeng sa austenitizing, e sa feteng mocheso o phahameng oa ho tima o bontšitsoeng ho Lethathamo la 2, ebe o tima ka metsing kapa ka oli.

Ka mor'a ho tima phala e tla besetsoa hape ka har'a mefuta ea phekolo ea mocheso ea pula e bontšitsoeng ho Lethathamo la 2 bakeng sa nako e tla khethoa ke moetsi.

Merero ea Liteko ea ASTM A671

Sebopeho sa Lik'hemik'hale

Ho ea ka litlhoko tse tsamaellanang tsa litekanyetso tsa ts'ebetsong ea lisebelisoa tse tala, tlhahlobo ea sebopeho sa lik'hemik'hale, liphetho tsa liteko ho fihlela litlhoko tse tloaelehileng.

Tension Test

Liphaephe tsohle tse cheselitsoeng tse entsoeng ho latela tlhaloso ena li tlameha ho ba le teko ea "cross-weld tensile" ka mor'a phekolo ea ho qetela ea mocheso, 'me liphetho li lokela ho lumellana le litlhoko tsa motheo bakeng sa matla a ho qetela a matla a poleiti e boletsoeng.

Ho feta moo, Lihlopha tsa CD XX le CJ XXX, ha tsena e le tsa Sehlopha sa 3x, 4x, kapa 5x, 'me Kereiti ea CP ea 6x le 7x e tla ba le tlhahlobo ea tšepe ea tšepe e feto-fetohang e etsoang ho mehlala e khaotsoeng ho tloha pipe e felileng. Liphetho tsa liteko tsena li tla kopana le litlhoko tse tlase tsa tlhahlobo ea mochini tsa litlhaloso tsa poleiti.

Transverse Guided Weld Bend Test

Teko ea bend e tla amoheleha haeba ho se na mapetsong kapa likoli tse ling tse fetang1/8ka. [3 limilimithara] ka tsela efe kapa efe ba teng ka tšepe weld kapa pakeng tsa tjheseletsa le tšepe botlaaseng ka mor'a ho kobeha.

Mapetso a hlahang mathōkong a mohlala nakong ea teko, 'me a ka tlaase ho1/4in. [6 limilimithara] e lekantsoeng ka nqa efe kapa efe e ke ke ea nkoa.

Teko ea Khatello

Phaephe ea lihlopha tsa X2 le X3 e tla lekoa ho latela Specification A530/A530M, Litlhoko tsa Teko ea Hydrostatic.

Tlhahlobo ea Radiographic

Bolelele bo felletseng ba weld ka 'ngoe ea Sehlopha sa X1 le X2 bo tla hlahlojoa ka radiographic ho latela le ho fihlela litlhoko tsa ASME Boiler le Pressure Vessel Code, Karolo ea VIII, Serapa sa UW-51.

Tlhahlobo ea radiographic e ka etsoa pele ho phekolo ea mocheso.

ASTM A671 Ponahalo

Peipi e felileng e ke ke ea e-ba le mefokolo e kotsi 'me e tla ba le qetello e kang ea mosebetsi.

Ho kheloha ho lumelletsoeng ka boholo

| Lipapali | Boleng ba ho Mamella | Hlokomela |

| Kantle Diameter | ±0.5% | E ipapisitse le tekanyo ea circumferential |

| Kantle ho Roundness | 1%. | Phapang lipakeng tsa bophara bo boholo le bo nyane ba kantle |

| Ho tsamaisana | 1/8 ho [3 limilimithara] | Ho sebelisa ntlha e otlolohileng ea limithara tse 10 e behiloeng e le hore mahlakore ka bobeli a kopane le phala |

| Botenya | 0.01 ho [0.3 limilimithara] | Botenya ba lebota bo tlase ho feta botenya bo boletsoeng |

| Bolelele | 0 - +0.5in [0 - +13mm] | dipheletso tse sa sebetsaneng |

Likopo tsa ASTM A671 Steel Tubing

Indasteri ea Matla

E sebelisetsoa ho tsamaisa metsi a cryogenic libakeng tsa phekolo ea khase ea tlhaho, libaka tsa ho hloekisa le lisebelisoa tsa ho lokisa lik'hemik'hale.

Mekhoa ea Lihatsetsi ea Liindasteri

Bakeng sa ho sebelisoa karolong ea cryogenic ea sehatsetsi le tsamaiso ea moea ho netefatsa botsitso le polokeho ea tsamaiso.

Lisebelisoa

Bakeng sa polokelo le lipalangoang bakeng sa likhase tse nang le mokelikeli.

Kaho le Kaho

E sebelisoa mererong ea litšebeletso tsa motheo ka mocheso o tlase kapa maemo a feteletseng a tikoloho, joalo ka kaho ea polokelo e batang.

Re e mong oa ba etellang pele welded carbon tšepe pipe le bahlahisi seamless tšepe liphaephe le bafani ba tsoang Chaena, ba nang le mefuta e mengata ea liphaephe tsa tšepe tsa boleng bo phahameng setokong, re ikemiselitse ho u fa tharollo e felletseng ea lipeipi tsa tšepe. Bakeng sa lintlha tse ling tsa sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona, re lebeletse ho u thusa ho fumana mekhoa e metle ea lipeipi tsa tšepe bakeng sa litlhoko tsa hau!

Tags: ASTM a671, efw, cc 60, sehlopha sa 22, bafani, bahlahisi, lifeme, li-stock, lik'hamphani, thekiso, theko, qotso, bongata, thekiso, litšenyehelo.

Nako ea poso: Apr-19-2024