BS EN 10219 tšepeke litšepe tse nang le sekoti tse entsoeng ka mokhoa o batang tse entsoeng ka litšepe tse se nang li-alloy le tse entsoeng hantle bakeng sa lisebelisoa tsa meralo ntle le phekolo ea mocheso e latelang.

EN 10219 le BS EN 10219 ke litekanyetso tse ts'oanang empa li na le mekhatlo e fapaneng.

Likonopo tsa ho Tsamaisa

Sehlopha sa BS EN 10219

BS EN 10219 boholo ba mefuta

Lisebelisuoa tse tala le Maemo a Phano

BS EN 10219 Lebitso la tšepe

Sebopeho sa Lik'hemik'hale sa BS EN 10219

Thepa ea Mechini ea BS EN 10219

Liteko tsa Tšusumetso

Teko e sa senyeheng

Ponahalo le Tokiso ea Bofokoli

Dimensional Tolerances

Sesetiloe

BS EN 10219 Ho tšoaea

Lisebelisoa

Lihlahisoa tsa rona tse Amanang

Sehlopha sa BS EN 10219

Ka Mofuta oa Tšepe

Litšepe tse khethehileng tse sa alloeng le tse kopantsoeng.

Litšepe tse sa kopantsoeng:

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H,S275NH, S275NLH, S355NH, S355NLH.

Litšepe tse khethehileng tse kopantsoeng:

S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH.

Tsela e bonolo ea ho bolela phapang: mefuta ea tšepe e nang le M kapa 4 ke li-alloys, 'me thepa ea tšepe ea tšepe e ka tsejoa kapele.

Ka Mokhoa oa Tlhahiso

Mekhoa ea tlhahiso e sebelisoang haholo ho etsa lipeipi tsa tšepe ho latela BS EN 10219 e kenyelletsaMotlakase Resistance Welding (ERW) le Submerged Arc Welding (SAW).

SAW e ka aroloa hape ho Longitudinal Submerged Arc Welding (LSAW) le Spiral Submerged Arc Welding (SSAW) ho ipapisitsoe le sebopeho sa seam sa weld.

Ka Sebopeho sa Cross-section

CFCHS: Cold Thehile likarolo tse chitja tse sekoti;

CFRHS: Cold Thehile likarolo tse sekoere kapa tse khutlonnetsepa;

CFEHS: Cold Thehile elliptical sekoti likarolo;

Pampiri ena e tsepamisitse maikutlo ho CFCHS (Cold Formed Circular Hollow Section).

BS EN 10219 boholo ba mefuta

Botenya ba lebota: T ≤ 40mm

Bophara ba ka ntle (D):

Potoloho (CHS): D ≤ 2500 mm;

Sekwere (RHS): D ≤ 500 mm × 500 mm;

Rectangular (RHS): D ≤ 500 mm × 300 mm;

Oval( EHS): D ≤ 480 mm × 240 mm.

Lisebelisuoa tse tala le Maemo a Phano

Litšepe tse se nang alloy

ho latela Sehlomathiso sa A, se Rothoetsoeng kapa sa Maemo se Khethiloeng/Se Tloaelehileng (N) bakeng saJR, J0, J2, le K2litšepe;

Litšepe tse ntle tsa lijo-thollo

Ho ea ka Sehlomathiso sa B, Ho Rolling e Tloaelehileng / E Tloaelehileng (N) bakeng saN le NLlitšepe;

Ho latela Sehlomathiso B.M le ML, litšepe li ne li rokoa ka thermomechanically (M).

Likarolo tse sekoti li tla fanoa li entsoe ka mokhoa o batang ntle le kalafo e latelang ea mocheso ntle le hore seam sa weld se ka ba maemong a tjheseletsang kapa a ts'oaroang mocheso.

Bakeng sa likarolo tse sekoti tsa SAW tse ka holimo ho 508 mm ka ntle ho bophara, ho ka 'na ha hlokahala ho etsa ts'ebetso e mofuthu ea ho bōpa, e sa ameng thepa ea mochine, e le ho finyella litlhoko tsa ho mamellana ka ntle ho pota-pota.

BS EN 10219 Lebitso la tšepe

Kopano ea mabitso ea BS EN 10219 e tšoana leBS EN 10210, e sebelisang maemo a EN10027-1.

Bakeng sa likarolo tsa sekoti tse se nang alloy, lebitso la tšepe le na le

Mohlala: Tšepe ea sebopeho (S) e nang le matla a fokolang a tlhahiso bakeng sa botenya bo sa feteng 16 mm ea 275 MPa, e nang le tšusumetso e fokolang ea boleng ba matla a 27 J ho 0 ℃(J), karolo e sekoti (H).

BS EN 10219-S275J0H

E na le likarolo tse 'nè:S, 275, J0, le H.

1. S: e bontša hore tšepe ea sebopeho.

2. Nomoro ea boleng (275): botenya ≤ 16mm bakeng sa bonyane ba matla a chai a boletsoeng, ho MPa.

3. JR: e bontša hore mocheso oa kamore o nang le thepa e khethehileng ea tšusumetso;

J0: e bontša hore ho 0 ℃ ka thepa e khethehileng ea tšusumetso;

J2 or K2: e bonts'itsoeng ka -20 ℃ ka thepa e khethehileng ea tšusumetso;

4. H: e bontša likarolo tse se nang letho.

Bakeng sa likarolo tsa tšepe tse ntle tsa lijo-thollo tse nang le sekoti, lebitso la tšepe le na le

Mohlala: Tšepe ea sebopeho (S) e nang le matla a fokolang a tlhahiso e boletsoeng bakeng sa botenya bo sa feteng 16 mm ea 355 MPa.normalized fine grain steel feedstock (N), e nang le tšusumetso e fokolang ea boleng ba matla a 27 J ho -50 ℃(L), karolo e sekoti (H).

EN 10219-S355NLH

E na le likarolo tse hlano:S, 355, N, L, le H.

1. S: e bontša tšepe ea mohaho.

2. Boleng ba palo(355): botenya ≤ 16mm bonyane bo boletsoeng matla a chai, yuniti ke MPa.

3. N: ho thetheha ho tloaelehileng kapa ho tloaheleha.

4. L: thepa ea tšusumetso e khethehileng ho -50 °C.

5. H: e bolela karolo e se nang letho.

Sebopeho sa Lik'hemik'hale sa BS EN 10219

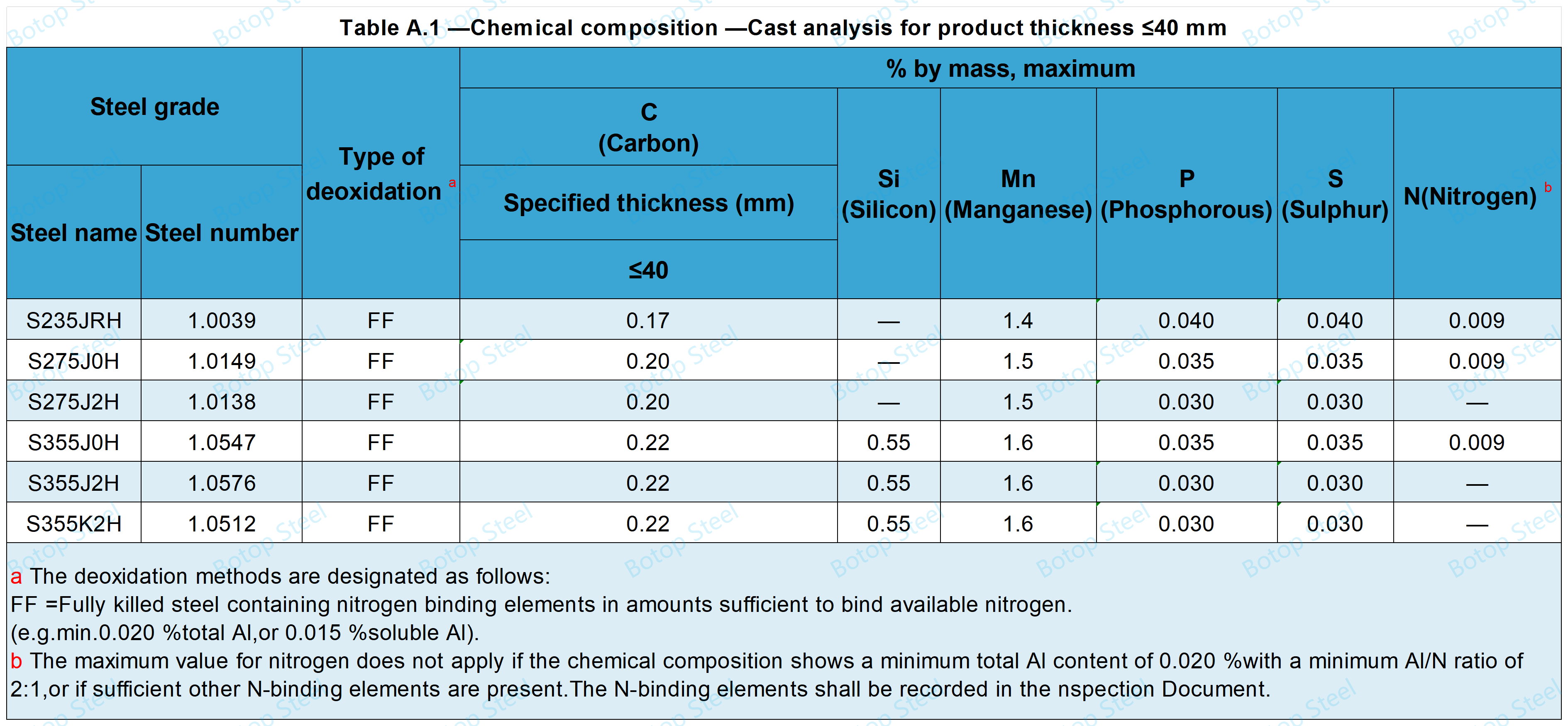

Litšepe tsa Non-alloy - Sebopeho sa Lik'hemik'hale

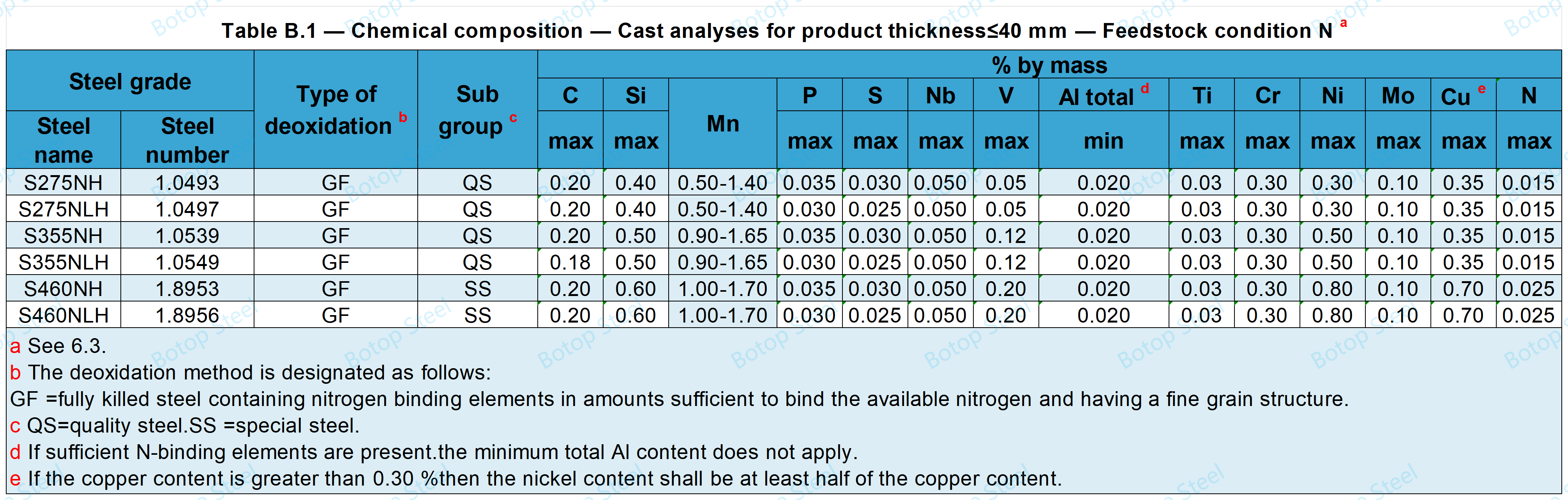

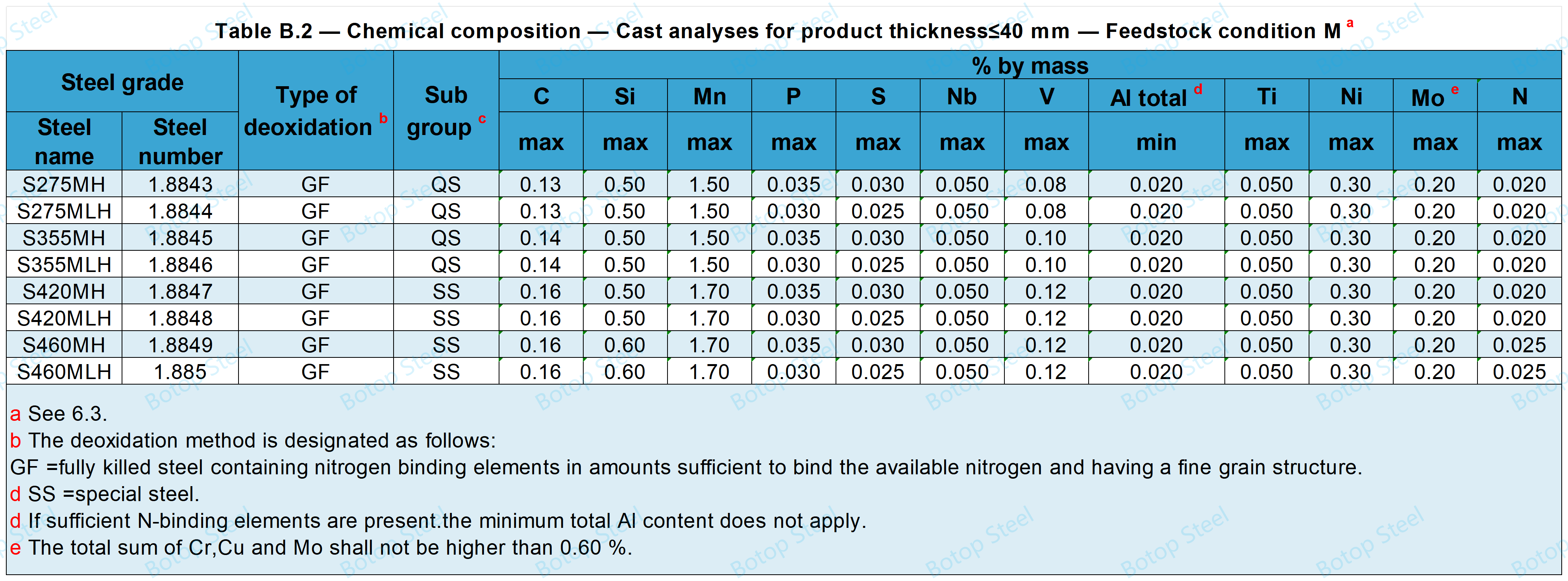

Fine Grain Steels - Sebopeho sa lik'hemik'hale

Ha tšepe e entsoeng hantle e sebelisoa e le thepa e tala, e ka aroloa ho M le N ho ea ka maemo a ho fana, 'me litlhoko tsa lik'hemik'hale tsa mefuta ena e' meli li ka fapana.

Ha ho etsoa qeto ea CEV ho tla sebelisoa foromo e latelang: CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Feedstock condition N

Boemo ba Feedstock M

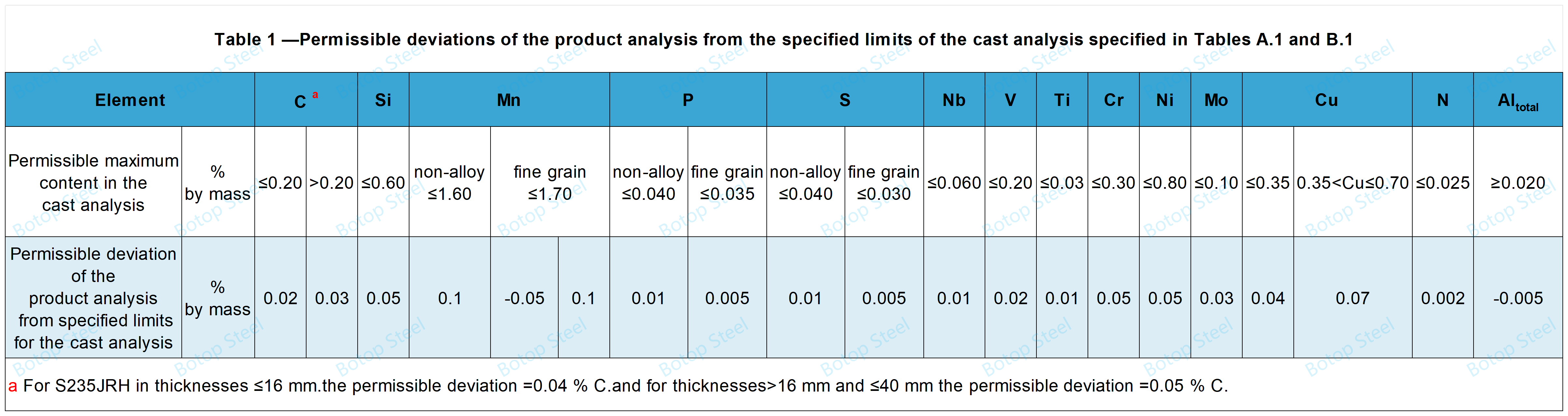

Ho kheloha ha Sebopeho sa Lik'hemik'hale

Thepa ea Mechini ea BS EN 10219

E tlameha ho etsoa ho latela EN 1000-2-1. Teko e lokela ho etsoa maemong a mocheso ho tloha ho 10°C ho isa ho 35°C.

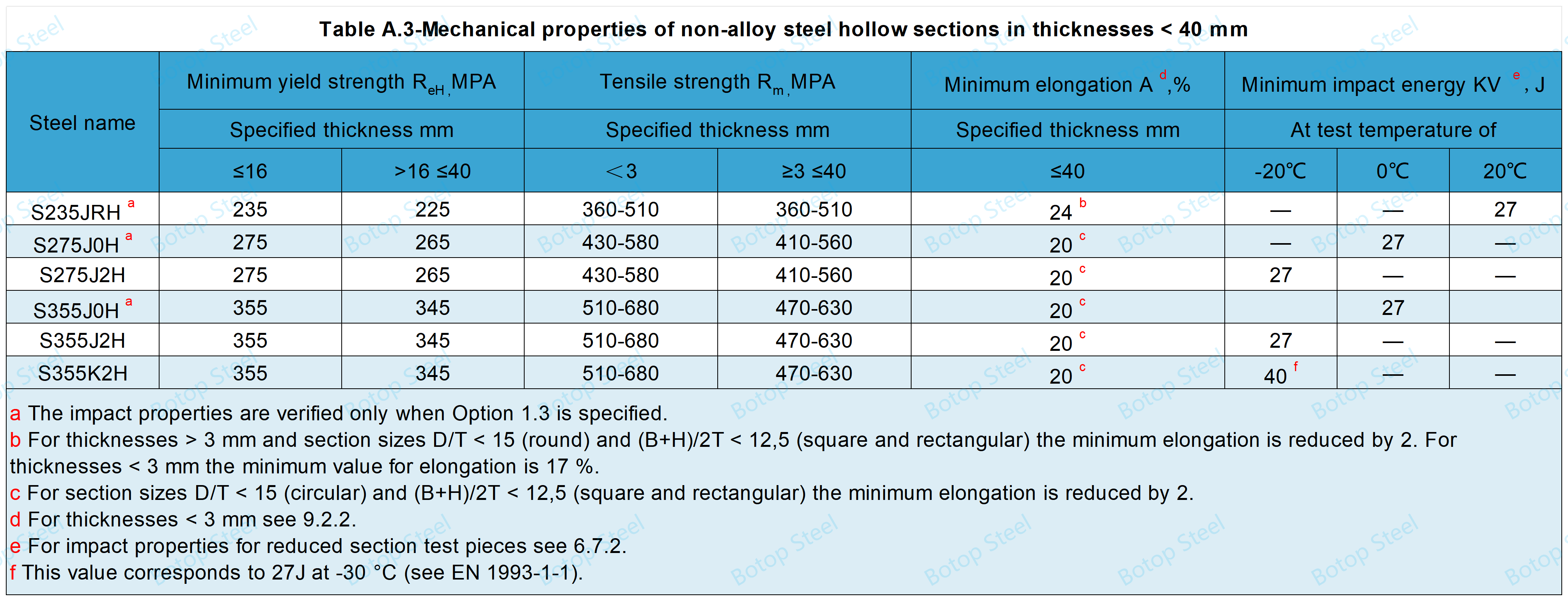

Litšepe tse se nang alloy - Thepa ea Mechanical

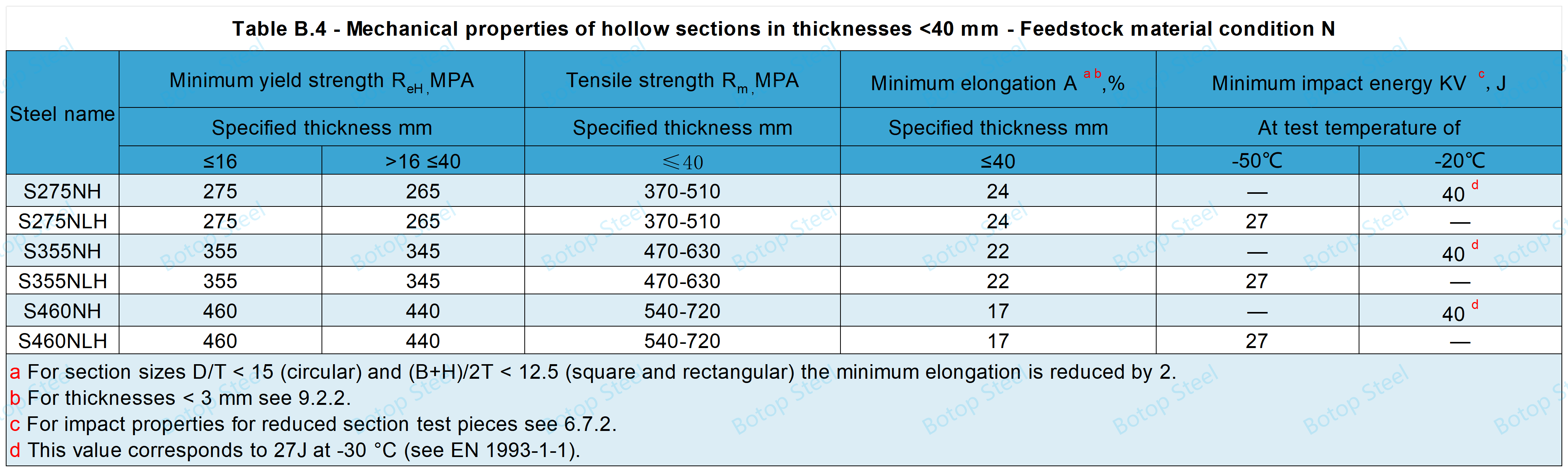

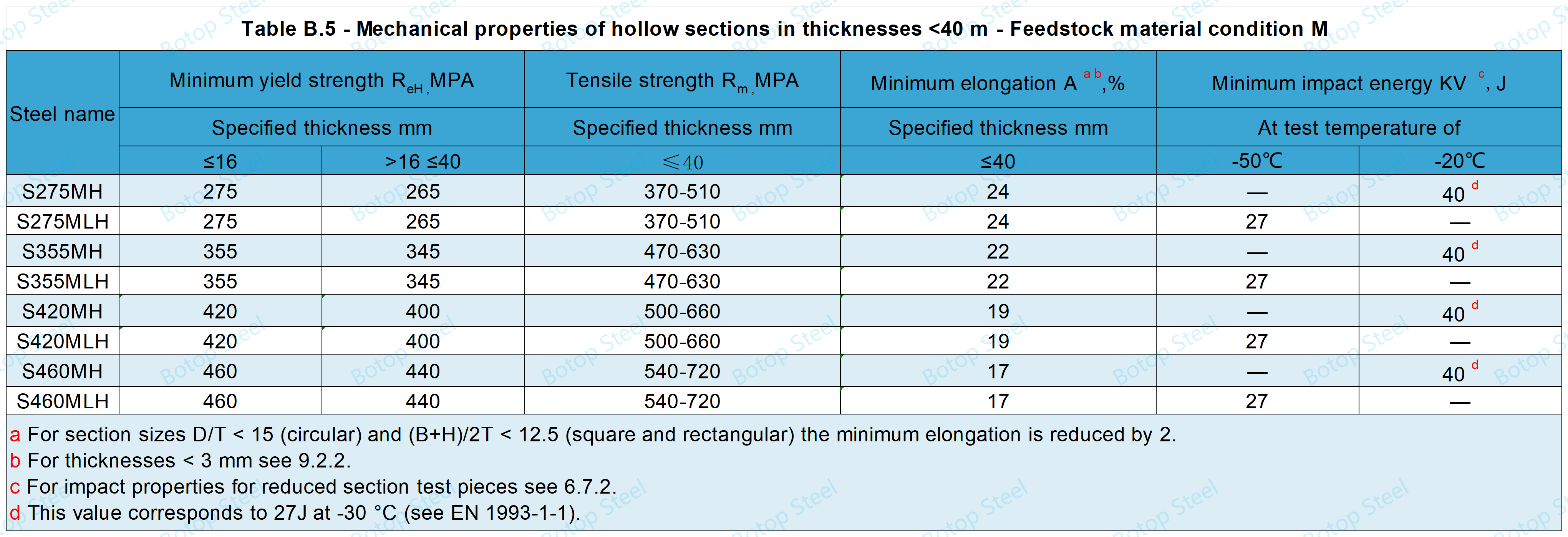

Litšepe Tse Ntle tsa Mabele - Thepa ea Mechini

Ha tšepe e entsoeng hantle e sebelisoa e le thepa e tala, e ka aroloa ka M le N ho ea ka maemo a ho fana, 'me thepa ea mechine ea mefuta ena e' meli e ka fapana.

Feedstock condition N

Boemo ba thepa ea Feedstock M

Liteko tsa Tšusumetso

Teko ea phello e tla etsoa ho latela EN 10045-1.

Kakaretso ea boleng ba sete ea mehlala e meraro e tla lekana kapa e kholo ho feta boleng bo boletsoeng.

Boleng ba motho ka mong bo ka ba tlase ho boleng bo boletsoeng, empa ha bo ka tlase ho 70% ea boleng boo.

Teko e sa senyeheng

Ha o etsa NDT ho li-welds likarolong tse se nang letho tsa meralo, litlhoko tse latelang li tlameha ho finyelloa.

Motlakase Welded likarolo

Kopana le e 'ngoe ea litlhokahalo tse latelang:

a) EN 10246-3 ho isa boemong ba kamohelo ea E4, ntle le hore mokhoa o potolohang oa li-tube/pancake coil o ke ke oa lumelloa;

b) EN 10246-5 ho isa boemong ba kamohelo F5;

c) EN 10246-8 ho isa boemong ba kamohelo ea U5.

Likarolo tse ka tlas'a metsi tsa Arc Welded

Sekhahla sa weld sa likarolo tse se nang metsi se tla lekoa ho latela EN 10246-9 ho ea boemong ba kamohelo ea U4 kapa ka radiography ho latela EN 10246-10 e nang le boleng ba setšoantšo sa R2.

Ponahalo le Tokiso ea Bofokoli

Ponahalo ya Sefahleho

Likarolo tse sekoti li tla ba le sebaka se boreleli se lumellanang le mokhoa oa ho etsa o sebelisitsoeng; li-bumps, li-grooves kapa li-grooves tse sa tebang tsa longitudinal tse bakoang ke ts'ebetso ea tlhahiso li lumelloa haeba botenya bo setseng bo le ka har'a mamello.

Lipheletso tsa karolo e sekoti li tla khaoloa ka mokhoa o ikhethileng ho ea ho axis ea sehlahisoa.

Ho Lokisa Sekoli

Mathata a kaholimo a ka tlosoa ka ho sila ha feela botenya bo se ka tlase ho botenya bo lumelletsoeng bo boletsoeng ho BS EN 10219-2 kamora ho lokisoa.

Bakeng sa likarolo tse ntle tsa lijo-thollo tse sekoti, ho lokisoa ha 'mele ka ho cheselletsa ho ke ke ha lumelloa ntle le haeba ho lumellanoe ka tsela e 'ngoe.

Mekhoa ea ho lokisa weld e tla lumellana le litlhoko tsa EN ISO 15607, EN ISO 15609-1, le EN ISO 15614-1.

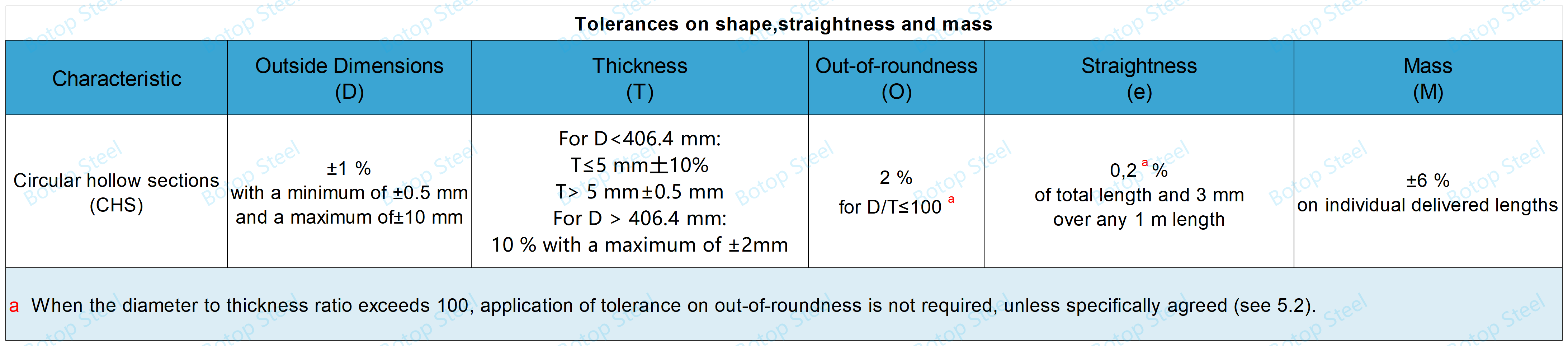

Dimensional Tolerances

Mamello ea boholo bo tla ba ho latela litlhoko tse tsamaellanang tsa EN 10219-2 mme ho tla lebisoa tlhokomelo ho sebopeho sa karolo ea sefapano.

Mamello ka Sebopeho, Ho otloloha le 'Misa

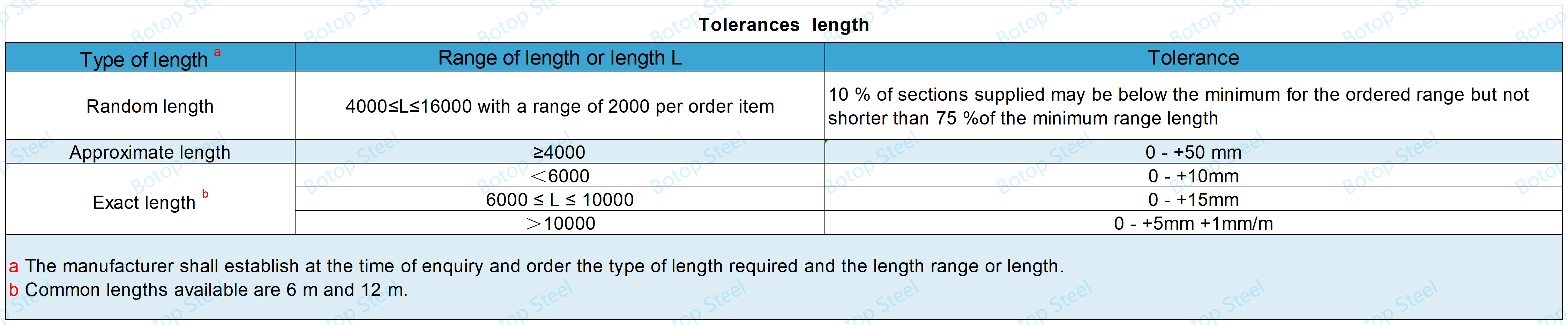

Mamello ea Bolelele

Seam Height ea SAW Weld

Mamello ka bophahamo ba ka hare le ka ntle weld seam bakeng sa submered arc welded hollow likarolo.

| Botenya, T | Bolelele ba lifaha tsa weld, limilimithara |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Sesetiloe

BS EN 10219 Tubing e se nang letho e ka tšeloa ka sekontiri se chesang bakeng sa bophelo bo bolelele ba ts'ebeletso.

Li-tubes tse sekoti li tšeloa ka bateng e nang le bonyane 98% ea dikahare tsa zinki ho etsa lesela la masenke.

BS EN 10219 Ho tšoaea

Likahare tsa letšoao la lipeipi tsa tšepe li lokela ho ba le:

Lebitso la tšepe, mohlala EN 10219-S275J0H.

Lebitso kapa letshwao la kgwebo la moetsi.

Khoutu ea boitsebiso, mohlala, nomoro ea odara.

TS EN 10219 li-tubes tsa tšepe li ka tšoauoa ka mekhoa e fapaneng ho etsa bonnete ba ho tsebahatsa le ho ts'oara habonolo, ebang ke ka ho penta, ho hatakela, lileibole tsa sekhomaretsi, kapa li-label tse ling tse ka sebelisoang ka bonngoe kapa ha li kopane.

Lisebelisoa

Ts'ebeliso ea maemo a BS EN 0219 e akaretsa likarolo tsohle tsa litlhoko tsa tšepe ea meralo.

Kaho:Lipeipi tsa tšepe tsa TS EN 10219 li sebelisoa haholo mererong ea kaho, joalo ka ho aha marokho, tšehetso ea meaho, jj.

Kaho ea meaho: li sebelisoa mererong ea ho boloka metsi, kaho ea litsela, tsamaiso ea lipeipi, le mererong e meng ea kaho ea meaho, joalo ka lipeipi tsa drainage, lipeipi tsa metsi, joalo-joalo.

Tlhahiso: Lipeipi tsena tsa tšepe li boetse li sebelisoa ha ho etsoa thepa ea mochini, litsamaiso tse tsamaisang thepa le lits'ebetso tse ling tsa indasteri.

Boenjiniere ba 'masepala: Boenjiniere ba masepala oa litoropo, lipeipi tsa tšepe tse tloaelehileng tsa BS EN 10219 li ka sebelisoa ho etsa litšepe, litšepe, litšitiso tsa litsela, joalo-joalo.

Mokhabiso oa meralo: Moralo o motle le matla a li-tubes tsa tšepe li etsa hore e be lisebelisoa tse tloaelehileng tse sebelisoang mokhabisong oa meralo, tse kang litepisi tsa litepisi, li-balustrade, li-brackets tse khabisitsoeng, joalo-joalo.

Lihlahisoa tsa rona tse Amanang

Ho tloha ha e thehoa ka 2014, Botop Steel e fetohile mofani oa pele oa lipeipi tsa tšepe tsa carbon steel Northern China, e tsejoang ka tšebeletso ea eona e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse feletseng. Sehlahisoa se pharalletseng sa k'hamphani se kenyelletsaliphaephe tse se nang moroko, tsa ERW, LSAW, le SSAW tsa tšepe, hammoho le lipeipi, li-flange, le litšepe tse khethehileng.

Ka boitlamo bo matla ba boleng, Botop Steel e sebelisa taolo le liteko tse thata ho netefatsa ho ts'epahala ha lihlahisoa tsa eona. Sehlopha sa eona se nang le boiphihlelo se fana ka litharollo tsa motho ka mong le tšehetso ea litsebi, se tsepamisitse maikutlo khotsofalong ea bareki.

Tags: bs en 10219, en 10219, chs, cfchs, s355j0h, s275j0h.

Nako ea poso: Apr-26-2024