Pipe ea tšepe ea carbonke phala e entsoeng ka tšepe ea carbon e nang le metsoako ea lik'hemik'hale eo, ha e hlahlojoa ka mocheso, e sa feteng moeli o ka holimo oa 2.00% bakeng sa carbon le 1.65% bakeng sa manganese.

Pipe ea tšepe ea carbon ke lisebelisoa tse tloaelehileng tsa liphaephe tse sebelisoang haholo indastering ho tsamaisa metsi le likhase.

Likonopo tsa ho Tsamaisa

Sehlopha sa Pipe ea tšepe ea Carbon

Carbon Steel Pipe Size Range

Maemo a Tloaelehileng a Phethahatso bakeng sa Pipe ea Tšepe ea Carbon

Lintlha tsa bohlokoa tsa Pipe ea tšepe ea Carbon

Carbon Steel Pipe Surface Coating

Melemo ea Pipe ea tšepe ea Carbon

Mathata a Carbon Steel Pipe

Tšebeliso ea Pipe ea tšepe ea Carbon

Mokhoa oa ho Khetha Mofani oa Pipe ea tšepe ea Carbon ea Tšepahalang

Mabapi le rona

Sehlopha sa Pipe ea tšepe ea Carbon

Ho arola ka Sepheo

Liphaephe tsa sebopeho: e sebelisoa haholo meahong ea meaho, joalo ka litšehetso tsa meaho, marokho le meaho ea indasteri.

Lipeipi tsa lipalangoang: Lipeipi tsena tsa carbon steel li sebelisetsoa ho tsamaisa maro a kang oli, khase le metsi.

Li-Tubes tsa Mechini: E sebelisoa mechini le boiketsetso moo ho hlokahalang litekanyo tse nepahetseng le thepa e itseng ea mochini.

Li-tubes tsa boiler: E khethehileng bakeng sa maemo a mocheso o phahameng le a khatello e phahameng, joalo ka li-boilers liteisheneng tsa motlakase le libaka tsa ho hloekisa oli.

Li-tubing tsa seliba sa oli le khase: e sebelisetsoang ho ntša oli le khase, e tlamehang ho khona ho mamella khatello e feteletseng le ho bola ha lik'hemik'hale.

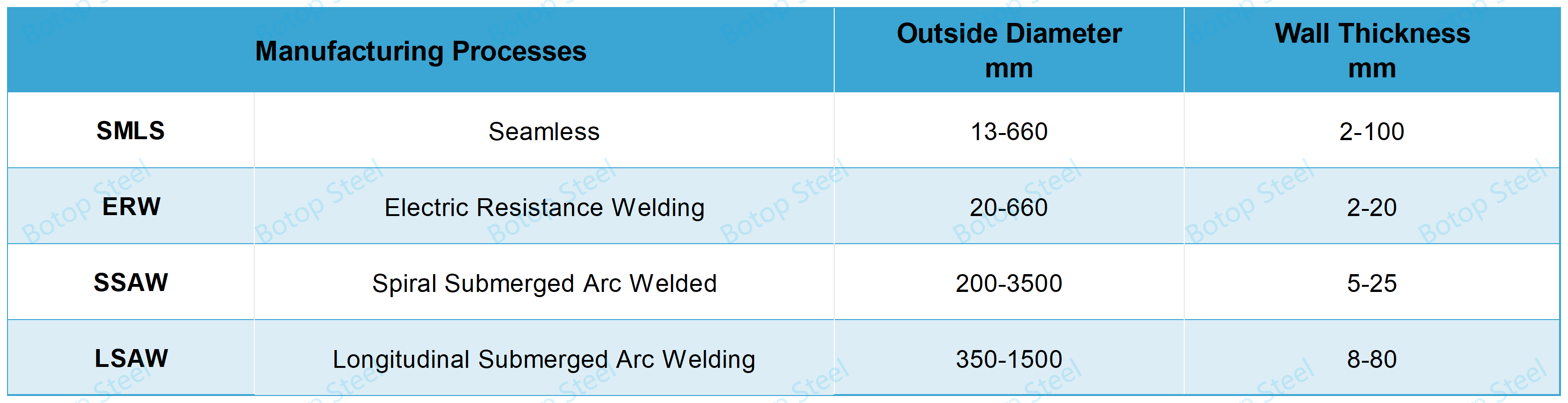

Classification Ho ea ka Manufacturing Process

Pipe ea tšepe e se nang seam: phala ea tšepe e entsoeng ka ho qeta ho chesa kapa mokhoa o batang oa ho qeta, ha ho na seam se cheselitsoeng, se sebelisoang hangata nakong ea khatello e phahameng.

Peipi ea tšepe e cheselitsoeng: e entsoe ka poleiti ea tšepe kapa khoele e hlobolang ka har'a tube, ka mokhoa oa ho tjheseletsa oa ho bopa.

Pipe ea tšepe e cheselitsoeng e ka aroloa ho latela ts'ebetso ea welding:

Resistance Welded Steel Pipe (ERW): Pipe e entsoeng ka moqolo e entsoeng ka mocheso o phahameng oa ho hanyetsa mocheso, tlhahiso ea phala ea tšepe ea carbon e nang le bophara bo fokolang le lebelo la tlhahiso e potlakileng.

Pipe e Welded ea Arc (BONA): e sebelisa mokhoa o iketsang oa ho tjheseletsa arc ho hlahisa liphaephe tsa tšepe tsa carbon tse nang le bophara bo boholo kapa botenya ba lebota.

BONApipe ea tšepe e ka boela ea aroloa kaLSAW(Longitudinal Submerged Arc Welding) leSSAW(Spiral Submerged Arc Welded) ho ea ka tataiso ea seam weld.

Haeba u batla ho tseba phapangpakeng tsa SMLS,ERW,LSAW,SSAW, o ka tobetsa ho e hlahloba.

Carbon Steel Pipe Size Range

Maemo a Tloaelehileng a Phethahatso bakeng sa Pipe ea Tšepe ea Carbon

ASTM A106: Seamless carbon tšepe pipe bakeng sa tšebeletso ea mocheso o phahameng.

ASTM A53: Li-tubes tsa tšepe tse cheselitsoeng le tse se nang moeli bakeng sa tšebeletso e akaretsang le ea khatello.

ASTM A333: Pipe ea tšepe e se nang seamless le e cheselitsoeng bakeng sa tšebeletso ea mocheso o tlase.

API 5L: Tlhaloso ea lipeipi tsa tšepe bakeng sa tsamaiso ea lipeipi tse sebelisoang indastering ea oli le khase.

DIN 2440: Li-tubes tsa tšepe tsa k'habone tse boima bo bohareng bakeng sa merero e akaretsang ea sebopeho le khatello ea ts'ebetso.

EN 10210: Li-tubes tsa tšepe tsa mohaho tse chesang tse entsoeng ka mokhoa o chesang bakeng sa merero ea moralo.

EN 10219: Lipeipi tsa tšepe tse entsoeng ka mokhoa o batang tse entsoeng ka tšepe bakeng sa merero ea ho haha.

JIS G3452: Lipeipi tsa tšepe tsa carbon bakeng sa liphaephe tse akaretsang.

JIS G3454: Lipeipi tsa tšepe tsa carbon bakeng sa liphaephe tsa khatello.

AS/NZS 1163: Li-tubes tsa tšepe tse entsoeng ka mokhoa o batang le likarolo tse sekoti bakeng sa lihlahisoa tsa meralo le tsamaiso ea lipeipi tsa sebopeho.

Lintlha tsa bohlokoa tsa Pipe ea tšepe ea Carbon

Boholo ba Tube

Mekhahlelo ea boholo ba pipe ea tšepe ea carbon e bohlokoa ho netefatsa ho kenngoa le ts'ebetso e nepahetseng ea tsamaiso ea liphaephe.

Bophara ba ka ntle (OD): Bophara ba bokantle ba phala, bo amana ka ho toba le ho hokahanya ha pipe le sebopeho.

Ka hare ho bophara (ID): bophara ba bokahare ba phala, bo amang lebelo la ho phalla le ho phalla ha metsi.

Botenya ba lebota (WT): botenya ba lerako la phala, e leng ntho ea bohlokoa ho mamella khatello le ho tiea ha phala.

Bolelele (L): Pipe e ka ba bolelele bo tsitsitseng kapa bo sa reroang.

Ho pota-pota le ho otloloha: etsa qeto ea boleng ba ho kenya phala le ho tiisa ho hokahanya.

Mofuta oa ho qetela oa tube: Qetello ea tube e ka ba e bataletseng, ea beveled, kapa ea khoele ho amohela mefuta e fapaneng ea khokahano.

Sebopeho sa Lik'hemik'hale

Motsoako oa lik'hemik'hale oa pipe ea tšepe ea carbon e etsa qeto ea ho thatafala ha eona, matla, ho tiea le ho hanyetsa ho bola.

Khabone (C): e eketsa boima le matla, empa haholo e fokotsa boima.

Manganese (Mn): eketsa matla le ho apara ho hanyetsa ha u ntse u boloka boima bo botle.

Silicon (Si): e matlafatsa elasticity le ho hanyetsa mocheso.

Sebabole (S)lephosphorus (P): hangata li nkuoa e le litšila 'me li hloka ho bolokoa maemong a tlase kaha li fokotsa ho tiea le ho cheseha.

Lintho tse ling tsa alloying(mohlala chromium, nickel, molybdenum): e ka ntlafatsa thepa e khethehileng ea mochini le ho hanyetsa ho bola.

Thepa ea Mechini

Lisebelisoa tsa thepa ea mechine li ama ka ho toba botsitso ba pipe ea tšepe ea carbon tlas'a maemo a tšebeletso.

Matla a tšepe: bokgoni ba thepa ho hanela ho robeha ha tsitsipano.

Ho hlahisa matla: khatello e phahameng ka ho fetisisa eo thepa e kenngoa ho eona pele e qala ho holofala ka ho sa feleng.

Elongation: Pontšo ea bokhoni ba thepa ea ho holofala ka polasetiki, hore na e ka lelefatsa hakae pele e robeha.

Ho thatafala: Bokhoni ba ntho e ka hanang ho indentation sebakeng, hangata ho lekanngoa ka liteko tsa boima ba Brinell, Rockwell, kapa Vickers.

Teko ea tšusumetso: Teko ea tšusumetso e entsoeng ka mocheso o itseng ho lekola ho tiea ha ntho.

Ha u khetha li-tubes tsa carbon steel, likarolo tsena tsa bohlokoa li tlameha ho lumellana le litlhoko tse khethehileng tsa kopo le litekanyetso tse lumellanang.

Carbon Steel Pipe Surface Coating

Tšireletso ea ho roala holim'a metsi bakeng sa pipe ea tšepe ea carbon ke mokhoa oa bohlokoa oa ho thibela ho bola le ho lelefatsa bophelo ba liphaephe. Mefuta e fapaneng ea ho roala e fana ka litekanyetso tse fapaneng tsa tšireletso 'me e loketse maemo le maemo a fapaneng a ts'ebetso.

Tse latelang ke mefuta e meng e tloaelehileng ea ho roala holim'a metsi bakeng sa pipe ea tšepe ea carbon:

Liaparo tsa epoxy: fana ka ho khomarela hantle le khanyetso ea lik'hemik'hale 'me hangata e sebelisoa bakeng sa ho thibela kutu le ho sebelisoa ka tlas'a metsi.

Liaparo tsa polyurethane: Fana ka maemo a leholimo a matle haholo le abrasion resistance mme li sebelisoa libakeng tse pepesehileng kantle.

Liaparo tse nang le zinc: E na le karolo e phahameng ea phofo ea zinki, e fana ka tšireletso ea cathodic 'me e loketse libaka tsa leoatle le tsa indasteri.

Ho galaletsa: E fana ka tšireletso ea cathodic ka ho cheka ho chesang kapa electroplating zinki 'me ke mokhoa oa setso oa ho thibela ho bola.

Aluminium plating: e fana ka tshireletso e phahameng ho galvanizing tlas'a maemo a itseng, haholo-holo libakeng tse phahameng tsa mocheso.

Polyethylene (PE).: E fana ka khanyetso e ntle ea lik'hemik'hale le tšusumetso 'me hangata e sebelisoa bakeng sa liphaephe tse ka tlas'a lefatše.

Ho roala ha polypropylene (PP).: e ts'oanang le ho roala ha PE empa e fana ka ts'ebetso e ntle ho mocheso o phahameng.

Lerako la seretse sa samente: E loketse liphaephe tsa likhoerekhoere le tsa phepelo ea metsi ho thibela kutu e ka hare le tšilafalo ea mokelikeli.

Lesela la rabara: E fana ka tšireletso ea 'mele 'me e fokotsa ho bola le maqeba a bakoang ke maro.

Mofuta o mong le o mong oa ho roala o na le maemo a ona a ts'ebeliso, melemo le mathata. Lintlha tse fapaneng tse kenyeletsang litšenyehelo, maemo a kaho, nako e lebeletsoeng ea bophelo, tšusumetso ea tikoloho, le litlhoko tsa tlhokomelo li hloka ho nahanoa ha ho khethoa seaparo se loketseng.

Melemo ea Pipe ea tšepe ea Carbon

Pipe ea tšepe ea carbon e fana ka melemo e mengata e etsang hore e be thepa ea khetho bakeng sa likopo tse ngata tsa indasteri.

1.Melemo ea theko: E theko e tlaase ho feta tšepe e sa hloekang kapa tšepe ea alloy, ke khetho e ntle ka ho fetisisa bakeng sa merero e meholo le liphaephe tse telele.

2. Matla a mochine: Li na le thepa e ntle ea mochini, ho kenyeletsoa matla a phahameng a tsitsipano le ho hanyetsa tšusumetso. Sena se bolela hore e ka mamella likhatello tse phahameng le maemo a thata a ho sebetsa.

3. Ho sebetsa habonolo: Ho bonolo ho seha, ho cheselletsa, le sebopeho bakeng sa ho kenya le ho hlokomela hamorao.

4. Molemo o motle oa ho futhumatsa mocheso: Tšepe ea carbon ke motlakase o motle oa mocheso 'me o loketse lits'ebetso tse kang lisebelisoa tsa mocheso le mekhoa ea ho futhumatsa moo ho hlokahalang hore ho fetise mocheso o nepahetseng.

5. Ho hanyetsa mocheso o phahameng: E boloka thepa ea eona ea 'mele ho mocheso o phahameng' me e loketse libaka tse hlokang mocheso o phahameng oa ts'ebetso, joalo ka litsamaiso tsa mouoane.

6. Recyclability: Ke thepa e ka sebelisoang hape e ka khutlisetsoang seboping hore e sebelisoe hape qetellong ea beke ea tšebeliso.

7. Ho hanyetsa abrasion: Boima bo botle bo lumella ho hanyetsa hantle ha abrasion ha ho tsamaisa thepa e senyang 'me, ka mohlala, ho sebelisoa haholo bakeng sa thepa e tsamaisang indasteri ea merafo le ea phofo.

8. Ho lumellana: E lumellana le mefuta e mengata e fapaneng ea likhokahanyo le lisebelisoa, e nang le lisebelisoa tse ngata tse fapaneng le ho fumana habonolo.

Mathata a Carbon Steel Pipe

Leha liphaephe tsa tšepe tsa carbon li sebelisoa haholo lits'ebetsong tse ngata tsa indasteri ka lebaka la melemo ea tsona e mengata, li boetse li na le mefokolo kapa mefokolo.

1. Ho bonolo ho senya: Haholo-holo libakeng tse metsi kapa tse senyang. Corrosion e ka fokotsa botenya ba lebota la phala ea tšepe, ea eketsa kotsi ea ho phatloha 'me qetellong ea lebisa ho lutla kapa ho hloleha.

2. Litšenyehelo tsa tlhokomelo: E le ho hanela kutu le ho lelefatsa bophelo ba bona ba ts'ebeletso, liphaephe tsa tšepe tsa carbon li ka hloka mehato e meng ea ts'ireletso e kang li-coatings, linings, kapa li-cathodic systems. Tlhokomelo ea kamehla le ho hlahlojoa hoa hlokahala ho pholletsa le bophelo ba pipe, e leng ho eketsang litšenyehelo tsohle.

3. Ha e lokele ho sebelisoa le lik'hemik'hale tse itseng: Tšepe ea carbon e na le kutloelo-bohloko lik'hemik'hale tse itseng 'me e ka senyeha kapele ka lebaka la tšusumetso ea lik'hemik'hale tsena. Mohlala, tšepe ea khabone e kotsing ea ho phatloha ho hoholo ha corrosion libakeng tse nang le hydrogen sulfide e ngata.

4. Mefokolo ea mocheso: Le hoja litšepe tsa carbon li ka mamella mefuta e mengata ea mocheso o phahameng, thepa ea mochine ea tšepe e senyeha ka mocheso o phahameng haholo, e leng se etsang hore matla a thepa a fokotsehe le ho fokotseha (deformation ho tloha nako e telele ho ea ho meroalo e phahameng).

5. Mocheso o tlase oa embrittlement: Ka lithempereichara tse tlase, ho tiea le ho brittleness hoa fokotseha, ho fella ka ho robeha ha brittle tlas'a tšusumetso.

6. Litaba tsa boima ba 'mele: Lipeipi tsa tšepe tsa carbon li boima ho feta lisebelisoa tse ling, tse kang lipolasetiki, 'me li ka fella ka litlhoko tse eketsehileng le litšenyehelo tsa ho kenya le ho tšehetsa mehaho.

7. Katoloso ea mocheso: Katoloso ea mocheso e etsahalang nakong ea phetoho ea mocheso, haholo-holo liphaepheng tsa libaka tse telele. Sena se lokela ho tsotelloa ha ho etsoa moralo le ho kenya liphaephe ho qoba khatello le ho senyeha ho bakoang ke ho fetoha ha mocheso.

Ho khetha pipe e nepahetseng bakeng sa litlhoko tsa kopo e itseng le / kapa ho nka mehato e nepahetseng ea tšireletso ke senotlolo sa ho netefatsa katleho.

Tšebeliso ea Pipe ea tšepe ea Carbon

1. Indasteri ea oli le khase:E sebelisoa haholo ho tsamaiseng oli e tala, khase ea tlhaho, le lihlahisoa tse ling tsa peterole, tsamaisong ea lipeipi tsa sebaka se selelele le ho cheka lipeipi tsa liliba tsa oli.

2. Liindasteri tsa lik'hemik'hale le tsa petrochemical: Liindasteri tsena li hloka liphaephe tse hanyetsanang le mocheso o phahameng le likhatello tsa ho tsamaisa lik'hemik'hale le maro 'me kahoo hangata li sebelisa lipeipi tsa tšepe tsa carbon tse hloekisitsoeng ka ho khetheha.

3. Tlhahiso: E ka sebelisoa ho etsa likarolo tsa mochini le lisebelisoa, li-ducts tsa ho tima, jj.

4. Kaho le kaho: Sebakeng sa kaho, li sebelisoa e le masapo a meaho ea meaho joalo ka maballo, litšiea le meaho e meng e tšehetsang. E boetse e sebelisoa ha ho etsoa scaffolding le meaho e meng ea nakoana.

5. Metsi le likhoerekhoere: E sebelisoa haholo mekhoeng ea liphaephe bakeng sa ho tsamaisa metsi le likhoerekhoere, liphaephe tsa tšepe li atisa ho koaheloa ka hare ka lera le loketseng la ho roala, le sebelisetsoang ho sireletsa liphaephe ho senya le ho lelefatsa bophelo ba bona ba tšebeletso.

6. Indasteri ea matla: Libakeng tsa motlakase, li sebelisetsoa ho tsamaisa mocheso o phahameng, o nang le khatello e phahameng ea mocheso. Li ka boela tsa sebelisoa ho etsa li-boilers le li-heaters tsa mocheso.

7. Lisebelisoa tsa ho futhumatsa le ho pholisa: Bakeng sa ho tsamaisa mecha ea litaba kapa mouoane ka har'a futhumatsang bohareng le tsamaiso ea conditioning moea.

8. Indasteri ea metsing: E sebelisoa kahong ea likepe bakeng sa meaho ea foreimi, lits'ebetso tsa drainage, le lits'ebetso tse ling tse fapaneng.

9. Liteishene tsa motlakase tse futhumatsang mocheso: Bakeng sa lipalangoang tsa mouoane le metsi liteisheneng tsa motlakase tse futhumatsang mocheso.

10. Mehaho le boenjiniere: Ka tloaelo e sebelisetsoa ho ts'ehetsa meaho ea marokho, lithanele, litsamaiso tsa metro le lits'ebeletso tse kholo tsa sechaba.

Hangata liphaephe tsa tšepe tsa carbon li khethoa ho itšetlehile ka bophara ba tsona, botenya ba lerako, bolelele, mokhoa oa tlhahiso, le hore na ho na le liphahlo tse eketsehileng kapa li-linings tse hlokahalang ho hanela kutu. Ha u li sebelisa, ho bohlokoa ho nahana ka mocheso, khatello le mofuta oa mecha ea litaba sebakeng sa mosebetsi.

Mokhoa oa ho Khetha Mofani oa Pipe ea tšepe ea Carbon ea Tšepahalang

1. Litšoaneleho le mangolo a tumello:Hlahloba hore na lihlahisoa tsa mofani oa thepa li lumellana le maemo a machaba le a indasteri ea lehae le hore li na le setifikeiti sa tsamaiso ea boleng (mohlala, ISO 9001).

2. Boleng ba sehlahisoa: Na mofani oa thepa o fana ka litlaleho tsa tlhahlobo mabapi le sebopeho sa lik'hemik'hale le thepa ea mochini ea lisebelisoa tse tala le lihlahisoa tse felileng. Le ho utloisisa mehato ea netefatso ea boleng, ho kenyelletsa tlhahlobo, tlhahlobo, le taolo ea boleng nakong ea ts'ebetso ea tlhahiso.

3. Bokhoni ba tlhahiso: Hlahloba hore na boholo ba mofani oa thepa le bokhoni ba tlhahiso bo ka finyella litlhoko tsa taelo. Hlahloba hore na mekhoa ea tlhahiso le lisebelisoa tse sebelisoang ke mofani oa thepa ke tsa morao-rao ho netefatsa boleng ba sehlahisoa.

4. Botumo ba 'maraka: Nahana ka phihlelo ea mofani oa thepa indastering ea lipeipi tsa tšepe ea carbon. Phihlelo ea nako e telele ea khoebo hangata e amahanngoa le ts'epo e phahameng. Kopa maikutlo le maikutlo ho tsoa ho bareki ba seng ba ntse ba le teng, haholo-holo mabapi le boleng ba sehlahisoa le khotsofalo ea litšebeletso.

5. Tšebeletso le tšehetso:Na mofani oa thepa o fana ka litšebeletso tse ntle tsa bareki, ho kenyelletsa karabo e potlakileng le ho rarolla mathata. Hore na morekisi a ka fana ka ts'ehetso ea botekgeniki nakong ea khetho ea sehlahisoa, tlhaloso ea ts'ebetso, le ho kenya.

6. Theko le litšenyehelo: Bapisa mantsoe a qotsitsoeng ho tsoa ho barekisi ba fapaneng ho netefatsa hore theko e lumellana le boemo ba 'maraka ebile e boloka litšenyehelo. Ela hloko litšenyehelo tse patiloeng tse hlahang ho tloha ho lipalangoang, ho paka, ho lieha ho ka bang teng, joalo-joalo.

7. Nako ea thomello:Hore na barekisi ba khona ho itlama le ho fihlela linako tse behiloeng, lekola marang-rang a thepa ho netefatsa hore lihlahisoa li ka tlisoa ka mokhoa o sireletsehileng le ka nako.

8. Ka mor'a-thekiso tšebeletso: Utloisisa leano la litšebeletso tsa ka mor'a thekiso ea mofani oa thepa, tse kang ho khutlisa le ho fapanyetsana, ho sebetsana le khanyetso ea boleng, joalo-joalo.

9. Patlisiso ea tlhahisoleseling ea Khampani: Sebelisa lisebelisoa tsa inthanete ho fumana lintlha tse eketsehileng. Ka mohlala, liwebsaete tsa k'hamphani, liforamu tsa indasteri, mecha ea litaba ea sechaba, joalo-joalo.

10. Ho etela libaka: Haeba ho khoneha, u ka etela setsi sa tlhahiso ea mofani oa thepa, le lisebelisoa tsa tlhahiso ka seqo.

11. Teko ea mohlala: Mehlala e ka kopuoa bakeng sa tlhahlobo ho netefatsa hore boleng ba 'nete ba sehlahisoa bo fihlela litlhoko.

Nakong ea ts'ebetso ea khetho, tlhahlobo e felletseng le kahlolo e masene ke tsa bohlokoa. Netefatsa hore morekisi eo u mo khethang ha a phahame feela ho latela theko, empa ke khetho e ntle ka ho fetisisa ho latela boleng, ts'epahalo, le boleng ka kakaretso.

Mabapi le rona

Ho tloha ha e thehoa ka 2014, Botop Steel e fetohile mofani oa pele oa lipeipi tsa tšepe tsa carbon steel Northern China, e tsejoang ka tšebeletso ea eona e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse feletseng. Lihlahisoa tse ngata tsa k'hamphani li kenyelletsa liphaephe tsa tšepe tse se nang seamless, ERW, LSAW, le SSAW, hammoho le lisebelisoa tsa liphaephe, li-flange le litšepe tse khethehileng.

Ka boitlamo bo matla ba boleng, Botop Steel e sebelisa taolo le liteko tse thata ho netefatsa ho ts'epahala ha lihlahisoa tsa eona. Sehlopha sa eona se nang le boiphihlelo se fana ka litharollo tsa motho ka mong le tšehetso ea litsebi, se tsepamisitse maikutlo khotsofalong ea bareki.

Tags: peipi ea tšepe ea carbon, bafani, bahlahisi, lifeme, li-stock, lik'hamphani, thekiso, reka, theko, qotso, bongata, thekiso, litšenyehelo.

Nako ea poso: May-03-2024