API 5L X70 ke boemo ba API 5L bakeng sa pipe ea mohala e nang le matla a fokolang a 70,000 psi.E sebelisoa haholo bakeng sa lipalangoang tse nang le khatello e phahameng ea khase ea tlhaho, oli le metsi.

Ho ithuta haholoanyane ka API 5L-46th, u ka khonatlanya mona!

Likonopo tsa ho Tsamaisa

Likarolo tsa API 5L X70

Matla a chai a phahameng: Matla a fokolang a tlhahiso ea 70,000 psi (hoo e ka bang 485 MPa), a loketse khatello e phahameng ea ka hare.

Matla a matle: e boloka ts'ebetso ka mocheso o tlase bakeng sa libaka tse batang le ts'ebeliso ea leoatle le tebileng.

Excellent weldability: Matla a phahameng ha a ntse a boloka ts'oaetso e ntle, ka li-welds tse lumellanang le thepa ea tšepe ea motheo.

Corrosion resistance: e ka matlafatsoa ke taolo ea sebopeho sa lik'hemik'hale le liphekolo tsa morao-rao (mohlala, lirafshoa), tse loketseng libaka tse ka thoko le tse senyang.

Tšoaneleho ea tikoloho: E ka etselitsoe ho sebelisoa libakeng tse tloaelehileng tsa naha, maoatle le lits'ebeletso tsa asiti.

Sustainability: Phokotso ea tšusumetso ea tikoloho le ts'ebetso e ntlafalitsoeng ea phetisetso joalo ka thepa e ka sebelisoang hape.

API 5L X70 Lihlopha

Mofuta oa Pipe: Pipe ea tšepe e cheselitsoeng le e se nang seam

Sehlopha sa lintlha tsa sehlahisoa: API 5L X70 PSL1 le API 5L X70 PSL2

Mokhoa oa ho etsa lipeipi: SMLS, LFW, HFW, LW, SAWL, SAWH, COWL, COWH

Mofuta oa ho qetela oa liphaephe: Qetello ea Beled, Qetello e hlakileng

Lisebelisoa tse so fetoloe

Li-ingot, li-billet, li-billet, li-strips (likhoele), kapa lipoleiti e le lisebelisoa tse tala bakeng sa ho etsa lipeipi tsa tšepe.

Thepa e tala bakeng sa phala ea tšepe ea PSL2 e tla ba tšepe e entsoeng ka lijo-thollo tse ntle.

Ho feta moo, mohala oa tšepe (coil) kapa poleiti e sebelisoang ho etsa phala ea tšepe ea PSL2 e ke ke ea jara li-welds tsa ho tlatsa.

Mokhoa oa Tlhahiso ea API 5L X70

| Mofuta oa Pipe | SMLS | LFW | HFW | LW | SAWLc | SAWHd | KHOMOc | KOKOd |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | - | X | - | X | X | X | X |

cPipe e nang le seam habeli e fumaneha haeba ho lumellanoe, empa e lekanyelitsoe phaepheng e nang le D ≥ 914 mm.

dPipe ea seam ea Helical e lekanyelitsoe ho pipe le D ≥ 114.3 mm.

Mefuta ea Pipe End bakeng sa API 5L X70

| Pipe End | Belled qetellonge | Qetello e hlakileng |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | - | X |

eBelled-end pipe e lekanyelitsoe ho pipe e nang le D ≤219.1 mm le t≤ 3.6 mm.

Boemo ba ho qetela ba Phano

Boemo ba ho qetela ba ho fana ka API 5L X70 (phekolo ea ho qetela ea mocheso oa phala ea tšepe e felileng) e ka aroloa ka: rolling, normalizing rolling, thermo-mechanical rolling, thermo-mechanical forming, normalizing forming, normalizing, normalizing and tempering kapa quenching le tempering.

| PSL | Boemo ba Phano | Pipe Grade/Steel Grade | |

| PSL1 | Ha e ntse e phuthoa, e tloaelehileng e kolobisitsoe, thermomechanical rolled, thermomechanical bopilwe, bo tloaeleha bo bopehile, bo tloaelehile, bo tloaelehe le bo halefileng kapa bo tingoe le bohale | X70 | L485 |

| PSL 2 | E khutsitsoe ebile e halefile | X70Q | L485Q |

| Thermomechanical rolled kapa thermomechanical thehoa | X70M | L485M | |

Linaha tsena tsa phano li netefatsa hore API 5L X70 tubing e sebetsa hantle lits'ebetsong tse fapaneng tse fapaneng, joalo ka ts'ebeliso maemong a khatello e phahameng, mocheso o tlase kapa tikolohong e senyang.

Sebopeho sa Lik'hemik'hale

API 5L X70 PSL1 Sebopeho sa Lik'hemik'hale

Motsoako oa lik'hemik'hale oa API 5L X70 PSL1 pipe ea tšepe e kenyelletsa khabone e tlase, palo e leka-lekaneng ea manganese, le phosphorus e nyane, sebabole le silicon.Ntle le moo, likarolo tsa alloying joalo ka chromium, nickel le koporo lia eketsoa ho matlafatsa matla le ho hanyetsa kutu.Li-micro-alloying elements tse kang vanadium, molybdenum le titanium li ntlafatsa ho tšoarella le ho fana ka thepa, ho netefatsa ts'ebetso maemong a thata.

| Sebopeho sa Lik'hemik'hale bakeng sa PSL 1 Pipe e nang le t≤25.0 mm (0.984 in.) | |||||||||

| Kereiti ea tšepe (Lebitso la tšepe) | Boholo ba Karolo, E Thehiloe ho Litlhahlobo tsa Mocheso le Sehlahisoaag % | ||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| maxb | maxb | min | max | max | max | max | max | ||

| Pipe e Seamless | |||||||||

| L485 | X70 | 0.28 | 1.40 | - | 0.03 | 0.03 | f | f | f |

| Pipe e cheselitsoeng | |||||||||

| L485 | X70 | 0.26e | 1.65e | - | 0.03 | 0.03 | f | f | f |

| a Cu≤0.50 %;Ni≤0.50%;Cr≤0.50 %le Mo≤0.15 %. b Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ka tlase ho palo e kholo e boletsoeng bakeng sa khabone, keketseho ea 0.05% ka holim'a khatello e phahameng e boletsoeng bakeng sa Mn e lumelletsoe, ho fihla ho 1.65% bakeng sa limaraka ≥L245 kapa B, empa ≤L360 kapa X52;ho fihlela boholo ba 1.75 % bakeng sa limaraka>L360 kapa X52, empa le ho fihla ho 2.00 % bakeng sa Kereiti ea L485 kapa X70. e Ntle le haeba ho lumellane ka tsela e 'ngoe f Ntle le ha ho dumellanwe ka tsela e nngwe, Nb+V+Ti≤0.15 %. g Ha ho tlatsetso e entsoeng ka boomo ea B e lumelletsoeng le masala a B≤0.001 %. | |||||||||

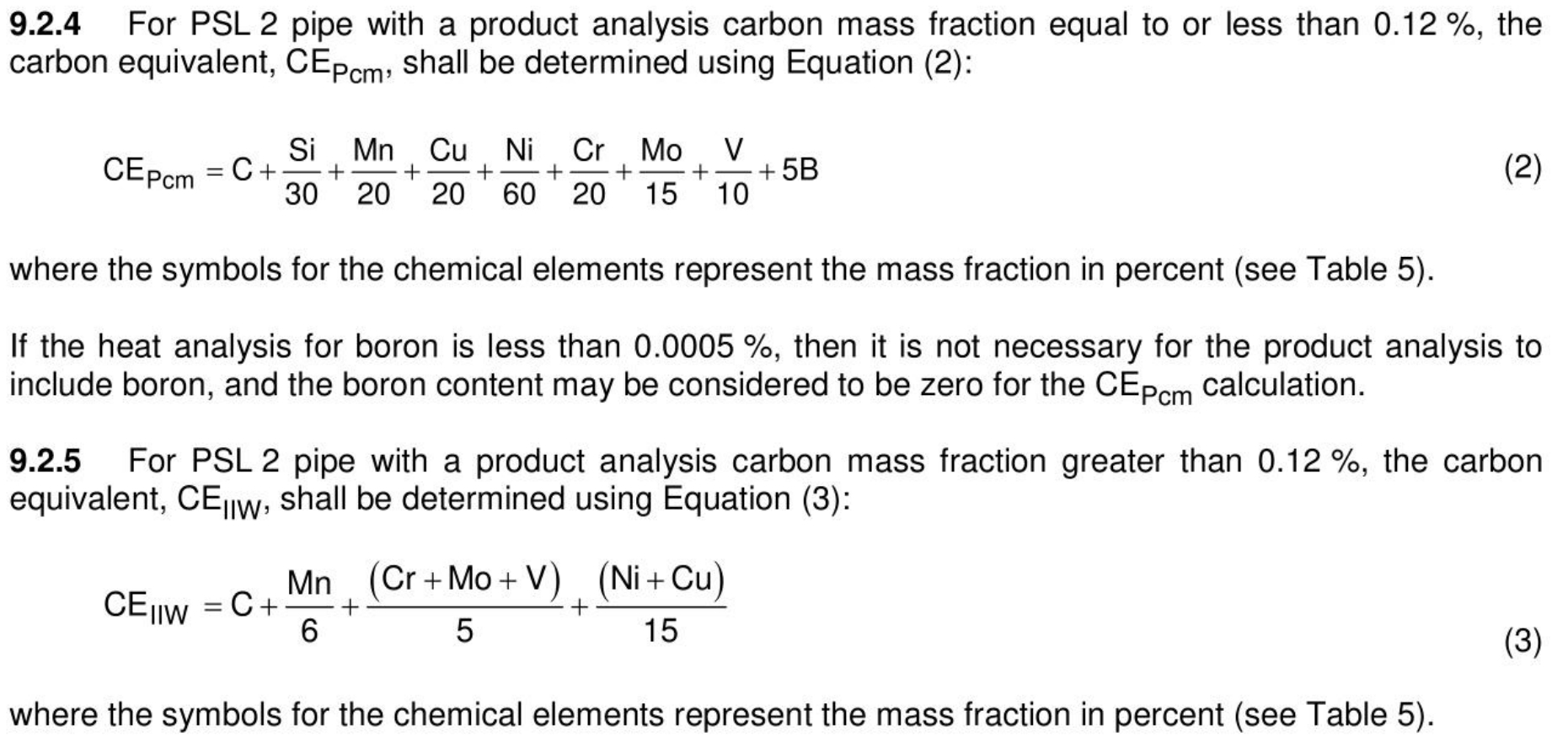

API 5L X70 PSL2 Sebopeho sa Lik'hemik'hale

Sebopeho sa lik'hemik'hale sa API 5L X70 PSL2 se kenyelletsa khabone e laoloang ka nepo, manganese, sebabole le phosphorus, hammoho le karolo e bohlale ea silicon, chromium, nickel le koporo.Taolo e tiileng ea mantlha ha e ntlafatse feela matla a chai le ho tiea ha phala empa hape e ntlafatsa ho hanyetsa ha kutu tlas'a maemo a feteletseng.Ho feta moo, ho lateloa lintho tse kang vanadium, molybdenum, le titanium li fetotsoe ho ntlafatsa ts'ebetso, ho etsa hore X70 PSL2 e be e loketseng ho sebetsana le maemo a kotsi haholo.

| Sebopeho sa Lik'hemik'hale bakeng sa PSL 2 Pipe e nang le t ≤ 25.0 mm (0.984 in.) | ||||||||||||

| Kereiti ea tšepe (Lebitso la tšepe) | Boholo ba Karolo, E Thehiloe ho Litlhahlobo tsa Mocheso le Sehlahisoa % boholo | Khabone E lekananga %max | ||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | Tse ding | CEllw | CEpcm | ||

| Pipe e se nang Seam le e Welded | ||||||||||||

| L485Q | X70Q | 0.18f | 0.45 f | 1.80f | 0.025 | 0.015 | g | g | g | h, ke | 0.43 | 0.25 |

| Pipe e cheselitsoeng | ||||||||||||

| L485M | X70M | 0.12 f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h, ke | 0.43 | |

| a Ho ipapisitsoe le tlhahlobo ea sehlahisoa, bakeng sa phala e se nang moeli e nang le t> 20.0 mm (0.787 in.), meeli ea CE e tla ba joalo ka ha ho lumellanoe;Meeli ea CEllw e sebetsa haeba C>0.12 %, 'me meeli ea CEpcm e sebetsa haeba C≤0.12 %. b Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ka tlase ho palo e boletsoeng bakeng sa C, keketseho ea 0.05% ka holimo ho palo e boletsoeng bakeng sa Mn e sa lumelloeng, ho fihla ho palo e kholo ea 1.65% bakeng sa limaraka≥L245 kapa B, empa≤L360 kapa X52;ho fihla ho boholo ba 1.75 % bakeng sa limaraka > L360 kapa X52, empaL555 kapa X80. c Ntle le haeba ho lumellanoe ka tsela e 'ngoe, Nb+V≤0.06 %. d Nb+V+Ti≤0.15%. e Ntle le ha ho dumellanwe ka tsela e nngwe, Cu≤0.50 %;Ni≤0.30 %;Cr≤0.30 %le Mo≤0.15%. f Ntle le ha ho dumellanwe ka tsela e nngwe. g Ntle le haeba ho dumellanwe ka tsela e nngwe, Nb+V+Ti≤0.15 %. h Ntle le ha ho dumellanwe ka tsela e nngwe, Cu≤0.50%;Ni≤0.50%;Cr≤0.50 %le Mo≤0.50%. i Ntle le ha ho dumellanwe ka tsela e nngwe, Cu≤0.50 %;Ni≤1.00%;Cr≤0.50%le Mo≤0.50%. j B≤0.004 %. k Ntle le haeba ho lumellanoe ka tsela e ’ngoe, Cu≤0.50 %;Ni≤1.00 %;Cr≤0.55 %le Mo≤0.80 %. l Bakeng sa limaraka tsa liphaephe tsa PSL 2 ntle le limaraka tseo mongolo o botlaaseng ba leqephe j) o seng o ntse o sebetsa, se latelang sea sebetsa: ntle le haeba ho lumellanoa ka mokhoa o mong ka ho eketsa ka boomo ea B ho lumelletsoe le ho sala B≤0.001 %. | ||||||||||||

Motsoako oa Lik'hemik'hale bakeng sa Maemo a Tšebeletso a Bolila API 5L X70 PSL2

Maemo a ts'ebeletso e bolila a bua haholo ka tšebeliso ea liphaephe libakeng tse nang le hydrogen sulfide (H₂S), e ka lebisang ho hydrogen sulfide stress corrosion cracking (HIC) le sulfide stress corrosion cracking (SSCC).

Phetoho ea sebopeho sa lik'hemik'hale: Tlas'a maemo ana, sebopeho sa lik'hemik'hale tsa lipeipi tsa tšepe li tlameha ho lokisoa ka nepo ho ntlafatsa ho hanyetsa ha tsona.Hangata, sena se kenyelletsa ho fokotsa lik'habone tsa thepa le ho eketsa likarolo tsa alloying tse kang molybdenum (Mo) le nickel (Ni), tse eketsang ho hanyetsa ha kutu le ho thatafala ha thepa.

| Letlapa H.1—Sebopeho sa Khemik'hale bakeng sa Pipe e nang le t≤25.0 mm (0.984 in.) | |||||||||||

| Kereiti ea tšepe | Karolo ea Boima e Thehiloe ho Litlhahlobo tsa Mocheso le Sehlahisoa% max | Khabone E lekananga % max | |||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Tse dingc,d | CEllw | CEpcm | |

| SMLS le Pipe e Welded | |||||||||||

| L485QS kapa X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.003e | 0.09 | 0.05 | 0.06 | g,ke,k | 0.42 | 0.22h |

| Pipe e cheselitsoeng | |||||||||||

| L485MS kapa X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002e | 0.10 | 0.08 | 0.06 | g,ke,j | - | 0.22 |

Lintlha tse qaqileng li ka fumanoa ho API 5L Sehlomathiso H.

Motsoako oa Lik'hemik'hale oa API 5L X70 PSL2 bakeng sa Maemo a Ts'ebeletso ea Offshore

Maemo a ts'ebeletso ea kantle ho naha a kenyelletsa tikoloho ea leoatle, ho kenyeletsoa ho pepesehela metsi a letsoai le maemo a leholimo a feteletseng.Maemo ana a hloka liphaephe tse nang le khanyetso e phahameng ea kutu le boima bo lekaneng ho thibela ho bola ha metsi a letsoai le litlamorao tse tlase tsa mocheso.

Phetoho ea sebopeho sa lik'hemik'hale: Bakeng sa ts'ebeletso ea kantle ho naha, motsoako oa phala hangata o eketseha ka chromium (Cr), nickel (Ni) le molybdenum (Mo) ho matlafatsa khanyetso ea eona khahlanong le ho bola ha metsi a leoatle.Palo ea li-micro-alloying elements tse kang vanadium (V) le niobium (Nb) le tsona li ka fetoloa ho matlafatsa boima ba mocheso o tlase.

| Letlapa J.1—Sebopeho sa K'hemik'hale bakeng sa Pipe e nang le t≤25.0 mm (0.984 in.) | ||||||||||||

| Kereiti ea tšepe | Karolo ea Boima e Thehiloe ho Litlhahlobo tsa Mocheso le Sehlahisoa max % | Khabone Equivalenta max % | ||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Tse dingc | CEllw | CEPcm | ||

| SMLS le Pipe e Welded | ||||||||||||

| L485QO | X70QO | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | e,h | 0.42 | 0.23g |

| Pipe e cheselitsoeng | ||||||||||||

| L485MO | X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 | e,h | - | 0.22 |

Lintlha tse felletseng li ka fumanoa ho API 5L Appendix J.

Ho feta moo, sebopeho sa lik'hemik'hale tsa phala ea tšepe bakeng sa maemo a ts'ebeletso ea kantle ho naha ho API 5L X70 PSL2 e ts'oana le litlhoko tsa phala bakeng sa lits'ebetso tse hlokang matla a polasetiki a longitudinal.Batho ba nang le thahasello ba ka sheba API 5L Sehlomathiso N.

Thepa ea Mechini

API 5L X70 PSL1 Mechanical Properties

| Letlapa la 6-Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 1 Pipe | ||||

| Phaephe Kereiti | Pipe 'Mele oa Pipe e Seamless le e Welded | Weld Seam ea EW, LW, SAW, le Pipe ea KHOMO | ||

| Hlahisa Matlaa Rho.5 MPa(psi) | Matla a tšepea Rm MPa(psi) | Elongation (ho 50 mm kapa 2 in.) Af % | Matla a tšepeb Rm MPa(psi) | |

| min | min | min | min | |

| L485 kapa X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Litekanyetso tse khethehileng li ka bonoa ho API 5L Lethathamo la 6.

API 5L X70 PSL2 thepa ea mochini

Li-tubes tsa PSL2 bakeng sa lits'ebetso tse khethehileng li fetoloa haholo bakeng sa sebopeho sa lik'hemik'hale, empa litlhoko tsa thepa ea mochini li tšoana.

| Letlapa la 7-Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 2 Pipe | |||||||

| Phaephe Kereiti | Pipe 'Mele oa Pipe e Seamless le e Welded | Weld Seam ea HFW BONA le Pipe ea CoW | |||||

| Hlahisa Matlaa Rho.5 MPa(psi) | Matla a tšepea Rm MPa (psi) | Karolelanoac Rt0.5/Rm | Elongation (ka 50 mm kapa 2 in.) Af % | Tensile Matlad Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L485Q kapa X70Q L485M kapa X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

Litekanyetso tse khethehileng li ka bonoa ho API 5L Lethathamo la 7.

Mekhoa ea Teko

| Sehlopha sa liteko | Mokhoa oa ho Leka |

| Sebopeho sa Lik'hemik'hale | ISO 9769 kapa ASTM A751 |

| Thepa ea Mechini | ISO 6892-1 kapa ASTM A370 |

| Teko ea Hydrostatic | API 5L 10.2.6 |

| Tlhahlobo e sa Senyeheng | API 5L Sehlomathiso E |

| Teko ea ho Koba | ISO 8491 kapa ASTM A370 |

| Tataiso ea Bend Test | ISO 5173 kapa ASTM A370 |

| Teko e bataletseng | ISO 8492 kapa ASTM A370 |

| Teko ea CVN Impact(PLS2) | ASTM A370 |

| Liteko tsa DWT(PSL2) | API 5L3 |

Likopo tsa API 5L X70

Liphaephe tsa oli: tse sebelisetsoang ho tsamaisa oli e tala kapa lihlahisoa tse hloekisitsoeng, haholo-holo lipalangoang tsa sebaka se selelele ho pholletsa le libaka kapa ka tlas'a metsi.

Liphaephe tsa khase: bakeng sa ho bokella le ho ajoa ha khase ea tlhaho, ho kenyeletsoa lipalangoang tsa sebaka se selelele le libaka tse nang le khatello e phahameng.

Lisebelisoa tsa meralo: Pipe ea tšepe ea API 5L X70 e boetse e sebelisoa mererong e khethehileng joalo ka sethala sa kantle ho naha kapa meaho ea tšehetso e matla haholo.

Lisebelisoa tsa indasteri: Litsamaiso tsa lipalangoang tse nang le metsi ka har'a limela tsa lik'hemik'hale, libaka tsa ho hloekisa, joalo-joalo.

Tikoloho e khethehileng ea ts'ebeliso: Ho hanyetsa kutu ha pipi ea tšepe ea API 5L X70 ho etsa hore e tšoanelehe ho sebelisoa libakeng tse fapaneng tse ikhethang, haholo-holo maemong a acidic le a kantle ho naha.

Lihlahisoa tsa rona tse Amanang

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Pipe ya Tshipi ya Carbon

Pipe End Processing

Ho khaola lipeipi

Liaparo tsa anti-corrosion: galvanized, pente, 3PE, FBE, joalo-joalo.

Re e mong oa ba etellang pele welded carbon tšepe pipe le bahlahisi seamless tšepe liphaephe le bafani ba tsoang Chaena, ba nang le mefuta e mengata ea liphaephe tsa tšepe tsa boleng bo phahameng setokong, re ikemiselitse ho u fa tharollo e felletseng ea lipeipi tsa tšepe.Bakeng sa lintlha tse ling tsa sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona, re lebeletse ho u thusa ho fumana mekhoa e metle ea lipeipi tsa tšepe bakeng sa litlhoko tsa hau!

Tags: X70, API 5l x70, ai 5l, bafani, bahlahisi, lifeme, li-stock, lik'hamphani, thekiso, theko, qotso, bongata, thekiso, litšenyehelo.

Nako ea poso: Apr-14-2024