JIS G 3456 lipeipi tsa tšepeke li-tubes tsa carbon steel li loketse haholo-holo ho sebelisoa libakeng tsa litšebeletso tse nang le bophara ba ka ntle pakeng tsa 10.5 mm le 660.4 mm mocheso o fetang 350 ℃.

Likonopo tsa ho Tsamaisa

JIS G 3456 Sehlopha sa Kereiti

Lisebelisoa tse so fetoloe

Mekhoa ea Tlhahiso ea JIS G 3456

Pipe End

Kalafo e Chesang

Likarolo tsa lik'hemik'hale tsa JIS G 3456

Teko ea Tensile ea JIS G 3456

Teko ea ho batalatsa

Teko ea Bendability

Teko ea Hydraulic kapa Teko e sa Senyeheng (NDT)

Chate ea Boima ba Pipe le Litlhophiso tsa Pipe tsa JIS G 3456

Dimensional Tolerances

Ponahalo

JIS G 3456 Ho tšoaea

JIS G 3456 Likopo tsa Pipe ea Tšepe

Maemo a Amanang le JIS G 3456

Lihlahisoa tsa rona tse Amanang

JIS G 3456 Sehlopha sa Kereiti

Tekanyetso ea JIS G 3456 e na le limaraka tse tharo ho ea ka matla a thata a phala.

STPT370,STPT410 le STPT480

Li emela li-tubes tse nang le matla a fokolang a 370, 410, le 480 N/mm² (MPa) ka ho latellana.

Lisebelisoa tse so fetoloe

Liphaephe li tla etsoa ka tšepe e bolailoeng.

Tšepe e bolailoeng ke mofuta o khethehileng oa tšepe o khetholloang ka ho eketsoa ha lintho tse itseng, tse kang aluminium le silicon, nakong ea ho qhibiliha ho monya le ho tlama oksijene le litšila tse ling tse kotsi ka har'a tšepe.

Ts'ebetso ena ka katleho e tlosa likhase le litšila, kahoo e ntlafatsa bohloeki le ho tšoana ha tšepe.

Mekhoa ea Tlhahiso ea JIS G 3456

E hlahisoa ho sebelisoa motsoako o nepahetseng oa mekhoa ea ho etsa li-tubes le mekhoa ea ho qetela.

| Letšoao la mophato | Letšoao la ts'ebetso ea tlhahiso | ||

| Mokhoa oa ho etsa liphaephe | Mokhoa oa ho qetela | Ho tshwaya | |

| STPT370 STPT410 STPT480 | Seamless:S | E felile:H Ha ho bata:C | Joalo ka ha ho fanoe ho 13 b). |

| Motlakase o hanyetsanang le welded:E Butt e cheselitsoe:B | E felile:H Ha ho bata:C Joalo ka ha ts'ireletso ea motlakase e cheselitsoe:G | ||

Bakeng saSetšoantšo sa 480phaephe ea boemo bo holimo, ho tla sebelisoa phala ea tšepe feela e se nang seam.

Haeba ho sebelisoa welding ea ho hanyetsa, li-welds tse ka hare le ka ntle tsa phala li tla tlosoa ho fumana weld e boreleli.

Pipe End

Pipe e lokela ho bapheletso e sephara.

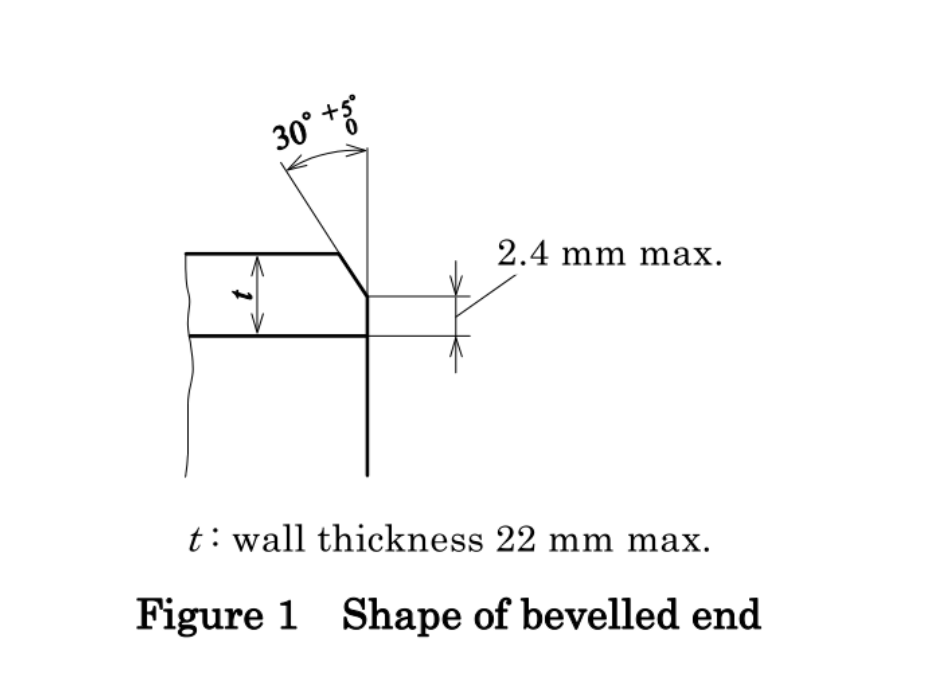

Haeba phala e hlokeha ho sebetsoa ka lehlakoreng le betliloeng, bakeng sa botenya ba lebota ≤ 22mm phala ea tšepe, angle ea bevel ke 30-35 °, bophara ba bevel ea bohale ba phala ea tšepe: ke max 2.4mm.

Botenya ba lebota bo boholo ho feta 22mm phala ea tšepe e thellang pheletsong, eo hangata e sebetsoang joalo ka bevel e kopaneng, ts'ebetsong ea litekanyetso e ka lebisa ho litlhoko tse amehang tsa ASME B36.19.

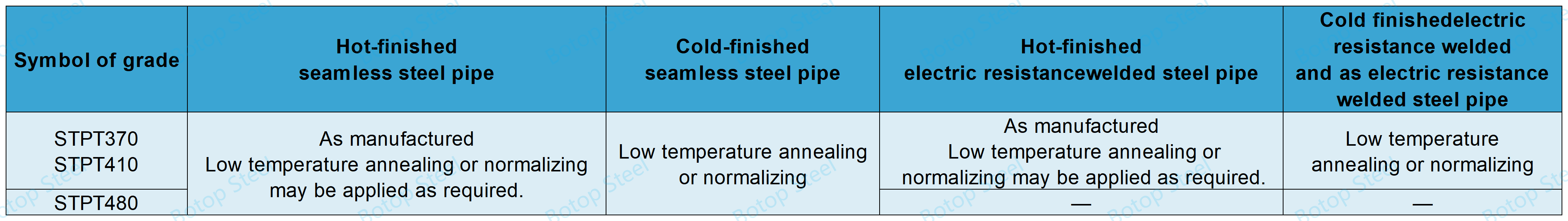

Kalafo e Chesang

Khetha mokhoa o nepahetseng oa phekolo ea mocheso ho latela boemo le mokhoa oa tlhahiso.

Likarolo tsa lik'hemik'hale tsa JIS G 3456

Teko ea Sebopeho sa Lik'hemik'hale

Mokhoa oa ho hlahloba mocheso o tla lumellana le JIS G 0320.

Mokhoa oa ho hlahloba sehlahisoa o tla lumellana le JIS G 0321.

| Letšoao la mophato | C(Khabone) | Si(Silikone) | Mn(Manganese) | P(Phosphorus) | S(Sebabole) |

| max | max | max | |||

| STPT370 | 0.25% | 0.10-0.35% | 0.30-0.90% | 0.035% | 0.035% |

| STPT410 | 0.30% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

| STPT480 | 0.33% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

Mamello bakeng sa Sebopeho sa Lik'hemik'hale

Lipeipi tsa tšepe tse se nang moroko li tla ba tlas'a mamello ho Lethathamo la 3 la JIS G 0321.

Liphaephe tsa tšepe tse cheselitsoeng tse hanyetsanang li tla ba tlas'a mamello ho Lethathamo la 2 la JIS G 0321.

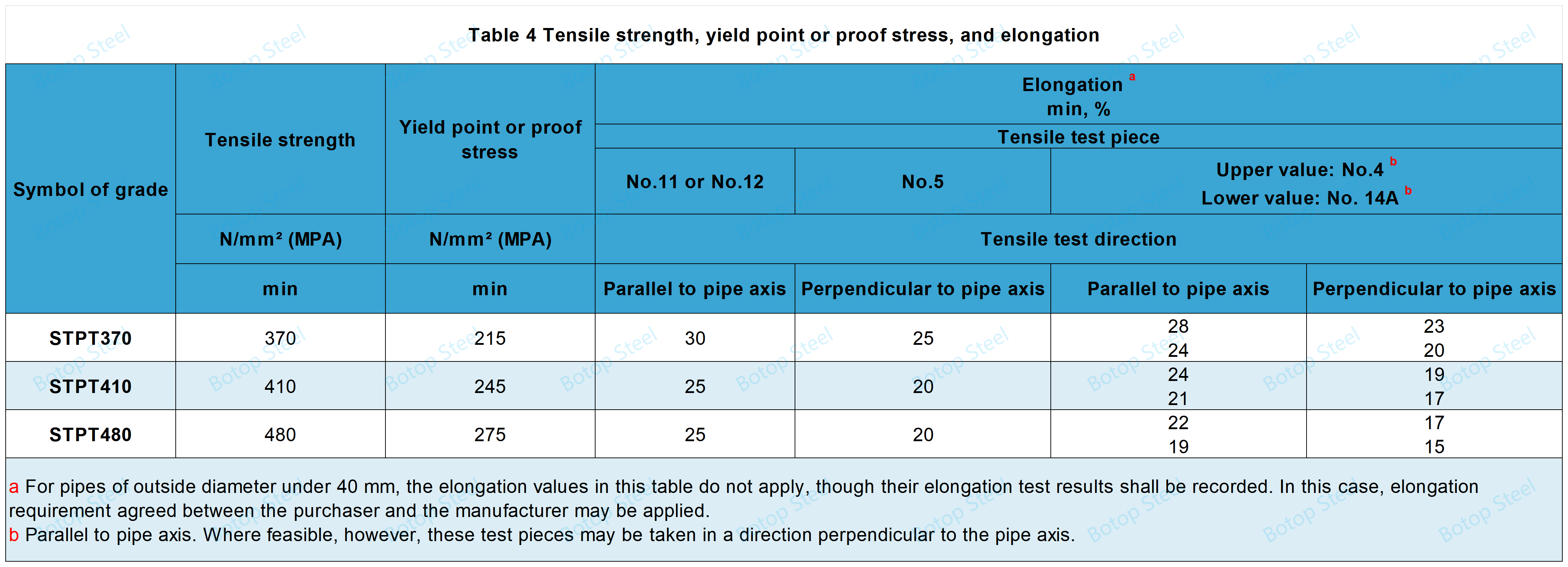

Teko ea Tensile ea JIS G 3456

Mekhoa ea Teko: Mekhoa ea tlhahlobo e tla lumellana le maemo a JIS Z.2241.

Pipe e tla finyella litlhoko tse fanoeng ho Lethathamo la 4 bakeng sa matla a ho tsitsa, matla a ho hlahisa le ho lelefatsa.

Karolo ea teko e sebelisitsoeng e tla ba ea No. 11, No. 12 (No. 12A, No. 12B, kapa No. 12C), No. 14A, No. 4 or No. 5 e boletsoeng ho JIS Z 2241.

Bophara ba sekhechana sa Test No. 4 e tla ba 14 mm (bolelele ba gauge 50 mm).

Likarolo tsa liteko No. 11 le No. 12 li tla nkoa ka ho bapa le axis ea pipe,

Likarolo tsa liteko No. 14A le No. 4, ebang ke ka tsela e bapileng kapa ea perpendicular ho axis ea pipe,

le Test piece No. 5, ka perpendicular ho axis pipe.

Teko sengoathoana No. 12 kapa No. 5 nkiloeng ho tloha motlakase ho hanyetsa welded tšepe phala e ke ke ea ba le tjheseletsa.

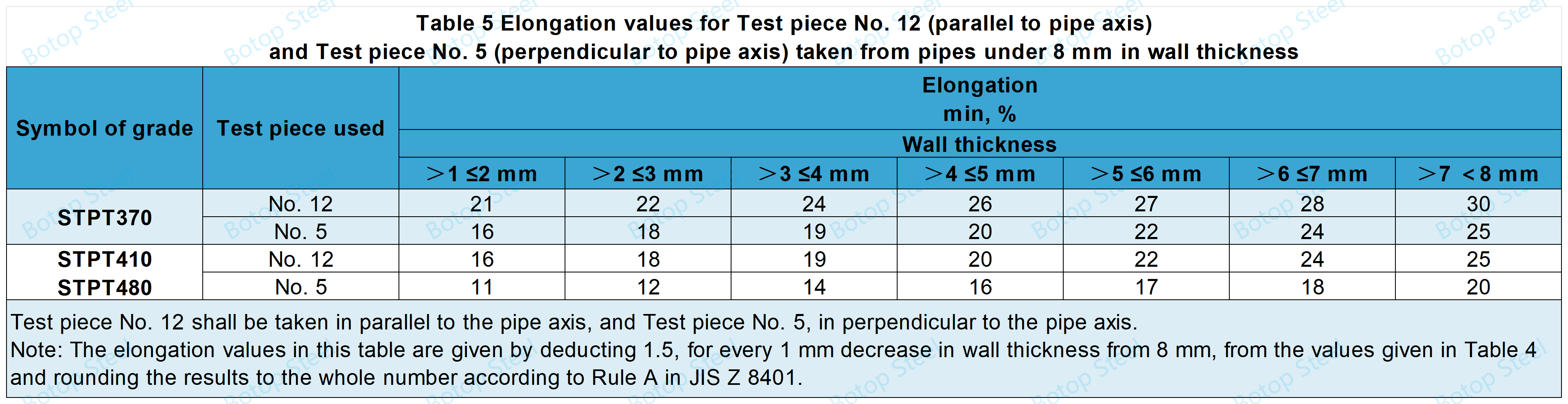

Bakeng sa teko ea tensile ea liphaephe tse ka tlas'a 8 mm ka botenya tse entsoeng ho sebelisoa Test piece No. 12 kapa Test piece No. 5, tlhokahalo ea elongation e fanoeng Lethathamong la 5 e tla sebetsa.

Teko ea ho batalatsa

Mocheso oa kamore (5 ° C - 35 ° C), batalatsa mohlala pakeng tsa li-platform tse peli ho fihlela osebaka (H) pakeng tsa bona se fihla ho boleng bo boletsoeng ebe u hlahloba mapetsong.

H=(1+e)t/(e+t/D)

нSebaka pakeng tsa li-platens (mm)

t: botenya ba lebota la phaephe (mm)

D: bophara ba phala e ka ntle (mm)

е: kamehla e hlalosoang bakeng sa sehlopha ka seng sa pipe:

0.08 bakeng sa STPT370,

0.07 bakeng sa STPT410 le STPT480

Teko ea Bendability

Bendability e sebetsa ho liphaephe tse nang le bophara ba ka ntle ba 60.5 mm kapa ka tlase.

Mokhoa oa teko Ka mocheso oa kamore (5 ° C ho ea ho 35 ° C), koba sengoathoana sa teko ho potoloha mandrel ho fihlela radius e ka hare e le makhetlo a 6 bophara ba ka ntle ba phala 'me u hlahlobe hore na ha ho na mapetsong. Tekong ena, weld e lokela ho behoa hoo e ka bang 90 ° ho tloha karolong e ka ntle ea ho kobeha.

Teko ea Bendability e ka boela ea etsoa ho latela tlhokahalo ea hore radius e ka hare e be makhetlo a mane bophara ba ka ntle ba phala le angle ea bend ke 180 °.

Teko ea Hydraulic kapa Teko e sa Senyeheng (NDT)

Teko ea haeteroliki kapa teko e sa senyeheng e tla etsoa phala e 'ngoe le e 'ngoe.

Teko ea Hydraulic

Tšoara phala bonyane ka khatello e fokolang ea tlhahlobo ea hydraulic e boletsoeng bonyane metsotsoana ea 5 'me u hlokomele hore phala e khona ho mamella khatello ntle le ho lutla.

Nako ea Hydraulic e hlalositsoe ho latela Kemiso ea pipe ea tšepe.

| Letlapa la 6 Khatello e fokolang ea tlhahlobo ea hydraulic | ||||||||||

| Botenya ba lebota ka lebitso | Nomoro ea Kemiso: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Khatello e tlase ea tlhahlobo ea haeteroliki, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Teko e sa Senyeheng

Haeba tlhahlobo ea ultrasonic e sebelisoa, matšoao a tsoang lisampoleng tsa litšupiso tse nang le litekanyetso tsa litšupiso tsa mofuta oa UD, joalokaha ho boletsoe ho JIS G 0582, li tla sebelisoa e le maemo a alamo; pontšo leha e le efe e tsoang phala e lekanang kapa e kholo ho feta boemo ba alamo e tla hanoa. Ho phaella moo, botebo bo fokolang ba likheo tsa lisekoere bakeng sa ho hlahloba liphaephe, ntle le ho qeta ho bata, e tla ba 0.3 mm.

Haeba tlhahlobo ea hona joale ea eddy e sebelisoa, matšoao a tsoang ho mofuta oa EY oa referense joalo ka ha ho boletsoe ho JIS G 0583 a tla sebelisoa e le boemo ba alamo; pontšo leha e le efe e tsoang phala e lekanang kapa e kholo ho feta boemo ba alamo e tla ba lebaka la ho hana.

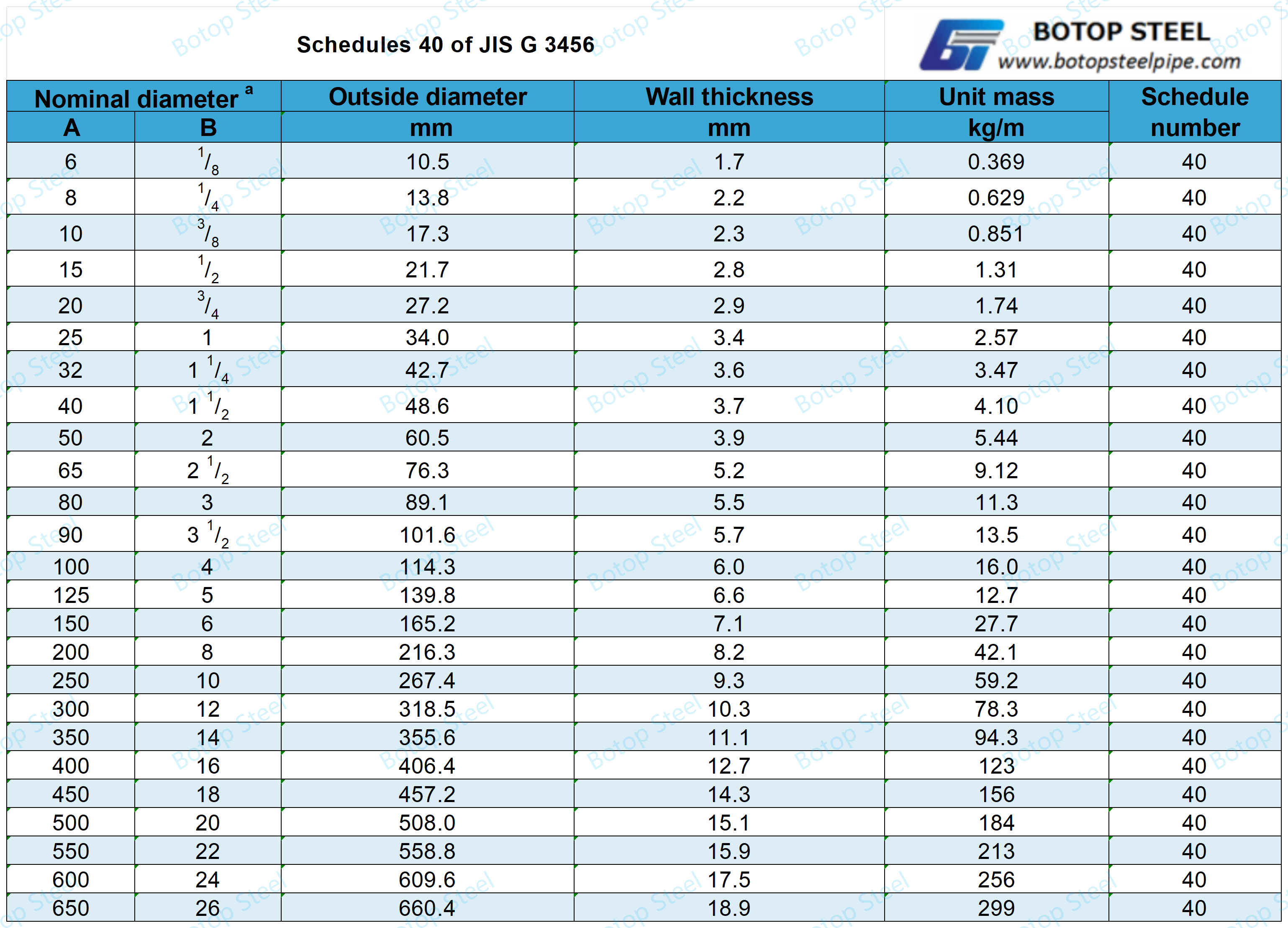

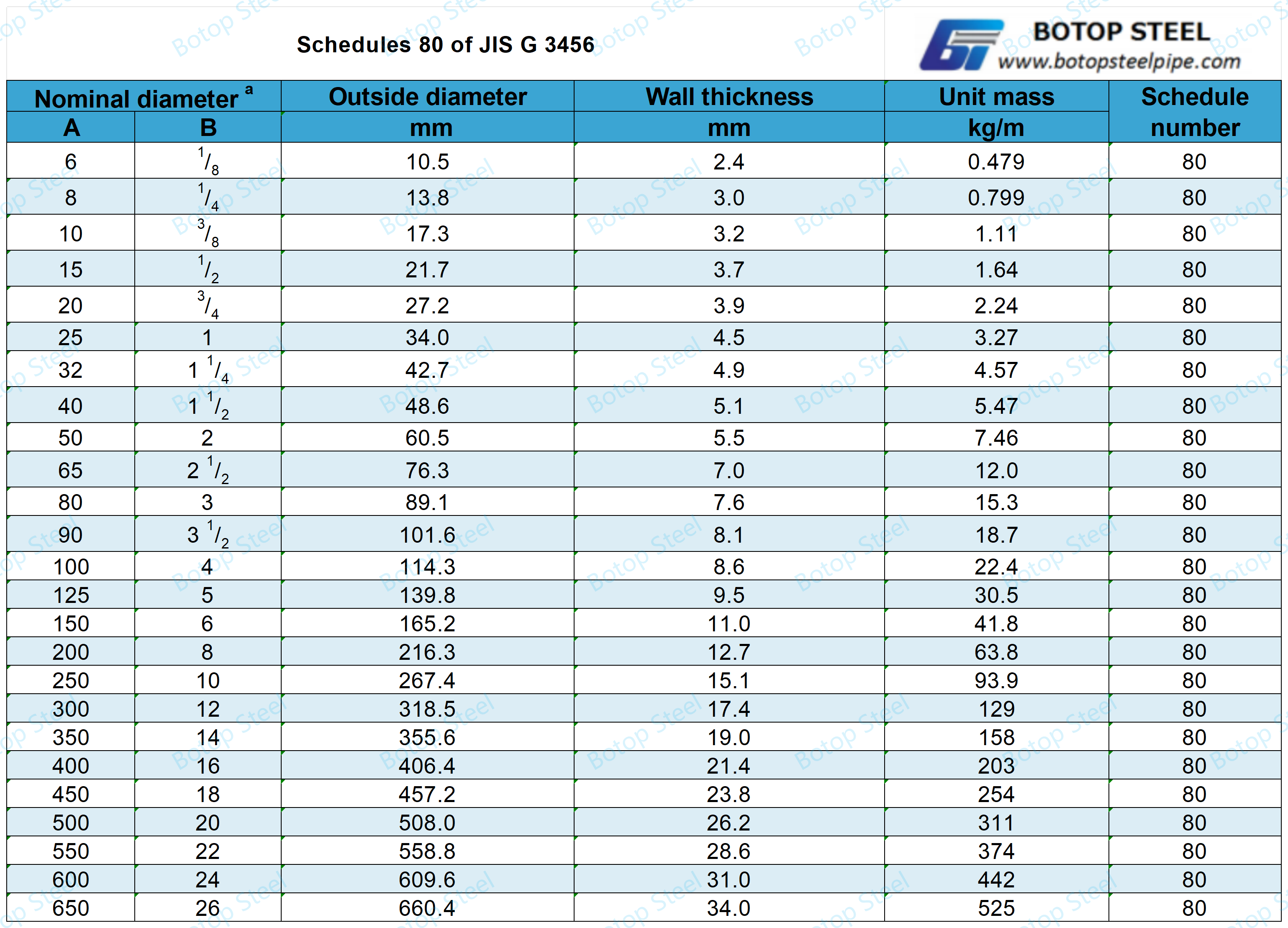

Chate ea Boima ba Pipe le Litlhophiso tsa Pipe tsa JIS G 3456

Thepa ea tšepe ea ho bala boima ba 'mele

Nka boima ba 7.85 g/cm³ bakeng sa tšupu ea tšepe 'me u pota-potile sephetho ho lipalo tse tharo tsa bohlokoa.

W=0.02466t(Dt)

W: boima ba yuniti ea pipe (kg/m)

t: botenya ba lebota la pipe (mm)

D: bophara ba phala e ka ntle (mm)

0.02466: ntlha ea phetoho bakeng sa ho fumana W

Chate ea Boima ba Pipe

Litafole tsa boima ba liphaephe le kemiso ke litšupiso tsa bohlokoa tse sebelisoang hangata ho boenjiniere ba liphaephe.

Lipeipi Kemiso

Kemiso ke motsoako o tloaelehileng oa botenya ba lebota le bophara ba phala.

Kemiso ea 40 le Schedule 80 li-tubes tsa tšepe li sebelisoa haholo indastering le kahong. Ke boholo bo tloaelehileng ba liphaephe tse nang le botenya bo fapaneng ba marako le bokhoni ba maemo a fapaneng a ts'ebeliso.

Haeba u batla ho tseba ho eketsehileng kaTafole ea boima ba liphaephe le kemiso ea liphaepheka maemo, o ka tobetsa ho e hlahloba!

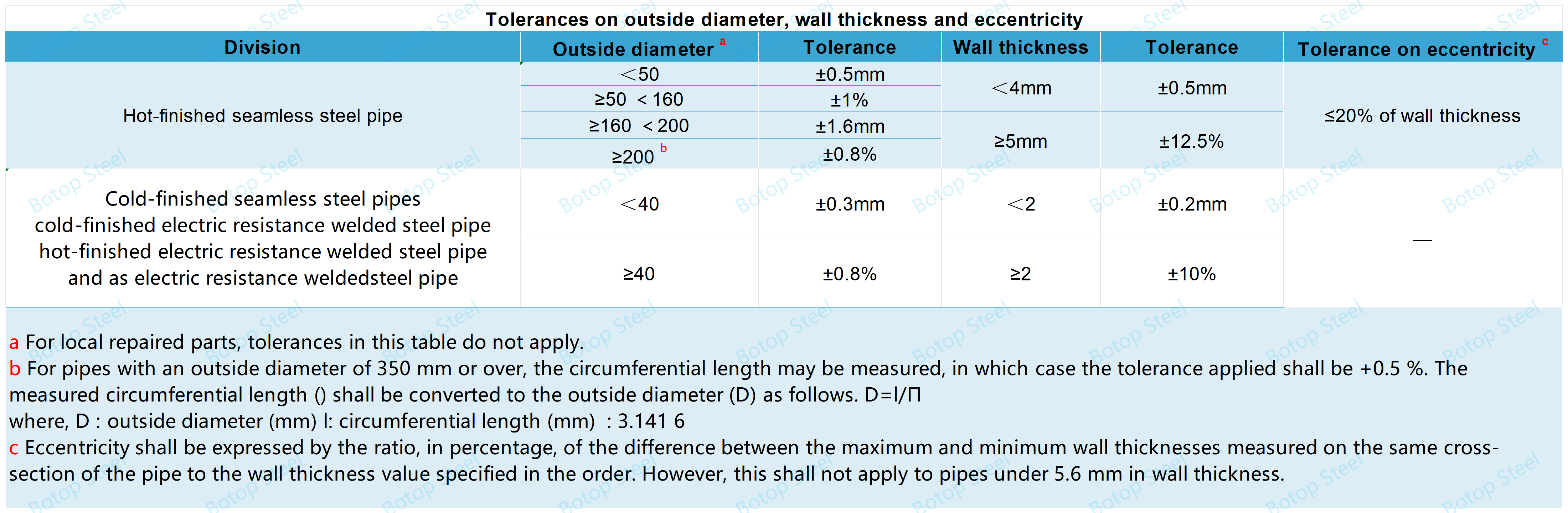

Dimensional Tolerances

Ponahalo

Libaka tse ka hare le tse ka ntle tsa phala li tla ba tse boreleli 'me li se na likoli tse sa rateheng ho li sebelisa.

Pipe e tla ba e otlolohileng, e nang le lipheletso ka mahlakoreng a nepahetseng ho ea ho axis ea pipe.

Liphaephe li ka lokisoa ka ho sila, mechine kapa mekhoa e meng, empa botenya ba lerako le lokisoang bo tla lula bo le ka har'a mamello e boletsoeng 'me sebaka se lokisoang se tla ba boreleli ho profil.

Botenya ba lerako la phala e lokisitsoeng bo tla bolokoa ka har'a mamello e boletsoeng mme bokaholimo ba phala e lokisoang bo tla ba boreleli profilaneng.

JIS G 3456 Ho tšoaea

Pipe e 'ngoe le e' ngoe e fetang tlhahlobo e lokela ho ngoloa ka boitsebiso bo latelang. Li-label li ka 'na tsa sebelisoa holim'a dingata bakeng sa liphaephe tsa bophara bo nyane.

a) Letšoao la mophato

b) Letšoao la ts'ebetso ea tlhahiso

Letšoao la ts'ebetso ea tlhahiso e tla ba ka tsela e latelang. Mehala e ka nkeloa sebaka ke likheo.

Peipi ea tšepe e se nang seamless e feliloeng ka ho chesa: -SH

Peipi ea tšepe e sa koalehang e batang: -SC

E le ho hanyetsa motlakase welded tšepe phala: -EG

Mocheso o felileng oa ho hanyetsa motlakase o cheselitsoeng phala ea tšepe: -EH

Mohatsela o feliloeng oa ho hanyetsa motlakase o cheselitsoeng phala ea tšepe: -EC

c) Litekanyo, e hlahisoang ka bophara ba lebitso × botenya ba lebota la lebitso, kapa bophara ba ka ntle × botenya ba lebota.

d) Lebitso la moetsi kapa mofuta oa khetho

Mohlala:BOTOP JIS G 3456 SH STPT370 50A×SHC40 HEAT NO.00001

JIS G 3456 Likopo tsa Pipe ea Tšepe

Pipe ea tšepe ea JIS G 3456 hangata e sebelisoa bakeng sa lisebelisoa le lisebelisoa tsa liphaephe libakeng tse nang le mocheso o phahameng le o nang le khatello e phahameng, joalo ka liboilers, li-heaters tsa mocheso, liphaephe tsa mouoane tse nang le khatello e phahameng ea mocheso, limela tsa matla a mocheso, limela tsa lik'hemik'hale le mechine ea pampiri.

Maemo a Amanang le JIS G 3456

Litekanyetso tse latelang li sebetsa ho lipeipi libakeng tsa mocheso o phahameng le tse nang le khatello e phahameng 'me li ka sebelisoa e le mokhoa o mong oa JIS G 3456.

ASTM A335/A335M: e sebetsa ho liphaephe tsa tšepe tsa alloy

DIN 17175: bakeng sa liphaephe tsa tšepe tse se nang moeli

TS EN 10216-2: Bakeng sa liphaephe tsa tšepe tse se nang moeli

GB 5310: e sebetsa ho phala ea tšepe e se nang moeli

ASTM A106/A106M: Li-tubes tsa tšepe tsa carbon tse se nang seam

ASTM A213/A213M: Li-tubes tse se nang moeli le liphaephe tsa tšepe ea alloy le tšepe e sa hloekang

TS EN 10217-2 E loketse liphaephe tse cheselitsoeng le liphaephe

TS ISO 9329-2: Liphaephe le liphaephe tsa khabone e se nang seam le alloy

NFA 49-211: bakeng sa li-tubes le liphaephe tsa tšepe tse se nang moeli

BS 3602-2: bakeng sa liphaephe le lisebelisoa tsa tšepe tse se nang moeli

Lihlahisoa tsa rona tse Amanang

Re moetsi oa liphaephe tsa tšepe tsa tšepe tsa boleng bo holimo tse cheselitsoeng le mofani oa thepa ea tsoang Chaena, hape re na le setoko sa liphaephe tsa tšepe tse se nang seam, tse u fang mefuta e mengata ea tharollo ea lipeipi tsa tšepe! Haeba u batla ho tseba haholoanyane ka lihlahisoa tsa tšepe phala, u ka ikopanya le rona.

Tags: JIS G 3456, SPTP370, STPT410, STPT480, STPT, bafani ba thepa, bahlahisi, lifeme, li-stock, lik'hamphani, thekiso, theko, qotso, bongata, thekiso, litšenyehelo.

Nako ea poso: Apr-29-2024