PSL1ke boemo ba tlhahiso ea lihlahisoa maemong a API 5L mme e sebelisoa haholo bakeng sa lipeipi tsa tšepe tsa liphaephe indastering ea oli le khase.

Karolelano

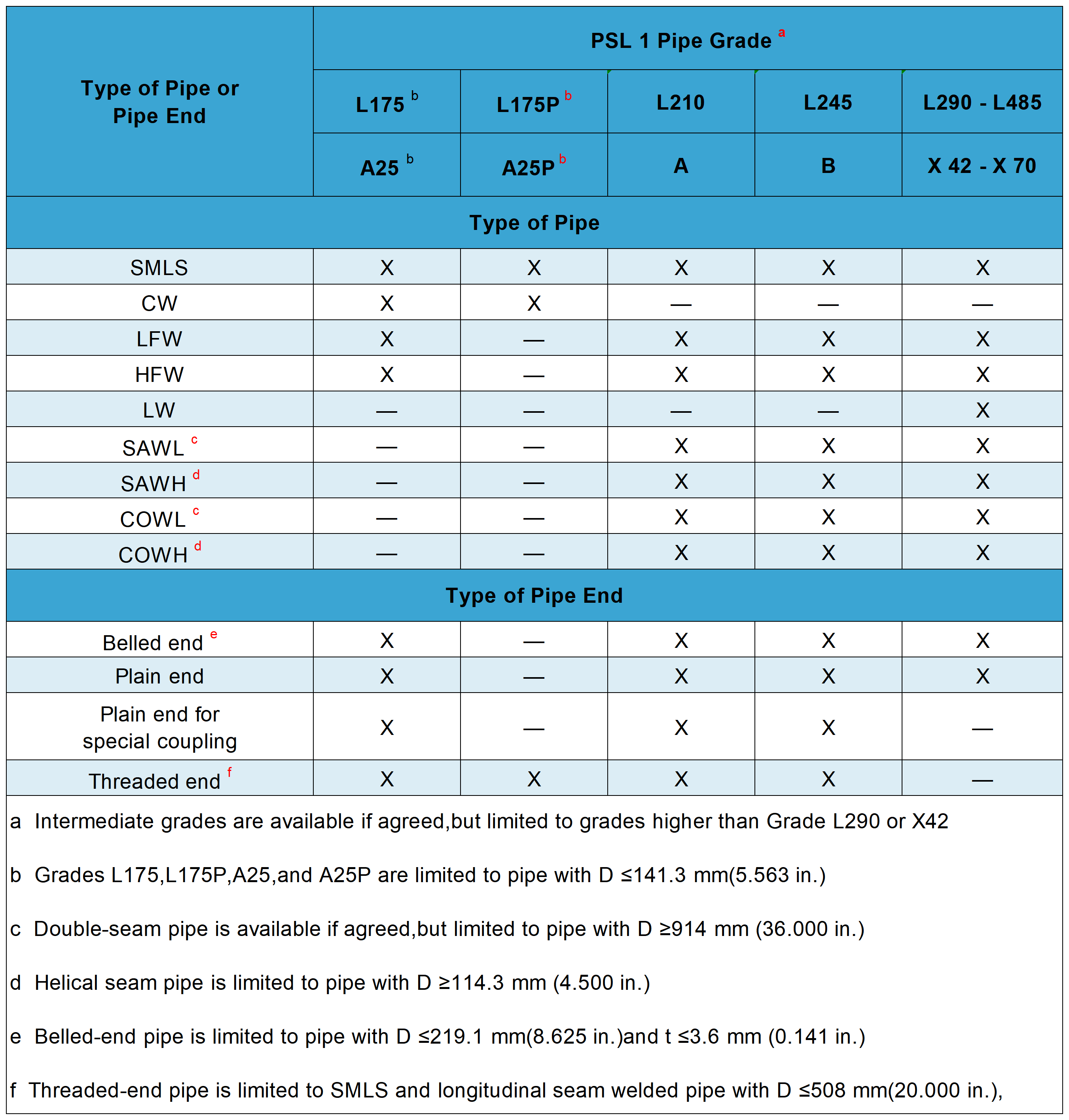

Ho latela mofuta oaphala ea tšepe: phala ea tšepe e se nang moeli le phala ea tšepe e cheselitsoeng.

Ho latela mofuta oapheletso ea peipi: pheletso e bataletseng, pheletso e khoele, pheletso ea sokete, le pheletso ea liphaephe bakeng sa li-clamps tse khethehileng.

Ho latelatšepe kereiti:

L-Series (L + bonyane ba tlhahiso ea matla ho MPa)

L175 le L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485

X-Series (X + bonyane matla a tlhahiso ho 1000 psi)

A25 le A25P,X42,X46,X52,X56,X60,X65,X70

Mephato e Tloaelehileng ea Tšepe

Sehlopha sa A le Sehlopha sa B ke limaraka tse tloaelehileng tsa tšepe tse sa hlalosoang ka litekanyetso tsa matla a tlhahiso, 'me Sehlopha sa A se tsamaellana le L210 le Sehlopha sa B se tsamaellanang le L245.

Ts'ebetso ea Tlhahiso ea PSL1 Pipe ea tšepe

Lisebelisoa tse so fetoloe

Ingot, billet, billet, strip (coil) kapa poleiti

b) mokhoa oa ho qhibilihisa sebōpi sa motlakase.

c) ho etsa litšepe tsa sebōpi tse bataletseng tse kopantsoeng le ho hloekisa ladle.

Maemo a thomello bakeng sa PSL1

Liphekolo tsa mocheso bakeng sa li-tubing tsa tšepe tsa PSL1 li kenyelletsa ho bilika, ho tloaeleha ho potoloha, ho thermo-mechanical rolling, thermo-mechanical forming, normalizing forming, normalizing, and normalizing and tempering, e leng se ntlafatsang thepa ea mochine le sebopeho sa sebopeho sa tubing.

| PSL | Boemo ba Phano | Pipe Grade/Steel Grade | |

| PSL1 | Joalo ka ha e phuthoa, e tloaeleha e phuthiloe, e tloaelehe, kapa e tloaelehe | L175 | A25 |

| L175P | A25P | ||

| L210 | A | ||

| Joalo ka ha e bililoe, e tloaeleha e phuthoa, e thermomechanical rolled, thermomechanical e bopehile, e tloaeleha e bopehile, e tloaelehe, e tloaelehe ebile e be bonolo; kapa, haeba ho lumellanoe, ho tima le ho halefa bakeng sa phaephe ea SMLS feela | L245 | B | |

| Joalo ka ha e bililoe, e tloaeleha e phuthoa, e thermomechanical rolled, thermomechanical bopehile, bo tloaeleha bo bopehile, bo tloaelehile, bo tloaelehile, bo bebofatsoe kapa bo tingoe le bohale | L290 | X42 | |

| L320 | X46 | ||

| L360 | X52 | ||

| L390 | X56 | ||

| L415 | X60 | ||

| L450 | X65 | ||

| L485 | X70 | ||

Lengolo la P ho L175P le bontša hore tšepe e na le palo e itseng ea phosphorus.

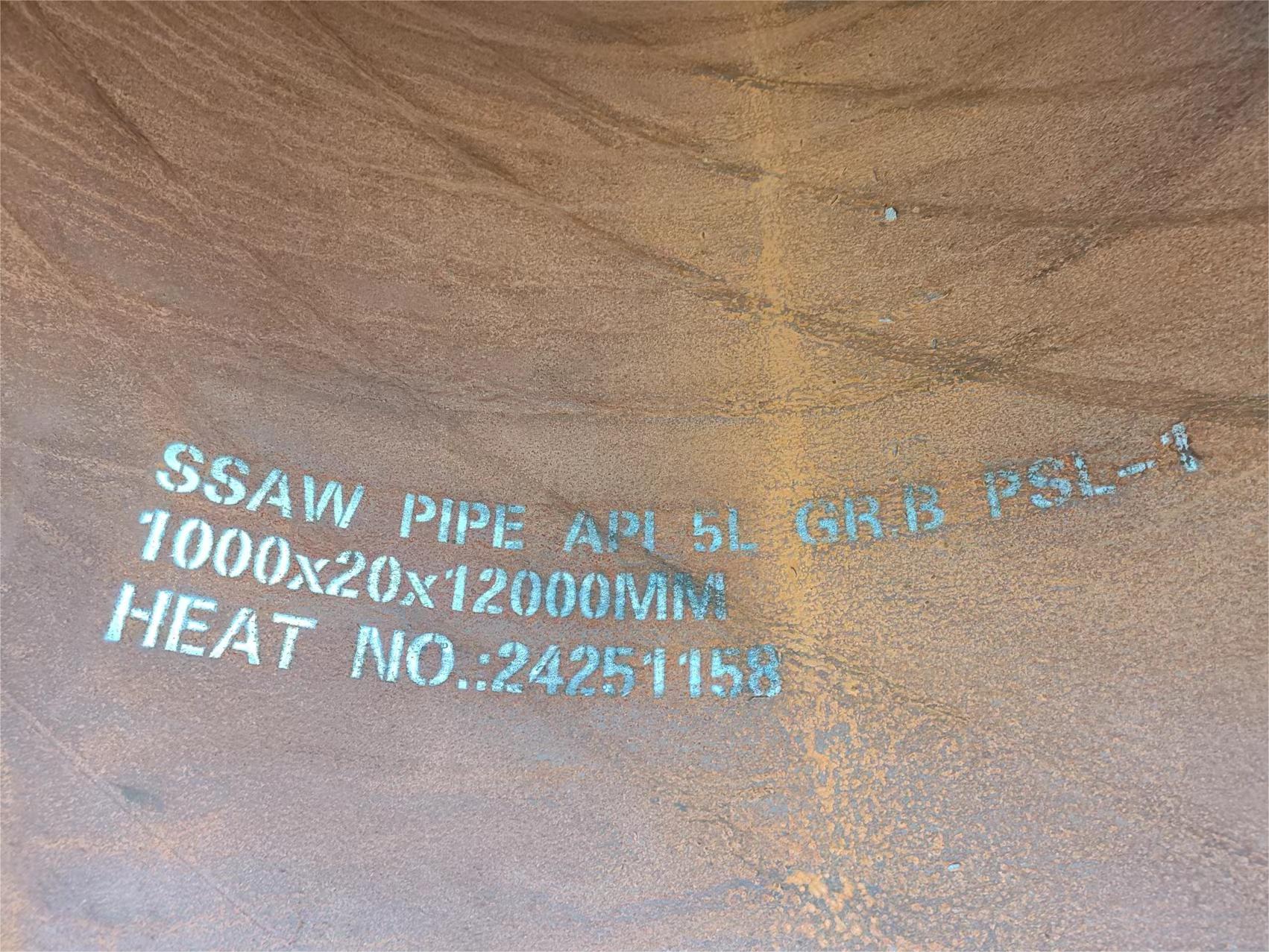

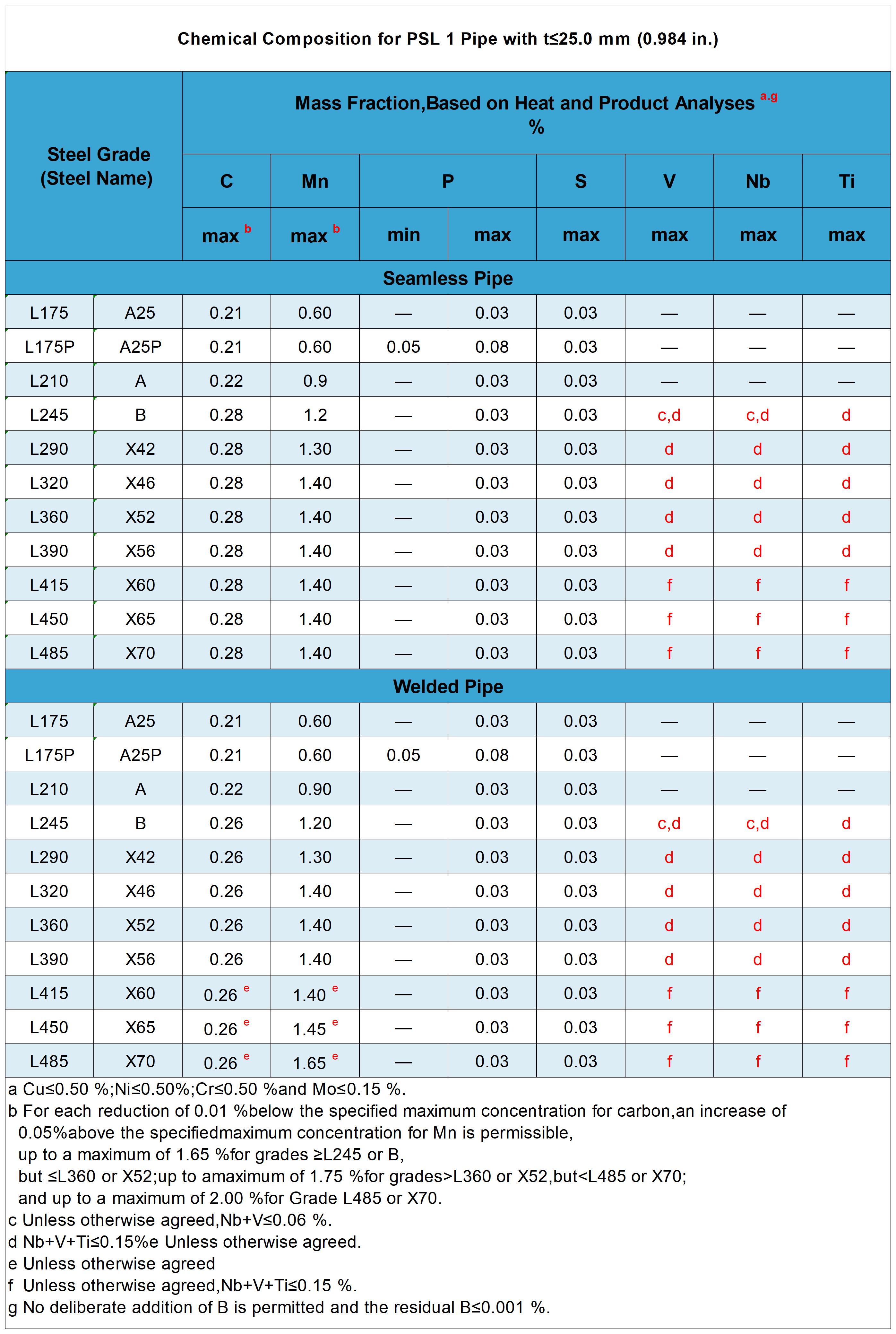

Sebopeho sa Lik'hemik'hale tsa PSL1 Pipe ea tšepe

Motsoako oa lik'hemik'hale oa pipe ea tšepe ea PSL1 o hlalosoa ka ho hlaka ka mokhoa oa API 5L ho etsa bonnete ba hore phala e na le thepa e ntle ea mochine le ho hanyetsa kutu ho ikamahanya le maemo a fapaneng a ho tsamaisa.

Motsoako oa lik'hemik'hale oa pipe ea tšepe ea PSL1 bakeng sa t> 25.0 mm e tla khethoa ka tumellano.

Thepa ea Mechini ea PSL1 Pipe ea tšepe

Thepa ea mochini ea li-tubes tsa PSL1 e fihlela litlhoko tse amehang ho API 5L, ho netefatsa hore li ka mamella maemo a itseng a ts'ebetso le tikoloho. Litekanyetso tsena tsa thepa ea mochini haholo-holo li kenyelletsa matla a chai, matla a tsitsipano le bolelele.

| Litlhoko tsa Liphetho tsa Teko ea Tensile bakeng sa PSL 1 Pipe | ||||

| Phaephe Kereiti | Pipe 'Mele oa Pipe e Seamless le e Welded | Weld Seam ea EW, LW, SAW, le Pipe ea KHOMO | ||

| Kotulo Matlaa Rho.5 MPa(psi) | Matla a tšepea Rm MPa(psi) | Elongation (ho 50 mm kapa 2 in.) Af % | Matla a tšepeb Rm MPa(psi) | |

| min | min | min | min | |

| L175 kapa A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| L175P kapa A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 kapa A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 kapa B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 kapa X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| L320 kapa X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 kapa X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| L390 kapa X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 kapa X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| L450 kapa X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| L485 kapa X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Teko ea Hydrostatic

Lipeipi tsohle tsa tšepe li tla lekoa ka hydrostatically 'me ha ho na ho lutla ho tsoa ho li-welds kapa 'mele oa liphaephe nakong ea tlhahlobo.

Liphaephe tse se nang moeli le phala ea tšepe e cheselitsoeng e nang le OD≤457mm:Nako ea ho tsitsa ha motlakase ≥5s

Peipi ea tšepe e cheselitsoeng e nang le OD> 457mm:Nako ea ho tsitsa ha motlakase ≥10s

Lipeipi tsa tšepe tse nang le likhoele le likhokahano tse nang le OD> 323.9 mm:Liteko li ka etsoa maemong a bataletseng.

Mekhoa ea Teko ea Lintho tsa Teko e sebetsang ho PSL1

| Sehlopha sa liteko | Mokhoa oa ho Leka |

| Sebopeho sa Lik'hemik'hale | ISO 9769 kapa ASTM A751 |

| Thepa ea Mechini | ISO 6892-1 kapa ASTM A370 |

| Teko ea Hydrostatic | API 5L 10.2.6 |

| Tlhahlobo e sa Senyeheng | API 5L Sehlomathiso E |

| Teko ea ho Koba | ISO 8491 kapa ASTM A370 |

| Tataiso ea Bend Test | ISO 5173 kapa ASTM A370 |

| Teko e bataletseng | ISO 8492 kapa ASTM A370 |

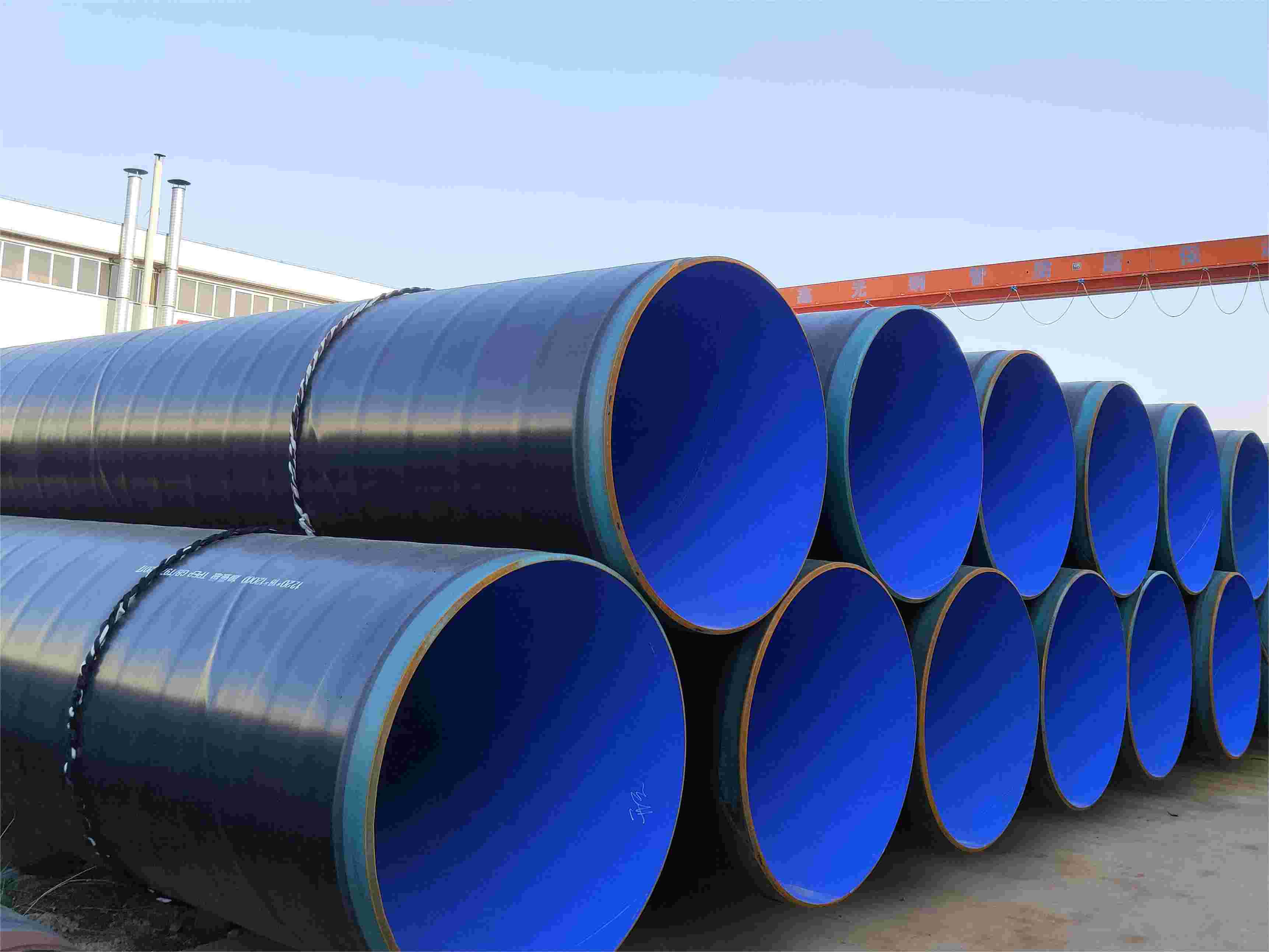

Boemo ba Bokaholimo ba PSL1 Ha e tlisoa

1.Liphaephe tse khanyang

2.Ho roala ka ntle ho nakoana:

Hangata ho sebelisoa lioli tse thibelang mafome, litlolo tse entsoeng ka oli, liphahlo tse thibelang mafome, joalo-joalo.

E ka qoba mafome nakong ea polokelo le ea lipalangoang.

3.Boemo bo khethehileng ba ho roala:

Tse tloaelehileng ke pente, 3LPE, 3LPP, TPEP FBE, joalo-joalo.

E fana ka tšireletso e ntlafetseng le ho ntlafatsa ts'ebetso ea pipe.

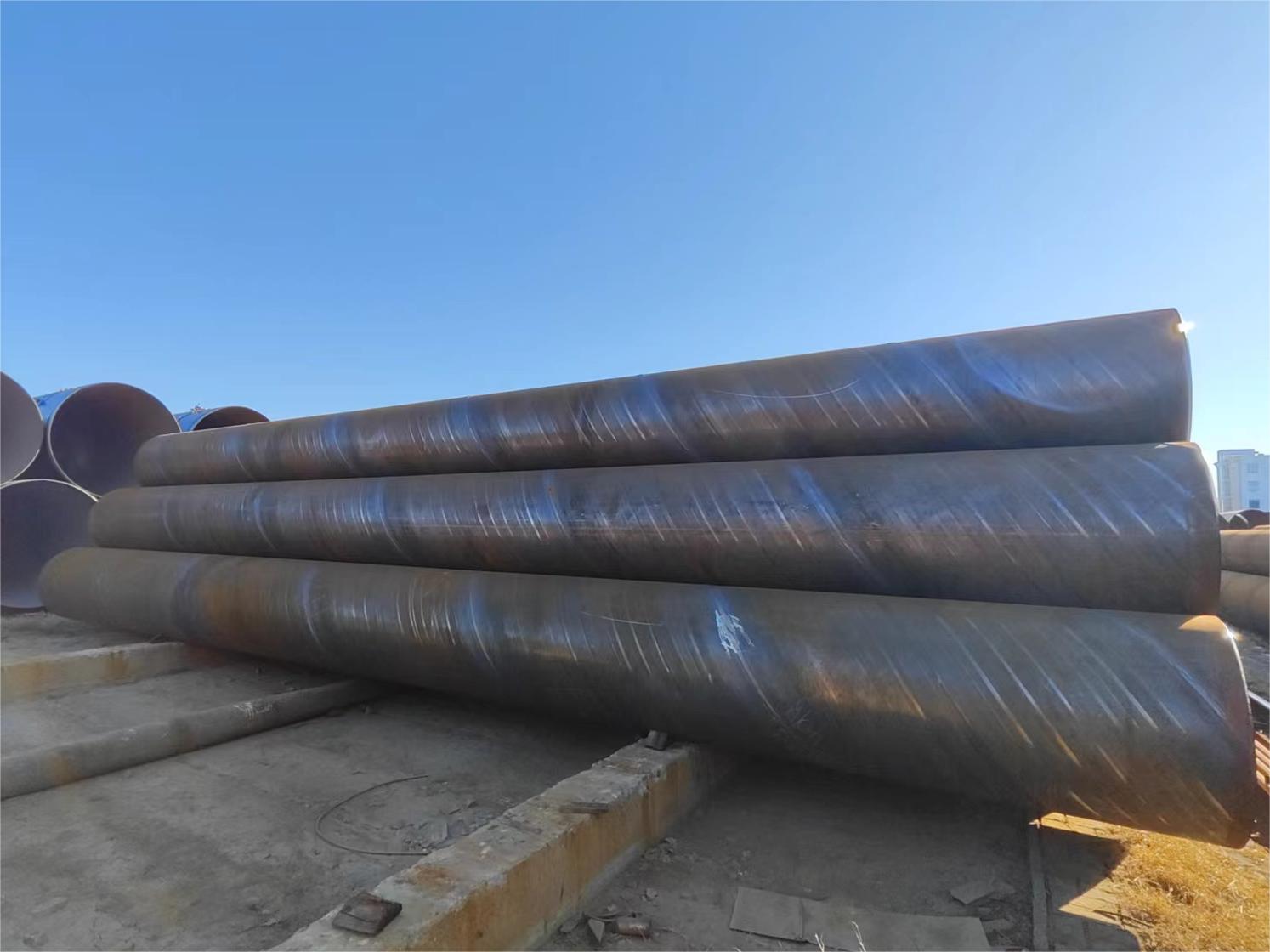

Libaka tsa Kopo

Oli le Gas Conveyor System: bakeng sa lipalangoang tse telele tsa oli e tala le khase ea tlhaho.

Mekhoa ea phepelo ea metsi: bakeng sa phepelo ea metsi litoropong le lits'ebetso tsa nosetso.

Kaho le Mehaho ea Motheo: bakeng sa marokho, kaho ea litsela, le merero e meng ea meralo ea motheo.

Limela le Lisebelisoa tsa Ts'ebetso: bakeng sa phetiso ea lik'hemik'hale le mouoane litsing tsa indasteri.

Matla: bakeng sa tšireletso ea cable le e le karolo ea mekhoa ea metsi a pholileng.

Lisebelisoa Tse Ling

Ha ho khethoa lisebelisoa tse ling, litlhoko tse khethehileng tsa sebopeho sa lik'hemik'hale le thepa ea mochini li tlameha ho hlahlojoa ho netefatsa hore lisebelisoa tse ling li kopana le litlhoko tsa morero o itseng.

American Standard

ASTM A106 Sehlopha sa B: Bakeng sa tšebeletso ea mocheso o phahameng.

ASTM A53 Sehlopha sa B: Bakeng sa lisebelisoa tse akaretsang tsa lipeipi tsa metsi le tsa meralo.

Melao ea Europe

TS EN 10208-1 L245GA ho L485GA: E sebelisetsoa liphaephe tse tsamaisang khase le oli.

ISO 3183 Kereiti ea L245 ho isa L485: E ts'oana haholo le maemo a API 5L a sebelisoang indastering ea oli le khase.

DIN EN 10208-2 L245NB, L290NB: Bakeng sa ho tsamaisa khase ea mafura le oli ea mafura libakeng tse nang le khatello.

Melao ea Majapane

JIS G3454 STPG 410: E sebelisoa bakeng sa lipalangoang tse nang le khatello e tlaase ea metsi.

JIS G3456 STPT 410: E sebelisetsoa maemo a phahameng a mocheso le khatello e phahameng joalo ka liphaephe tsa motlakase.

Boemo ba Australia

AS/NZS 1163 C350L0: Li-tubes tse chitja bakeng sa merero ea meralo le ka kakaretso.

Maemo a Sechaena

GB/T 9711 L245, L290, L320: E sebelisoa indastering ea oli le khase, e tšoanang le ISO 3183.

GB/T 8163 20 #, Q345: E sebelisoa bakeng sa liphaephe tse akaretsang tsa lipalangoang tsa mokelikeli.

Lihlahisoa tsa rona tse Amanang

Re e mong oa ba etellang pele welded carbon tšepe pipe le bahlahisi seamless tšepe liphaephe le bafani ba tsoang Chaena, ba nang le mefuta e mengata ea liphaephe tsa tšepe tsa boleng bo phahameng setokong, re ikemiselitse ho u fa tharollo e felletseng ea lipeipi tsa tšepe. Bakeng sa lintlha tse ling tsa sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona, re lebeletse ho u thusa ho fumana mekhoa e metle ea lipeipi tsa tšepe bakeng sa litlhoko tsa hau!

Tags:psl1, api 5l psl1, psl1 pipe, bafani, bahlahisi, lifeme, li-stock, lik'hamphani, thekiso, theko, qotsa, bongata, thekiso, litšenyehelo.

Nako ea poso: Apr-13-2024